Assembly Notes /Getting Started (A) page 6

Instructions for Kit #B 1925

Identify and label all of the parts

Preassemble the Foundation, Rear Roof, Stairs, Postbases

Finish the oors,

Paint everything* one coat (see page 11)

Sand everything until the paint is smooth, transparent,

and some of the wood is showing through

Build the housebody up to the Roof

Second-coat the Walls

Mark, paint, and attach the Roofs

(don’t glue on the Rear Roof yet)

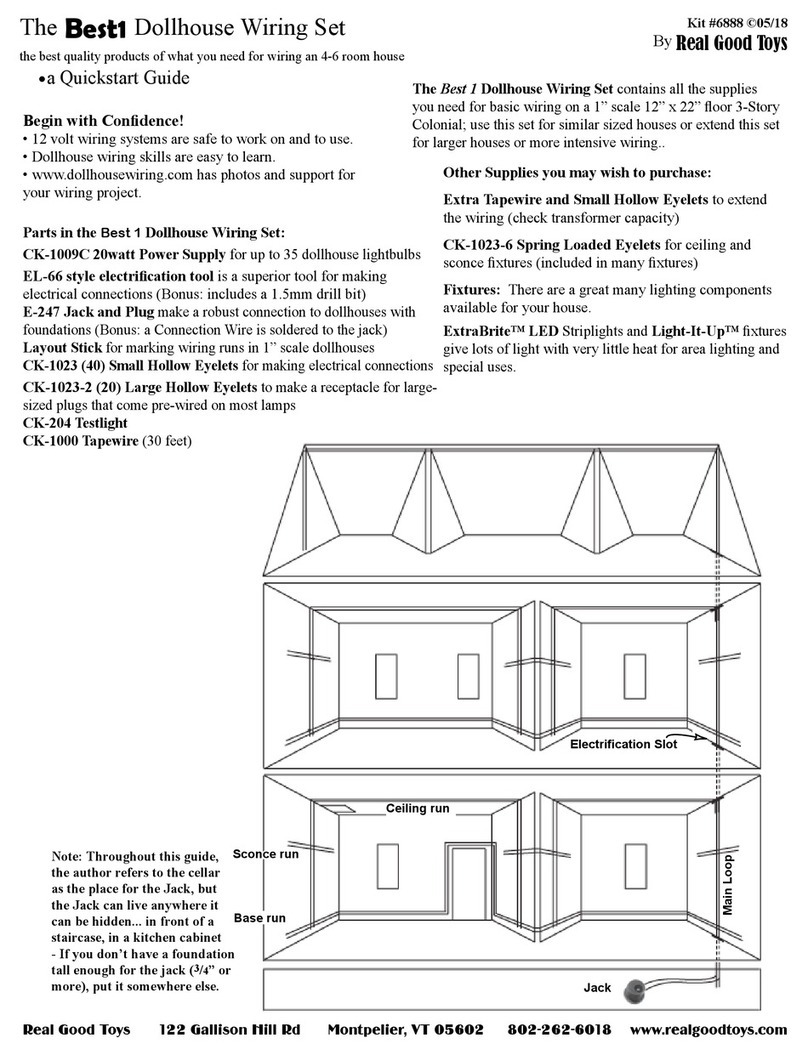

Optional: Start the wiring

Foundation

Install the Dividers

Optional: Finish the wiring

Assemble and nish painting everything else

Finish the Attic - attach the Rear Roof

Finish the outside

Finish the inside

Assembly Tips:

A large, clutter-free, well-lighted work area is helpful

during assembly, but a at work surface is essential.

Read the instructions carefully; look at each of the

illustrations. !With the parts in your hands!, think the

assembly through before you proceed.

Test t each time you are ready to glue a piece in

place...then you’ll know you have it right.

If more tape or a helper is needed, it’s good to know

that before the parts have glue on them.

Don’t be stingy with glue or tape; use generous

amounts. Always wipe off excess glue immediately.

Keep one damp rag and one dry rag handy all the time.

Have weights available for holding things tight as

glue joints dry (stacks of books, gallons of pure Ver-

mont Maple Syrup - anything heavy).

Glue the body of your dollhouse together with

white, water clean-up glue that dries clear. Do not use

instant-bond (super glue), fast-tack, rubber cement,

silicone, or hot melt glues. They are all used in some

wood applications, but they all have some characteris-

tic that makes them un-desirable for the body of your

dollhouse. Carpenter Glue works well, but glue-smear

dries yellow or tan; many of the things you glue onto

the house are pre-painted – extra glue will show.

I use Aleene’s Tacky Glue® for housebody assembly

(available at www.realgoodtoys.com).

Make sure everything is straight and at as glue

dries... That’s the shape that will be permanent.

Q: Can I wallpaper before I assemble the doll house?

A: Yes you can (it’s your house!) Many experienced builders

are advocates of papering before construction - I am not.

My biggest objection to papering rst is that you are always

too skimpy with glue so none will squeeze out and get on the

paper. I try to use the amount of glue that lls the joint, so

some will squeeze out in every joint and be wiped up. But

wiping glue off of wallpaper leaves a streak, so the tempta-

tion is to go skimpy, and the joints aren’t as strong.

Second, I can always tell a house that was pre-papered

because the corners show a void instead of being continuous

(see the slideshows about how to crowd the papers together

in the corner... you can’t do that with pre-papered walls).

Third, I have had to replace paper too often that has gotten

damaged by glue or tape during construction... that wastes

time and paper ($) and can make it so you are left deciding

whether to replace a damaged paper or letting it slide because

you don’t have any more of that pattern and you’ll have to

order it and that takes too much time (running out but then

needing another piece is a distressing moment).

Finally, I don’t nd pre-papering to be faster. By the time I

have done all of the extra planning that getting the papers in

the right place requires, I have used up any potential advan-

tage. I have great big blacksmith’s hands, and papering in a

nished house is easy for me.

All that having been said, I do pre-cut the papers used in the

attic before attaching the Roofs.

Glue the shingles on with glue that doesn’t have any water

in it! If the glue says ”water clean-up”, it will curl the wooden

shingles. Look carefully at the glue you intend to use to be

sure it is solvent-based, or use hot-melt glue (use the high

temp version and watch out for the burns). I use a “Sub-Floor

Adhesive” glue which comes in a caulking-gun tube at the

hardware or building supply store. It says “Caution: Flamma-

ble” on the front, and that’s how I am sure it is solvent based.

Check ingredients and warnings!

If you Wallpaper,use Grandma Stover’s

www.realgoodtoys.com

or pre-mixed Roman’s “Border” paste.

Brush paste on the wallpaper, then the wall, and nally

smooth the wallpaper into position.

Taking things apart: Heat softens glue. If you have to take

things apart, warm the part in the oven at 170ofor up to a half

hour to let the heat get into the joint where the glue is. Don’t let

it get hotter than you can touch or the paint may scorch. Don’t

heat window panes. www.realgoodtoys.help has more info.

When glue is drying, skip ahead to up-coming assembly

steps and prepare the parts that will be used.

Before you begin, read the “Finish the Inside” section at

the end of these instructions.

Overview of the Build:

Details of each step will be expanded along the way, but lots

of folks like to see how it all ts together before they start

Slideshows, demos, useful links, details, and photos are all at:

www.realgoodtoys.help

Wiring? www.realgoodtoys.help

for wiring information specic to this house.

*avoid painting grooves, edges, and surfaces that will be glued (like the outside of the roofs)