Überprüfen Sie täglich vor dem

Einschalten der Maschine die

einwandfreie Funktion und das

Vorhandensein der erforderlichen

Schutzeinrichtungen.

Festgestellte Mängel an der Maschine

oder den Sicherheitseinrichtungen sind

zu melden und von den beauftragten

Personen zu beheben.

Nehmen Sie die Maschine in solchen

Fällen nicht in Betrieb, sichern Sie die

Maschine gegen Einschalten durch

Ziehen des Netzsteckers.

Zum Schutz von langem Kopfhaar

Mütze oder Haarnetz aufsetzen.

Enganliegende Kleidung tragen,

Schmuck, Ringe und Armbanduhren

ablegen.

Tragen Sie Schutzschuhe, keinesfalls

Freizeitschuhe oder Sandalen.

Verwenden Sie die durch Vorschriften

geforderte persönliche

Schutzausrüstung.

Beim Arbeiten an der Maschine keine

Handschuhe tragen.

Zum Handhaben des Sägebandes

geeignete Arbeitshandschuhe tragen.

Beim Sägen von Rundholz das

Werkstück gegen Verdrehen sichern.

Beim Sägen von unhandlichen

Werkstücken geeignete Hilfsmittel zum

Abstützen verwenden.

Die Bandführungen möglichst nahe an

das Werkstück anstellen.

Abgesägte, eingeklemmte Werkstücke

nur bei ausgeschaltetem Motor und

Stillstand des Sägebandes entfernen.

Die Maschine so aufstellen, dass

genügend Platz zum Bedienen und

zum Führen der Werkstücke gegeben

ist.

Sorgen Sie für gute Beleuchtung.

Die Aufstellung der Maschine sollte in

geschlossenen Räumen erfolgen.

Die Aufstellfläche muss ausreichend

eben und belastungsfähig sein.

Beachten Sie dass die elektrische

Zuleitung nicht den Arbeitsablauf

behindert und nicht zur Stolperstelle

wird

Den Arbeitsplatz frei von behindernden

Werkstücken, etc. halten.

Seien Sie aufmerksam und

konzentriert. Gehen Sie mit Vernunft

an die Arbeit.

Arbeiten Sie niemals unter dem

Einfluss von Rauschmitteln wie Alkohol

und Drogen an der Maschine.

Beachten Sie, dass auch Medikamente

Einfluss auf Ihr Verhalten nehmen

können.

Halten Sie Unbeteiligte, insbesondere

Kinder vom Gefahrenbereich fern.

Niemals in die laufende Maschine

greifen.

Die laufende Maschine nie

unbeaufsichtigt lassen.

Vor dem Verlassen des Arbeitsplatzes

die Maschine ausschalten.

Benützen Sie die Maschine nicht in der

Nähe von brennbaren Flüssigkeiten

oder Gasen.

Beachten Sie die Brandmelde- und

Brandbekämpfungsmöglichkeiten z.B.

Standort und Bedienung von

Feuerlöschern.

Benützen Sie die Maschine nicht in

feuchter Umgebung und setzen Sie sie

nicht dem Regen aus.

Angaben über die min. und max.

Werkstückabmessungen müssen

eingehalten werden.

Späne und Werkstückteile nur bei

stehender Maschine entfernen.

Die Maschine nie bei entfernten

Schutzeinrichtungen in Betrieb

nehmen große Verletzungsgefahr!

Arbeiten an der elektrischen

Ausrüstung der Maschine dürfen nur

durch eine Elektrofachkraft

vorgenommen werden.

Tauschen Sie ein beschädigtes

Netzkabel sofort aus.

Umrüst-, Einstell- und

Reinigungsarbeiten nur im

Maschinenstillstand und bei

gezogenem Netzstecker vornehmen.

Schadhafte Sägeblätter sofort ersetzen.

3.3 Restrisiken

Auch bei vorschriftsmäßiger

Benutzung der Maschine bestehen die

nachfolgend aufgeführten Restrisiken:

Verletzungsgefahr durch das frei

laufende Sägeband im Arbeitsbereich.

Gefährdung durch Bruch des

Sägebandes.

Gefährdung durch Lärm und

wegfliegende Späne.

Unbedingt persönliche

Schutzausrüstung wie Augen- und

Gehörschutz tragen.

Gefährdung durch Strom, bei nicht

ordnungsgemäßer Verkabelung.

4. Maschinenspezifikation

4.1 Technische Daten

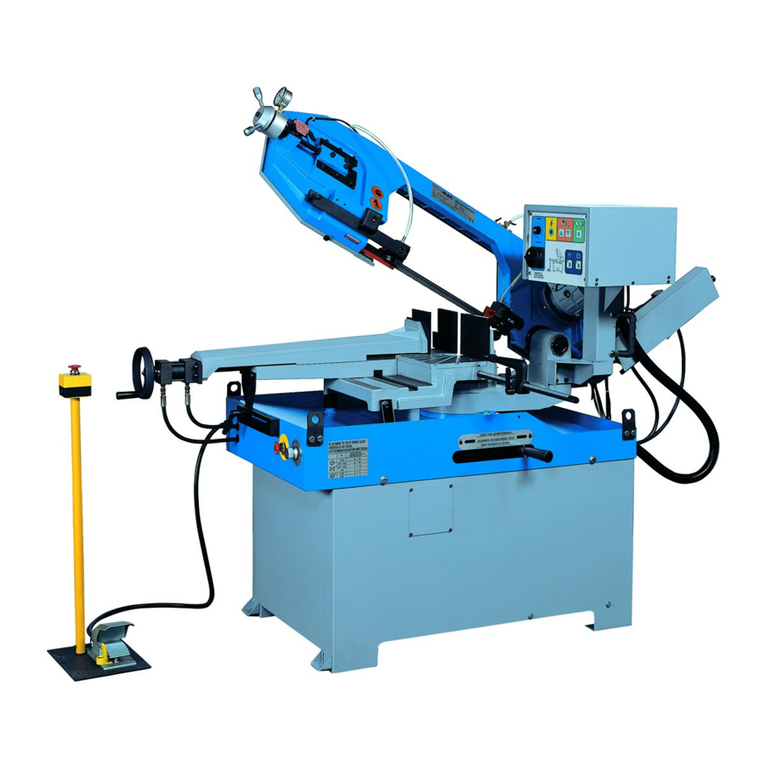

Rollendurchmesser 187 mm

Schnittbreite bei 90° max 150 mm

Schnittbreite bei 45° max 75 mm

Schnittbreite bei 60° max 44mm

Schnitthöhe max 125 mm

Sägebandlänge 1640 mm

Sägebandbreite 13 mm

Sägebandstärke 0,6 mm

Schnittgeschwindigkeit 20/30/50 m/min

Sägearm-Schwenkbereich -45°/0°/+60°

Schraubstock/Boden 755mm

Maschinenabmessung

(L x B x H) 1050x560x1500mm

Gewicht 80 kg

Netzanschluss 230V ~1/N/PE 50Hz

Abgabeleistung 0.36 kW (1/2 HP)S1

Betriebsstrom 3 A

Anschlussleitung H07RN-F): 3x1,5mm²

Bauseitige Absicherung 10 A

4.2 Schallemission

Schalldruckpegel ( nach EN 11202):

Leerlauf 74,2 dB(A)

Bearbeitung 87,8 dB(A)

Die angegebenen Werte sind

Emissionspegel und sind nicht

notwendigerweise Pegel für sicheres

Arbeiten.

Sie sollen dem Anwender eine

Abschätzung der Gefährdung und des

Risikos ermöglichen.

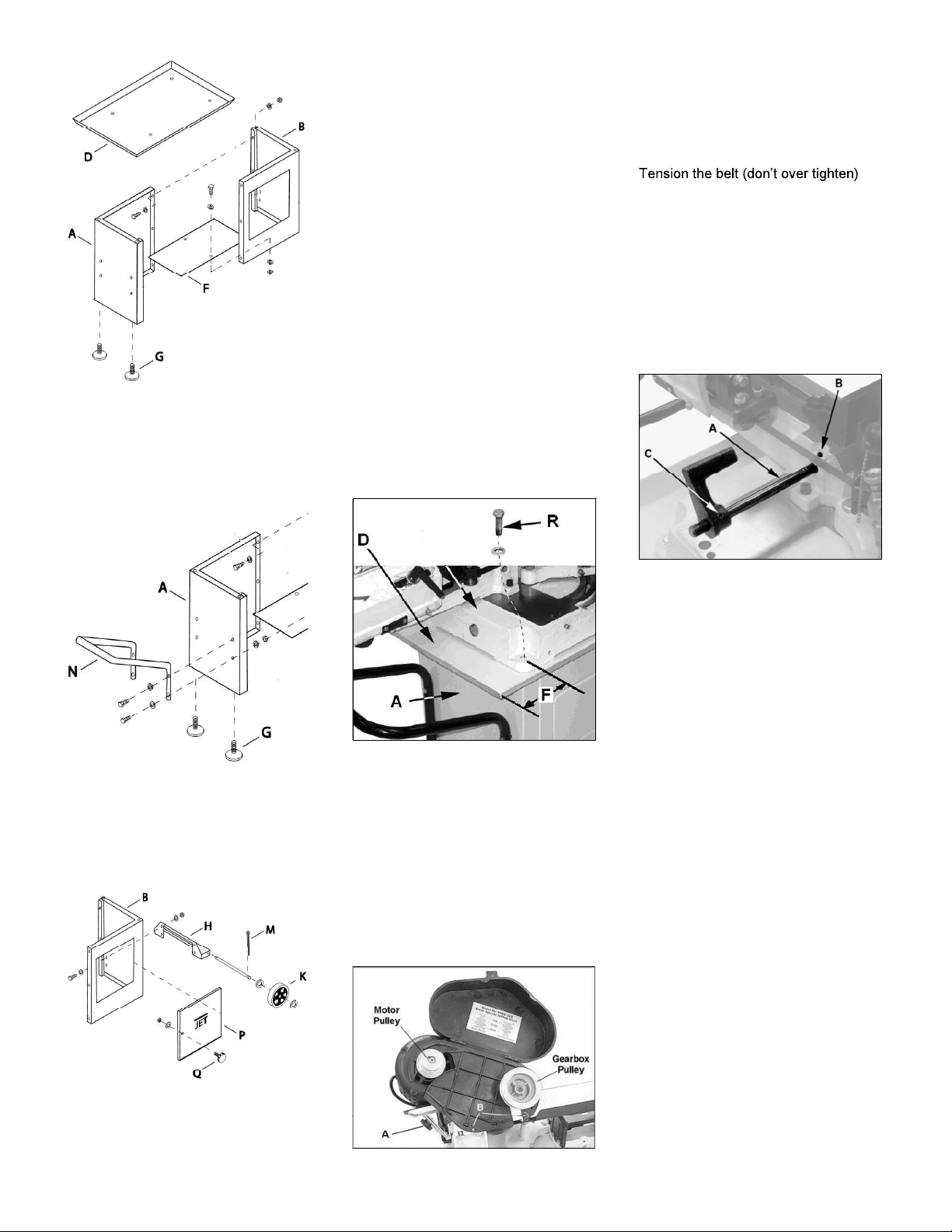

4.3 Lieferumfang

Maschinenuntersatz mit Rädern

Bi-Metall-Sägeblatt

Einstellbarer Ablänganschlag

Riemenantrieb und Abdeckung

Hydraulikzylinder

Spänetasse

Montagezubehör

Gebrauchsanleitung

Ersatzteilliste

5. Transport und Inbetriebnahme

5.1.Transport und Aufstellung

Zum Transport verwenden Sie einen

handelsüblichen Stapler oder

Hubwagen. Sichern Sie die Maschine

beim Transport gegen Umfallen.

Die Aufstellung der Maschine sollte in

geschlossenen Räumen erfolgen.