10. OTHER PARAMETERS ................................................................. 37

10.1. Available menu languages ................................................................... 37

10.2. Access levels ....................................................................................... 37

10.3. „Beep” sound – response to pressing function button .......................... 38

10.4. Backlight and adjusting display brightness .......................................... 38

10.5. Backlight turn-off time .......................................................................... 38

10.6. Auto switch-off ..................................................................................... 38

10.7. Date ..................................................................................................... 39

10.8. Time ..................................................................................................... 39

10.9. Date format .......................................................................................... 39

10.10. Time format.......................................................................................... 40

11. INFORMATION ON BALANCE...................................................... 40

12. BALANCE ADJUSTMENT ............................................................. 41

12.1. Adjustment menu settings ................................................................... 41

12.2. Manual adjustment .............................................................................. 42

12.2.1.Internal adjustment ................................................................................ 42

12.2.2.User adjustment ..................................................................................... 43

12.3. Adjustment report printout ................................................................... 44

12.4. Temperature adjustment (P1.3 THERM CAL) ..................................... 44

12.5. Drying process test (P1.4 TEMPERATURE TEST) ............................. 48

13. DETERMINING PRINTOUT CONTENT ........................................ 50

13.1. Adjustment report ................................................................................ 50

13.2. Header printout .................................................................................... 52

13.3. Printout of measurement result – GLP PRINTOUT ............................. 54

13.4. Footer printout ..................................................................................... 56

13.5. Printout of report on drying process ..................................................... 58

13.5.1.Report on drying – header ..................................................................... 59

13.5.2.Report on drying – measurement........................................................... 60

13.5.3.Report on drying – footer ....................................................................... 61

13.6. Non-standard printouts ........................................................................ 62

13.6.1.Inserting texts ........................................................................................ 62

13.7. Variables .............................................................................................. 65

14. DATABASES.................................................................................. 66

14.1. Users ................................................................................................... 66

14.2. Products .............................................................................................. 69

14.3. Drying programs .................................................................................. 70

14.4. Tares ................................................................................................... 72

14.5. Weighments ......................................................................................... 73

14.6. Reports on drying process ................................................................... 76

15. DATABASES EKSPORT AND IMPORT ....................................... 80

15.1. Database export .................................................................................. 81

15.2. Database import .................................................................................. 82

15.3. Measurement data printout .................................................................. 82

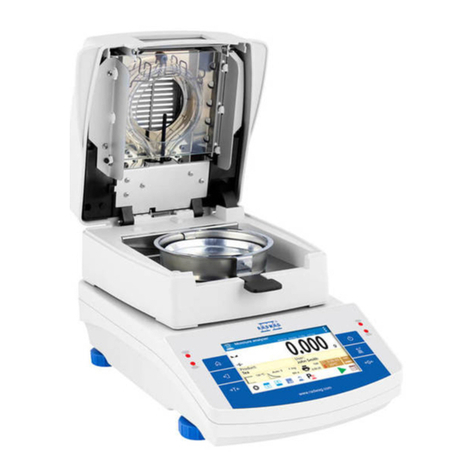

16. PREPARING SAMPLES FOR DRYING ........................................ 84

16.1. Rules for measurement of moisture analyzer humidity content ........... 84

16.2. Sampling and preparation .................................................................... 84

17. SELECTION OF DRYING PARAMETERS .................................... 88

17.1. Selecting optimum mass for a sample ................................................. 88