4. Open upper access door and rotate blade

wheel by hand until weld portion of blade is

between the two fingers.

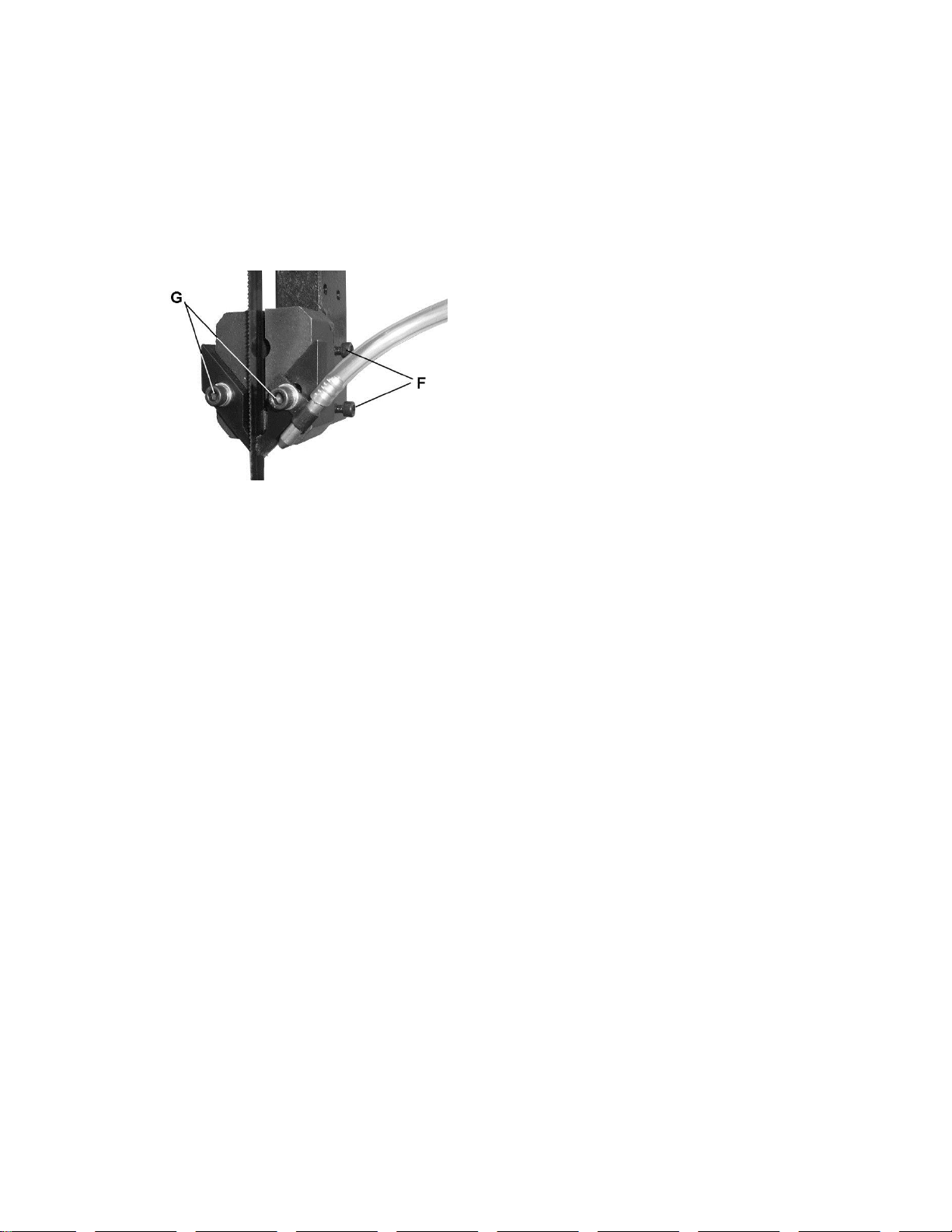

5. Loosen two socket head cap screws (G, Figure

9) and adjust each finger toward the blade.

They should not touch the blade. Adjust for

0.25mm clearance on either side.

6. Retighten the two screws (G, Figure 9) once

proper adjustment has been made. Be sure that

adjustment for air nozzle has not changed and

it directs the flow of air to the cut.

Figure 9

7. Adjust lower blade guides in similar manner.

Note: Even properly adjusted blade guides will show

wear after continual use. Readjust as necessary. If

the blade guides become difficult to adjust, switch

the left and right blade guides.

8.4 Top guide adjustment

Always position top guide to within 3mm of the top

surface of workpiece. This minimizes exposure of

operator’s hands to the saw blade.

8.5 Changing saw blades

1. Disconnect saw from power source.

2. Move upper blade guide to its highest position

and lock in place.

3. Open both wheel doors. Turn tension

adjustment handwheel counterclockwise to

loosen tension on blade.

4. Remove blade from both wheels and maneuver

it around blade guard on column and protective

shield on upper blade guide. Use gloves when

handling blades.

5. Install new blade by maneuvering around blade

guard on column and protective shield on upper

blade guide.

6. Place it between the fingers of both blade

guides and onto both wheels. Position next to

both wheel flanges. Make sure teeth point down

toward table. NOTE: If teeth will not point

downward regardless of blade orientation, the

blade is inside-out. Twist blade outside-in and

reinstall.

7. Tension blade by turning tension handwheel.

Rotate wheel by hand and make sure blade is

properly seated in blade guides. Blade guides

will have to be adjusted if the replacement blade

is a different type and width.

8. Turn on saw and check blade tracking. Adjust

tracking if necessary.

8.6 Work lamp

The work lamp uses a standard 20W/24V Halogen

light.

9.0 Blade selection

Proper blade selection is just as important to band

saw operation as is blade speed and material feed.

Proper blade selection will impact blade life,

straightness of cut, cut finish, and efficiency of

operation. Excessive blade breakage, stripping of

teeth, and waviness of cut are some of the results of

improper blade selection.

Blades are classified by material composition, tooth

shape, tooth pitch, tooth set, gage of the band

material, and kerf of the set (width of cut).

9.1 Material composition

Carbon Steel –low cost, for use with non-ferrous

materials, wood, and plastics.

High Speed Steel –resists heat generated by dry

cutting. Used for ferrous metals.

Alloy Steel –tough and wear resistant, cuts faster

with longer blade life. Used on hard materials. More

expensive than carbon or high speed steel.

Carbide Tipped –for cutting unusual materials

such as uranium, titanium, or beryllium.

9.2 Tooth shape

Note: When cutting thin materials, the rule for blade

pitch is to have a minimum of two teeth engaging

the material being cut at all times.

Standard Tooth - generally used to cut ferrous

metals, hard bronze, hard brass, and thin metals.

Skip Tooth - have better chip clearance (larger

gullet) and are used on softer, non-ferrous materials

such as aluminum, copper, magnesium, and soft

brass.

Hook Tooth - provides a chip breaker and has less

tendency to gum up in softer materials. Used in the

same materials as skip tooth but can be fed faster

than standard or skip tooth blades.

9.3 Set type

Straight Set –used for free cutting non-ferrous

materials; i.e., aluminum, magnesium, plastics, and

wood.