PPI Zenex Plus User manual

Zenex Plus User Manual

User Manual

Multi-Purpose Temperature Controller

with Graphic Display

Zenex Plus

Zenex Plus User Manual

CONTENTS

1. FRONT PANEL LAYOUT 1

2. BASIC OPERATION 2

3. OPERATOR PARAMETERS 5

4. SUPERVISORY PARAMETERS 7

5. FACTORY PARAMETER 12

6. PANEL MOUNTING AND ELECTRICAL CONNECTIONS 21

1

Zenex Plus User Manual

GRAPHIC READOUT

The Graphic Readout is a X Pixel Monochrome LCD Display. In Normal operation mode the Readout shows 128 64 measured

Temperature Value, Set Temperature Value, Alarm / Process Status & Balance Time (if enabled & running). The Process

Status Information can be viewed using screen scroll feature.

In Mode, the Readout displays parameter names and values that can be edited using front keys.Set-up

KEYS

There are six tactile keys provided on the front panel for configuring the and setting-up the parameter values. controller

The Table 1. below lists each key (identified by the front panel symbol) and the associated function. 1

Section 1

The Controller front panel comprises of Graphic Readout and Membrane Keys as shown in Figure 1.1 below.

FRONT PANEL LAYOUT

Table 1.1

Figure 1.1

Symbol

Key Function

DOWN

UP

ENTER

SET-UP Press to enter or exit set-up mode.

Press to store the set parameter value and to scroll to the next

parameter.

Press to increase the parameter value. Pressing once

increases the value by one count; keeping pressed speeds up

the change.

Press to decrease the parameter value. Pressing once

decreases the value by one count; keeping pressed speeds up

the change.

Press to scroll through various Process Information Screens in

Normal Operation Mode.

Scroll

Press to acknowledge and mute (if active) alarm output.

Alarm

Acknowledge

Zenex Plus

PPI

°C

25.8

25.0

0:10:00 SP

TEMP HIGH

Graphic

Readout Keys

2

Zenex Plus User Manual

POWER-UP DISPLAY

Upon power-up the controller displays model name, Hardware Version

and Software Version for 2 seconds as shown in figure 2.1.

BASIC OPERATIONS

Section 2

RUN MODE

After the Power-up display the controller enters into RUN Mode. This is the normal operation mode wherein the controller

starts PV measurements, Alarm monitoring and Control Loop execution.

Main Screen

This is the default screen and its appearance depends upon whether a timer function is enabled or disabled as shown in the

figures 2.2 (a) & 2.2 (b) respectively.

Figure 2.2(a) : Timer Disabled

Figure 2.1

Figure 2.2(b) : Timer Enabled

°C

25.0

25.0

TEMP HIGH SP

Measured Temperature

Alarm / Process

Status Set Temperature

°C

25.0

25.0

0:10:00 SP

TEMP HIGH

Set Temperature

Measured

Temperature

Alarm / Process

Status

Balance Time

In case of measured value errors, the messages listed in Table 2.1 flash in place of process value as illustrated in Figure 2.3.

Message Error Type Cause

Sensor Open

Under-range

Over-range

RTD Pt100 / Thermocouple is Broken / Open

Temperature above Max. Specified Range

Temperature below Min. Specified Range

OPEN

Table 2.1

OVR

UNR

Figure 2.3

Note :

The Balance Time is shown in either HHH:MM or H:MM:SS

depending upon the remaining time counts as under :

HHH:MM for 249:59 to 10:00

H:MM:SS for 9:59:59 to 0:00:00

°C

OPEN

25.0

TEMP HIGH SP

H/W Version

S/W Version

02

07

3

Zenex Plus User Manual

The Alarm / Process Status space on the screen may show one or more of the several messages listed in Table 2.2 depending

upon the existence of active alarms or process events. In case of co-existence of multiple active alarms or process events, the

messages are scrolled one after the other with an approximate time interval of 3 seconds. Also if there is no active alarm or

process event, the message space is blank.

Table 2.2

Process Status Screen

The Process Status Screen is shown upon pressing (Scroll) key from Main Screen or upon acknowledging a new Alarm by

pressing (Acknowledge) key. As depicted in Figure 2.4(a) for Old Version & 2.4(b) for New Version; the screen shows

Temperature Alarm Status, Door Open / Close Status, the Heater Output Status (ON / OFF or % Power) & Compressor ON /

OFF Status.

Figure 2.4(a) :

Old Version

Message String Alarm / Process Status

The Controller is Self Tuning.

Temp High

Temp Low

Tuning

The measured temperature is in Process High

Alarm State.

The measured temperature is in Process Low

Alarm State.

Door Open The Equipment / Chamber door is open for a time

longer than the set ‘DOOR ALRM DLY’ time.

Timer Hold The Countdown Timer is paused since the PV is

outside Hold Band.

°C

PROCESS STATUS

High

Door

Close

Compressor

OFF

Heating

0.0%

Heating Control

Output Power

Compressor

Output Status

Temperature

Alarm Status Door Status

Process Status

High

Door

Close

Compressor

OFF

Heater

0.0%

Heating Control

Output Power

Compressor

Output Status

Temperature

Alarm Status Door Status

Temp

Figure 2.4(b) :

New Version

4

Zenex Plus User Manual

The Controller provides programmable Low & High deviation

limits around the temperature control setpoint to monitor Alarm

conditions. The screen shows either Normal or Low or High

Status, as shown in Figure 2.5 (a) depending upon the

deviation of measured temperature value from the control

setpoint and set limits.

The Controller provides a Digital Input for interfacing Door

switch that senses the door position, Open or Close. The

screen indicates the door status as shown in Figure 2.5 (b).

Door

Open

Door

Close

Door Status

Figure 2.5 (b)

Figure 2.5 (a)

Temp

Normal

Temperature Alarm Status

Within

Limits

Below

Low Limit

Above

High Limit

Temp

Low

Temp

High

5

Zenex Plus User Manual

OPERATOR PARAMETERS

Section 3

Parameter Description Settings

(Default Value)

Table 3.1

Yes

No

(Default : No)

The Table 3.1 below described the Operator Parameters in detail.

Figure 3.1

°C

25.0

25.0

TEMP HIGH SP

or

Next Parameter

HI DEVIATION >>

2.0

LO DEVIATION >>

2.0

Desired Parameter

LO DEVIATION >>

5.0

Desired Value

Press UP/DOWN Keys

to adjust Parameter Value

Press ENTER Key

to store the New Value

& to move to Next Parameter

ENTER PASSWORD >>

0

CTRL SET VALUE >>

25.0

RUN Mode

Main Screen

Default Password

for Operator Parameters

First Parameter

Press SET-UP Key

for Password Entry

Press ENTER Key

To open Operator

Parameter List

Press & Release

ENTER Key until Desired

Parameter appears

(Available only if Timer is Enabled)

These two commands are mutually exclusive.

Set to Yes to start Timer, if not already started.

Set to Yes to abort a running timer.

TIME START COMMAND >>

TIME ABORT COMMAND >>

0.01 to 249.59

(HH:MM)

(Default : 0.10)

TIME INTERVAL (H:M) >>

(Available only if Timer is Enabled)

The set time value for the timer in Hours : Minutes.

The Operator Parameters are accessible under PASSWORD 0. The list includes parameters for adjusting Control Setpoint,

Alarm Setpoints & Zero-offset. If Timer is enabled then Time Interval value & Timer Start / Abort commands are also available.

The Figure 3.1 shows how to access Operator Parameters. The Example illustrates changing the Low Deviation alarm value

from 2.0 to 5.0. (The Example is shown with Timer disabled).

6

Zenex Plus User Manual

Parameter Description Settings

(Default Value)

Setpoint LO limit to

Setpoint HI limit

(Default : 25.0)

CTRL SET VALUE >>

This parameter sets the value at which the controller atte to mpts

maintain the measured temperature value.

0.2 to 99.9

(Default : 2.0)

LO DEVIATION >>

This Parameter sets a negative deviation (offset) limit with respect

to the ‘ ’. The Alarm is activated if the measured Control Set-point

temperature value falls below this limit.

0.2 to 99.9

(Default : 2.0)

HI DEVIATION >>

This Parameter sets a negative deviation (offset) limit with respect

to the ‘Control Set-point’. The Alarm is activated if the measured

temperature value exceeds this limit.

CHANGE PASSWORD >>

The Controller is shipped from the factory with a default password

(0) for accessing the parameters reserved for Operator. However,

if required the password can be changed by setting the new value

for this parameter.

(The new password replaces the old password. That is, the old

password is no longer valid. it is user’s responsibility to memorize

the password.)

1 to 100

(Default : 0)

7

Zenex Plus User Manual

SUPERVISORY PARAMETERS

Section 4

Accessing Group & Parameters

The Figure 4.1 below illustrates how to access the group and parameters. The example shows changing the value for the

parameter ‘Setpoint High Limit’ from 600.0 to 100.0 that is located under group ‘Control’.

Figure 4.1

The various parameters have been assembled in different groups under the default factory password 123.

Refer Table 4.1 below for a quick summary of parameters under different groups. Each parameter has been described in

subsequent sections.

Table 4.1

Password Change Password

Parameters

Group

Control

Tune, Setpoint Low Limit, Setpoint High Limit,

Compressor Set-point, Compressor Hysteresis,

Heat Control Action, Heat Hysteresis,

CZ Proportional Band, CZ Integral Time, CZ Derivative Time,

HZ Proportional Band, HZ Integral Time, HZ Derivative Time,

Cycle Time, Overshoot Inhibit, Cutoff Factor

Device ID, Baud Rate, Parity, Serial Write

Serial Parameter

Zero Offset

Sensor Input

ENTER PASSWORD >>

0

RUN Mode

Main Screen

Default Password

for Operator Parameters

Press SET-UP Key

for Password Entry

Press UP/DOWN Keys

To adjust Password Value

Press & Release

ENTER Key for the

First (Desired) Group

ENTER PASSWORD >>

123

or

Password for

Supervisory Parameters

First Group

Press ENTER Key

to Access Parameters

First Parameter in

selected Group

SELECT GROUP>>

SERIAL

TUNE >>

NO

Desired Parameter

SETPOINT HI LIMIT >>

600.0

or

Press UP/DOWN Keys

to Select Desired Parameter

°C

25.0

25.0

TEMP HIGH SP

or

Press UP/DOWN Keys

to adjust Parameter Value

Next Parameter

Press ENTER Key to

store the Value

and move to Next

Parameter

HEAT CTRL ACTION >>

PID

Desired Parameter

Value

SETPOINT HI LIMIT >>

100.0

Desired Group

SELECT GROUP>>

CONTROL

or

Press UP/DOWN Keys

to Select Desired Group

Exit Exit Setup Mode

8

Zenex Plus User Manual

Notes

The Last Parameter in the selected Group rolls back to the ‘SELECT GROUP’ screen again to avoid re-entering the password in case

parameters under multiple groups need to be set.

Parameter Descriptions

The various Supervisory Parameters have been described with their respective group & sub-group.

SUPERVISORY SERIAL PARAMETERS

Unique numeric code assigned to the for identification by indicator

the host. Set the value as required by the host.

DEVICE ID >>

Communication speed in ‘Bits per Second’. Set the value to match

with the host baud rate.

BAUD RATE >> 2400

4800

9600

19200

38400

57600

(Default : )9600

(Default : 1)

1 to 127

Parameter Description Settings

(Default Value)

PARITY >>

One of the communication error trapping features. Select the data

packet parity as implemented by the host protocol.

None

Even

Odd

(Default : Even)

SERIAL WRITE PERMISSION >>

Setting to ‘No’ disallows the host to set / modify any parameter

value. The host, however, can read the value. (Default : No)

No

Yes

SUPERVISORY SENSOR INPUT

Parameter Description Settings

(Default Value)

This value is algebraically added to the measured Temperature

Value at control channel to derive the final value that is displayed

and compared for alarm / control. Use this value to nullify any

known constant error.

Final Value = Measured Value + Offset

ZERO OFFSET >>

-50.0 to 50.0

(Default : 0.0)

9

Zenex Plus User Manual

ON-OFF

PID

(Default : PID)

0.1 to 99.9

(Default : 0.2)

SUPERVISORY CONTROL

(Available for Heat Only / Heat+Cool Control Strategy)

Set ‘Yes’ to activate and ‘No’ to abort the Tuning operation.

TUNE >>

This parameter sets the minimum limit on the Control Setpoint

value.

SETPOINT LO LIMIT >>

(Default : No)

Yes

No

Parameter Description Settings

(Default Value)

SETPOINT HI LIMIT >>

This parameter sets the maximum limit on the Control Setpoint

value.

For Thermocouple Input :

Setpoint LO Limit to 9999

For RTD Input :

Setpoint LO Limit to 600.0

(Default : 600.0)

COMPRESSOR HYST >>

(Available for ‘Cool Only’ ‘Heat + Cool’ Control & with

Compressor PV based Strategy)

Differential (dead) band between the compressor ON and OFF

states.

0.1 to 99.9

(Default : 2.0)

COMPRESSOR SETPOINT >>

(Available for ‘Heat + Cool’ Control Compressor PV with

based Strategy)

This Setpoint Value is compared with the process value to switch

the compressor On/Off with the set compressor hysteresis.

(Default : 45.0)

0.0 to 100.0

For Thermocouple Input :

-200 to Setpoint HI Limit

For RTD Input :

-99.9 to Setpoint HI Limit

(Default : 0.0)

HEAT CTRL ACTION >>

(Available for ‘Heat Only’ & ‘Heat+Cool’ Control Strategy)

On-Off

The control algorithm tends to maintain the PV at SP by either

switching the output (say, Heater) fully OFF or fully ON. The On

and Off switching is differentiated by the user settable ‘Hysteresis

Band’.

PID

The control algorithm uses a 2nd order equation to compute the

‘% Output Power’ required to maintain the PV at SP. The constants

P, I, D are automatically set by the controller.

HEAT HYST >>

(Available for ‘ON-OFF’ Heat Control Action)

Sets a differential (dead) band between the ON and OFF states.

Keep it large enough to avoid frequent switching of the load

without losing the desired control accuracy.

10

Zenex Plus User Manual

HZ INTEGRAL TIME >>

0 to 3600 sec

(Default : 100 sec)

Integral Time for

Heat Pre-dominant zone

HZ DERIVATIVE TIME >>

0 to 600 sec

(Default : 16 sec)

Derivative Time for

Heat Pre-dominant zone

CYCLE TIME >>

0.5 to 100.0 sec

(Default : 10.0 sec)

OVERSHOOT INHIBIT >>

Enable

Disable

(Default : Disable)

CUTOFF FACTOR >>

1.0 to 2.0 sec

(Default : 1.2 sec)

OVERSHOOT INHIBIT >>

Enable

Disable

(Default : Disable)

CUTOFF FACTOR >>

1.0 to 2.0 sec

(Default : 1.2 sec)

OVERSHOOT INHIBIT >>

Enable

Disable

(Default : Disable)

CUTOFF FACTOR >>

1.0 to 2.0 sec

(Default : 1.2 sec)

PROPORTIONAL BAND >>

0.1 to 999.9

(Default : 50.0)

INTEGRAL TIME >>

0 to 3600 sec

(Default : 100 sec)

DERIVATIVE TIME >>

0 to 600 sec

(Default : 16 sec)

PROPORTIONAL BAND >>

0.1 to 999.9

(Default : 50.0)

INTEGRAL TIME >>

DERIVATIVE TIME >>

0 to 3600 sec

(Default : 100 sec)

0 to 600 sec

(Default : 16 sec)

CZ PROP BAND >>

0.1 to 999.9

(Default : 50.0)

Proportional Band for

Cool Pre-dominant zone

CZ INTEGRAL TIME >>

0 to 3600 sec

(Default : 100 sec)

Integral Time for

Cool Pre-dominant zone

CZ DERIVATIVE TIME >>

0 to 600 sec

(Default : 16 sec)

Derivative Time for

Cool Pre-dominant zone

Heat Only Control Heat + Cool

Control Zone : Single

Heat + Cool

Control Zone : Dual

HZ PROP BAND >>

0.1 to 999.9

(Default : 50.0)

Proportional Band for

Heat Pre-dominant zone

CYCLE TIME >>

0.5 to 100.0 sec

(Default : 10.0 sec)

CYCLE TIME >>

0.5 to 100.0 sec

(Default : 10.0 sec)

11

Zenex Plus User Manual

SUPERVISORY PASSWORD

Parameter Description Settings

(Default Value)

CHANGE PASSWORD >>

The Controller is shipped from the factory with a default password

( ) for accessing the parameters reserved for the 123 equipment

manufacturer. owever, if required the password can be changed H

by setting the new value for this parameter.

(The new password replaces the old password. hat is, the old T

password is no longer valid. it is user’s responsibility to memorize

the password.)

(Default : 123)

1000 to 1999

SUPERVISORY EXIT

Parameter Description

EXIT SETUP MODE >>

Select to quit Setup mode and return to Main Display mode.

PROPORTIONAL BAND

Sets proportional gain (% power per unit error). Defined in same units and resolution as that for PV.

INTEGRAL TIME

Sets integral time constant in Seconds. Setting the value to 0, cuts-off the integral action.

DERIVATIVE TIME

Sets derivative time constant in seconds. Setting the value to 0, cuts-off the derivative action.

CYCLE TIME

Sets the total ‘On + Off’ time in seconds for time proportional power output through Relay / SSR for OP1.

OVERSHOOT INHIBIT

Set this parameter to ‘Enable’ if the process exhibits unacceptable overshoot upon start-up or a step change in SP. If enabled,

the controller controls the rate of change of PV to minimize overshoot while approaching the target SP.

CUTOFF FACTOR

This parameter adjusts the effectiveness of the Overshoot Inhibit feature. Increase the value if the overshoot is curbed but the

PV takes longer to reach the SP. Decreases the value if the overshoot persists.

12

Zenex Plus User Manual

Figure 5.1

FACTORY PARAMETERS

Section 5

Table 5.1

The various parameters have been assembled in various group under the default factory password 321.

Refer Table 5.1 below for a quick summary of parameters under different groups. Each parameter has been described in

subsequent sections.

Accessing Group & Parameters

The Figure 5.1 below illustrates how to access the group and parameters. The example shows changing the value for the

parameter ‘Hysteresis’ that is located under group ‘Alarm’ from 0.2°C to 0.5°C.

Alarm Hysteresis, Inhibit

Door Open Enable/Disable, Switch Logic, Door Alarm Delay

Factory Default Set to Default Yes/No

Parameters

Group

Sensor Input Input Type, Filter Constant

Heat Cool Select Control Strategy, Compressor Strategy, Boundary Set Value,

Control Zones, Time Delay (Sec)

Timer Enable, Start Band, Holdback Strategy, Hold Band,

Heat Off, Cool Off, Power Recovery

Password Change Password

HYSTERESIS >>

0.2

SELECT GROUP>>

CTRL SENSOR INPUT

First Group

or

First Parameter in

selected group

Desired Group

Press UP/DOWN

Keys to Select

Desired Group

Press ENTER Key

to Access

Desired Parameters

ENTER PASSWORD >>

0

RUN Mode

Main Screen

Default Password

for Operator Parameters

Press SET-UP Key

for Password Entry

Press UP/DOWN Keys

To adjust Password

Value

Press & Release

ENTER Key for the

First Group

ENTER PASSWORD >>

321

or

Desired Password

SELECT GROUP>>

ALARM

or

Press UP/DOWN

Keys to Adjust

parameter Value

HYSTERESIS >>

0.5

Desired Parameter

Value

Press ENTER Key

to Store the New Value

& Move to Next Parameters

INHIBIT >>

YES

Next Parameter in

selected group

°C

25.0

25.0

TEMP HIGH SP

Notes

The Last Parameter in the selected Group rolls back to the ‘SELECT GROUP’ screen again to avoid re-entering the password in case

parameters under multiple groups need to be set.

Exit Exit Setup Mode

13

Zenex Plus User Manual

Table 5.2

Parameter Description Settings

(Default Value)

Select Input type in accordance with the type of Temperature

sensor (Thermocouple / RTD) connected for measurement.

INPUT TYPE >>

(Default : RTD Pt100)

Refer Table 5.2

FACTORY CONTROL SENSOR INPUT

Parameter Descriptions

The various Factory Parameters have been described with their respective group & sub-group.

Option Range (Min. to Max.)

Type J (Fe-K)

Type K (Cr-Al)

Type T (Cu-Con)

0 to +960°C

-200 to +1376°C

-200 to +387°C

Type R (Rh-13%)

Type S (Rh-10%)

Type B

Type N

0 to +1771°C

0 to +1768°C

0 to +1826°C

0 to +1314°C

RTD Pt100

1 °C

0.1 °C

Reserved for customer specific Thermocouple

type not listed above. The type shall be specified

in accordance with the ordered (optional on

request) Thermocouple type.

-99.9 to +600.0°C

Resolution & Unit

Sets the time constant, in Seconds, for the low-pass digital filter

applied to the measured PV. The filter helps smoothing /

averaging the signal input and removing the undesired noise. The

higher the filter value the lower the indication response to the PV

changes and vice-a-versa.

FILTER CONSTANT >>

(Default : 0.5)

0.5 to 60.0

14

Zenex Plus User Manual

FACTORY ALARM PARAMETERS

Parameter Description Settings

(Default Value)

This parameter sets a differential (dead) band between the ON

and OFF Alarm status change. Keep it large enough to avoid

frequent switching of the Alarm Status/Relay.

HYSTERESIS >>

(Default : 0.2)

0.1 to 99.9

Yes

The Alarm activation is suppressed until the Temperature value is

within Alarm limits from the time the controller is switched ON. This

allows suppressing the Alarm during the start-up Alarm

conditions.

No

The Alarm is not suppressed during the start-up Alarm conditions.

INHIBIT >>

(Default : YES)

YES

NO

FACTORY

The PPI “Multi-Purpuse Temperature Controller” provides control outputs for driving, both, heating & cooling sources. The

user can enable any one or both outputs depending upon the test equipment type and application. If both outputs are enabled

(by setting the parameter ‘Control Strategy’ to Heat + Cool) and if the cooling source is compressor then the controller offers

various strategies for switching the compressor as described below.

Compressor Switching Strategies

1. Compressor Off

The compressor is kept Off. This strategy is usually selected for temperature values significantly above the ambient

temperature.

2. Compressor On

The compressor is kept On regardless of the measured or set temperature value. This strategy is usually selected for

temperature values significantly below the ambient temperature.

3. SP Based Strategy

In this strategy, the chamber temperature range is split in two zones by setting the parameter 'Boundary Set-point' (BSP).

Refer Figure 5.2.

HEAT COOL SELECT

15

Zenex Plus User Manual

The zone at and above the boundary SP ( ) is referred as Heat Pre-dominant zone and that below the boundary SP ) (

is referred as Cool Pre-dominant zone. The controller automatically switches between the two zones depending upon the

Temperature SP. If the Temperature SP is below boundary SP, Cool Pre-dominant zone is active and the compressor is kept

ON. If the Temperature SP is at or above boundary SP, Heat Pre-dominant zone is active and the compressor is kept OFF. This

strategy eliminates the need for the user to manually switch the compressor ON or OFF.

IControl Zones “Dual”; separate tuning can be performed in the Cool and Heat Pre-dominant zones for f the parameter is set to

accurate control in each zone. The controller maintains separate sets of Proportional Band, Integral Time & Derivative Time

constants for each zone that are automatically selected and used by the controller depending upon the active zone.

However, if the parameter Control Zones is set to “Single”; the controller uses a single set of Proportional Band, Integral Time

& Derivative Time constants for both zones.

Figure 5.2

70°C

0°C

45°C

30°C

50°C

Temp. Control SP in

Cool Pre-dominant Zone

Temp. Control SP in

Heat Pre-dominant Zone

Compressor Status

Boundary Set-point

ON

OFF

4. PV Based Strategy

In this strategy, the compressor is switched to cool down the air temperature. The controller switches the compressor ON

or OFF based on the comparison between the et emperature values. Refer Figure below.Measured & S T 5.3

The compressor is turned ON if the chamber air temperature value is above the Temperature SP by an amount set by the

parameter 'Compressor Set-point'. That is;

Compressor Switch - ON Level = (Temperature SP) + (Compressor Set-point)

Figure 5.3

Measured Temperature

Temperature SP

Compressor Switch-ON Level

Compressor Switch-OFF Level

Compressor Switch-ON Level = 20.0 + 1.0 = 21.0°C

Temperature SP = 20.0°C

Compressor Set-point = 1.0°C

Compressor Hysteresis = 1.2°C

Compressor Switch-OFF Level = 21.0 - 1.2 = 19.8°C

Compressor Status

OFF

ON

20.0

19.8

21.0

°C

16

Zenex Plus User Manual

Compressor Time Delay

Once the compressor is switched off, a time delay is desired before it is turned ON again. The time delay prevents the possible

damage due to short cycling. When the compressor switches off, it spins backward as pressure equalizes. If compressor is

energized while it is still spinning backward, it continues to run backward until it trips on internal overloads. This may cause

damage to the compressor.

The time delay cycle is executed every time the compressor is turned off. The compressor turning off may be a result of power

failure or the on-off control algorithm executed by the controller. The controller in “Auto Mode” monitors the Process Value (PV)

against the Set-Point (SP) and attempts to switch the compressor ON or OFF depending upon whether the PV is above or

below the SP.

The time delay starts counting down from the instance the compressor is switched off. The compressor is inhibited from

switching-on until the delay elapses regardless of the difference between the PV and SP. Once the time delay is elapsed, the

control algorithm switches the compressor ON as and when the PV is above SP.

Figure 5.4

PV (Temperature)

SP

Compressor Switch-ON Level

Compressor Switch-OFF Level

Compressor Switch-ON Level = 20.0 + 1.0 = 21.0°C

Temperature SP = 20.0°C

Compressor Set-point = 1.0°C

Compressor Hysteresis = 1.2°C

Compressor Switch-OFF Level = 21.0 - 1.2 = 19.8°C

Compressor Status

OFF

ON

20.0

19.8

21.0

°C

Case 2 Case 3Case 1

The figure 5.4 above illustrates 3 cases. Case (1) illustrates power-up delay. In case (2); the time elapses before PV rises

above the SP. The compressor is thus switched ON as soon as the PV rises above the SP. In case (3); the PV rises above the

SP while the time delay is still in progress. The compressor is switched ON as soon as the delay time elapses.

Table 5.2 lists various parameters required for setting-up appropriate compressor switching strategy and associated

parameters.

For parameter description the user is requested to read the preceding section.

Once the air temperature falls below Compressor Switch-ON Level by an amount set by the parameter 'Compressor

Hysteresis', the compressor is turned OFF. That is;

Compressor Switch - OFF Level = (Compressor Switch-ON Level) – (Compressor Hysteresis)

The hysteresis inserts a dead band between the Compressor Switch-ON Level and Compressor Switch-OFF Level to avoid

frequent switching of the compressor.

17

Zenex Plus User Manual

CONTROL ZONES >>

(Default : SINGLE)

SINGLE

DUAL

TIME DELAY (SEC) >>

(Default : 200 Sec)

0 to 1000 Sec

TIME DELAY (SEC) >>

(Default : 200 Sec)

0 to 1000 Sec

BOUNDARY SET VALUE >>

(Default : 45.0)

0.0 to 100.0

CONT. ON SP BASED PV BASED

COMPRESSOR >>STRATEGY

(Default : SP BASED)

CONT. OFF

CONT. ON

SP BASED

PV BASED

Parameter Description Settings

(Default Value)

Heat Only

Used in applications like Heating Oven, Vacuum Oven, Muffle

Furnace, etc.; that require raising the temperature above ambient.

The (Heater) control output switches ‘heating source’ for HTR

maintaining the temperature at desired setpoint. The CMP

(Compressor) control output is inactive (kept off).

Cool Only

Used in applications like Deep Freezer, Cold Cabinet, Lab

Refrigerator, etc.; that require lowering the temperature below

ambient. The (Compressor) control output switches ‘cooling CMP

source’ for maintaining the temperature at desired setpoint. The

HTR (Heater) control output is inactive (kept off).

Heat + Cool

Used in applications like Environment Chamber, BOD Incubator,

etc.; that require either lowering the temperature below or rasing

the temperature above ambient. Both, the (Compressor) CMP

and (Heater) control outputs switch ‘cooling source’ & HTR

‘heating source’, respectively, for maintaining the temperature at

desired setpoint.

CONTROL STRATEGY >>

(Default : Heat + Cool)

Heat Only

Cool Only

Heat + Cool

TIME DELAY (SEC) >>

(Default : 200 Sec)

0 to 1000 Sec

Control Strategy : Cool Only

Table 5.2

Control Strategy : Heat + Cool

TIME DELAY (SEC) >>

(Default : 200 Sec)

0 to 1000 Sec

18

Zenex Plus User Manual

Parameter Description Settings

(Default Value)

Yes

Timer function and Start / Abort commands are enabled.

No

Timer function and Start / Abort commands are disabled.

ENABLE >>

(Default : No)

No

Yes

After issuance of start command, the timer starts counting down

once the PV enters the process band around SP defined by this

parameter value.

START BAND >>

(Default : 0.5)

0 to 999.9

(Default : None)

None

Up

Down

Both

None

PV based timer pause is not required.

Up

Timer is paused if PV is outside holdband SP.above

Down

Timer is paused if PV is outside holdband SP.below

Both

Timer is paused if PV is outside holdband either above or below

SP.

HOLDBACK STRATEGY >>

Sets the temperature limit(s) with respect to the SP for the timer to

pause. The timer holds on counting should the PV cross the

limit(s).

HOLD BAND >>

(Default : 0.5)

0.1 to 999.9

Heater is turned off, once Timer operation is over.

HEAT OFF >>

Compressor is turned off, once Timer operation is over.

COOL OFF >>

(Default : No)

No

Yes

(Default : No)

No

Yes

FACTORY TIMER PARAMETERS

Abort

The timer operation is suspended until a new start command is

issued.

Re-Start

The timer re-runs the complete time.

Continue

The Timer resumes operation for the balance time.

POWER RECOVERY >>

(Default : Restart)

Abort

Restart

Continuous

Table of contents

Other PPI Controllers manuals

PPI

PPI HumiTherm-c Series User manual

PPI

PPI FLOREX User manual

PPI

PPI HumiTherm Plus User manual

PPI

PPI neuro 102 EX User manual

PPI

PPI neuro 202 User manual

PPI

PPI Clavex Pro User manual

PPI

PPI claveX Series User manual

PPI

PPI Epsilon 48 User manual

PPI

PPI neuro 105 User manual

PPI

PPI neuro 102L Plus User manual

Popular Controllers manuals by other brands

Kenwood

Kenwood KCA-CM50 instruction manual

Roberts Gorden

Roberts Gorden UltraVac URVCCL installation manual

Burkert

Burkert 5470 operating instructions

rotorgeeks

rotorgeeks SSD manual

Dometic

Dometic Marine Air Systems Fx-Maxx SDL Operation manual

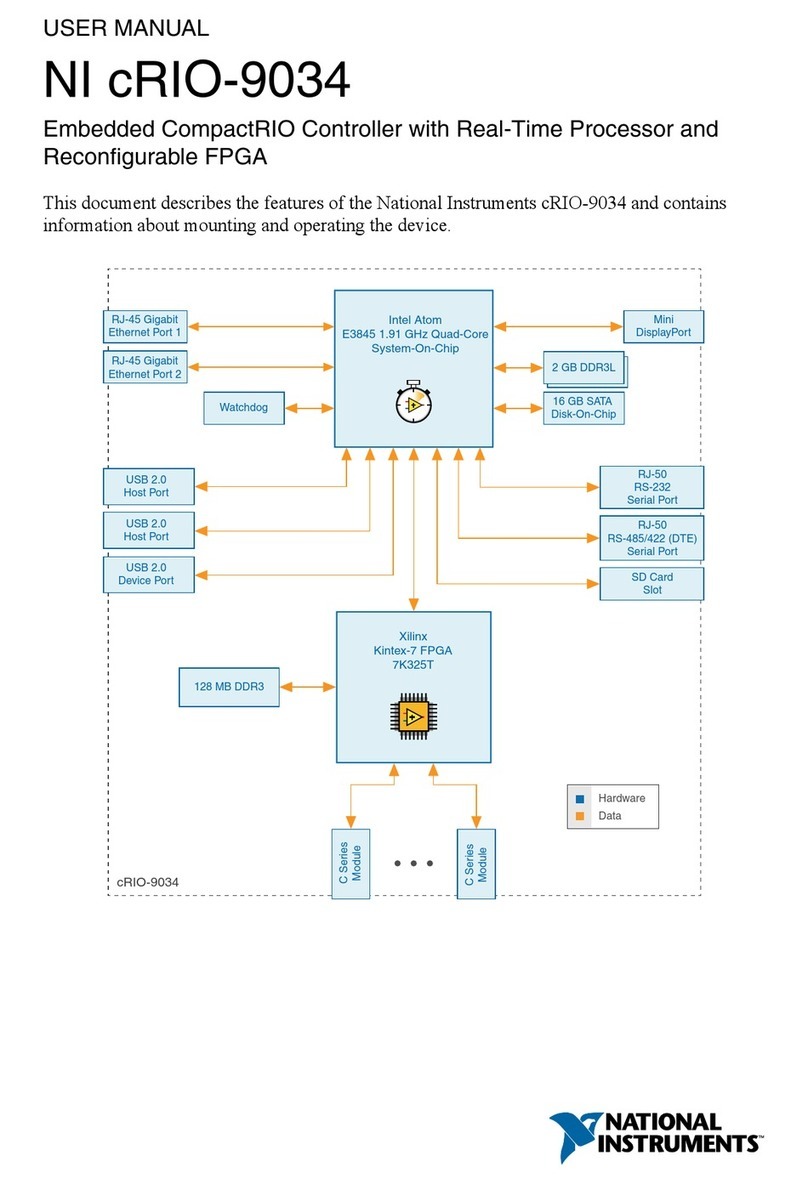

National Instruments

National Instruments cRIO-9034 user manual