3

1. General Information

HOMEOWNER INFORMATION FOR GAS

TO START UP THE APPLIANCE

1. STOP! Read the safety information on the side of the boiler. DO NOT START THE BOILER UNLESS

ALL CLEANOUT DOORS ARE SECURED AND SEALED. (Skip to step 9 for oil burning boilers)

2. Set thermostat to lowest setting

3. Turn off all electric power to the appliance

4. Do not attempt to light the burner by hand

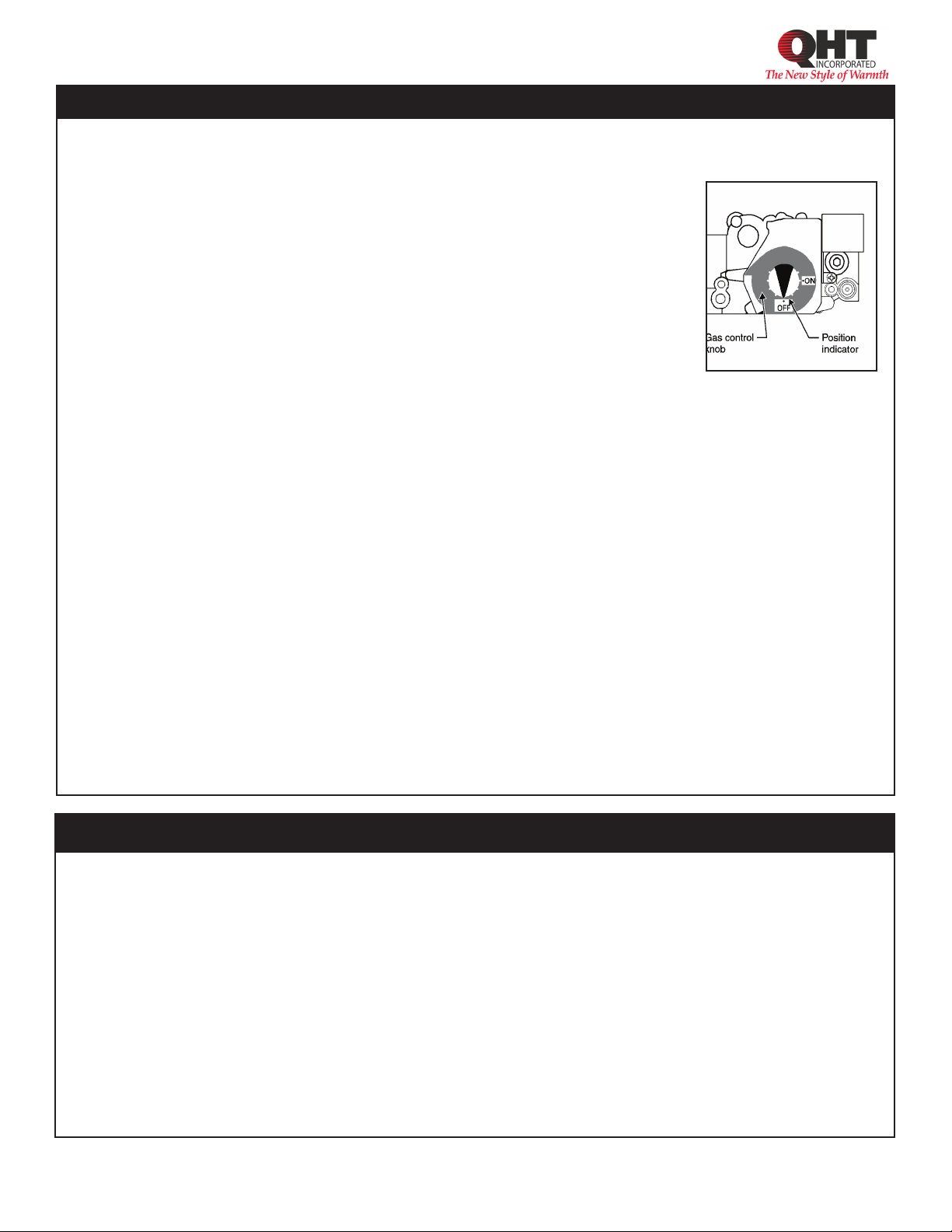

5. Turn the manual shut off on the combination gas valve clockwise to

the off position.

6. Wait five minutes to clear out any gas. Then smell for gas, including

near the floor.

If you smell gas, STOP!

• Do not try to light any appliance

• Do not touch any electric switch; do not use any phone in your building

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

• If you can not reach your gas supplier call the fire department

7. If you don’t smell gas, go to the next step.

8. Return the manual valve on the combination gas valve to the on position by reversing

step “5”.

9. Turn on all electric power to the appliance.

10. Set thermostat to the desired setting.

11. If the burner fails to light you may press the reset button once. If the appliance will not

operate, follow the instructions “To Turn Off Gas To Appliance” and call your service technician

or gas supplier. DO NOT ATTEMPT TO START THE BURNER WHEN EXCESS GAS HAS ACCUMULATED,

WHEN THE UNIT IS FULL OF VAPOR, OR WHEN THE COMBUSTION CHAMBER IS VERY HOT.

NOTE: ALWAYS KEEP THE MANUAL FUEL SUPPLY VALVE SHUT OFF IF THE BURNER IS SHUT DOWN FOR

AN EXTENDED PERIOD OF TIME.

TO TURN OFF GAS APPLIANCE

Set the thermostat to the lowest setting.

Turn off electric power to the appliance if service is to be performed.

Turn the gas control valve to the off position.

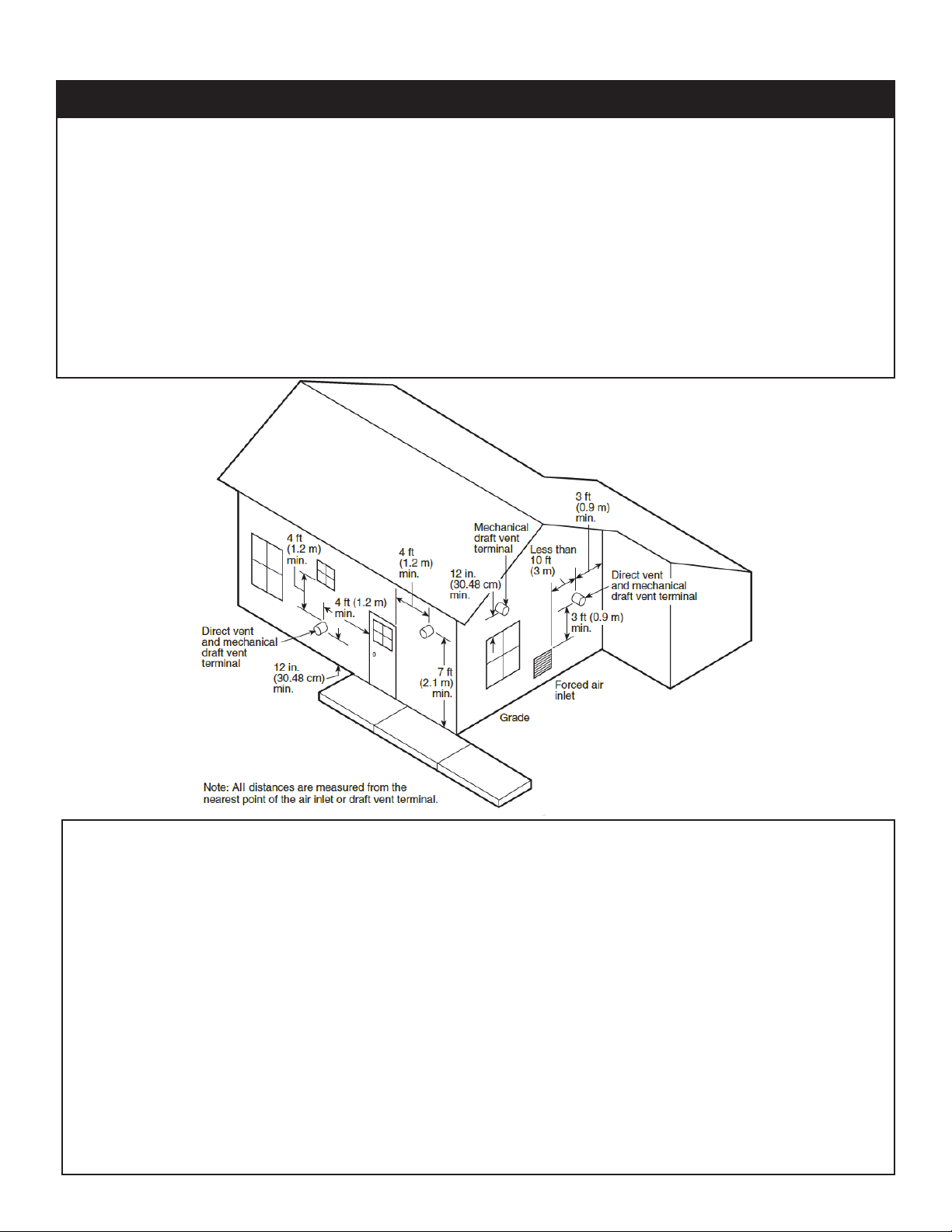

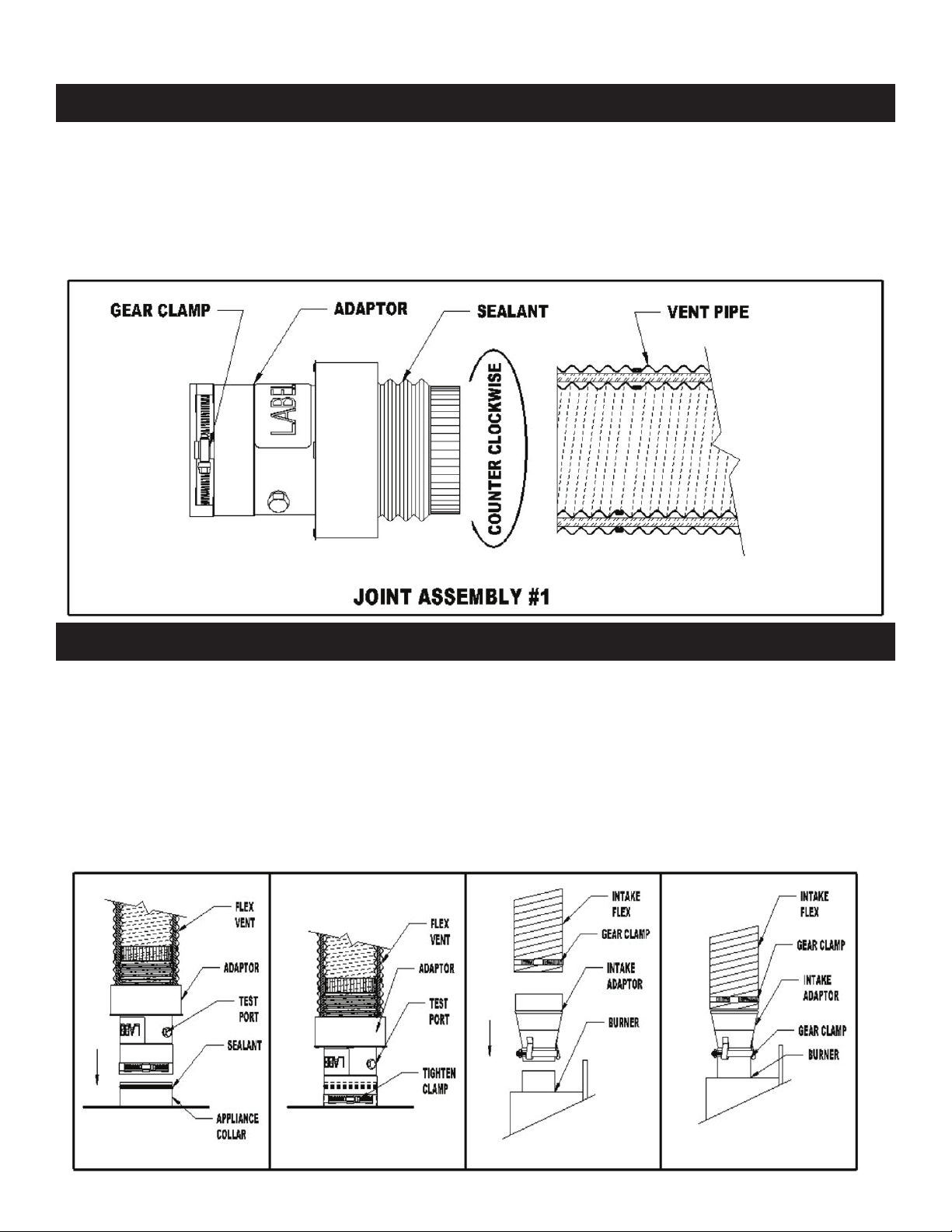

The QHT Direct Vent components have been designed and packaged so that the Biasi

B-10 boilers, Saint Roch UNIVERSAL boilers can be directly vented to the outside. Properly

maintained, these boiler systems are unsurpassed in efficiency and will provide years of

trouble-free operation.

In addition to the standard Biasi or Saint Roch boiler package, the Direct Vent Package

is supplied with a kit containing the standard make-up air and appropriate exhaust system

piping and hoods for your application. The last piece of the complete package is a direct vent

specific burner.

The Direct Vent Systems are a non-powered positive pressure vent hood system for gas

or oil fired appliances that provides an outlet for exhaust gases and an intake for combustion

air. The hood is designed to direct the hot exhaust gases away from the structure without the

aid of a motorized fan. All of the internal parts in contact with the flue gases are made from

corrosion resistant stainless steel.