4 5

IMPORTANT SAFETY INSTRUCTIONS

RECOMMENDATION:

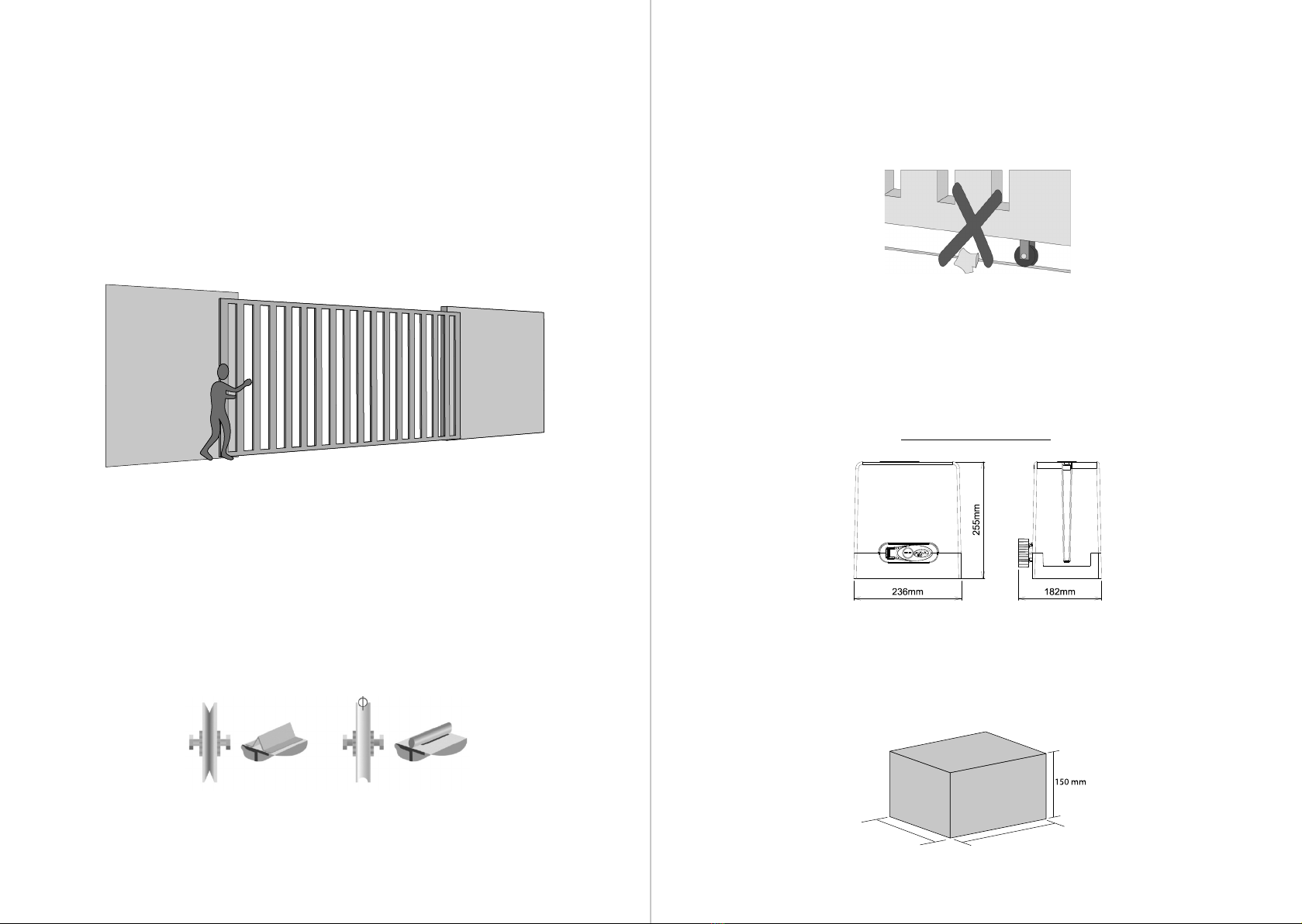

The installer must be a PPA specialized ins-

taller to install DZ HUB R. Follow all the in-s-

tructions given on the TECHNICAL MANUAL

and USER’S MANUAL.

With the USER’S MANUAL in hands, the ins-

taller must show the equipment’s informa-

tion, applications, and security items to the

user.

Before using the operator, closely read and

follow the instructions contained in this

manu-al.

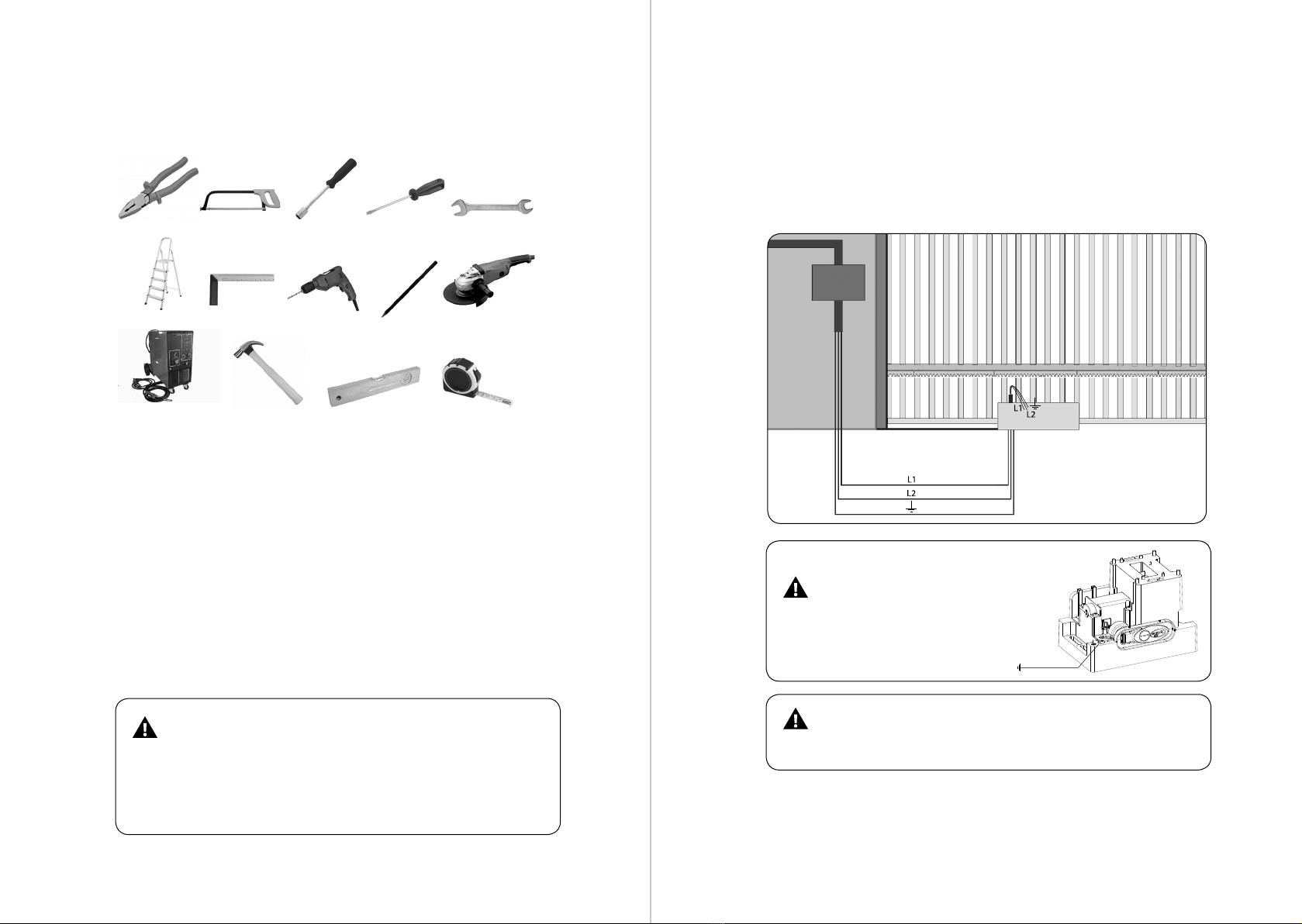

- Before installing the operator, make sure

the local electric power supply is compa-

ti-ble with the one required on the equip-

ment identication label.

- Do not turn on the electric power supply

until installation or maintenance are com-

pleted. Always make the control board

electrical connections with the power su-

pply turned o.

- Once installation is complete, ensure the

gate parts do not extend into the paths and

public sidewalk.

- Using total shutdown devices when ins-

talling an operator is mandatory.

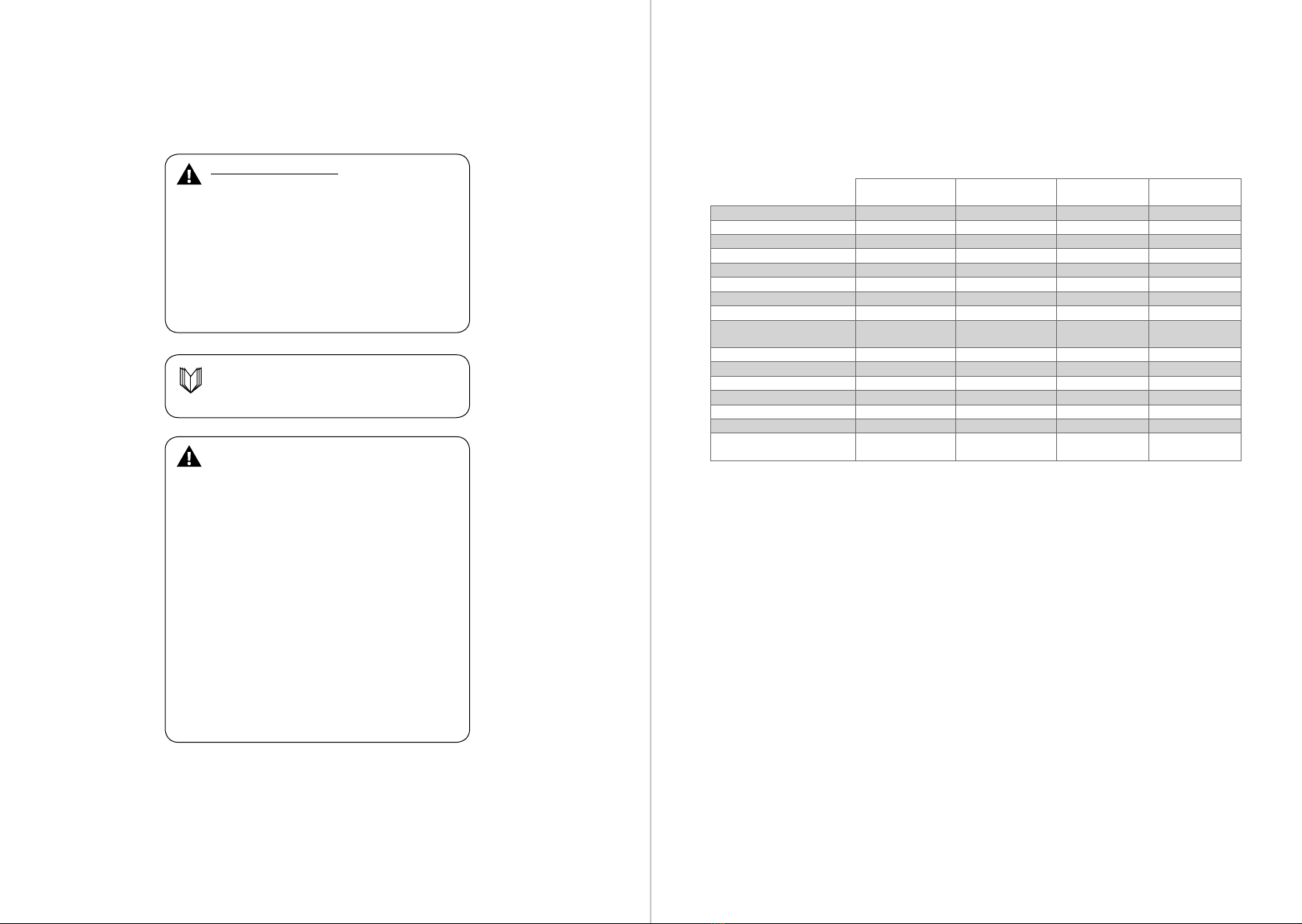

TECHNICAL FEATURES

DZ HUB R 600 DZ HUB R 350

JETFLEX

DZ HUB R 550

JETFLEX

DZ HUB R 450

24V

TYPE OF OPERATOR Sliding Sliding Sliding Sliding

MODEL Single-phase Jetex Jetex Brushless 24V

RATED VOLTAGE 127 V / 220 V 127 V / 220 V 127 V / 220 V 85 – 265 V

NOMINAL FREQUENCY 60 Hz 60 Hz 60 Hz 60 Hz

NOMINAL POWER 250 W / 400 W 280 W / 340 W 450 W / 500 W 50 W

MOTOR ROTATION 1740 RPM 5800 RPM 5800 RPM 2200 RPM

NOMINAL CURRENT 2.3 A / 2.0 A 2.5 A / 2.4 A 4.5 A / 3.5 A 0.7 A

REDUCTION RATIO 1:23 1:23 1:23 1:23

LINEAR SPEED 17.1 m/min (Z18)

20.9 m/min (Z22) 57 m/min (Z18) 57 m/min (Z18) 16,8 m/min (Z14)

21.6 m/min (Z18)

CYCLES/HOUR 30 to 60 30 40 40

DEGREE OF PROTECTION IPX4 IPX4 IPX4 IPX4

TEMPERATURE RANGE -5° C / +50° C -5° C / +50° C -5° C / +50° C -5° C / +50° C

INSULATION TYPE Class B, 130° C Class B, 130° C Class B, 130° C Class B, 130° C

LIMIT SWITCH Analog or Digital Hybrid Hybrid Hybrid

GATE LEAF MAX. MASS 600 Kg 350 Kg 550 Kg 450 Kg

GATE MAX. DIMENSION HEIGHT = 2.5 m

LENGTH = 3.0 m

HEIGHT = 2.5 m

LENGTH = 3.0 m

HEIGHT = 2.5 m

LENGTH = 3.0 m

HEIGHT = 2.5 m

LENGTH = 3.0 m