- 1 -

Specifications

Please reference the ST-774 manual for the full specifications on the ultra-low dissolved oxygen sensor.

1.1. ST-774 Porta-Panel Overview + Specification (P/N 42096)

Product Description

The ST-774 Porta-Panel (P/N-42096) is a prefabricated panel ideally

suited for those desiring to use the ST-774 Ultra-Low DO sensor

with local display and data acquisition in a portable fashion for

oxygen measurement (ie. deaerator performance studies). The

Porta-Panel is pre-mounted on an easy-carry self-standing 316L

stainless-steel panel with the ST-774 sensor, flow-cell and

appropriate water sample/calibration gas flow hardware. The

panel comes equipped with an integrated UC-50 Display/Data

Logging Terminal for connected to the ST-774 via RS-485 Modbus

offering live data display, calibration interface and data logging of

the sensor. The UC-50 offers 1x contact relay output and has RS-

485 Modbus and 1x 4-20mA outputs for passing the sensor value

onto another device. The UC-50 also offers Bluetooth 5.0

capability for those desiring to use the uPyxis mobile or desktop

apps for wireless calibration and diagnostics of the Pyxis sensor

connected.

Product Features

•Ideal for Dissolved Oxygen Studies

•Portable Free-Standing Panel –316L SS

•Fully Integrated Plumbing + Flow Cell

•Measurement of Water Sample or Calibration Gas

•Premounted ST-774 Ultra-Low DO Sensor

•0.0-2,000 μg/L measurement range

•0.1 μg/L Lower Limit of Detection

•Built-in temperature and pressure sensors

•Premounted UC-50 Data Logger + Display Panel

•Direct RS-485 Modbus Connection to UC-50 Display

•Fully Integrated Zero + Slope Calibration Interface

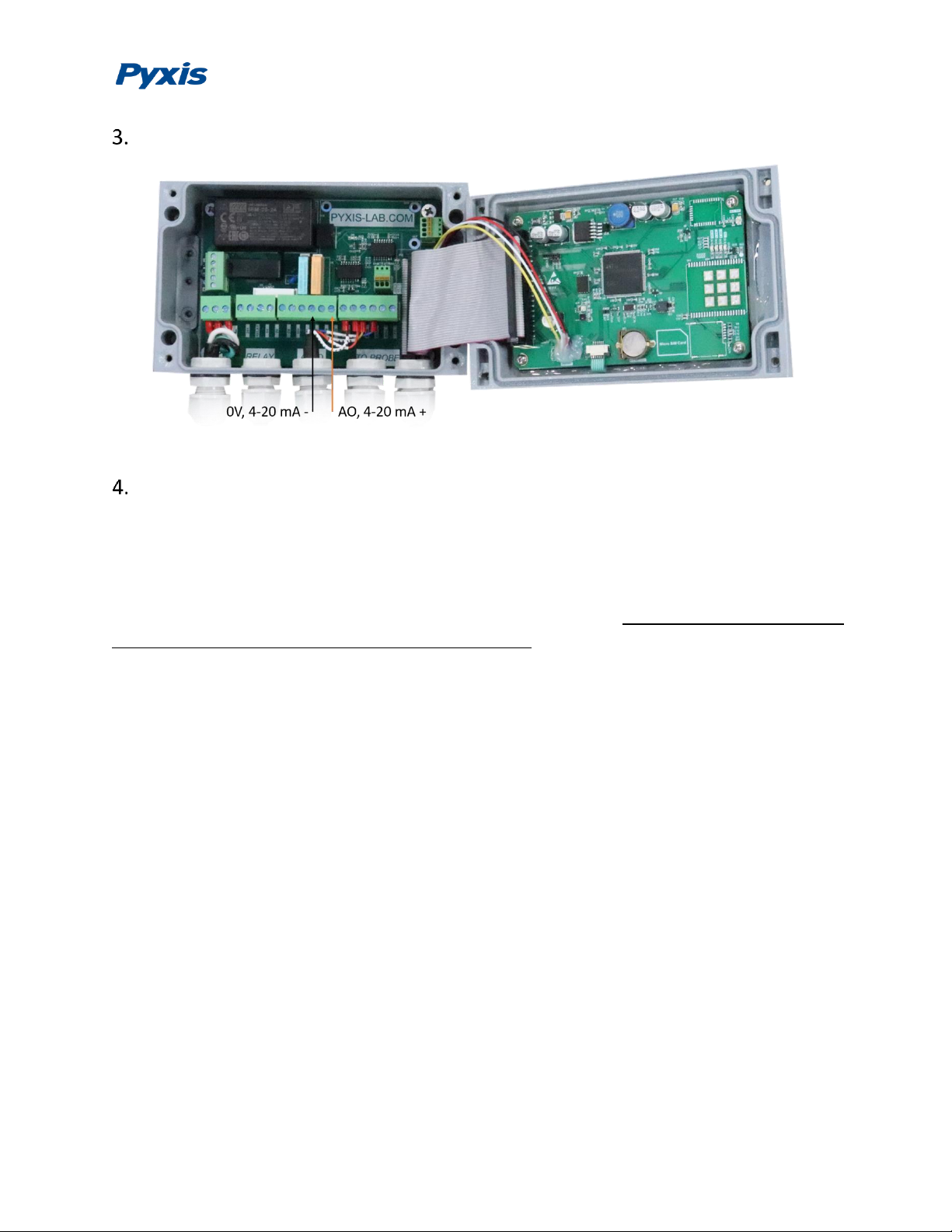

•Integrated 4-20mA + RS-485 Output

•1x Contact Alarm Relay and USB Data Logger