8 98 9

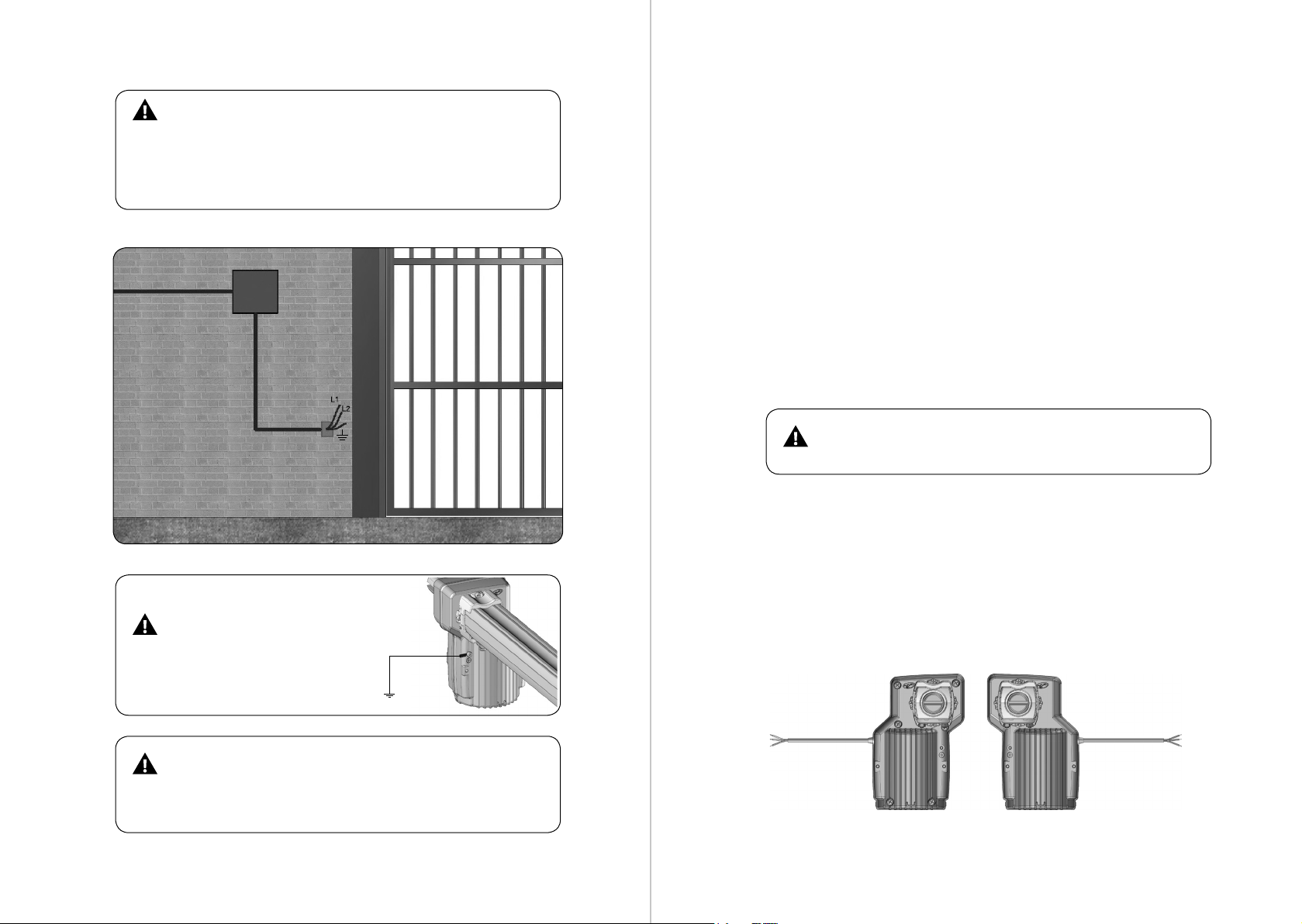

To check which leaf of the gate is on the left and which is on the right, stand on the

inside of the property, in front of the gate. In this way, the leaf of the gate that is on

your right side is on the right and the one on your left is on the left.

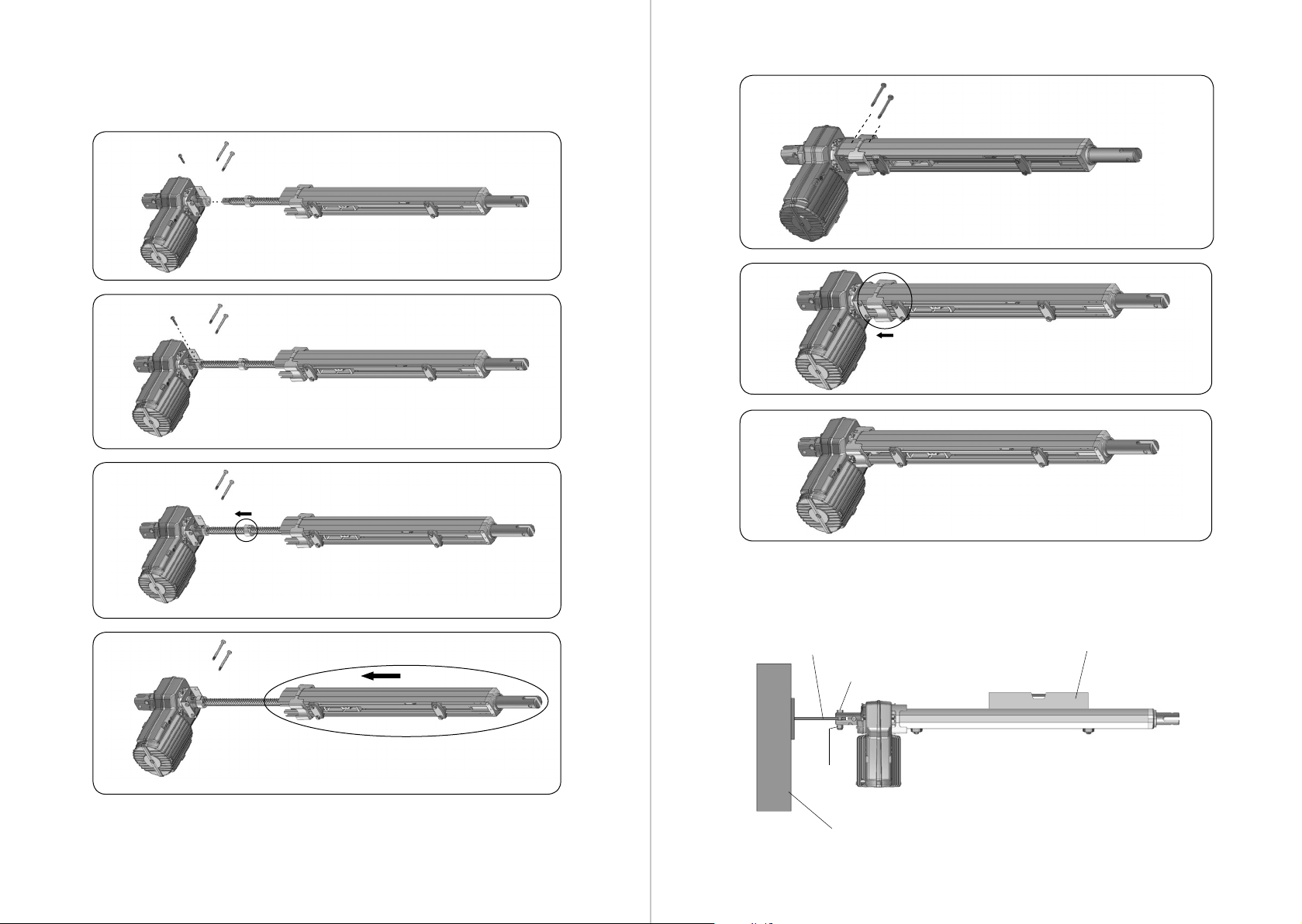

To x the equipment, carefully follow the instructions below:

1st Step: The gate must open to the interior of the property. Provide a 150mm x

150mm x 1/4”at iron base. This will be the base of the xture.

2nd Step: Fix, on the wall or on the gate column, the base of the xing bracket at

a distance of 85 to 100 mm from the turning point of the gate and at the desired

height for xing the operator to the gate, as shown in the gure below.

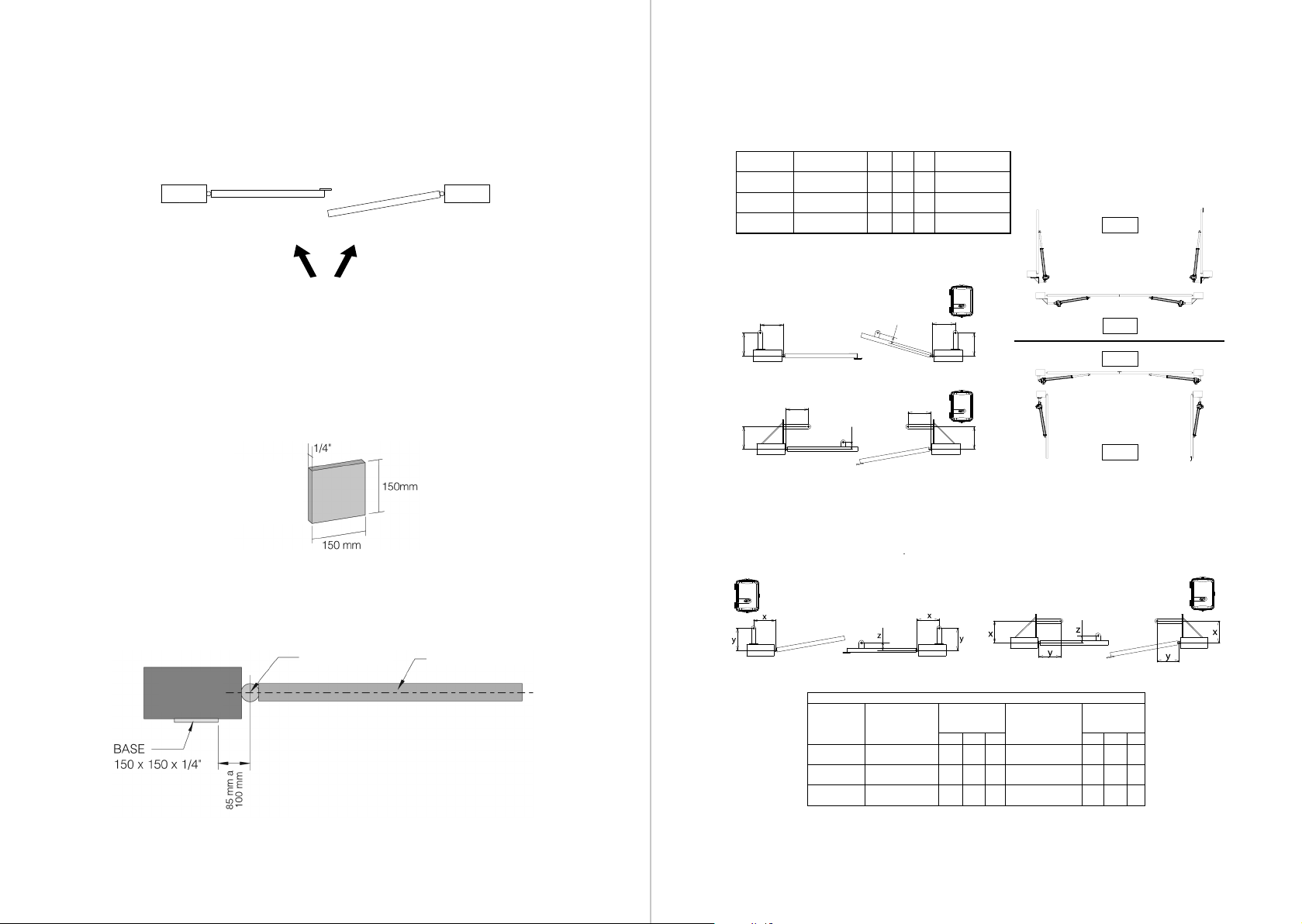

3rd Step: Weld the xing bracket on the base, according to instructions /

illustrations below:

ABERTURA INTERNA (CENTRAL DUPLA)

TABELA DE REFERÊNCIA (CENTRAL DUPLA)

ABERTURA EXTERNA (CENTRAL DUPLA)

yy

xx

z

yy

xx

z

AUTOMATIZADORES

PIVOTANTES

GUIA DE INSTALAÇÃO

P03817 - Rev. 4

Medidas máxima permitidas para instalação padrão (em milímetros).

Retardo Fechamento (RF)

Retardo Fechamento (RF)

Retardo Abertura (RA)

Retardo Abertura (RA)

ACIONAMENTO AUTOMATIZADOR X Y Z

COMPRIMENTO MÁXIMO

DA FOLHA

PIVO HOME 160 160 50 1500

SK 130 130

SK PREDIAL 175 175

PISTON PREDIAL

PISTON CONDOMINIUM

PIVO HOME 270 270

SK 215 215 50 3000

SK PREDIAL 350 350

PISTON PREDIAL

PISTON CONDOMINIUM

SK PREDIAL

PISTON PREDIAL

PISTON CONDOMINIUM

3500

370 370

SUPER

190 190

STANDARD

200050

50

MEGA 400 400 50 4500

ABERTURA EXTERNA (COM RETARDO MECÂNICO)

SUPORTE PARA RETARDO MECÂNICO PPA

ABERTURA INTERNA (COM RETARDO MECÂNICO)

Medida para instalação da chapa

Medidas máxima permitidas para instalação padrão (em milímetros).

STANDARD

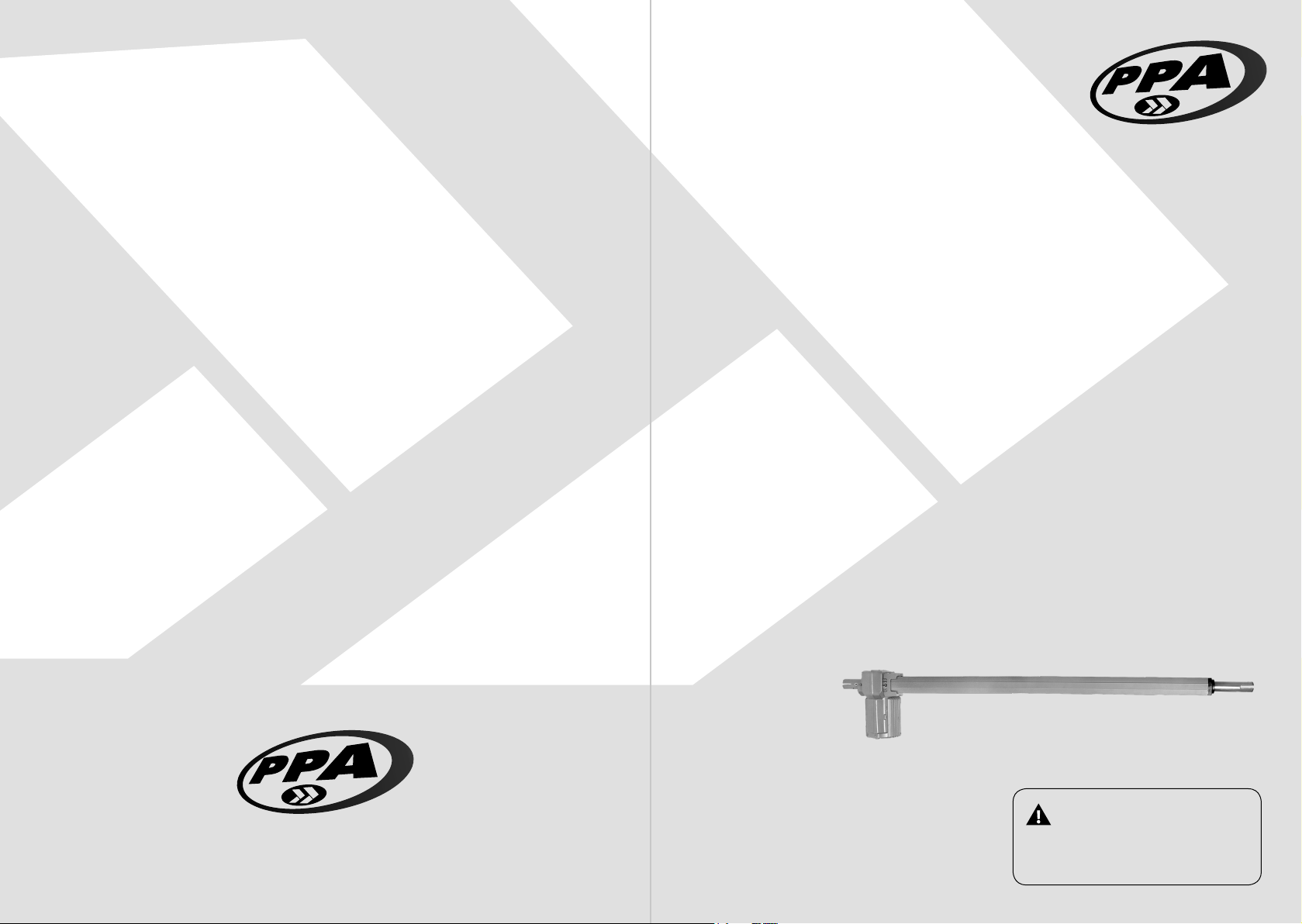

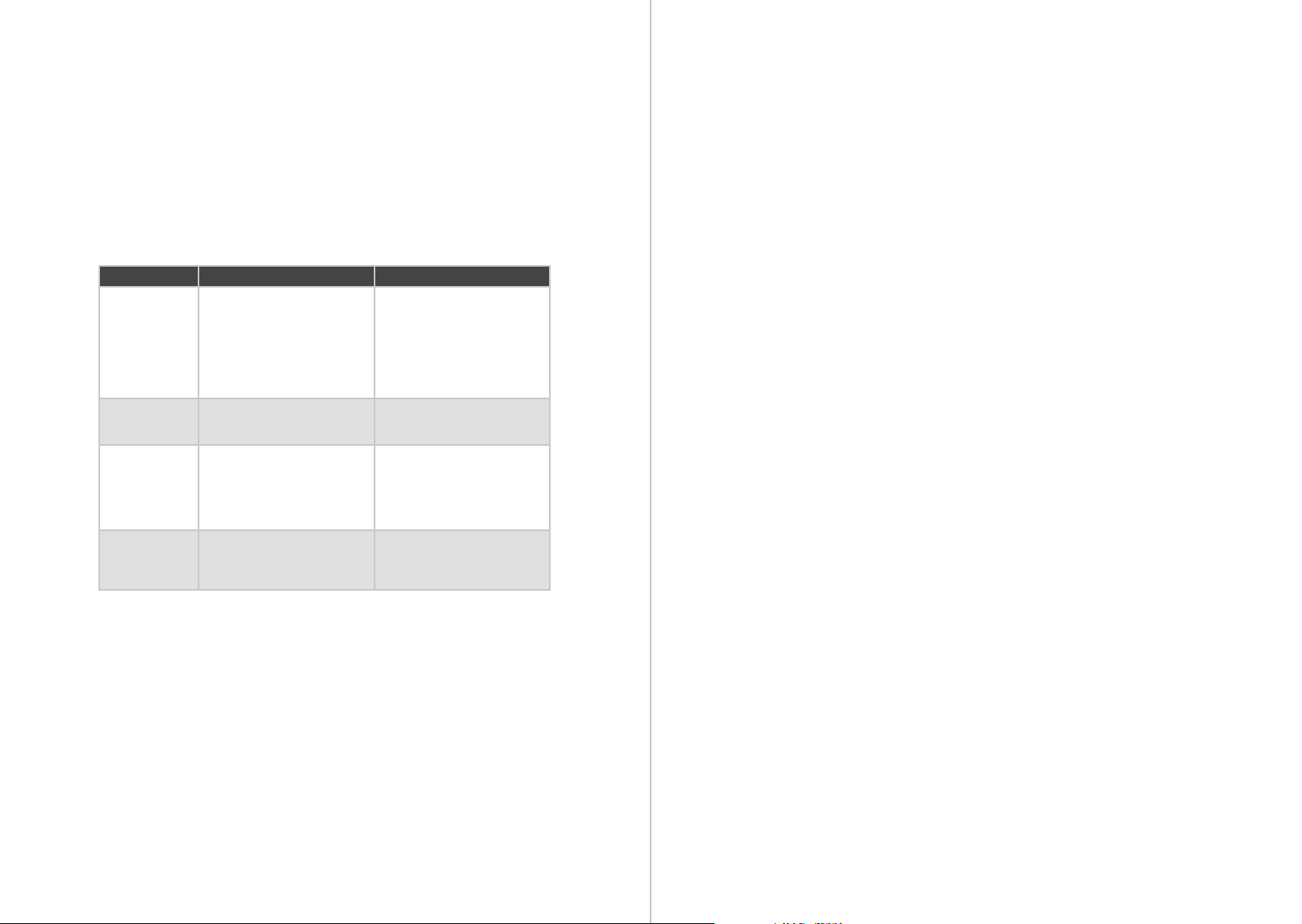

ACTIVATION OPERATOR X Y Z MAXIMUM LEAF

LENGTH

STANDARD PISTON

CONDOMINIUM 190 190 50 2000

SUPER PISTON

CONDOMINIUM 370 370 50 3500

MEGA PISTON

CONDOMINIUM 400 400 50 4500

Maximum allowable measurements for standard installation (in

millimeters).

SUPPORT MEASURES FOR INSTALLING PPA PIVOTING OPERATORS WITH MECHANICAL DELAY

ACTIVATION OPERATOR

SLAVE LEAF

Internal opening

or external

LENGTH

MAXIMUM SHEET

MASTER LEAF

X Y Z X Y Z

STANDARD PISTON

CONDOMINIUM 180 180 50 2000 190 190 50

SUPER PISTON

CONDOMINIUM 360 360 50 3500 370 370 50

MEGA PISTON

CONDOMINIUM 390 390 50 4500 400 400 50

Maximum allowable measurements for standard installation (in millimeters).

LEFT LEAF

BASE OF THE

FIXTURE

TURNING POINT GATE LEAF

COLUMN

RIGHT LEAF

INSIDE THE

PROPERTY

REFERENCE TABLE (DOUBLE CENTER)

INTERNAL OPENING (DOUBLE CENTRAL)

INTERNAL OPENING

SUPPORT FOR MECHANICAL DELAY PPA

INTERNAL OPENING (WITH MECHANICAL DELAY) EXTERNAL OPENING (WITH MECHANICAL DELAY)

EXTERNAL OPENING (DOUBLE CENTRAL)

EXTERNAL OPENING

Opening Delay (RA)

STREET

STREET

CLOSED

CLOSED

HOUSE

HOUSE

Opening Delay (RA)

Measure for installing the leaf

Master

Master

Slave Slave

Closing Delay (RF)

Closing Delay (RF)