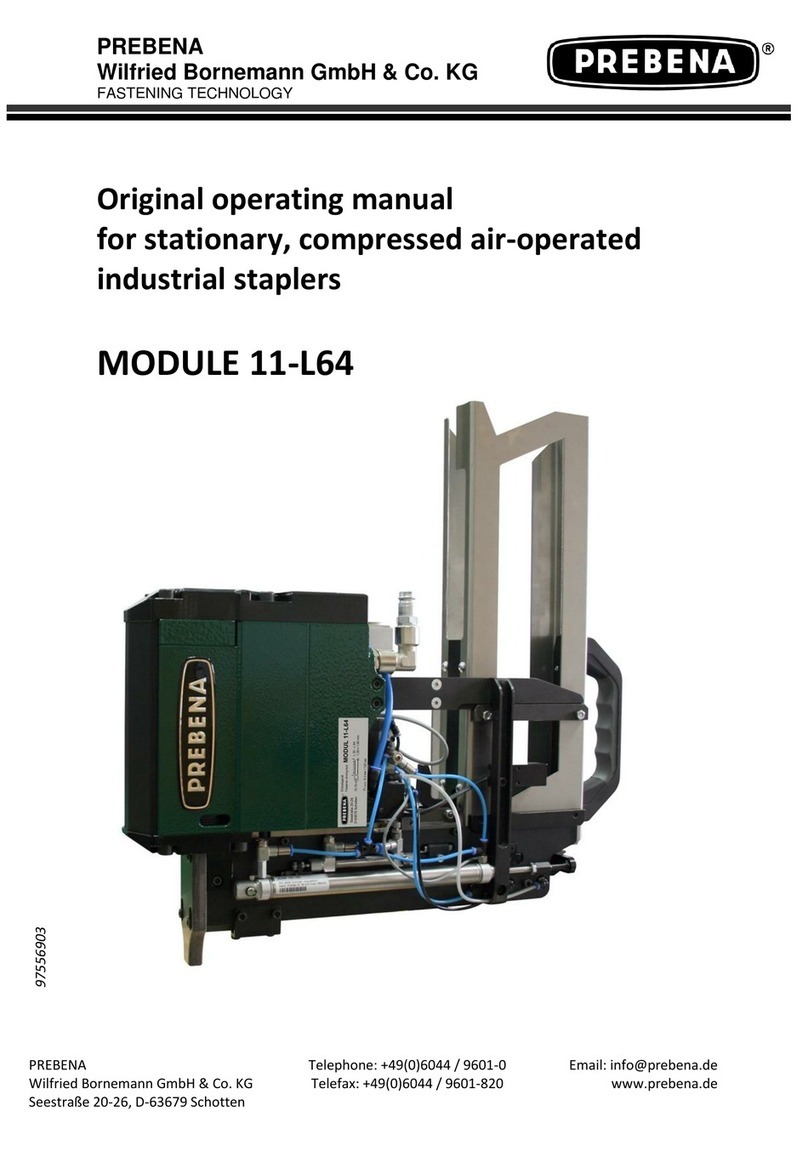

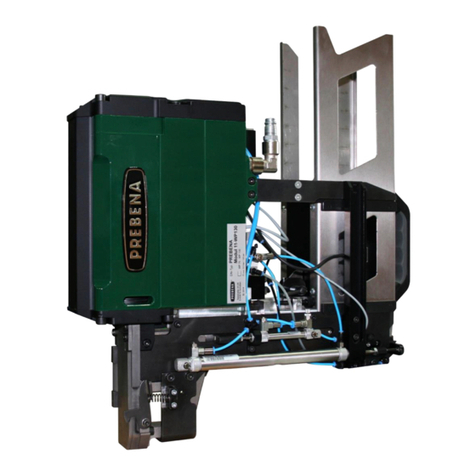

Prebena PKT-7-RK90 Installation instructions

PREBENA Wilfried Bornemann GmbH & Co. KG

Seestraße 20 – 26, 63679 Schotten, Germany

Tel.: +49 (0) 60 44 / 96 01 – 0, Fax: +49 (0) 60 44 / 96 01 – 80

eMail: info@prebena.com

www.prebena.de, www.kartuschen-tausch.de

Original Operating Manual for the

Pneumatic Tool

PREBENA PKT-7-RK90

Introduction

This operating manual is an aid for

•proper,

•safe, and

•advantageous

use of the pneumatic tool, PKT-7-RK90 and PKT-7-RK90-S.

We assume that every user of the pneumatic tool has experience

handling devices that are powered by compressed air, and

experience with the materials used. Those who do not have this

experience must be instructed in the operation of the pneumatic tool.

Every person who

operates,

cleans, or

disposes of

this pneumatic tool must have read and understood this operating

manual.

This operating manual is considered as a component of the product.

Always keep this operating with the pneumatic tool. If you sell the

pneumatic tool, or provide it to another party, ensure that the

operating manual is included with the pneumatic tool.

Table of Contents

Organizational Features.................................................................. 5

General Organizational Features ................................................. 5

Features of the safety instructions ............................................... 6

Basic safety instructions ...................................................... 7

Proper Use ................................................................................... 7

Hazard - avoid fatal injuries.......................................................... 8

Avoid explosion hazards .............................................................. 8

Avoid injury hazards ..................................................................... 8

Avoid damage to the pneumatic tool............................................ 9

Description ..................................................................................... 10

Device overview and scope of delivery ...................................... 10

Function...................................................................................... 12

Product features ......................................................................... 12

Left/right and direction information............................................. 12

Safety fixtures............................................................................. 13

Accessories ................................................................................ 15

Rating plate information ............................................................. 15

Preparing the pneumatic tool....................................................... 16

Unpacking the pneumatic tool .................................................... 16

Check the condition.................................................................... 17

Connecting the pneumatic tool to the compressed air supply ... 18

Filling the magazine ................................................................... 25

Adjust the air discharge.............................................................. 27

Check the function...................................................................... 28

Operating the pneumatic tool ...................................................... 29

Selecting the release setting ......................................................29

Adjusting depth-of-drive..............................................................31

Driving nails ................................................................................34

Interrupting operation .................................................................38

Reloading the magazine (lock-out safety device).......................39

After operation ...............................................................................40

Disconnecting the compressed air supply..................................40

Emptying the magazine ..............................................................41

Transporting and storing the pneumatic tool.............................43

Packing .......................................................................................43

Transport ....................................................................................45

Storage .......................................................................................46

Maintaining the pneumatic tool....................................................47

Cleaning the housing and exterior surfaces...............................47

Lubricating the pneumatic tool....................................................48

Charging compressed air cartridges ..........................................49

Test the compressed air cartridge..............................................49

Troubleshooting ............................................................................50

Ordering accessories .................................................................... 54

Ordering nails .............................................................................54

Ordering additional compressed air cartridges...........................54

Ordering other accessories ........................................................55

Pneumatic tool disposal ...............................................................56

Technical data................................................................................57

Pneumatic tool PKT-7-RK90 ......................................................57

KT-3500 compressed air cartridge .............................................57

Manufacturer's address ................................................................58

Guarantee .......................................................................................59

Index................................................................................................60

Organizational Features

5

Organizational Features

General Organizational Features

Different elements of the operating manual have specific

organizational features. These features make it easy to differentiate

normal text,Text,

listings, or

action steps.

These instructions contain additional information, such as

special tips on economical use of the pneumatic tool.

Organizational Features

6

Features of the safety instructions

All safety instructions contained in this operating manual are

structured on the same pattern. To the left there is a symbol that

indicates the type of hazard. To the right a signal word that indicates

the seriousness of the hazard. Below there is a description of the

hazard source and instructions on how you can avoid this hazard.

HAZARD

Instructions with the word HAZARD warn of

hazards that directly result in serious or fatal

injuries.

WARNING

Instructions with the word WARNING warn of

hazards that could possibly result in serious or

fatal injuries.

CAUTION

Instructions with the word CAUTION warn of

hazards in which light to medium severity

injuries, property damage, or damage to the

environment can possibly occur.

Basic safety instructions

7

Basic safety instructions

Comply with and heed all warnings and instructions in this operating

manual and on the pneumatic tool when handling the pneumatic tool.

Proper Use

The pneumatic tool is used to drive nails into wood. Using the

pneumatic tool on other materials is only permitted after consultation

with the manufacturer. Proper use also includes compliance with

accident prevention regulations and legal guidelines and standards

applicable at the site of implementation. Any other use is considered

to be improper use and can result in property damage, or even

personal injury.

Improper use particularly includes operation

by persons who have no experience operating pneumatic tools, or

no experience with the materials used,

with bypassed safety fixtures,

of pneumatic tools that have been modified without the

manufacturer's authorization,

with accessories other than those listed in this operating manual,

with compressed air sources that are not listed in this operating

manual.

in the "bump fire" release setting

-

for work that requires movement over scaffolds, stairs, ladders

or ladder-like structures,

-

for sealing crates or bins, or for attaching transport

safeguards.

PREBENA WILFRIED BORNEMANN GMBH & CO. KG assumes no

liability for damage that occurs due to improper use.

Basic safety instructions

8

Hazard - avoid fatal injuries

Never point the pneumatic tool at people, animals, or body parts.

Only release the pneumatic tool when the nose of the tool is firmly

pressed against the material.

Do not let children play with packaging; there is risk of

suffocation.

Ensure that nails are not driven into electrical lines.

Avoid explosion hazards

Do not use the pneumatic tool at locations where there is an

explosion hazard.

Never operate the pneumatic tool with oxygen or other flammable

gasses or gas mixtures.

Never expose the compressed air cartridge to temperatures in

excess of 100 °C.

Avoid injury hazards

Store the pneumatic tool where it is inaccessible to children and

other unauthorized persons.

Detach the pneumatic tool from the compressed air supply prior

to every transport.

Wear protective goggles, ear protection, and stable work clothing

when operating the pneumatic tool.

Hold the pneumatic tool in such a manner that you cannot be

injured by possible recoil.

Always adopt sure footing and a stable position when using the

pneumatic tool. Refrain particularly from operating the pneumatic

tool from a ladder or scaffold.

Basic safety instructions

9

Avoid damage to the pneumatic tool

Never open the pneumatic tool. Only have qualified specialists

perform repair work.

Do not use the pneumatic tool if it has fallen down or is damaged.

Have it checked by qualified, specialized personnel before you

operate it again.

Do not connect the pneumatic tool to a compressed air supply

that exceeds the maximum operating pressure of 8.3 bar.

Only install permanently mounted pneumatic tools in securely

anchored holding fixtures. The pneumatic tool should not turn or

shift in the holding fixture. The holder should not damage the

pneumatic tool or its accessories.

Description

10

Description

Device overview and scope of delivery

Description

11

No.

Explanation

1

Manometer for pneumatic tool operating pressure

2

Magazine block

3

Pusher

4

Magazine with nails

5

Safety device

6

Adjusting wheel of the safety device

7

Manometer for th

e pressure of the compressed air cartridge (fill

-

level

indicator

8

Safety valve for operation with the compressed air cartridge

9

Connection for the compressed air cartridge with sealing plug

10

Discharge with selector switch for the release setting

1

1

Holders for the compressed air cartridges

12

Regulator for the operating pressure

13

Connection for the pressure hose

14

Safety valve for the operating pressure with release at 10 bar

15

Housing head with thread for suspension hook

16

KT

-

3500 compre

ssed air cartridge, (only for PKT

-

7

-

RK90

-

S

17

Four Allen wrenches (sizes 3, 4, 5 and 6

18

Protective goggles

–

Metal transport case (not shown

–

Declaration of Conformity (not shown

Description

12

Function

The pneumatic tool drives single nails into a piece of wood. You can

use either a compressed air cartridge mounted on the pneumatic

tool, or a pressure hose for the compressed air supply. Excess

pressure is discharged through pressure relief valves.

You can adjust depth-of-drive by regulating the air pressure or with

the adjusting wheel for the safety device.

Product features

The pneumatic tool has the following additional features:

Operation either with compressed air cartridge or a compressed

air system,

Trigger safety with single fire or bump fire,

Lock-out safety device,

Magazine with rear-loading system,

Adjustable exhaust air discharge and

Depth adjustment.

Left/right and direction information

The left/right or direction information in this operating manual is

based on view direction towards the material.

The direction information for the compressed air regulator is based

on the view from behind looking at the operating pressure regulator.

Description

13

Safety fixtures

Safety device

The pneumatic tool has a safety device on the tool nose. Discharge

is only released when the safety device is pushed in.

WARNING

The most serious injuries are possible when

operating the pneumatic tool without a

functioning safety device.

Only use the pneumatic tool if the safety

device is functional.

Lock-out safety device

The pneumatic tool is equipped with a lock-out safety device on the

top end of the magazine. The lock-out safety device blocks the

discharge when there are fewer than three to four nails left in the

magazine.

Description

14

Warning signs attached to the pneumatic tool

The following modes of implementation are prohibited in the "bump

fire" release setting:

Work that requires movement over scaffolds, stairs, ladders, or

ladder-like structures and

using the tool to close crates or bins, as well as for attaching

transport safeguards

The respective warning symbol is affixed to the front side of the

pneumatic tool.

Three stickers are affixed next to the rating plate. These stickers

have the following meaning:

Sticker

Meaning

Wear ear protection when operating the pneumatic tool

Wear protective goggles when operating the pneumatic tool

Read the operating manual prior to operating the pneumatic

tool

Description

15

Accessories

The following accessories are available for the pneumatic tool:

KT-3500 compressed air cartridge

Compressor for compressed air cartridge PKT-FILLMASTER 350

(not included in the scope of supply)

Spiral hose with 9 mm inside diameter and 4 m work length (not

included in scope of supply)

Compressed air hose set (not included in scope of supply)

Hose drum (not included in scope of supply)

Type RK and RKP round-headed nails (see section "Ordering

nails" on page 54).

Special PREBENA nailer oil.

Rating plate information

The rating plate is affixed to the rear of the magazine. It contains the

following information:

Company name and country of origin,

type designation of the pneumatic tool

Type designation of the round head nails that can be used

Max. permissible operating pressure

CE mark (the product satisfies the standards listed in the

accompanying Declaration of Conformity)

GS mark (the product has a passed a safety inspection in

accordance with the Equipment and Product Safety Act).

Inverted triangle. (This triangle indicates that you should only

operate this device if the safety device is functional).

Preparing the pneumatic tool

16

Preparing the pneumatic tool

Unpacking the pneumatic tool

Remove the pneumatic tool from the packaging.

Remove all packaging material, such as foil, fill material, and

packing box.

WARNING

A risk of suffocation exists for children when

playing with the packaging foil.

Never permit children to play with

packaging foil.

Store packaging material where it is

inaccessible to children.

Store the packaging for later use.

Keep the transport case for transport of the pneumatic tool.

Only transport the pneumatic tool in the transport case.

Preparing the pneumatic tool

17

Check the condition

WARNING

An injury hazard exists when operating a

damaged pneumatic tool, or if accessories are

not properly mounted.

Check the condition of the pneumatic tool

prior to each use.

Only use pneumatic tools that are in

trouble-free condition.

Check the following points in particular:

-

The hose line should not be damaged.

-

All pneumatic tool parts and all accessory parts must be

securely attached.

-

The safety devices should not be blocked or otherwise

impaired in function.

-

The spring of the safety device should not be damaged.

-

There should be no external damage to any parts of the

pneumatic tool or the accessories, such as scratches or dents.

Scratches in the paint of the housing or of the magazine are

not considered damage.

Do not connect a damaged pneumatic tool to a compressed air

supply.

Have specialized personnel repair a damaged pneumatic tool

before placing it in service.

Preparing the pneumatic tool

18

Connecting the pneumatic tool to the compressed air

supply

You can connect the pneumatic tool to a compressed air system or

to compressed air cartridge.

If you connect the pneumatic tool to a compressed air system, you

can economically execute frequent driving processes at the same

location. Moreover you can feed lubricating oil into the pneumatic

tool via the compressed air system.

When you connect the pneumatic tool to a compressed air cartridge

you are independent of a stationary system.

You can connect the pneumatic tool to both sources of

compressed air at the same time. In this case the compressed

air in the cartridge will be consumed first. Then the

compressed air will be consumed from the compressed air

system.

The permissible operating pressure of the pneumatic tool is 8.3 bar.

If the permissible operating pressure is exceeded then the pointer in

the manometer for the operating pressure is in the red area.

This can occur under the following conditions:

If both safety valves are defective and

You have connected the pneumatic tool to a compressed air

system with excessive pressure, or to an unsuitable compressed

air cartridge.

WARNING

Explosion hazard when exceeding the

maximum operating pressure.

In this case disconnect the pneumatic tool

immediately from the compressed air

supply.

Preparing the pneumatic tool

19

Attaching the compressed air cartridge

Unscrew the sealing plug from the connecting thread (1.).

Check the connection and the connection thread of the

compressed air cartridge for foreign objects and fouling.

Clean the connection and the connection thread if necessary.

Check the condition of the pneumatic tool (see page 17).

WARNING

Inadvertent release can result in serious or

fatal injuries.

Do not point the pneumatic tool at people

or animals.

Empty the magazine before connecting.

Preparing the pneumatic tool

20

WARNING

Operation with unsuitable compressed air

cartridges can result in damage to the

pneumatic tool.

Only operate the pneumatic tool with type

KT-3500 compressed air cartridges.

Unscrew the sealing cap from the compressed air cartridge.

Slide the compressed air cartridge into the holders (2.).

Screw the compressed air cartridge hand-tight into the thread on

the connection element (3.).

The manometer on the connection for the compressed air cartridge

now shows the actual pressure available in the cartridge. The

pneumatic tool is ready for operation when the pointer of the

manometer is in the green area.

The manometer for the operating pressure shows the actual

operating pressure.

This manual suits for next models

1

Table of contents

Other Prebena Power Tools manuals

Prebena

Prebena PKT-8-PR100 Installation instructions

Prebena

Prebena SLIDER 4C-Z50 Quick start guide

Prebena

Prebena KTVH-B19D User manual

Prebena

Prebena 1A-AZ16BNH Quick start guide

Prebena

Prebena 3X-CNW50 User manual

Prebena

Prebena 11-WP130 User manual

Prebena

Prebena KTVH-B19D User manual

Prebena

Prebena 1GP-ALK35 User manual

Prebena

Prebena SLIDER 4C-Z50 User manual

Prebena

Prebena 3X-CNW50 User manual