8

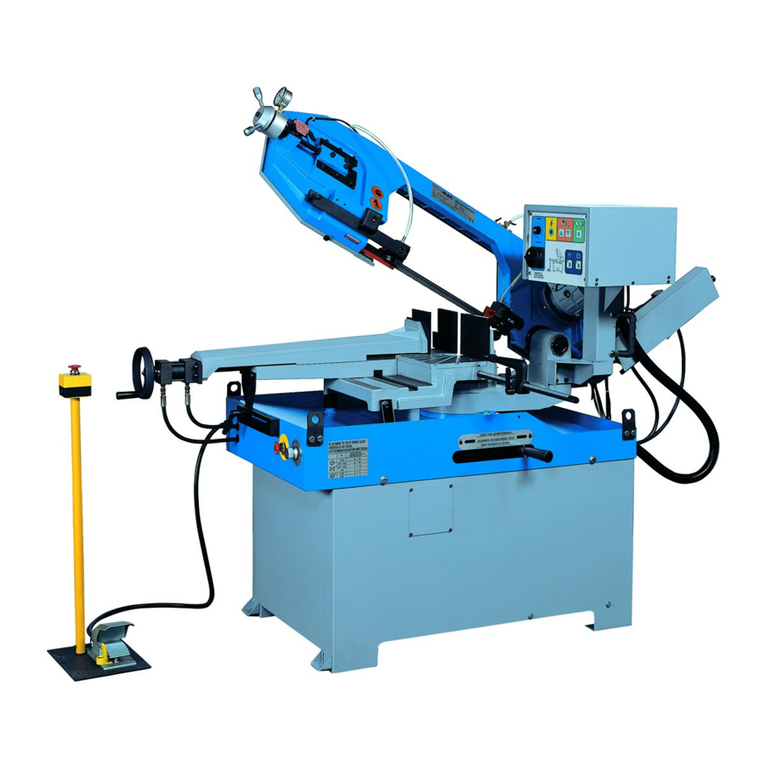

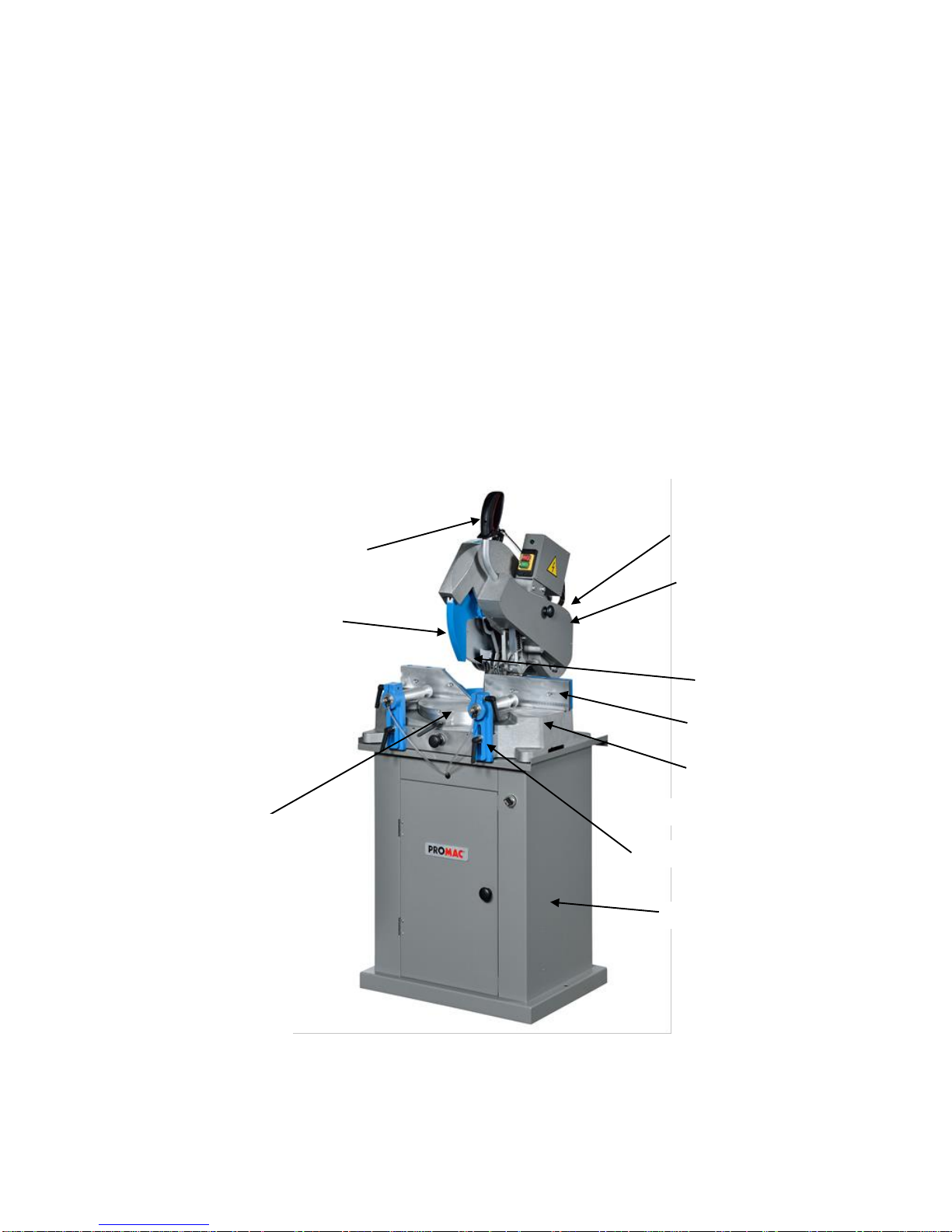

Controls and Indicators

Keep this manual in a good state and

available at a close distance from the

machine.

Foreword

For the preparation of this manual, we

have considered all operations referring

to normal use and regular maintenance

of the machine. Therefore, for correct

and optimal use of the machine, it is

necessary to carefully follow the

instructions described herein. The use

of the machine should be entrusted only

to authorized and skilled personnel.

Attention: It is recommended not to

carry out any repair or intervention

unless not indicated. All operations

requiring the disassembly of machine

parts should be entrusted to specialized

technical personnel.

Warranty

The machine is guaranteed for a period

of 24 months starting from the date of

the purchase invoice. It consists of a

free of charge replacement of all

mechanical parts showing material or

manufacturing defects.

All electric and electronic components

are excluded from this warranty. The

warranty does not cover breakages or

defects arising out of external factors,

maintenance mistakes or other causes,

improper use of the machine, use of the

machine overloaded, normal wear,

assembly mistakes which we may not

be held responsible for. Replacements

are shipped ex our factory. The machine

must be returned on a free port basis,

even when covered by the warranty.

Communication

For any written or verbal communication

with the Dealer or with the Firm about

the machine, it is necessary to supply

the following information:

Machine model

Serial number

Voltage & frequency of the machine

Name of the dealer from which the

machine was purchased.

Description of the defect found, if any

description of the type of operation

carried out working hours per day.

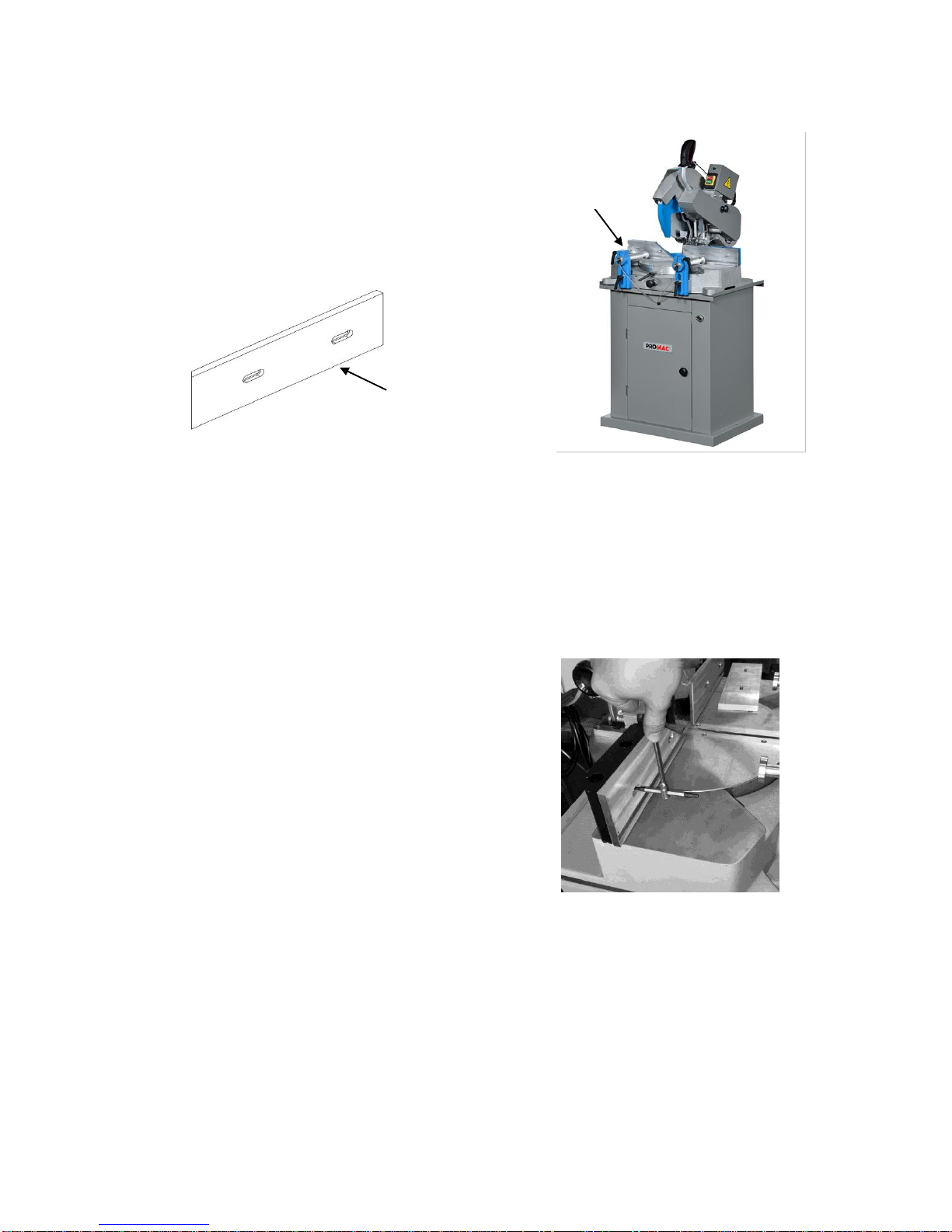

Machine identification

The machine model is identified by a

plate situated at the front of the base,

showing the following data:

Serial number

Year of manufacture

Manufacturer’s name

Use and limitations to use

The machine is for professional use and

has been designed and conceived for

cutting wooden semi-finished materials

and their sub-products and, with suitable

adaptations (a suitable blade and a

“vise” accessory plastic materials (PVC)

or light alloys (aluminum).The protection

rating of the electrical installation is IP

54. Only the user may be held

responsible for any damage arising out

of a different use of the machine other

than that indicates.

Attention:

1. In particular, the machine is not

suitable for cutting ferrous materials.

2. The machine cannot be used in

explosive environments.

Expected machine life

The expected life of the machine under

conditions of normal use and regular

maintenance is to be considered of at

least 5 years.

Machine disposal

When the machine is no longer

operative, it can be disposed of by

means of a standard disposal center for

industrial wastes, as it is classified as

standard solid waste material.