ATTENTION

01 Main features

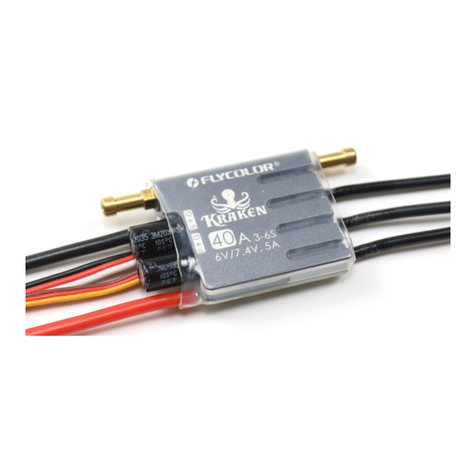

BEC

ATTENTION

06 Attention

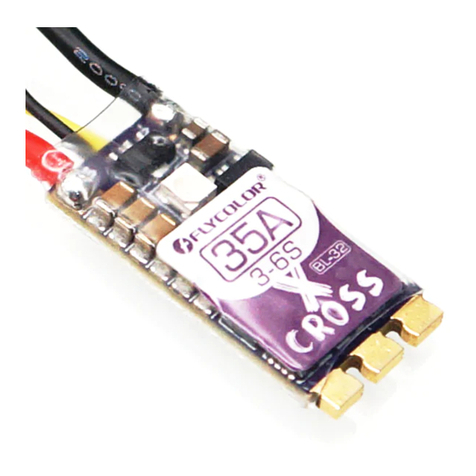

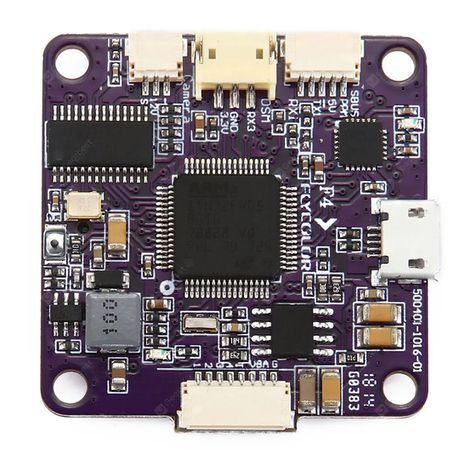

* Compatible with the general FC. Recom mend

the Flycolor X-Tower F4 Fligh t Control ler.

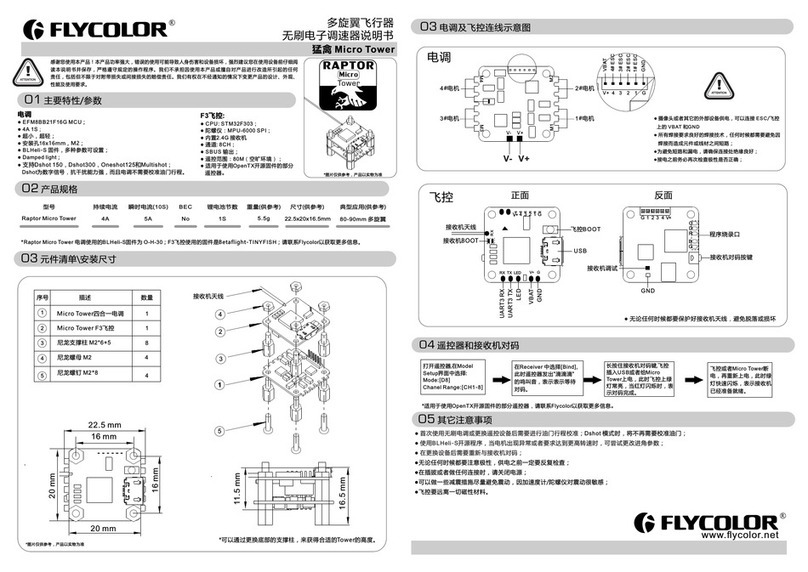

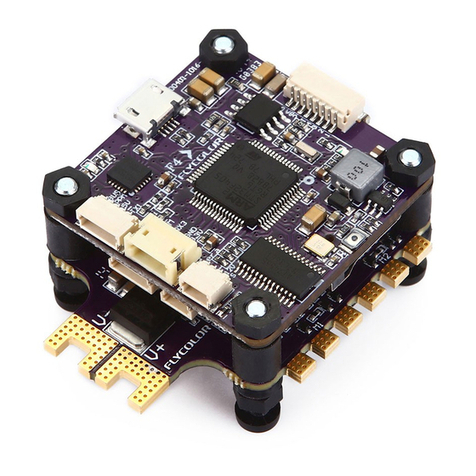

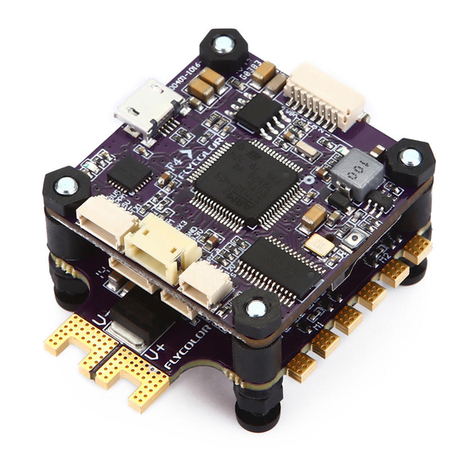

Install Dimensions(mm)

User Manual

Multi-Rotor Brushless ESC

Thank you for using our product. Any Improper operation may cause personal injury damage to the

product and related equipments. This high power system for RC model can be dangerous ,we strongly

recommend reading the user manual carefully and completely. We will not assume any responsibility for any

losses caused by unauthorized modifications to our product. We have the right to change the design,

appearance, performance and usage requirements of the product without notice.

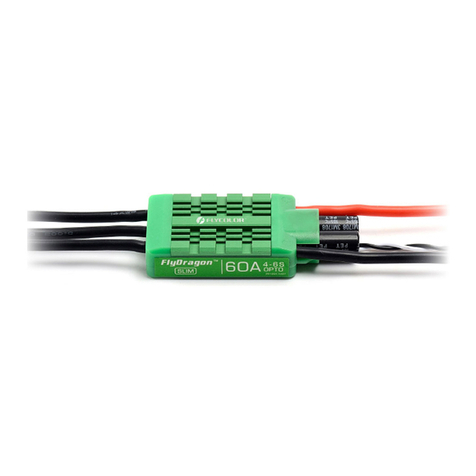

Con. Current Burst Current

(10S)

Size

( For reference )

Weight

LiPo cells Typical Application

( For reference )

Model

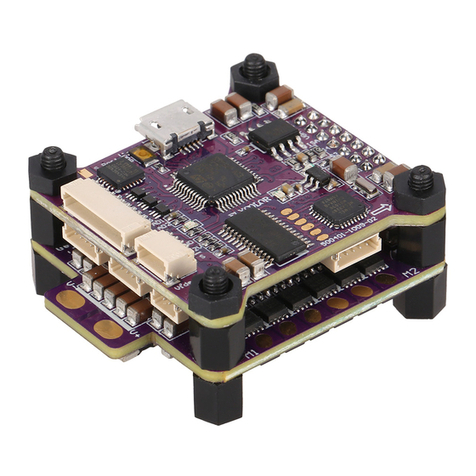

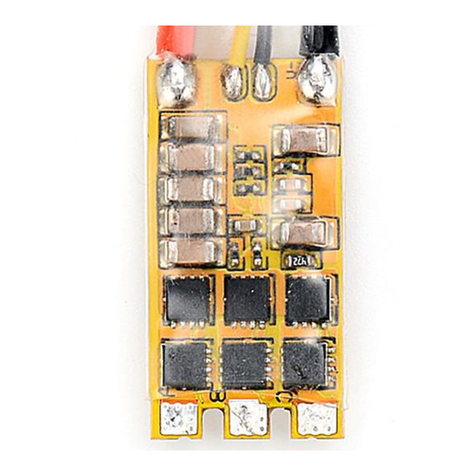

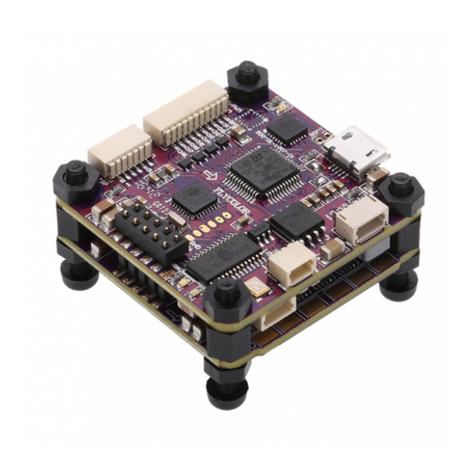

X-Tower BL-32 4in1ESC

Nylon spacer M3*6+6

Nylon Nut M3

Nylon screw M3*10

1

2

3

4

1

4

4

4

Item Description Qty.

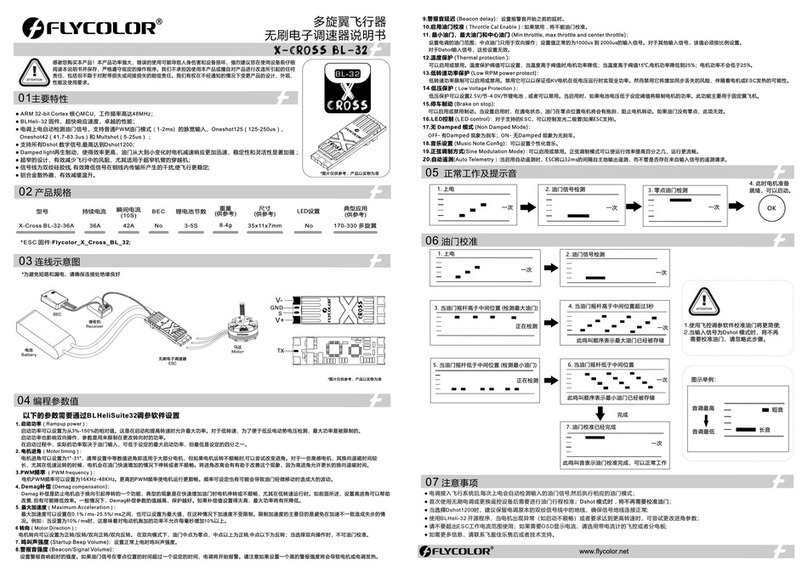

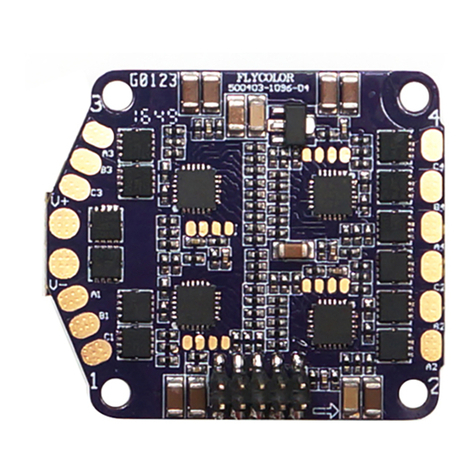

1. ESC a ddition al provid e:

One 8-Pin cable (8P S H1.0 termina ls) for con nection

with Flight Controller;

One 14AW G po wer input c able(X T6 0 terminal).

2.To enhance performance of filtering, users can solder the electrolytic

capacitor which are included in the accessory pack to the posi tive and

negative terminals.

*All pictures are for reference only

● All welding requires good welding technology,

short circuit between the element or the wire

should be avoided at any time.

● Please ensure all solder joints are insulated

with heat shrink where necessary.

● Please double-check the polarity is correct

before power up.

● VBAT is battery output, make sure your device

operating voltage is matched if you want to use

VBAT.

● ISA port can be connect to the port on F.C

for current meter.

Firmware:Flycolor_X_Cross_B L_32;

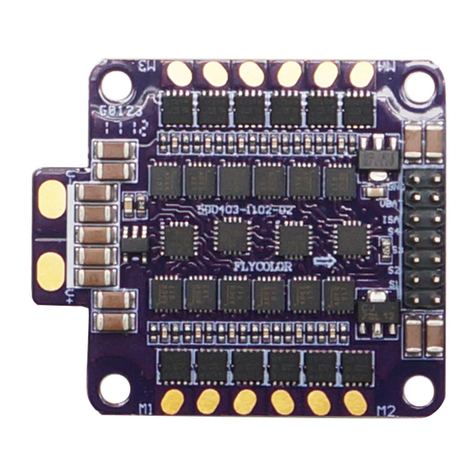

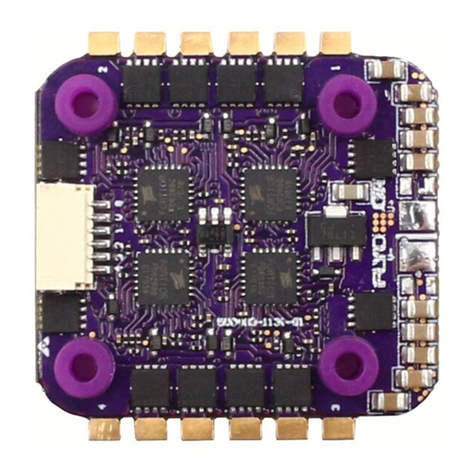

3#Motor

1#Motor

4#Motor

2#Motor

Battery v-

Battery v-

251400-1097,V 1.1

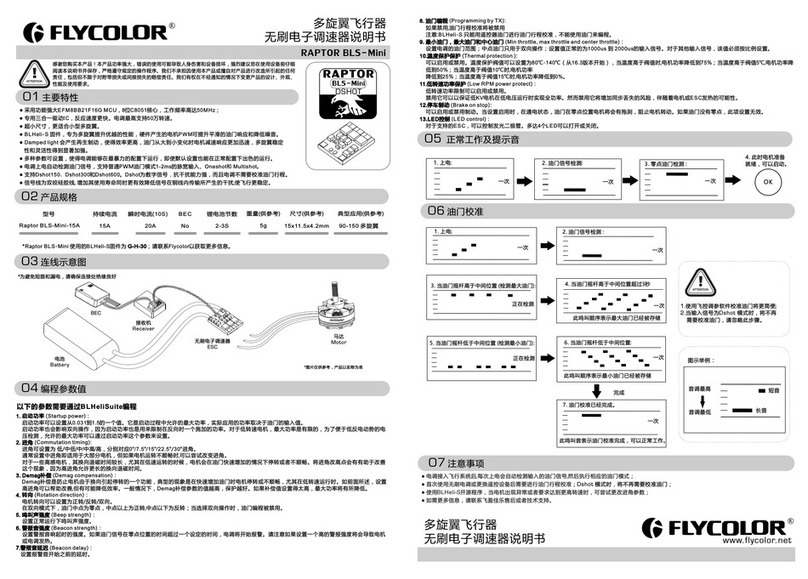

1. Rampup power:

Rampup power can be set to relative values from 3% to 150%. This i s the maxim um power th at is allow ed when ram ping up at lo w rpms and du ring star tup. For

low rpms, the maximum power to the motor is limited, in o rder to fac ilitate d etectio n of low B EMF voltages.

Rampup power also affects bidirectional operation, as the paramete r is used to li mit the pow er applie d during di rection r eversal .

During startup, the actual applied power depends on thrott le input, a nd can be low er than the m aximum le vel set by th e rampup po wer param eter, but the

minimum level is a quarter of the maximum level.

2. Motor timing:

Motor timing can be set between approximately 1° and approxi mately 31 ° in approx imately 1 ° increme nts (actu al accura te values here are 15/16ths of a degree).

Typically a medium setting will work fine, but if the motor stut ters it can b e benefici al to incre ase timin g. Some mot ors with hi gh inductance can have a very long

commutation demagnetization time. This can result in m otor stop o r stutter u pon quick t hrottle i ncrease , particularly when running at a low rpm. Setting timing

to high will allow more time for demagnetization, and often he lps.

3. PW M frequency:

Motor pwm frequency can be programmed between 16kHz and 48kH z. Higher p wm freque ncy can run m otors smo other. Pro grammab le frequency also allows for

moving of small but potentially disturbing humps in the thro ttle resp onse. All E SCs have these bumps, with BLH eli_32 th ey can be mov ed in the rpm range, to a

place where the system has low sensitivity to them.

4. Demag compensation:

Demag compensation is a feature to protect from mot or stalls c aused by lo ng windin g demagne tizatio n time afte r commutation. The typical symptom is motor

stop or stutter upon quick throttle increase, par ticular ly when run ning at a low r pm. As mentioned above, setting high commutation timing normally helps, but

at the cost of efficiency. Generally, a higher valu e of the comp ensatio n paramet er gives be tter prot ection. If demag compensation is set too high, maximum power

can be somewhat reduced.

5. Maximum Acceleration:

Maximum acceleration can be set between 0.1%/ms a nd 25.5%/ ms. It can al so be set to ma ximum, in w hich case a ccelera tion is not limited. Limiting acceleration

is primarily intended as a backup parameter that can be used in ca ses where t oo hard acc elerati on gives de syncs. Wh en settin g to e.g. 10%/ms, it means that the

power applied to the motor is not allowed to increase by more than 1 0% per mill isecond .

6. Direction:

Rotation direction can be set to fwd/rev/bidire ctional f wd/bidi rection al rev. In b idirect ional mod e, center t hrottle is zero and above is fwd rotation and below is

reverse rotation. When bidirectional operation is sele cted, thr ottle cal ibratio n is disabl ed.

7. Beep strength: Set s the stren gth of beeps under normal operation.

8. Beacon strength:

Sets the strength of beeps when beeping beacon beeps. The E SC will st art beeping beacon beeps if the throttle signal has been zero for a giventime. Note that

setting a high beacon strength can cause hot motors or ESC s!

9. Beacon delay: Beacon delay sets the delay before beacon beeping starts.

10.Throttle Cal Enable: If disabled, throttle calibration is disabled.

11. Min throttle, max throttle and center throttle:

These settings set the throttle range of the E SC. Center throttle is only used for bidirectional operation. The values given for these settings are for a normal

1000us to 2000us input signal, and for the other input signals , the value s must be sca led. For Ds hot input s ignal, th ese settings have no effect.

12.Thermal protection:

Thermal protection can be enabled or disabled. And the temperature t hreshol d can be prog rammed The progr ammable t hreshol d is primar ily meant as a support

for hardware manufacturers to use, as different ha rdwares c an have diff erent tol erances o n the max tem peratur es of the various components used.

13.Low R P M power protect:

Power limiting for low RP Ms c an be enabl ed or disab led. Disa bling it ca n be necess ary in order to achieve full power on some low kV motors running on a low

supply voltage. However, disabling it increases the risk of s ync loss, w ith the pos sibilit y of toasti ng motor or ES C.

14.Low Voltage Protection:

Low voltage protection can be set between 2.5V and 4.0V per lipo c ell. Or it ca n be disabl ed. When en abled, it w ill limit p ower appl ied to the motor if the battery

voltage drops below the programmed threshold. This feat ure is prim arily intended for fixed wing crafts.

15.Brake on stop:

Brake on stop can be set between 1% and 100%, or disabled. When not di sabled, b rake will b e applied w hen throt tle is zero . For nonze ro throttle, this setting

has no effect.

16.LE D Control: LE Ds can be controlled on E SCs that support it.

17.Non Damped Mode:OFF- Damped light is available ; ON- No Damped light。

18.Music Note Config: Se t up person alized mu sic.

Programming parameters below can be accessed from the configuration software (B LHeliSuite32):

4

1

2

3

48.5mm

30.5mm

40.8mm

30.5mm

● .ARM 32-bit Cor tex MCU, frequency up to 48 MH Z

● 4in1 ES C using cable for quick connection makes the installatio n faster and more convenient.

BLH eli_32 fir mware,whi ch is desig ned for sup erior fun ctional ity and per formanc e.●

● 4in1 ES C built-in current sensor.

● Supports regular 1-2m s pulse width input, as wel l as Oneshot125 (125-250us), Oneshot42 (41.7-83.3us) and

Multshot (5- 25us). The input signal is automatically detected b y the ESC upon power up.

● Dshot signal is support ed at any rate up to at least Dshot1200.

● Damped light does regenerative braking, caus ing very fast motor retardation, and inherently also does active

freewheeling.

● Supports higher KV motor and m ore power load, more suitable for violent flight of racing drone .

BL-32 4IN1

X-Tower BL-32 4in1 ESC

X-Tower BL-32 4in1-40A 40A 45A 3-6S 48.5x40.8x6m m

12.3g

No

170-450 Multi

● ESC will automatically detect the input throttle signals every time as soon as it powered on, and then execute the corresponding signal-receiving

mode.

● User need to calibrate the throttle range when starting to use a new ESC or another transmitter. When the input signal is Dshot, throttle calibration

is disabled.

● BLHeli-32 firmware, please don't flash any other firmware except “Flycolor_X_Cross_B L_32”.

● Observe polarity at all times. Check and double check before applying power.

● Power off before unplugging ,plugging in or making any connections.

● Please do not exceed the current range.

● Do everything you can to prevent vibrations.

● Please contact Flycolor sales or technical support for more information.

05 ES C Programming parameter

04 Wiring diagram of E SC

03 Part list / Install Dimensions

02 Specification