Prebena 3X-CNW50 User manual

_____________________________________________________

PREBENA Wilfried Bornemann GmbH & CO. KG

Seestraße 20 – 26, 63679 Schotten, Germany

Tel.: +49 (0) 60 44 / 96 01-0, Fax: +49 (0) 60 44 / 96 01-820

info@prebena.com

,

www.prebena.de

Original operating instructions for

Pneumatic Coilnailers

PREBENA 3X-CNW50

PREBENA 4X-CNZ45

PREBENA 5F-CNW65

PREBENA 7F-CNW90

PREBENA 9F-CNW100EPAL

Nr. 98683203

Foreword

This operating manual helps you in the

proper,

safe and

effective

use of the following pneumatic coilnailers:

3X-CNW50

4X-CNZ45

5F-CNW65

7F-CNW90

9F-CNW100EPAL.

In this operating manual, these coilnailers are referred to as tackers for

short.

We assume that every user of the tacker is familiar with the use of

pneumatic equipment and the materials employed. Persons without this

know-how must be instructed in the use of the tacker by an experienced

user.

This operating manual is intended for the following persons:

Persons who operate this tacker,

Persons who clean this tacker, or

Persons who dispose of this tacker.

Each of these persons must have been familiarised with and understood the

content of this operating manual.

This operating manual forms an integral part of the product. Always store the

operating manual together with the tacker. Pass on the operating manual if

you resell the tacker or pass it on to other persons in any other way.

Table of Contents

Layout Features.......................................................................................... 5

General layout features........................................................................... 5

Features of the danger warnings ............................................................ 5

Features of the warnings on material damage or environmental pollution5

Safety........................................................................................................... 6

Intended use ........................................................................................... 6

Unauthorised use.................................................................................... 6

Avoid risk of fatal injuries ........................................................................ 7

Avoid explosion hazards ......................................................................... 7

Avoid injury risks ..................................................................................... 7

Avoid damage to the tacker .................................................................... 7

Description.................................................................................................. 8

Tacker overview...................................................................................... 8

Scope of supply .................................................................................... 10

Product features of the tackers ............................................................. 11

Safety devices....................................................................................... 11

Accessories........................................................................................... 13

Data on the rating plate......................................................................... 13

Preparing the tacker................................................................................. 14

Unpacking the tacker ............................................................................ 14

Check condition .................................................................................... 14

Connect tacker to compressed air supply ............................................. 15

Open magazine..................................................................................... 17

Set nail length ....................................................................................... 19

Inserting nails........................................................................................ 21

Close magazine .................................................................................... 22

Adjusting the vent ................................................................................. 22

Use of the stop on Type 4X-CNZ45...................................................... 23

Attaching the handle to Type 9F-CNW100EPAL .................................. 23

Use with a weight balancer ................................................................... 24

Check function ...................................................................................... 24

Using the tacker ....................................................................................... 25

Select firing setting ............................................................................... 25

Set nailing depth................................................................................... 26

Adjusting Type 7F-CNW90................................................................... 27

Adjusting the nailing depth via the working pressure............................ 27

Checking nailing depth ......................................................................... 28

Driving in nails ...................................................................................... 28

After use.................................................................................................... 30

Disconnect the compressed air supply ................................................. 30

Empty magazine................................................................................... 31

Transporting and storing the tacker....................................................... 31

Packing................................................................................................. 31

Transporting ......................................................................................... 32

Storage................................................................................................. 33

Servicing the tacker ................................................................................. 33

Cleaning housing and outer surfaces ................................................... 33

Oiling the tacker.................................................................................... 34

Malfunctions ............................................................................................. 34

Malfunctions in the transport of nails to the firing channel .................... 34

Other malfunctions ............................................................................... 35

Troubleshooting chart........................................................................... 35

Ordering accessories............................................................................... 37

Re-ordering nails .................................................................................. 37

Ordering further accessories ................................................................ 38

Disposal of tacker .................................................................................... 38

Technical data .......................................................................................... 39

Manufacturer's address........................................................................... 41

Guarantee ................................................................................................. 42

Index.......................................................................................................... 43

Layout Features

5

Layout Features

General layout features

Various elements in the operating manual are marked with specific layout

features. This allows you to easily distinguish whether it is

normal text, ●lists or work steps that you are reading.

Tips contain additional information, such as for example special

instructions for effective use of the tacker.

Features of the danger warnings

All danger warnings in this operating manual have the same form. On the left

you will find a symbol indicating the type of danger. To the right of this you

will see a further symbol and a signal word indicating the severity of the

danger. Under that you will find a description of the source of danger and

instructions on how to avoid this danger.

DANGER

Warnings with the word DANGER indicate

hazards with an immediate impending risk of

serious or even fatal injuries.

WARNING

Warnings with the word WARNING warn of

hazards that can lead to potentially serious or

even fatal injuries.

CAUTION

Warnings with the word CAUTION warn of

hazards that can lead to potentially slight to

moderate injuries.

Features of the warnings on material damage or environmental

pollution

ATTENTION

These warnings warn of hazards that can lead to material

damage or environmental pollution.

Safety

6

Safety

Observe and follow all the warnings and instructions in this operating manual

and on the tacker when using the tacker. The spare parts list supplied with

the tool forms an integral part of this operating manual.

Intended use

The 3X-CNW50, 5F-CNW65, 7F-CNW90 and 9F-CNW100EPAL tackers are

intended for driving coilnails into wood. The 4X-CNZ45 tacker is intended for

driving coilnails into roofing felt, bitumen shingles, insulating material and

packagings. Use of the tackers with other materials is only permitted after

consultation with the manufacturer. The intended use also includes

compliance with the accident prevent regulations and the statutory

regulations and standards in force at the place of use. Use in any other way

is not considered an intended use and can result in material damage or even

personal injury.

Unauthorised use

An unauthorised use constitutes in particular operation

by persons without the necessary know-how in the use of tackers and

the materials used,

with the safety device bypassed,

of tackers modified without the authorisation of the manufacturer,

using other than original PREBENA coilnails, see page 37,

in the trigger position "repeat firing"

-

for work requiring movements over scaffolds, stairs, ladders or

ladder-like constructions,

-

for closing boxes or crates or for the attachment of transport locks.

PREBENA WILFRIED BORNEMANN GMBH & CO. KG accepts no liability

for any damage resulting from any such unauthorised use.

Safety

7

Avoid risk of fatal injuries

Never direct the tacker at people, animals or parts of their body.

Only actuate the tacker when the tool nose is pressed against the

workpiece.

Do not allow children to play with packaging films - risk of suffocation.

Ensure that the coilnails are not driven into power cables.

Avoid explosion hazards

Do not use the tacker in areas with an explosion hazard.

Never operate the tacker with oxygen or other explosive gases or gas

mixtures.

Do not expose the compressor to temperatures over 100°C.

Avoid injury risks

Store the tacker out of the reach of children and other unauthorised

persons.

Always disconnect the tacker from the compressed air supply before

transporting.

Wear protective goggles, ear protectors and sturdy working clothes when

working with the tacker.

Hold the tacker in such a way that you cannot be injured by a possible

recoil.

Use the tacker when you are standing with a firm footing.

Avoid damage to the tacker

Never open the housing of the tacker. Always leave repairs to qualified

personnel.

Do not use the tacker if it has been dropped or is damaged. Have it

inspected by qualified personnel before putting it into use again.

Description

8

Description

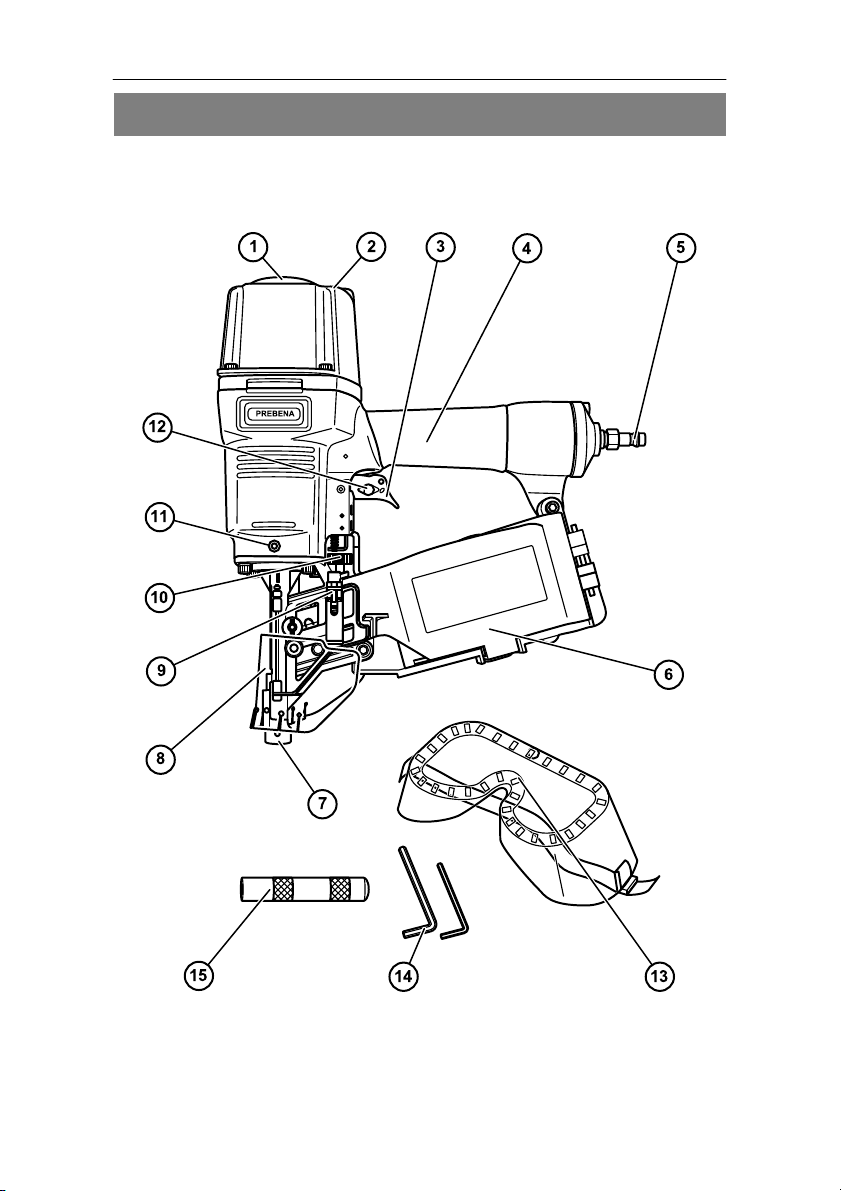

Tacker overview

1234

12

10

11

7

6

8

9

5

1314

15

Description

9

No.

Explanation

1

Vent

2

Housing head

(On Type 5F-CNW65, 7F-CNW90 and 9F-CNW100 PAL with thread for a hanging

device)

3

Trigger lever

4

Handle

5

Connection for the compressed air hose

6

Magazine

7

Tool nose with trigger lock

8

Pro

tective cover

9

Magazine lock

10

Adjusting wheel

for adjusting the nailing depth

(Type 3X-CNW50, 4X-CNZ45, 5F-CNW65, 7F-CNW90 only)

11

Thread for attachment of an additi

onal handle

(Typ 9F-CNW100 PAL)

12

Selector switch for setting the firing mode

(Type 3X-CNW50, 4X-CNZ45, 5F-CNW65, 7F-CNW90 only)

13

Protective goggles

14

Allen key

15

a

dditional handlef

(Typ 9F-CNW100 PAL only)

Description

10

Scope of supply

3X-CNW50

The scope of supply of the 3X-CNW50 includes:

Tacker

Protective goggles

One Allen key

Plastic case

Declaration of Conformity

4X-CNZ45

The scope of supply of the 4X-CNZ45 includes:

Tacker

Protective goggles

Two Allen keys

Plastic case

Declaration of Conformity

5F-CNW65

The scope of supply of the 5F-CNW65 includes:

Tacker

Protective goggles

Two Allen keys

Plastic case

Declaration of Conformity

7F-CNW90

The scope of supply of the 7F-CNW90 includes:

Tacker

Protective goggles

Two Allen keys

Metal case

Declaration of Conformity

9F-CNW100EPAL

The scope of supply of the 9F-CNW100EPAL includes:

Tacker

Protective goggles

Two Allen keys

One additional handle

Metal case

Declaration of Conformity

Function

The 3X-CNW50, 5F-CNW65, 7F-CNW90 and 9F-CNW100EPAL tackers

drive PREBENA coilnails individually into wood and packagings using

compressed air. The 4X-CNZ45 tacker drives PREBENA roofing felt nails

individually into roofing felt and bitumen shingles using compressed air. The

9F-CNW100EPAL tacker is used for manufacturing and repairing

Europallets.

PREBENA compressors are used as the compressed air source. An

overview of the compressors can be found from page 39.

An overview of the coilnails that can be used can be found from page 37.

Description

11

Product features of the tackers

All types

The tackers have the following common features:

Firing protection Silencer

3X-CNW50

The tacker has the following additional features:

Recoil-free

No-mar tip

Single and bump firing

Setting of the nailing depth

4X-CNZ45

The tacker has the following additional features:

Recoil-free

Quick loading system

Single and bump firing

Setting of the nailing depth

Adjustable spacer

Rubber-coated device

protection bracket

5F-CNW65

The tacker has the following additional features:

Single and bump firing

Setting of the nailing depth

Thread for a hanging device

7F-CNW90

The tacker has the following additional features:

Single and bump firing

Setting of the nailing depth

Thread for a hanging device

9F-CNW100EPAL

The tacker has the following additional features:

Thread for a hanging device Additional handle

Safety devices

Firing protection

The tacker is equipped with a firing protection device on the tool nose. The

trigger is only enabled when the firing protection device is depressed.

Description

12

WARNING

Danger of very serious injuries if the tacker is

operated with defective or by-passed firing

protection device.

Use the tacker only with a fully functional firing

protection device.

Fire the tacker only when the tool nose is

pressed firmly against the material.

Warning signs on the tacker

The following applications are not permitted with the trigger setting "repeat

firing":

Work requiring movements over scaffolds, stairs, ladders or ladder-like

constructions, and

Use for closing boxes or crates and for the attachment of transport locks.

The corresponding warning symbol (see below) is

attached to the upper side of the tacker.

Two further stickers are attached alongside the rating plate. These have the

following meaning:

Sticker

Meaning

Wear ear protectors when using the tacker.

Wear protective goggles when using the tacker.

Read the operating manual before putting the tacker into operation.

Description

13

Accessories

The following accessories are available for the tackers:

All tackers

Nails (see overview from page

37)

PREBENA special nailer oil

Z 200.10

Oil atomizer Z 200.00

9 mm hose set Z 200.20

Spiral hose Z 160.12

Hose reel Z 180.00

5F-CNW65

Hanger loop ET 99300122 Weight balancer Z 110.32

7F-CNW90

Hanger loop ET 99300122 Weight balancer Z 110.32

9F-CNW100EPAL

Hanger loop ET 99300122 Weight balancer Z 110.32

Data on the rating plate

The rating plate is attached to the magazine or the housing. It contains the

following information:

Company name and country of origin,

Type designation of the tacker,

Type designation of the coilnails that may be used,

The CE symbol (the product conforms to the standards listed in the

Declaration of Conformity supplied),

The inverted triangle (this triangle indicates that this tacker may only be

operated with fully functional firing protection device).

Preparing the tacker

14

Preparing the tacker

Unpacking the tacker

Remove the tacker from the packaging.

Remove all packaging materials, such as plastic films, filler material and

the cardboard box.´

WARNING

Do not allow children to play with plastic

packaging films. Risk of suffocation!

Do not allow children to play with plastic packaging films.

Store the packaging materials out of the reach of children.

Save the packaging material for later use.

Keep the transport case for the transport of the tacker.

The tacker may only be transported in the transport case.

Check condition

Warning

Risk of injury when using a damaged tacker

or if accessories are not correctly attached.

Check the condition of the tacker before every use

Always ensure that the tacker is in a safe working condition.

Check in particular the following points:

-

The air hose must be undamaged.

-

All parts of the tacker and all accessories must be securely attached.

-

The safety devices must not be blocked or otherwise impaired in their

function.

-

The spring of the firing protection device must not be damaged.

-

No parts of the tacker or the accessories may show visible signs of

damage, such as scratches or dents.

Scratches in the paintwork of the housing or magazine are not

"damage".

Preparing the tacker

15

Do not connect a damaged tacker to a compressed air supply.

Have a damaged tacker repaired by qualified personnel before putting it

into operation.

Connect tacker to compressed air supply

The tacker can be connected to a compressor or compressed air system.

Operation with a compressor or compressed air system is only permitted

under the following conditions:

The working pressure of the compressor or compressed air system must

not be more than 10% of the maximum working pressure of the tacker.

Information on the working pressure of the tackers can be found in this

chapter on page.

If the compressed air system has a higher working pressure, a pressure

control valve (pressure reducer) with downline pressure relief valve must

be installed in the compressed air line.

The compressed air must be filtered, dry and oiled with PREBENA

special nailer oil.

An air conditioner must be installed on the coupling side of the outlet

ports for the compressed air line to the tacker. This should comprise

-

Filter,

-

Water trap and

-

Oiler.

If no oiler is installed, the length of the air line to the tacker must not

exceed max. 10 metres. Otherwise pour three to five drops of PREBENA

special nailer oil directly into the air inlet port of the tacker every day

before starting work.

The compressed air system must be able to maintain the working

pressure even with the desired air consumption.

The inside diameter of the air line must be at least 9 mm.

The connection for the tacker must be fitted with a quick coupler with NW

7.2 and with an inside diameter of at least 6.5 mm.

Preparing the tacker

16

CAUTION

Operation on compressed air systems not

satisfying the preconditions described above

can result in damage to the tacker.

Operate the tacker only on suitable compressed

air systems.

Operate the tacker only when it is in a safe

working condition.

Check the condition of the tacker (see page 14).

Pull the plug out of the connection for the compressed air hose.

Inspect the connection for the compressed air hose for foreign matter

and soiling and clean, if necessary.

Set the working pressure at the pressure regulator of the compressor to

5 - 8.3 bar.

WARNING

Inadvertent firing during connection to the

compressed air supply can result in serious or

even fatal injuries.

Never direct the tacker at people or animals.

Empty the magazine before connecting.

CAUTION

Damaged hoses can burst and result in

injuries.

Inspect the compressed air system and tacker

for damage before connection.

Connect the tacker only to a fully functional

compressed air system.

ATTENTION

Damaged hoses can burst and and cause material damage due

to the escaping compressed air.

Inspect the compressed air system and tacker for damage before

connection.

Connect the tacker only to a fully functional compressed air system.

Preparing the tacker

17

1

2

3

2

1

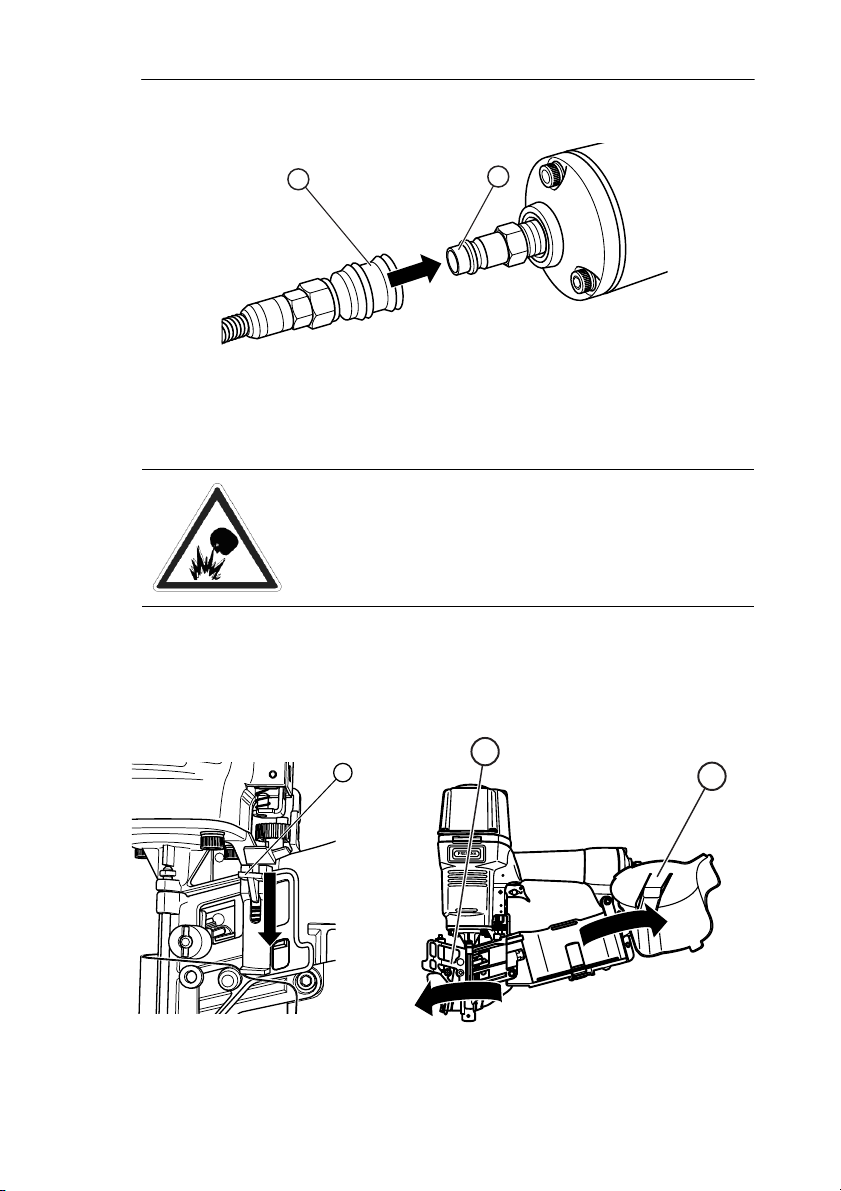

Push the quick coupler (1) of the compressed air hose onto the

connection (2) until it engages audibly.

Check the working pressure at the pressure gauge of the compressor.

The maximum admissible working pressure for the tackers 3X-CNW50, 4X-

CNZ45, 5F-CNW65, 7F-CNW90 und 9F-CNW100EPAL is 8.3 bar.

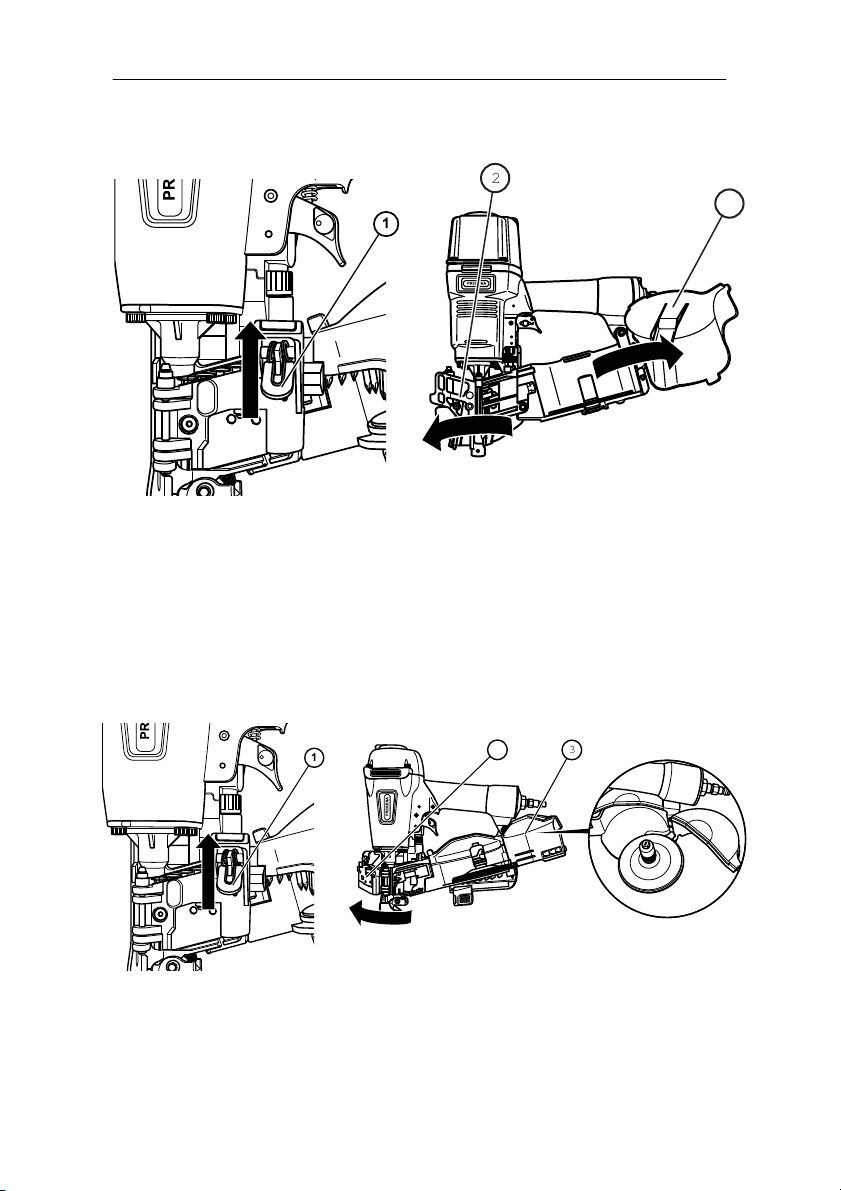

WARNING

Risk of explosion if the maximum working

pressure is exceeded.

In this case immediately disconnect the

compressed air hose from the tacker.

Open magazine

Type 3X-CNW50, 5F-CNW65 and 7F-CNW90

To open the magazine, press the magazine catch (1) downwards in the

direction of the arrow.

Slide out the magazine lock to the left (2).

Slide out the magazine to the right (3).

Preparing the tacker

18

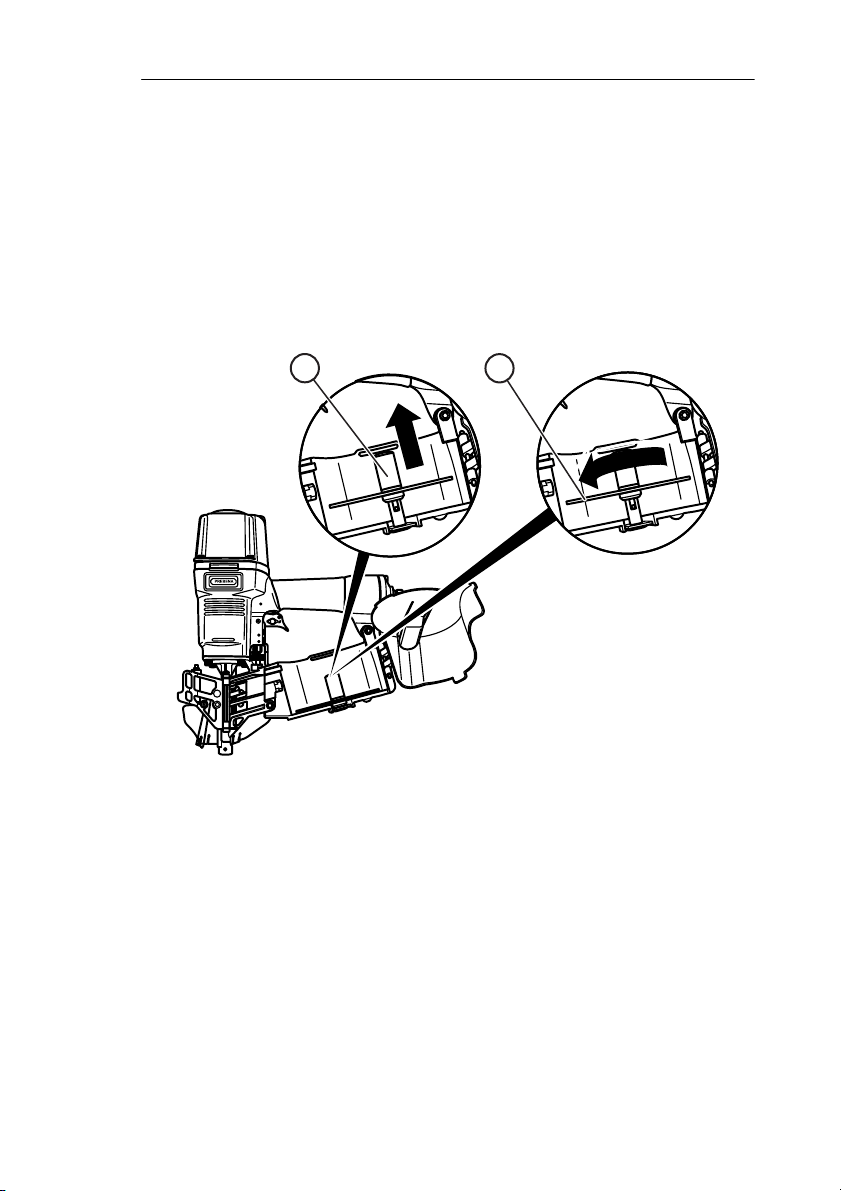

Type 9F-CNW100EPAL

To open the magazine, press the magazine catch (1) upwards in the

direction of the arrow.

Slide out the magazine lock (2) to the left.

Slide out the magazine (3) to the right.

Type 4X-CNZ45

The 4X-CNZ45 tacker is equipped with a quick loading system. By contrast

with the other tackers, the magazine of the 4X-CNZ45 slides out

automatically when the magazine lock is opened.

To open the magazine, press the magazine catch (1) upwards in the

direction of the arrow.

Lift the magazine lock (2).

The magazine (3) slides out automatically.

1

2

3

1

23

Preparing the tacker

19

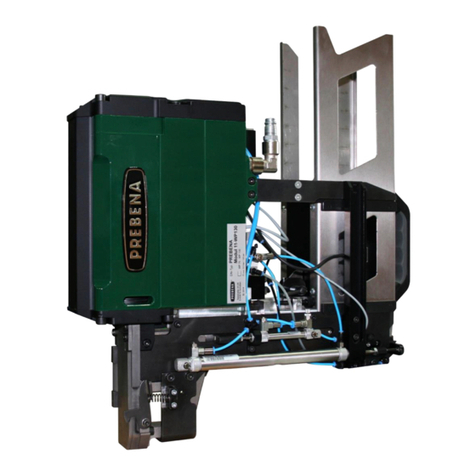

Set nail length

Type 3X-CNW50, 5F-CNW65, 7F-CNW90 and 9F-CNW100EPAL

Inside the magazine are two scales with centimetre and inch graduations.

These scales indicate the selectable nail length in each case for the tacker.

To use longer nails, pull the magazine shaft (1) out to the desired

position.

To engage the magazine disc (2) in the desired position, turn the

magazine shaft (1) in clockwise direction up to the stop.

The magazine disc engages.

12

To use shorter nails, pull the magazine shaft out slightly.

Turn the magazine shaft in anti-clockwise direction.

Push the magazine shaft into the desired position.

To engage the magazine disc in the desired position, turn the magazine

shaft in clockwise direction up to the stop.

The magazine disc engages.

Preparing the tacker

20

Type 4X-CNZ45

Inside the magazine are two scales with centimetre and inch graduations.

These scales indicate the selectable nail lengths in each case for the tacker.

To use longer nails, grip the magazine shaft (1) at the handle (2).

Pull the magazine shaft out to the desired position.

The magazine disc engages automatically.

2

1

To use shorter nails, push the magazine shaft inwards.

Push the magazine shaft into the desired position.

The magazine disc engages automatically.

Other manuals for 3X-CNW50

1

This manual suits for next models

4

Table of contents

Other Prebena Power Tools manuals

Prebena

Prebena 11-WP130 User manual

Prebena

Prebena SLIDER 4C-Z50 User manual

Prebena

Prebena PKT-8-PR100 Installation instructions

Prebena

Prebena 1GP-ALK35 User manual

Prebena

Prebena SLIDER 4C-Z50 Quick start guide

Prebena

Prebena KTVH-B19D User manual

Prebena

Prebena 1A-AZ16BNH User manual

Prebena

Prebena KTVH-B19D User manual

Prebena

Prebena PKT-7-RK90 Installation instructions

Prebena

Prebena 1A-AZ16BNH Quick start guide