Aqua-Nui Distiller Parts List

Item # 100V 120 V 240V Description

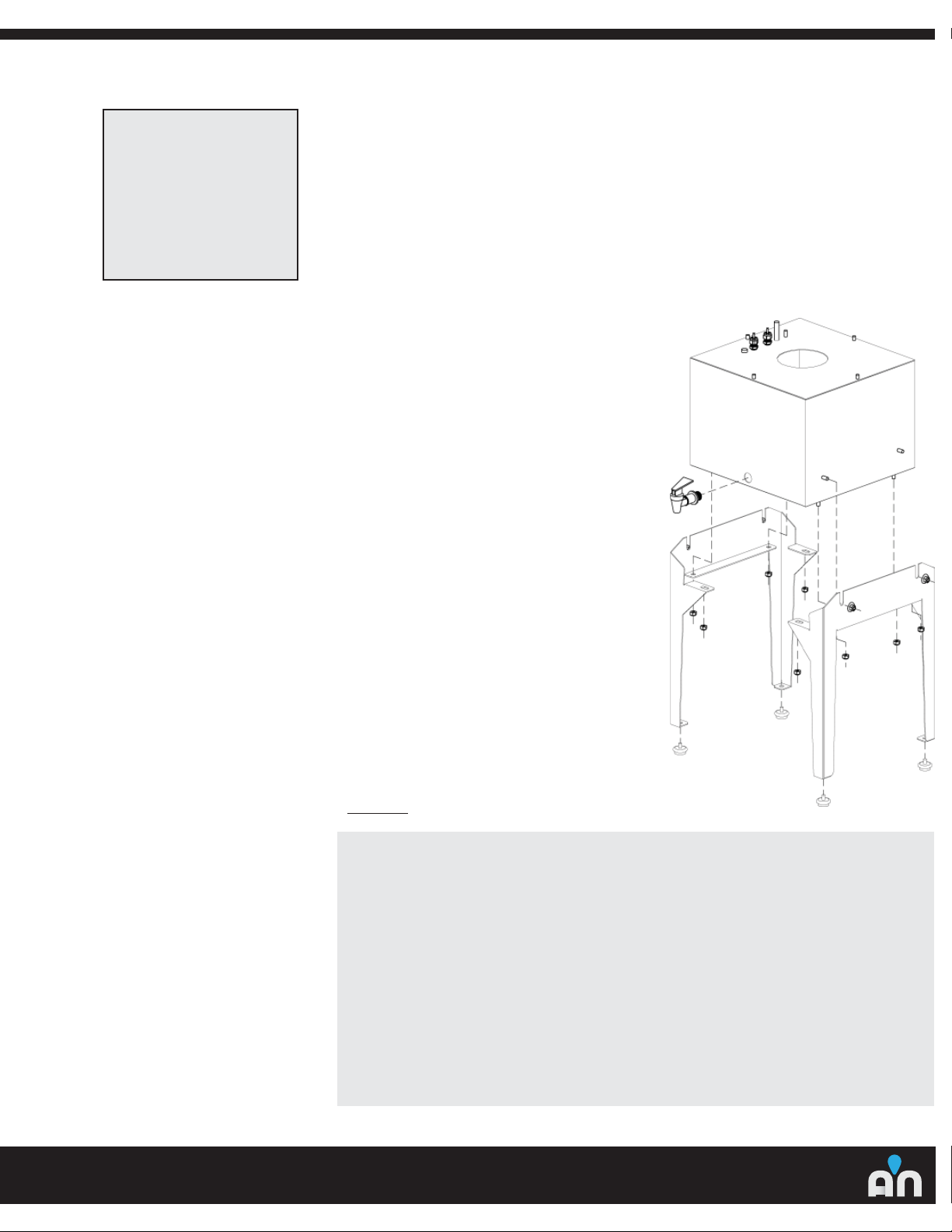

1 21005 21005 21005 PANEL, TOP, AQUANUI

2 9029 9029 9029 SCREW, #10-16 X 1/2”, SHT.MTL.

3 9019 9019 9019 SCREW, #8-32 X 3/4”,PHD, PLPS

4 9342 9342 9342 GUARD, FAN, 6”, METAL

5 9344BJ 9344B 9344B FAN, AXIAL, 170CFM, 110/220V

6 9003 9003 9003 NUT, #8-32, NYLOCK, HEX, S.S.

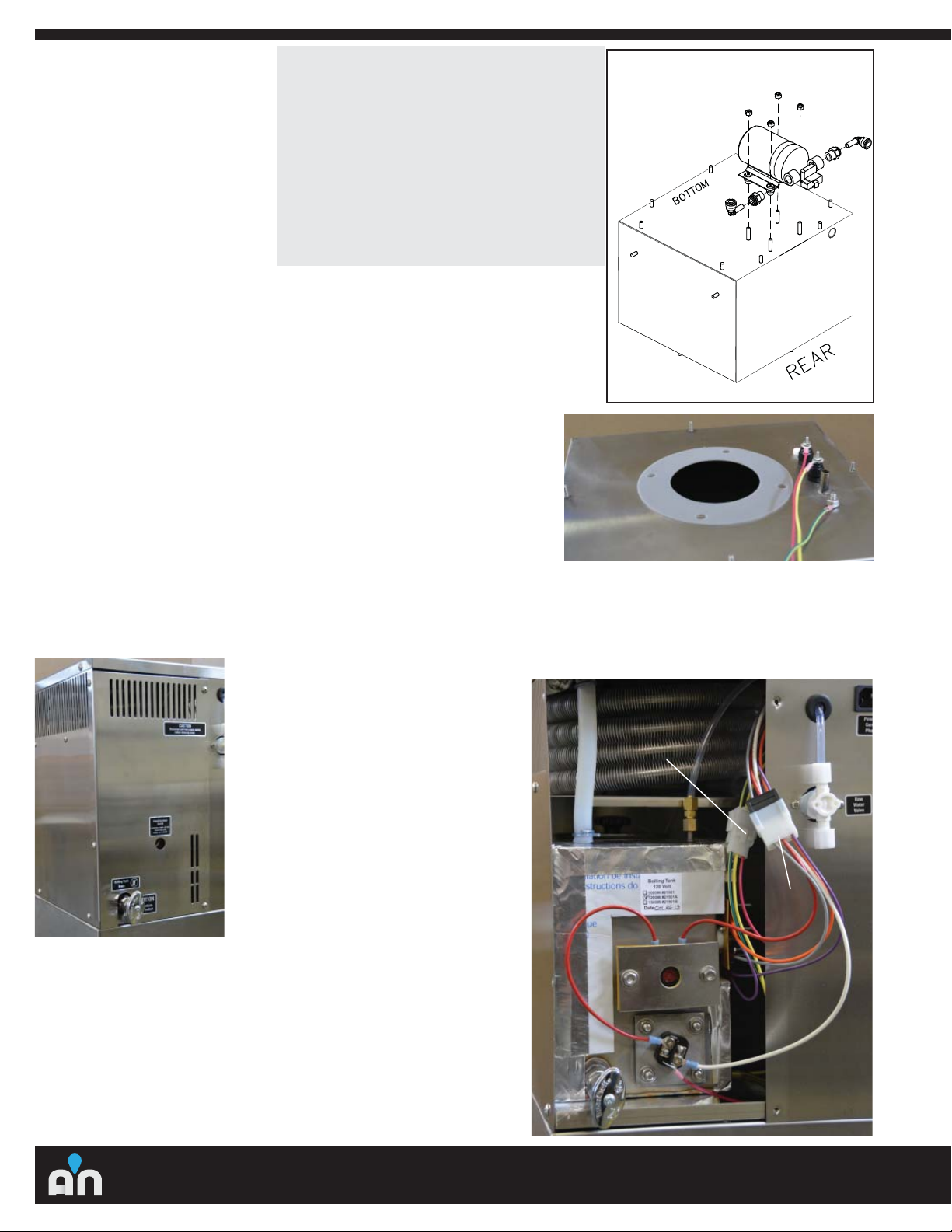

7 21020 21020 21020 COIL, CONDENSING, AQUANUI

8 7246 7246 7246 TIE, CABLE, HIGH TEMP 14.7” BLK

9 9111 9111 9111 BLOCK, TERMINAL, 3 X 2 X 4

10 7206 7206 7206V RELAY, POWER, SPDT, 120VAC 15A

11 9106 9106 9106 RELAY, LIQUID LEVEL CONTROL

12 21503J 21503 21503V TRAY, ELECTRICAL, AQUANUI, COMPLETE

13 7276 7276 7276 CORD, POWER, IEC, 15 AMP

14 7275 7275 7275 CONNECTOR, IEC FEMALE, SNAP-IN

15 7232 7232 7232 SWITCH, LIGHTED, RED

16 7228 7228 7228 SWITCH, ON/OFF, W/O BEZAL, 15A

17 21006 21006 21006 CLADDING, WRAPAROUND, AQUANUI

18 21059 21059 21059 TUBING, HIGH TEMPERATURE, 1/4”

20 63419 63419 63419 UNION, BRASS, 1/4” COMP (USE DELRIN SLEEVES)

21 9550 9550 9550 NUT, COMP, 1/4”, PLASTIC

22 9019 9019 9019 SCREW, #8-32 X 3/4”,PHD, PLPS

23 7197 7231 70106 VALVE, SOL, 1/4”COMP, N/C

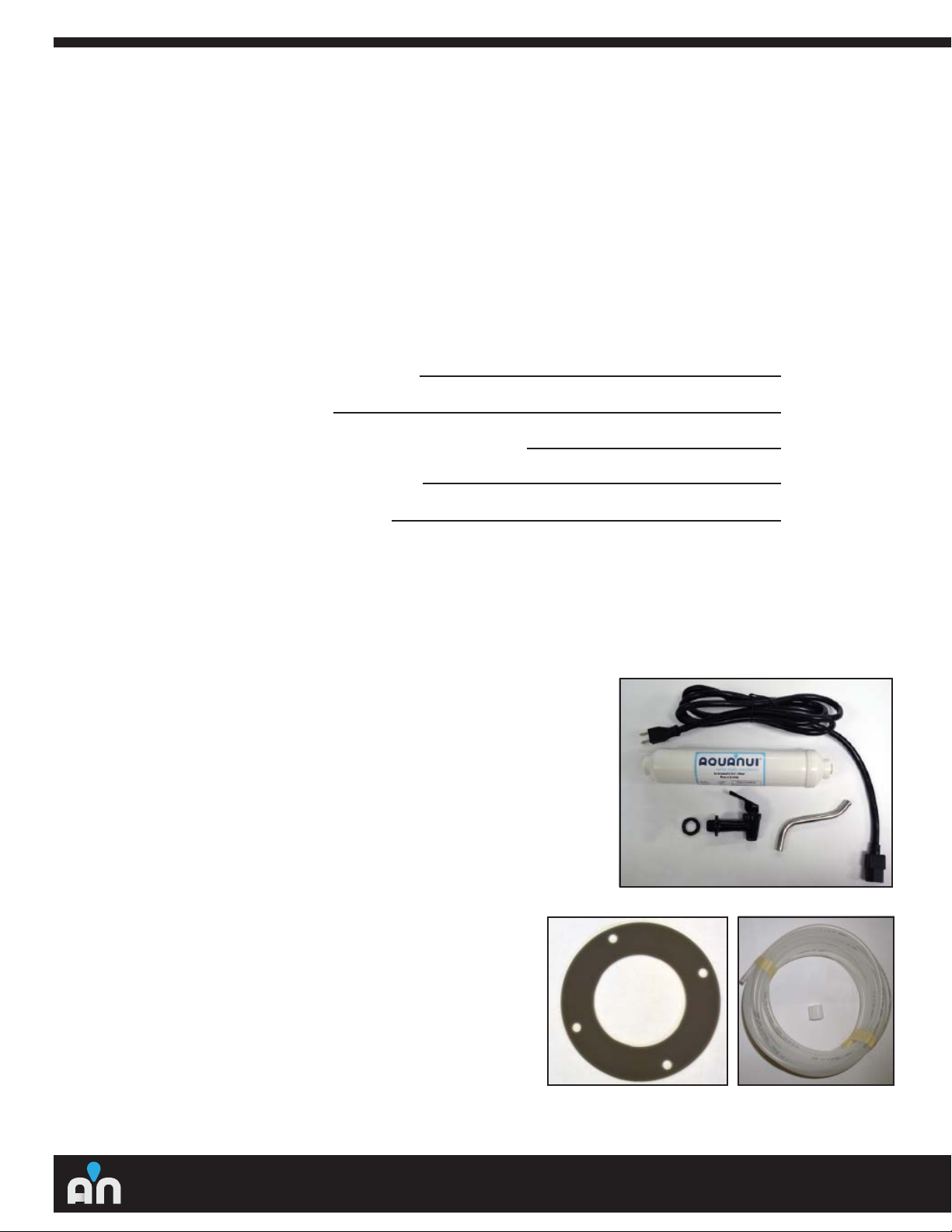

24 21048 21048 21048 FILTER, VOC, AQUANUI PREFILTER

25 9541 9541 9541 TUBING, 5/8” OD x 3/8” ID

26 9921 9921 9921 CLAMP, HOSE, WIRE SPRING, 5/8”

27 21007-02 21007-02 21007-02 PAN, BOTTOM, STUDDED

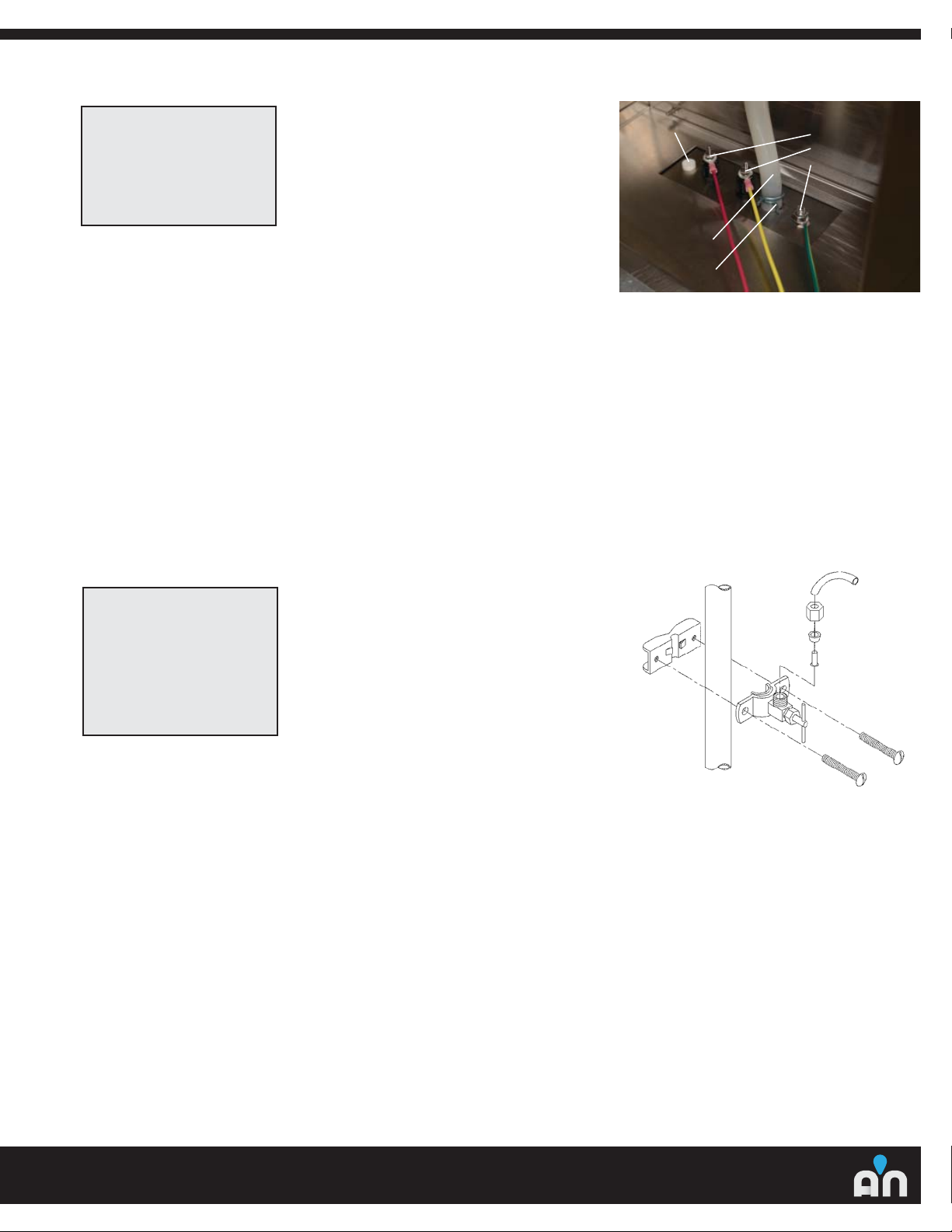

28 654 654 654 MICROSWITCH KIT

29 21063 21063 21063 FLOAT AND ACTUATING ARM KIT

30 406 406 406 BOILING TANK LID KIT

34 633J 633 633V 1000 WATT HEATER KIT

34 738J 738 738V 1200 WATT HEATER KIT

34 764J 764 764V 1500 WATT HEATER KIT

35 7069 7069 7069 RESET, 66T, 220F(+8F/-0)

36 510 510 510 PLATE, RETAINER, RESET, PC

37 424A 424A 424A ASSY., RESET RETAINER PLATE

38 9009 9009 9009 WASHER, 1/4” X 5/8”OD, FLAT

39 9045 9045 9045 NUT, 1/4-20, HEX, S.S.

40 21501-02 21501-02 21501-02 TANK, STUDDED, BOILING AQUANUI

41 9508 9508 9508 VALVE, DRAIN, BRASS STEM, 1/2”

42 611 611 611 TUBE, DRAIN EXTENSION

43 21009 21009 21009 PANEL, BACK, AQUANUI

44 21041 21041 21041 GROMMET, 1/2” ID BLACK RUBBER