PPI Clavex Pro User manual

User Manual

Clavex Pro

User Manual

Enhanced

Autoclave Sterilization Controller

Clavex Pro

User Manual

Clavex Pro

CONTENTS

1. FRONT PANEL LAYOUT 1

2. BASIC OPERATION 3

3. SET UP MODE : ACCESS & OPERATION 6

4. PAGE 10 : INPUT / OUTPUT CONFIGURATION PARAMETERS 8

5. PAGE 15 : SOAK TIMER PARAMETERS & OPERATION DETAILS 9

6. PAGE 11 : SUPERVISORY PARAMETERS 11

7. PAGE 50 : ADDITIONAL CONTROL PARAMETER 13

8. MECHANICAL INSTALLATION 14

9. ELECTRICAL CONNECTIONS 16

1

User Manual

Clavex Pro

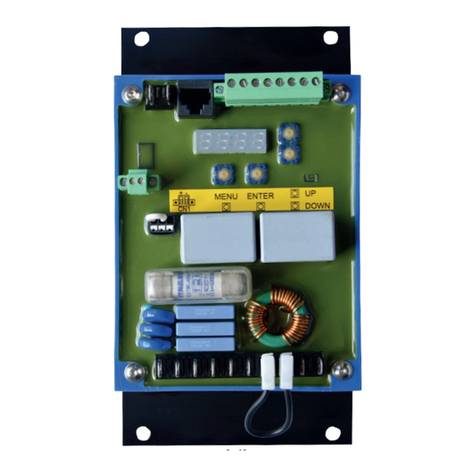

Indicator Function

Heater ON/OFF Status.

HTR

AIR

ALM

WLO

COM

Air Outlet Valve Open / Close status.

Alarm Status. Flashes while Alarm is Active.

Water Level Status. Flashes if water level is LOW.

Serial Communication Status. Flashes when data is being exchanged

with Master Device.

SOK

PRS

Unused.

L1

Glows / Flashes while the lower readout is indicating elapsed soak time.

Glows when the lower readout is indicating autoclave pressure value.

READOUTS

The Upper Readout is a 4 digit, 7-segment bright green LED display and usually displays the Temperature Value in °C. In

Program Mode, the Upper Readout displays parameter values/options.

The Lower Readout is a 4 digit, 7-segment bright green LED display and usually displays either Control Setpoint value or

Saturated Steam Pressure value or the balance Soak Time value, depending on the autoclave cycle state. In Program Mode,

the Lower Readout displays parameter names (prompts).

INDICATORS

There are 8 front panel red LED indicators. These indicator show various statuses. The Table 1.1 below lists each LED

indicator (identified by the front panel legend) and the associated status it indicates.

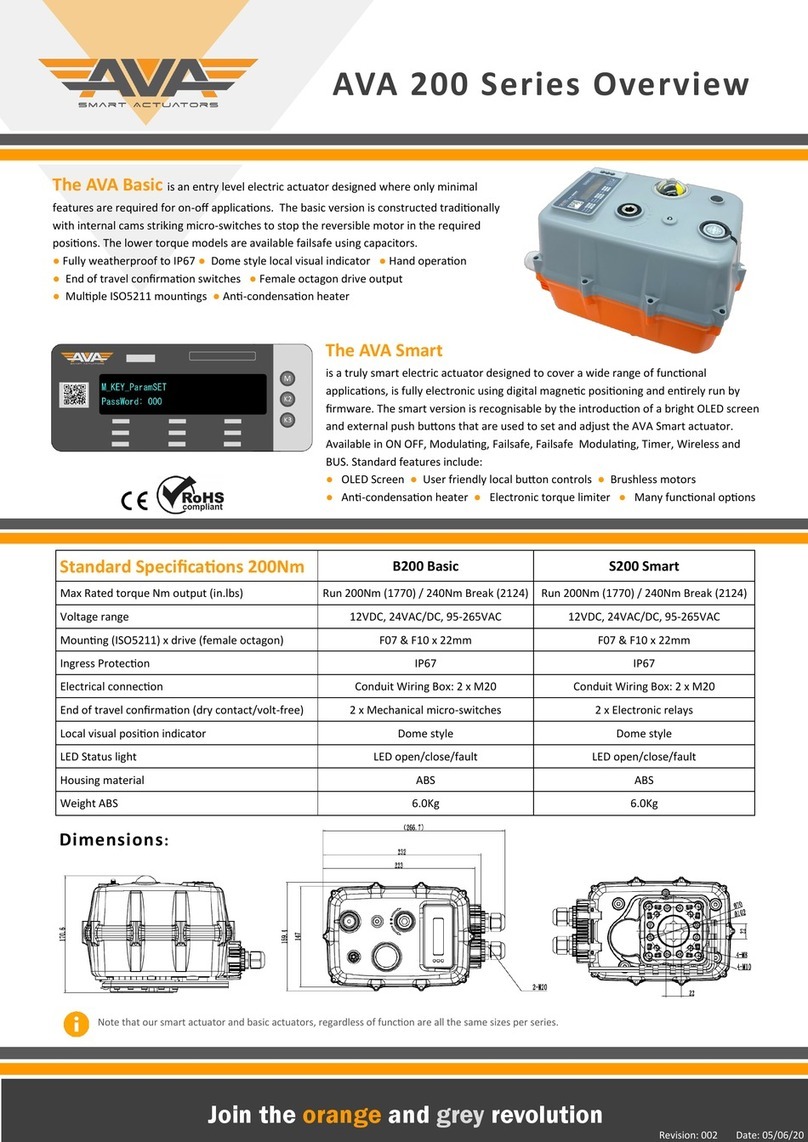

FRONT PANEL LAYOUT

Section 1

The controller front panel comprises of digital readouts, LED indicators and tactile keys as shown in Figure 1.1 below.

Figure 1.1

Table 1.1

HTR

AIR

SOK

PRS

Clavex Pro

ALM WLO

L1COM

Upper Readout

Lower Readout

ENTER Key

UP Key

DOWN Key

PAGE Key

Serial Comm. Indicator

Alarm Status Indicator

Lower Readout - Pressure

Water Low Indicator

Heater Status Indicator

Air Valve Status Indicator

Lower Readout - Soak Timer

2

User Manual

Clavex Pro

KEYS

The Table 1.2 lists the four front panel keys and the associated function.

Table 1.2

Symbol Key Function

Press to enter or exit set-up mode.

DOWN

UP

ENTER Press to store the set parameter value and to scroll to the next

parameter on the PAGE.

Press to increase the parameter value. Pressing once

increases the value by one count; holding pressed speeds up

the change.

Press to decrease the parameter value. Pressing once

decreases the value by one count; keeping pressed speeds up

the change.

PAGE

3

User Manual

Clavex Pro

BASIC OPERATIONS

POWER-UP

Upon power-up all displays and indicators are lit on for approximately 3 seconds. This is followed by the indication of the

controller model name (CLAv) on the Upper Readout and the firmware version (01.05) on the Lower Readout, for

approximately 1 second.

MAIN DISPLAY MODE

After the Power-up display sequence, the Upper Readout starts showing the Temperature Value in °C and the Lower Readout

indication depends on the autoclave cycle state (described below). This is the MAIN Display Mode that shall be used most

often.

Autoclave Cycle Operation

Control SP

Air Outlet SP

Ambient

Start

Command

Air

Outlet

Close

Soak

Time

Start

Cycle

End

Time

Temp.

Soak Time

Figure 2.1

Step 0 (Idle State - Start Command Awaited)

The Lower Readout shows the message (Start). The front panel indicators SOK and PRS are off. The heater is kept OFF and

the air outlet is kept ON. Use either front panel ‘ENTER’ Key or back panel Remote Key to issue ‘Start’ command to initiate a

new autoclave cycle.

Step 1 (Temperature Raised to Air Outlet SP)

The Lower Readout shows the Control Setpoint value. The front panel indicators SOK and PRS are both on, indicating that the

SP value is being shown on the Lower Readout. Both the heater and air outlet are maintained ON. As soon as the temperature

reaches the Air Outlet SP, the air outlet is turned OFF.

Step 2 (Temperature Raised to Control SP)

The Lower Readout shows the Saturated Steam Pressure value in either Kg/cm² or PSI after the temperature crosses

100.0 C. The front panel indicator SOK is off while PRS is on, indicating that the Pressure value is being shown on the Lower °

Readout. The heater is kept ON until the temperature reaches the Control SP. As soon as the temperature reaches the Control

SP, the soak timer starts counting down. (For the detailed Soak Timer operation, refer Section 5 : Soak Timer Parameters.)

Step 3 (Temperature Maintained at Control SP)

The Lower Readout shows the balance Soak Time in Minutes:Seconds format. The front panel indicator PRS is off. The

indicator SOK flashes if the timer is counting down and glows steadily if the timer is in hold state. The heater is appropriately

switched ON and OFF to maintain the temperature at Control SP while the Soak Timer is counting down to 0. During this time

the Saturated Steam Pressure value can be viewed by holding the UP or DOWN key pressed.

Upon completion of Soak Time, the cycle ends and the controller re-enters Step 0 (Idle State).

Section 2

3

4

User Manual

Clavex Pro

Notes

1) The running cycle is aborted if Low water level is detected. Also, a new start command is not accepted until the

water level error is removed. While the level is low, the Lower Readout flashes the message (Low Level).

2) After start of the Soak timer; if for any reason, the temperature falls below the Air Outlet SP or rises above the

Control SP by more than the ‘Fail-safe Deviation’, the Autoclave cycle is aborted.

PV above Max. Range

PV below Min. Range

Message Error Type Cause

Sensor Open / broken

Sensor Open

Under-range

Over-range

Table 2.1

PV Error Indications

The PV Error type is flashed on the Upper Readout. Refer Table 2.1.

ALARM FUNCTIONS

The Output - 3 Relay/SSR is provided as an Alarm Output that activates under the following conditions.

1. End of Soak Timer

The Alarm activates as soon as the soak timer reaches 0.This alarm indicates the end of the currently running autoclave

cycle.

2. Process High

The Alarm activates if the temperature deviates above the control setpoint by more than the set band value (see ‘Operator

Page and Parameters’).

3. PV Error

The Alarm activates if the measured temperature value crosses the specified Max. or Min. range for the selected sensor

type (that is, under or over range). The Alarm also activates if the sensor input is disconnected.

Under any of the above Alarm conditions, press the front panel ‘ENTER’ key to acknowledge the Alarm (de-activated the relay).

OPERATOR PAGE AND PARAMETERS

The controller provides a separate page that contains parameters that require frequent settings by the operator. The page is

called Operator Page and the parameters are called Operator Parameters. The availability of operator parameters is

controlled at supervisory level and these parameters are not affected by the master lock status.

Accessing Operator Page & Adjusting Parameters

Step through the following sequence to open the operator page and to adjust the operator parameter values.

1. Press and release PAGE key. The Lower Readout shows (PAGE) and Upper Readout shows (0).

5

User Manual

Clavex Pro

CYCLE ABORT PASS CODE

After setting the Cycle Abort Command to ‘Yes’, set this pass code

to an appropriate value for actual cycle abortion.

CYCLE ABORT COMMAND

Set to ‘Yes’ (to be followed by proper pass code entry) to abort a

running autoclave cycle.

FAIL-SAFE DEVIATION SETPOINT

The positive deviation value above the control setpoint for

automatic abortion of the cycle for safety. Upon abortion, the

heater is switched off and the air outlet valve is opened to release

the pressure.

The positive deviation value above the control setpoint for

Process High Alarm.

HIGH ALARM DEVIATION SETPOINT

SOAK TIME

The time duration in ‘Minutes’ for which the autoclave temperature

is maintained at the set control setpoint value.

AIR OUTLET SETPOINT

The setpoint value at and above which the Air Outlet valve is kept

closed to build saturated steam pressure.

The Setpoint value at which the autoclave temperature value is

maintained for the set soak time duration.

CONTROL SETPOINT

(Default : )100.0

Setpoint Low Limit to

Setpoint High Limit

2. Press ENTER key. The Lower Readout shows prompt for the first available operator parameter and the Upper Readout

shows value for the parameter.

3. Use UP/DOWN keys to adjust the value and then press ENTER key to store the set value and scroll to the next parameter.

The controller automatically reverts to MAIN Display Mode upon scrolling through the last operator parameter. Alternatively,

use PAGE key to return to MAIN Display Mode.

The PAGE 0 : Operator Parameters are described in Table 2.2 below.

Setpoint Low Limit to

Setpoint High Limit

(Default : )121.0

Parameter Description Settings

(Default Value)

Table 2.2

1 to 999 Minutes

(Default : 20)

1 to 10 or

0.1 to 10.0

(Default : 5.0)

3 to 20 or

0.3 to 20.0

(Default : 10.0)

0 to 250

(Default : 0)

Yes

No

6

User Manual

Clavex Pro

The various parameters are arranged in different groups, called PAGES, depending upon the functions they represent. Each

group is assigned a unique numeric value, called PAGE NUMBER, for its access.

The parameters are always presented in a fixed format: The Lower Readout displays the parameter prompt (Identification

Name) and the Upper Readout displays the set value. The parameters appear in the same sequence as listed in their

respective sections.

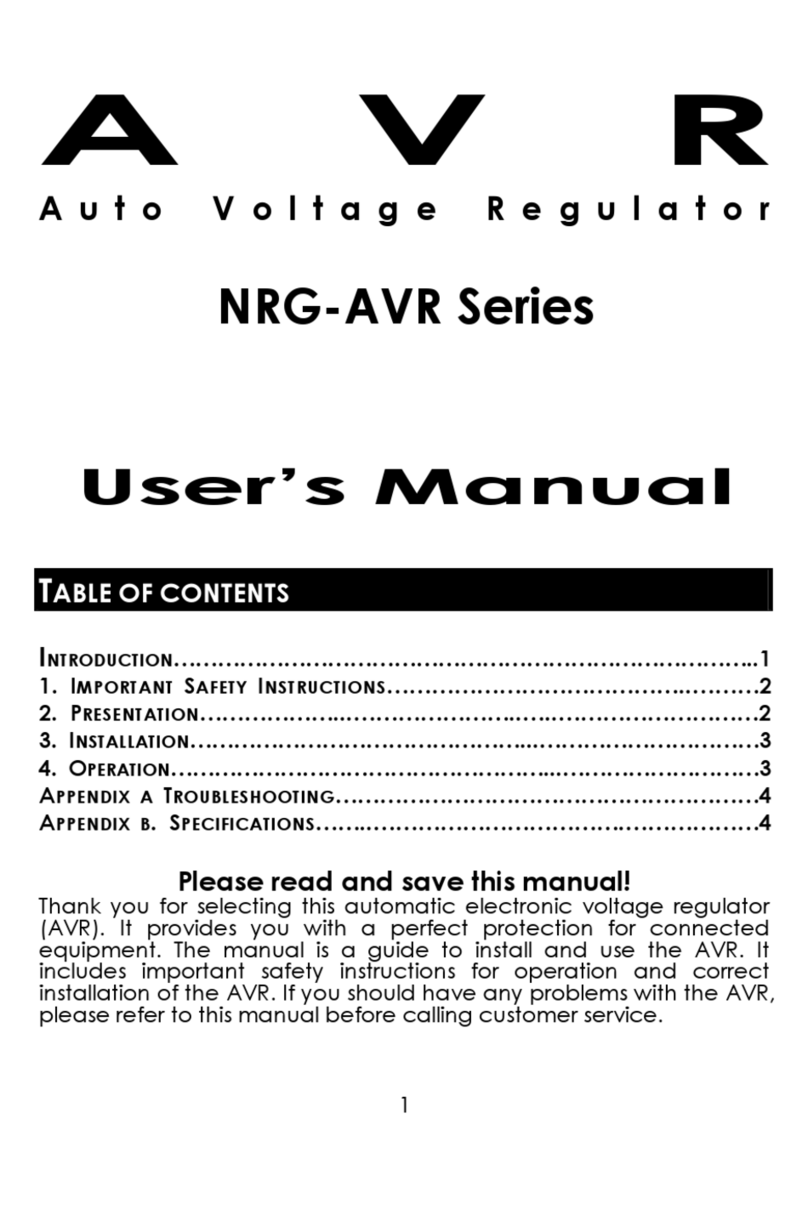

SET-UP MODE

The Set-up Mode allows the user to view and modify the parameter values. Follow the steps below for setting the parameter

values:

1. Press and release PAGE key. The Lower Readout shows PAGE and the Upper Readout shows page number 0. Refer

Figure 3.1.

2. Use UP / DOWN keys to set the desired PAGE NUMBER.

3. Press and release ENTER key. The Lower Readout shows the prompt for the first parameter listed in the set PAGE and

the Upper Readout shows its current value. If the entered PAGE NUMBER is invalid (contains no parameter list or any

associated function), the controller reverts to the MAIN Display Mode.

4. Press and release the ENTER key until the prompt for the required parameter appears on the Lower Readout. (The last

parameter in the list rolls back to the first parameter).

5. Use UP / DOWN keys to adjust the parameter value. (The display flashes if UP key is pressed after reaching the

maximum value or DOWN key is pressed after reaching the minimum value).

6. Press and release the ENTER key. The new value gets stored in the controller’s non-volatile memory and the next

parameter in the list is displayed.

The Figure 3.1 illustrates the example of altering the value for the parameter ‘Input Type’.

Figure 3.1

Use UP/DOWN

keys to change

the value

Press ENTER

key to store the value &

move to next parameter

First Parameter

on Page-10

New Parameter

value

Next Parameter

on Page-10

Main Display

Mode

Default Page Page Number

Press PAGE

key to enter

Set-up Mode

Use UP/DOWN

key to set the

Page Number

Press ENTER

key to open

the Page

SET-UP MODE : ACCESS AND OPERATION

Notes

1. To exit the set-up mode and return to the MAIN Display Mode, press and release PAGE key.

2. If no key is pressed for approximately 30 seconds, the set-up mode times out and reverts to the MAIN Display Mode.

or or

Section 3

7

User Manual

Clavex Pro

MAIN Display

Mode

Default Page Locking Code MAIN Display

Mode

Press PAGE

key to enter

Set-up Mode

Use UP/DOWN

key to set the

‘Locking Code’

Press ENTER key

to Lock & Return to

Main Mode

Locking

1. Press and release PAGE key while the controller is in the MAIN Display Mode. The Lower Readout shows PAGE and the

Upper Readout shows 0.

2. Use UP / DOWN keys to set the Page Number to 123 on the Upper Readout.

3. Press and release ENTER key. The controller returns to the MAIN Display Mode with the Lock enabled.

The Figure 3.2 below illustrates the Locking procedure.

Figure 3.2

UnLocking

Repeat the Locking procedure twice for unlocking.

MASTER LOCKING

The controller facilitates locking all the PAGES (except Operator PAGE) by applying Master Lock Code. Under Locking, the

parameters are available for view only and cannot be adjusted. The Master Lock, however does not lock the operator

parameters . This feature allows protecting the rather less frequently used parameters against any inadvertent changes while

making the frequently used operator parameters still available for any editing.

For enabling / disabling the Lock, step through the following sequence:

or

8

User Manual

Clavex Pro

PAGE 10 : INPUT / OUTPUT CONFIGURATION PARAMETERS

Select the units for saturated steam pressure from Kg/cm and ²

PSI.

UNITS FOR PRESSURE

SETPOINT HIGH LIMIT

Use this limit to prevent accidental over settings of the ‘Control’

and ‘Air Outlet’ setpoints.

SETPOINT LOW LIMIT

Use this limit to prevent accidental under settings of the ‘Control’

and ‘Air Outlet’ setpoints.

HYSTERESIS

Sets a differential (dead) band between the ON and OFF heater

states. Keep it large enough to avoid frequent switching of the

heater without losing the desired control accuracy.

1 to 999°C or

0.1 to 999.9°C

(Default : )2.0

Table 4.1

Parameter Description Settings

(Default Value)

INPUT TYPE

Select Input Type depending upon the resolution required.

Section 4

(Default : )RTD Pt100, 0.1°C

RTD Pt100, 1°C

RTD Pt100, 0.1°C

(Default : 9 °C)0.0

Min. Range for the selected

Input Type to Setpoint High

(Default : °C)150.0

Setpoint Low to Max. Range

for the selected Input Type

(Default : ²)Kg/cm

PSI

Kg/cm²

9

User Manual

Clavex Pro

Abort

The timer operation is suspended until a new start command is

issued.

Start

The timer re-runs the complete soak time.

Continue

The Soak Timer resumes operation for the balance time.

POWER-FAIL RECOVERY METHOD

5 to 250 Sec.

(Default : 10 Sec.)

END-OF-SOAK ALARM TIME

The Output-3 Relay/SSR activates at the end of soak timer to

indicate an end of the running autoclave cycle. This parameter

value sets the time interval for which the Alarm output remains

activated before turning off.

(The user can also use Acknowledgment key to turn off the

output.)

HOLD BAND

Sets the temperature limit(s) with respect to the SP for the soak

timer to pause. This ensures guaranteed soak time elapse.

1 to 5 or

0.1 to 5.0

(Default : 1.0)

(Re)Start

Abort

Continue

(Default : Continue)

(Refer end of this section for detailed Soak Timer Operation)

Table 5.1

TIMER-START BAND

The temperature band around the control setpoint. The soak timer

starts counting down once the Temperature enters this band.

HOLDBACK STRATEGY

None

Temperature based timer pause is not required.

Up

Timer is paused if Temperature is outside holdband and above

Control SP .

Down

Timer is paused if Temperature is outside holdband below Control

SP.

Both

Timer is paused if Temperature is outside holdband both above

and below Control SP.

None

Up

Down

Both

(Default : Down)

SOAK TIME

The time duration in ‘Minutes’ for which the autoclave temperature

is maintained at the set control setpoint value.

1 to 999 Minutes

(Default : 20)

PAGE 15 : SOAK TIMER PARAMETERS

Parameter Description Settings

(Default Value)

1 to 5 or

0.1 to 5.0

(Default : 1.0)

Section 5

10

User Manual

Clavex Pro

SOAK TIMER OPERATION

Figure 5.1

SP

PV

Time

PV

Set Time

Timer count down starts

PV enters start band,

Start Band

Basic Operation

The Soak Timer is essentially a Setpoint Dependent Timer. That is, after issuance of Start Command, the count down starts

only after the Temperature Value reaches within timer ‘Start Band’. The timer start band is a symmetrical band centered

around the Control Setpoint. For example, for a start band of 1.0°C and Control Setpoint value of 121.0°C, the count down

begins once the Temperature Value reaches within 120.0°C (Control Setpoint - Start Band) to122.0°C (Control Setpoint +

Start Band). Note that, once the Temperature Value enters ‘Start Band’, the timer continues to run regardless of whether the

Temperature Value remains within or outside the ‘Start Band’.

Hold Band Operation

The timer is also provided with a ‘Hold Band’ that can be enabled to make sure that the timer counts down only while the

Temperature Value is within the ‘Hold Band’. That is, the timer pauses (stops counting down) whenever the Temperature Value

is outside the ‘Hold Band’. The ‘Hold Band’ is set with respect to the Control Setpoint and can be set above or below or above

and below the Control Setpoint. For example, a 1.0°C Hold Band below the Control Setpoint (say,121.0°C) will force the timer

in pause state whenever the Temperature Value is equal to or less than 120.0°C (Control Setpoint - Hold Band).

Power-fail Recovery Modes

The timer facilitates 3 different power-fail recovery modes, viz., Continue, Re-start and Abort. In Continue mode, the timer

resumes to execute the balance soak time once the Temperature Value is detected within Hold Band. In Re-start mode, the

timer executes the complete set time all over again. In Abort mode, the timer stops execution until a start command is issued.

11

User Manual

Clavex Pro

SLAVE ID

This parameter assigns a unique identification number that the

Master Device can use to address the instrument for data

transactions.

PAGE-11 : SUPERVISORY PARAMETERS

Parameter Description Settings

(Default Value)

Table 6.1

PASS CODE FOR CYCLE ABORT

Set the pass code that the operator must enter if he needs to abort

a running autoclave cycle by setting the Abort command to ‘Yes’

on the operator page.

OPERATOR PARAMETER LOCKING

Setting this parameter to ‘Yes’ enables the supervisor to disallow

the operator to edit the Control Setpoint, Air Outlet Setpoint and

the Soak Time duration on the Operator Page.

DIGITAL FILTER FOR TEMPERATURE VALUE

This value determines the averaging rate of change of Measured

Temperature Value and thus helps removing undesired rapid

changes in the measured . The higher the filter Temperature Value

value the better the averaging but the slower the response to

actual changes.

OFFSET FOR TEMPERATURE VALUE

This parameter adds positive or negative offset to the Measured

Temperature Value for removal of thermal gradient or known

sensor error.

(Default : )22

1 to 250

0.5 to 25.0 Seconds

in steps of 0.5 Seconds

(Default : )1.0

-1999 to 9999 or

-199.9 to 999.9

(Default : )0.0

(Default : )No

Yes

No

1 to 127

(Default : )1

Section 6

BAUD RATE

Communication speed in ‘Bits per Second’. Set the value to match

with the host baud rate.

(Default : 9600)

4800

9600

19200

Parity setting for serial communication protocol

PARITY

(Default : Even)

None

Even

Odd

12

User Manual

Clavex Pro

Parameter Description Settings

(Default Value)

WATER LEVEL SWITCH LOGIC

Open

The Water Level is considered LOW if the switch contacts are

open.

Close

The Water Level is considered LOW if the switch contacts are

close.

Yes

No

(Default : )Yes

COMMUNICATION WRITE ENABLE

No

The Read/Write parameters can only be accessed for reading.

That is, the parameter values cannot be altered through serial

communication.

Yes

The Read/Write parameters can be accessed for both reading and

writing.

PRESSURE VIEW

Set this parameter to ‘Enable’ if it is desired to indicate the

Saturated Steam Pressure (computed based on Autoclave

Temperature) on the lower readout.

If ‘Disable’ the Saturated Steam Pressure indication is

suppressed.

(Default : Enable)

Disable

Enable

(Default : Open)

Open

Close

13

User Manual

Clavex Pro

PAGE 50 : ADDITIONAL CONTROL PARAMETER

Parameter Description Settings

(Default Value)

Table 7.1

SETPOINT OFFSET

This parameter value is algebraically added to the control setpoint

in order to provide positive offset for switching the heater.

Switching off the heater above the setpoint helps reduce the

undershoot that might result in pausing the soak timer.

0.0 to 10.0

(Default : )0.0

Section 7

14

User Manual

Clavex Pro

OUTER DIMENSIONS AND PANEL CUTOUT

The Figure 8.1 shows the controller outer dimensions.

Figure 8.1

MECHANICAL INSTALLATION

Section 8

Figure 8.2

94mm

(3.70in)

7mm (0.276in)

Side View

48mm

(1.89in)

48mm

(1.89in)

Front View

HTR

AIR

ALM

SOK

WLO

Clavex Pro

PRS

COM L1

PANEL CUTOUT

The Figure 8.2 shows the panel cutout requirements for a single controller.

V

H

Parameter Dimensions

mm inches

H

V

45 (-0, +0.5)

45 (-0, +0.5)

1.77 (-0, +0.02)

1.77 (-0, +0.02)

15

User Manual

Clavex Pro

PANEL MOUNTING

Follow the steps below for mounting the controller on panel:

1. Prepare a square cutout to the size shown in Figure 8.2.

2. Remove the Panel Mounting Clamp from the controller Enclosure and insert the rear of the controller housing through the

panel cutout from the front of the mounting panel.

3. Hold the controller gently against the mounting panel such that it positions squarely against the panel wall, see Figure 8.3.

Apply pressure only on the bezel and not on the front label.

4. Insert the mounting clamps on either side of the controller in the slots provided for the purpose. Rotate the screws clock-

wise so that they move forward until they push firmly against the rear face of the mounting panel for secured mounting.

Figure 8.3

Clamps

Bezel

Controller

Mounting Panel with

Square Cutout

16

User Manual

Clavex Pro

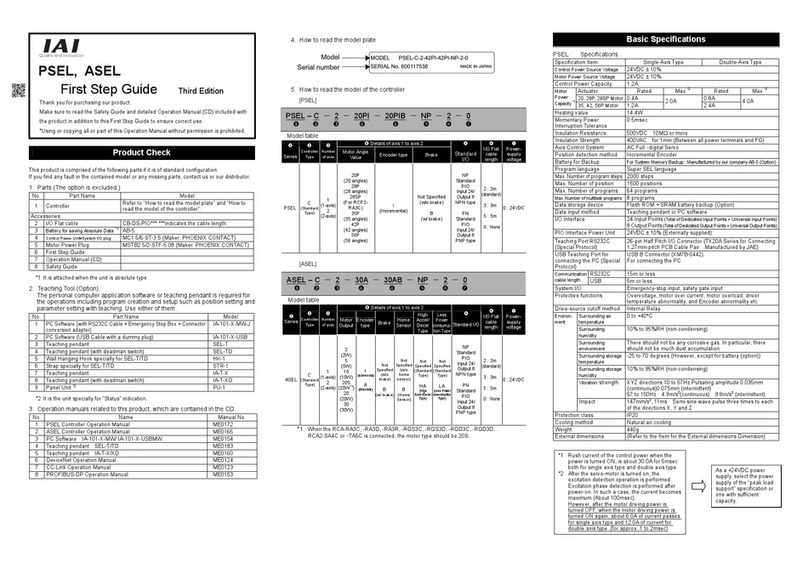

ELECTRICAL CONNECTIONS

Figure 9.1

Section 9

1 2 345

21

20

19

18

L N

NO C

85~264

VAC

Relay

ALM O/P

HEATER AIR O/P

B+ B-

RS485

PV INPUT

+

-

SSR

Water

Level

10

1112

13

14

1516

17

RTD

6

7

8

9

+

-

SSR

NOCNC

RLY

NO C NC

RLY

Cycle

Start

48X48

WARNING

MISHANDLING / NEGLIGENCE CAN

RESULT IN PERSONAL DEATH OR

SERIOUS INJURY.

1. The user must rigidly observe the Local Electrical Regulations.

2. Do not make any connections to the unused terminals for making a tie-point for other wires (or for any other reasons) as

they may have some internal connections. Failing to observe this may result in permanent damage to the controller.

3. Run power supply cables separated from the low-level signal cables (like RTD, DC Linear (Voltage) signals, etc.). If the

cables are run through conduits, use separate conduits for power supply cable and low-level signal cables.

4. Use appropriate fuses and switches, wherever necessary, for driving the high voltage loads to protect the controller from

any possible damage due to high voltage surges of extended duration or short-circuits on loads.

5. Take care not to over-tighten the terminal screws while making connections.

6. Make sure that the controller supply is switched-off while making/removing any connections or removing the controller

from its enclosure.

CONNECTION DIAGRAM

The Electrical Connection Diagram is shown on the top side of the enclosure. The diagram shows the terminals viewed from

the REAR SIDE with the controller label upright. The connecters provided for wiring are pluggable male-female type. The

female parts are soldered on the controller PCBs while the male parts are with screws and removable. The rear panel

electrical wiring connection diagram is shown in Figure 9.1.

17

User Manual

Clavex Pro

DESCRIPTIONS

PV INPUT : RTD Pt100, 3-Wire (Terminals 17, 16, 15)

Connect single leaded end of RTD bulb to terminal 17 and the double leaded ends to terminal 16 and

15 (interchangeable) as shown in Figure 9.2 (a). Use copper conductor leads of very low resistance

ensuring that all 3 leads are of the same gauge and length. Avoid joints in the cable.

1516

17

Figure 9.2

Water Level : Low Water-Level Detection Digital Input (Terminals : 14, 13)

Potential-free contact closure input terminals are provided as digital inputs for low water level

detection. An user programmable ‘Open’ or ‘Close’ switch position is detected as water level low.

14 13

Figure 9.3

Cycle Start : Remote Cycle Start Digital Input (Terminals : 13, 12)

Potential-free contact closure input terminals are provided as digital inputs for issuance of remote

Cycle Start command. An Open - to - Close transition is taken as Cycle Start Command. If the cycle is in

progress, the switch position is ignored.

13 12

Figure 9.4

HEATER : Relay / SSR Drive for Heater Control (Terminals 18, 19 & 20)

AIR O/P : Relay / SSR Drive for Air Valve (Terminals 7, 8 & 9)

Relay Output

Potential-free Relay changeover contacts NO (Normally Open) and C (Common) rated 10A/240 VAC (resistive load). Refer

Figure 9.5(a).

SSR Output

Connect (+) and (-) terminals of SSR to terminals 18 /9 & 19 / 8, respectively. Use Zero-Crossover, 3 to 30 VDC operated SSR.

Refer Figure 9.5(b).

Figure 9.5(b) : SSR

Figure 9.5(a) : Relay

18

19

9

8

NO

C

NC

9

8

7

18

19

20

18

User Manual

Clavex Pro

Relay ALM O/P : Potential-free Relay Contacts for Alarm Output (Terminals 3, 4)

Potential-free Relay changeover contacts N/O (Normally Open) and C (Common) rated 2A/240 VAC

(resistive load) are provided as Relay output. Use external auxiliary device like contactor with

appropriate contact rating for driving the actual load.

N/O C

34

Figure 9.6

Figure 9.7

RS485 : Serial Communication Port (Terminals 10, 11)

Connect terminal 11 and 10 of the controller to (+) and (-) RS485 terminals of the Master device.

To ensure reliable operation of the Serial Communication Link (without data corruption due to line noise or reflections), use a

pair of twisted wires inside screened cable with the terminating resistor (100 to 150 Ohms) at one end, as shown in Figure 9.7

below.

Terminating Resistor

Screened Cable

Twisted

Wire Pair

(100 to 150 Ohms)

HOST

B-

B+

Master Device

Serial Comm.

Terminals

B-

10

B+

11

Figure 9.8

85~264 VAC : Power Supply (Terminals 1, 2)

The controller is supplied with power connections suited for 85 to 264 VAC line supply. Use well-insulated copper conductor

2

wire of the size not smaller than 0.5mm for power supply connections. Connect Line (Phase) supply line to terminal 1 and the

Neutral (Return) supply line to terminal 2 as shown in Figure 9.8 below. The controller is not provided with fuse and power

switch. If necessary, mount them separately. Use a time lag fuse rated 1A @ 240 VAC.

Line

Neutral

2 Pole

Isolating Switch

Fuse

Power Supply

Terminal

L

1

N

2

Table of contents

Other PPI Controllers manuals

PPI

PPI neuro 202 User manual

PPI

PPI HumiTherm-c Series User manual

PPI

PPI FLOREX User manual

PPI

PPI neuro 105 User manual

PPI

PPI Neuro 102EX User manual

PPI

PPI neuro 105 User manual

PPI

PPI HumiTherm Plus User manual

PPI

PPI neuro 102 EX User manual

PPI

PPI claveX Series User manual

PPI

PPI neuro 102 User manual