Raven OMNiDRIVE User manual

Other Raven Farm Equipment manuals

Raven

Raven AutoBoom User manual

Raven

Raven SmarTrax User manual

Raven

Raven SmarTrax User manual

Raven

Raven AccuBoom User manual

Raven

Raven AccuBoom User manual

Raven

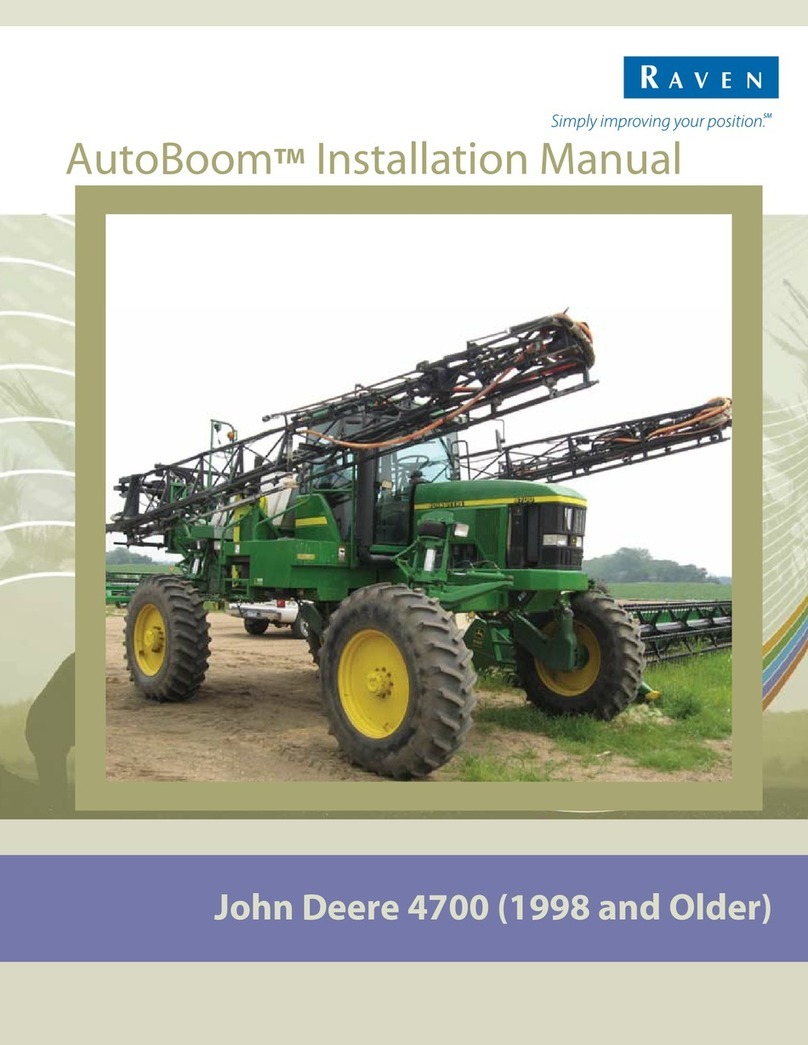

Raven AutoBoom John Deere 4700 User manual

Raven

Raven VSN User manual

Raven

Raven Cruizer II User manual

Raven

Raven AutoBoom User manual

Raven

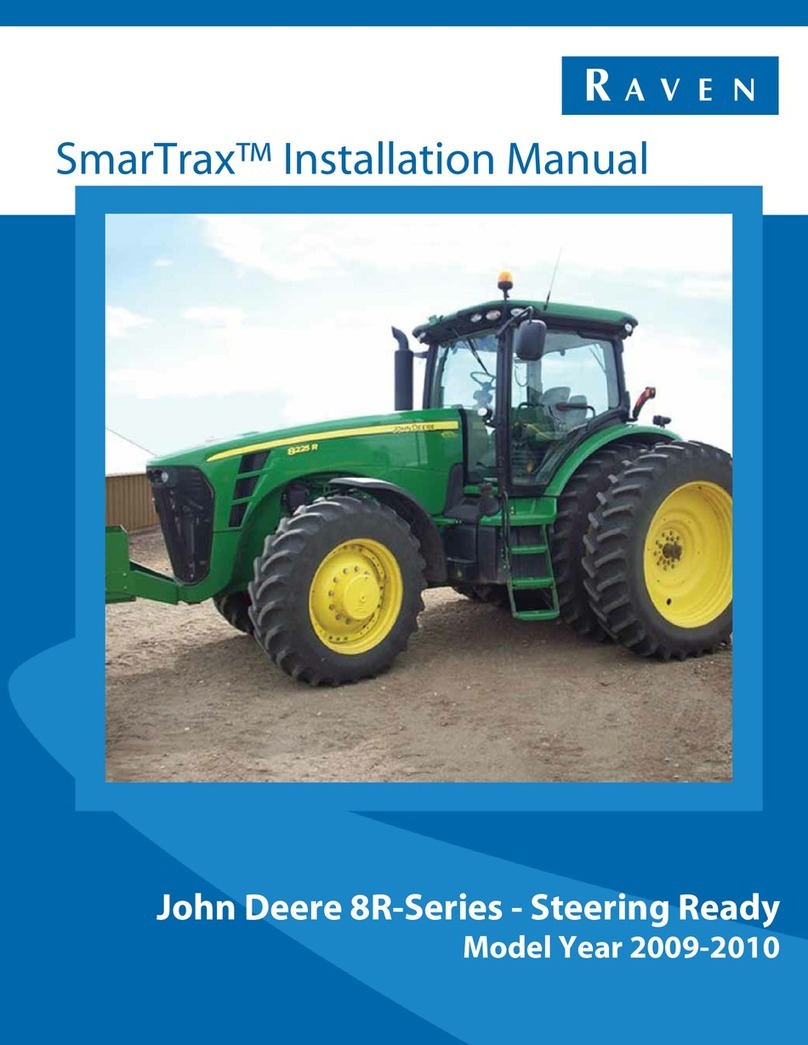

Raven SmarTrax John Deere 8R 2009 Series User manual

Raven

Raven SmarTrax User manual

Raven

Raven AutoBoom User manual

Raven

Raven CR7 Technical manual

Raven

Raven AutoBoom XRT User manual

Raven

Raven SmarTrax User manual

Raven

Raven SmarTrax User manual

Raven

Raven VSN User manual

Raven

Raven Case IH Patriot 3XX0 User manual

Raven

Raven SmarTrax User manual

Raven

Raven SmarTrax User manual