Table of contents

Foreword .............................................................................................................................................................................2

Table of contents.................................................................................................................................................................3

Layout characteristics.........................................................................................................................................................4

General layout characteristics..........................................................................................................................................4

Features of the danger warnings......................................................................................................................................4

Features of the notices on damage to property or the environment....................................................................................4

Safety...................................................................................................................................................................................5

Correct use......................................................................................................................................................................5

Improper use...................................................................................................................................................................5

Avoiding the risk of fatal injuries.......................................................................................................................................5

Preventing the risk of explosion........................................................................................................................................5

Avoiding the risk of injury.................................................................................................................................................6

Avoiding damage to the tacker.........................................................................................................................................6

Description..........................................................................................................................................................................7

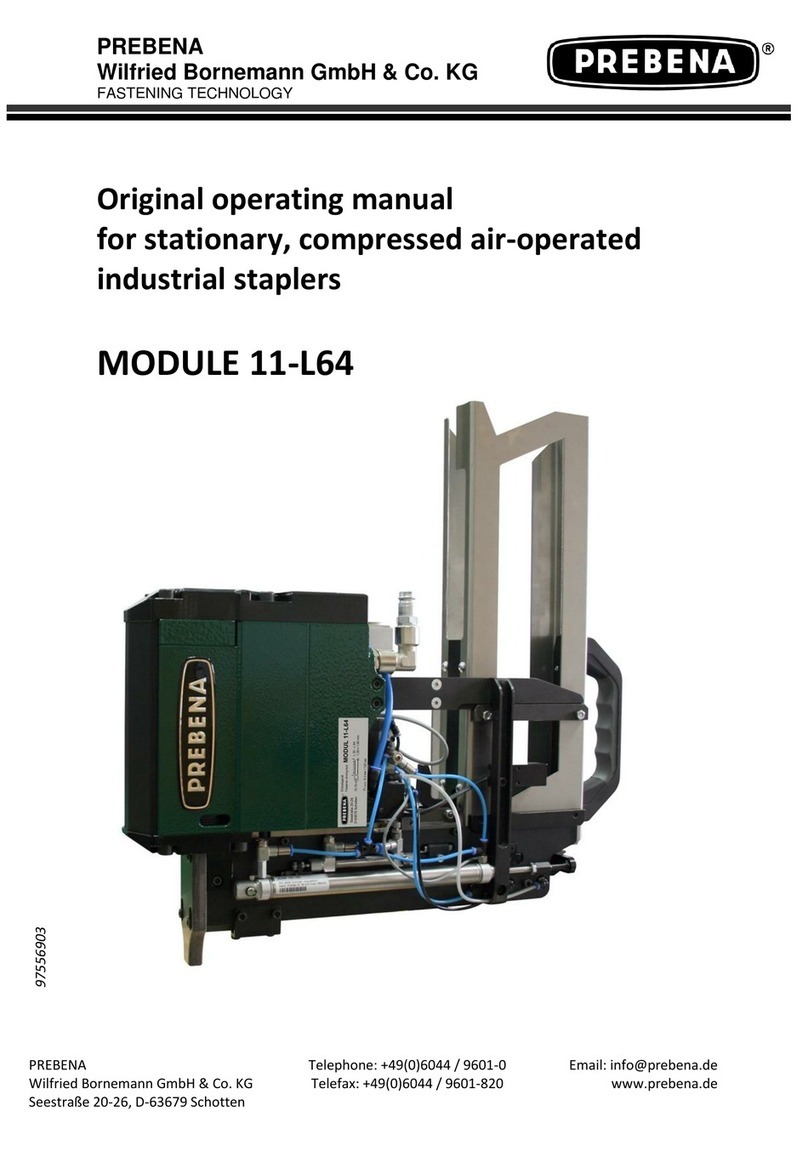

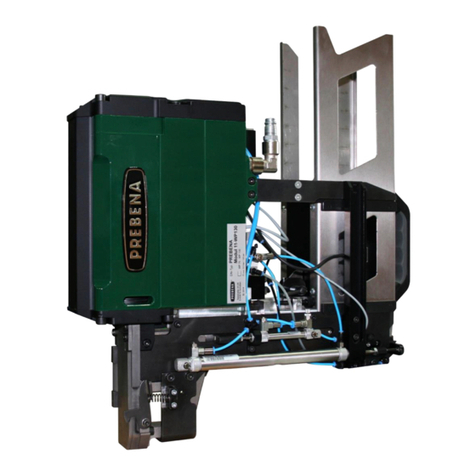

Tool overview and scope of delivery.................................................................................................................................7

Tool overview and scope of delivery.................................................................................................................................8

How it works....................................................................................................................................................................8

Product features..............................................................................................................................................................9

Safety devices.................................................................................................................................................................9

Information signs on the Slider.......................................................................................................................................10

.....................................................................................................................................................................................10

Information on the rating plate........................................................................................................................................10

Preparing the Slider ..........................................................................................................................................................11

Unpacking the Slider......................................................................................................................................................11

Checking the condition...................................................................................................................................................11

Connecting the Slider to the compressed air supply........................................................................................................12

Filling the magazine.......................................................................................................................................................13

Adjusting the exhaust outlet...........................................................................................................................................14

Checking the function ....................................................................................................................................................15

Operating the Slider ..........................................................................................................................................................16

Using the parallel guide or guide sight slot......................................................................................................................16

Selecting the staple distance..........................................................................................................................................17

Adjusting the driving depth.............................................................................................................................................17

Checking the driving depth.............................................................................................................................................18

Driving in fasteners........................................................................................................................................................19

Releasing jams..............................................................................................................................................................21

Reloading the magazine (empty shot safety device) .......................................................................................................22

After operation ..................................................................................................................................................................23

Disconnecting the compressed air supply.......................................................................................................................23

Emptying the magazine .................................................................................................................................................23

Transporting and storing the Slider..................................................................................................................................24

Packing.........................................................................................................................................................................24

Transporting..................................................................................................................................................................24

Storing ..........................................................................................................................................................................25

Servicing the Slider...........................................................................................................................................................26

One-off service after 25 hours of operation.....................................................................................................................26

Cleaning the housing and external surfaces ...................................................................................................................26

Oiling the Slider.............................................................................................................................................................27

Service intervals............................................................................................................................................................27

Faults.................................................................................................................................................................................28

Faults............................................................................................................................................................................28

Overview of faults..........................................................................................................................................................28

Ordering accessories........................................................................................................................................................29

Ordering fasteners.........................................................................................................................................................29

Ordering other accessories ............................................................................................................................................29

Disposing of the Slider......................................................................................................................................................30

Manufacturer's address.....................................................................................................................................................30

Warranty ............................................................................................................................................................................31

Index..................................................................................................................................................................................32