103 Fairview Park Drive, Elmsford, New York 10523

Bulletin 034 Rev. D

Bulletin 034 Rev. D

1. Cover plate attachment (Plain or Perforated) with

¾ (19mm) assembly adjustment.

2. Smooth aesthetic ceiling profile.

3. Factory installed protective cap.

4. Available in Chrome and White as Standard Finish-

es. Special Application Finishes are also available.

5. Ordinary and Intermediate temperature rating.

1. Underwriters Laboratories Inc. and cULus -

Quick Response

G5-80, G5-56 - Light Hazard and Ordinary

Hazard Occupancies

G5-42 - Light Hazard Occupancies

G5-28 - Light Hazard Occupancies

2. Factory Mutual Research Corp. (FM) -

Standard Response (See Page 3)

G5-56 & G5-28 only.

See the most recent FM Global Property

Loss Prevention Data Sheets for installation

and use guidelines.

3. Loss Prevention Council (LPCB, UK) -

Standard Response

G5-56 - Light Hazard and Ordinary Hazard

Occupancies

4. VdS Schadenverhütung GmbH -

Standard Response

5. EC-Certificate of Conformity 0832-CPD-2062

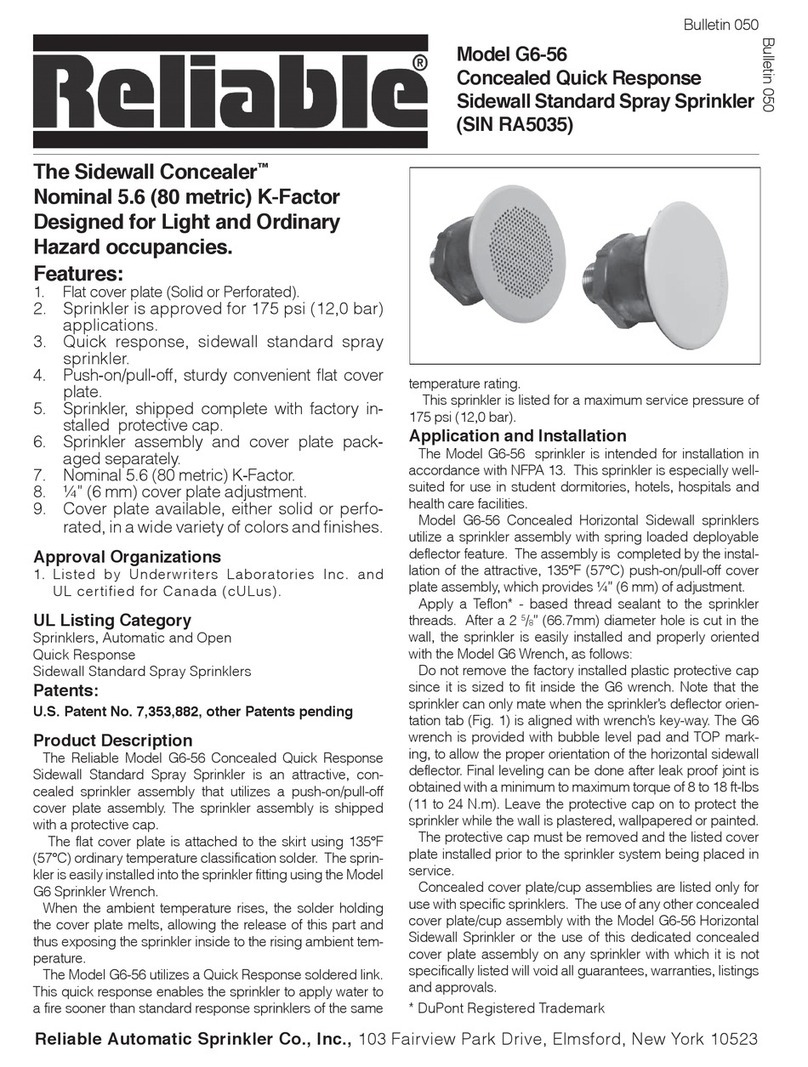

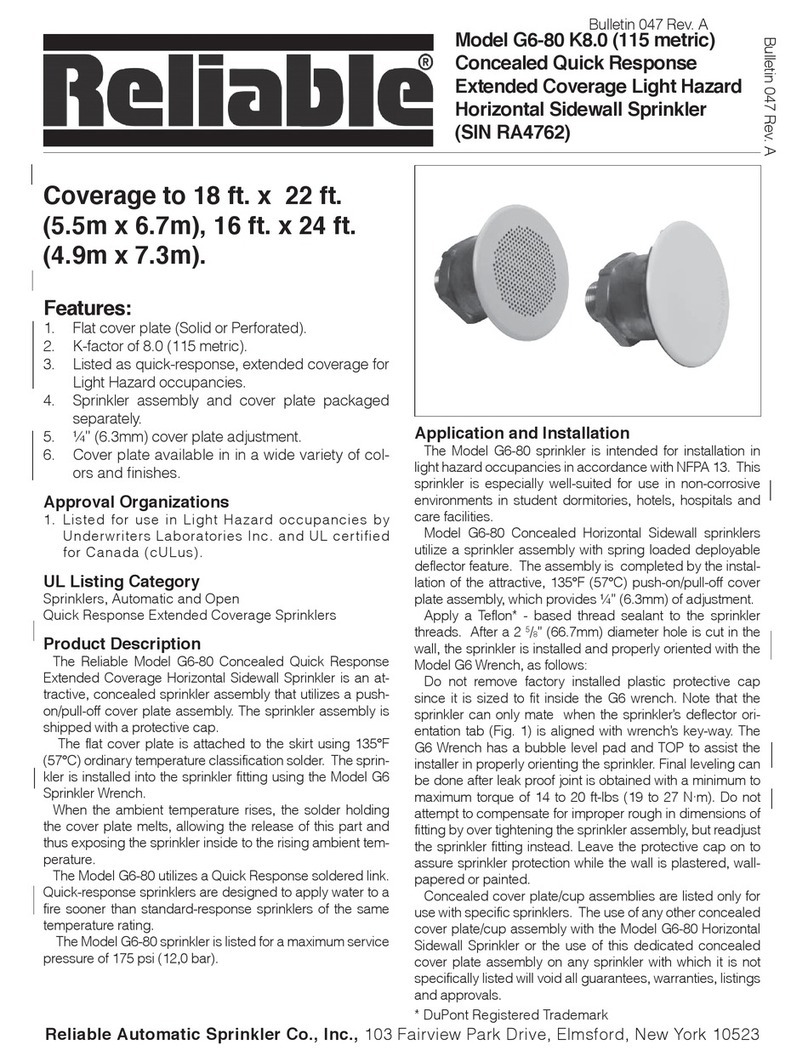

The Reliable Model G5-80, G5-56, G5-42 and G5-28 are

the most versatile quick response concealed sprinklers avail-

able. It provides the best form of fire protection while offering

an attractive appearance and 3/4 (19mm) of cover adjust-

ment for ease of installation. The small diameter cover plate

assembly is easily attached and blends into the ceiling, con-

cealing the most dependable fire protection available, an au-

tomatic sprinkler system.

The Model G5-80, G5-56, G5-42 and G5-28 are designed

for use where aesthetic appearance is important. Offices, hos-

pitals, motels and restaurants are but a few of the applications

where it can be used.

The Model G5-80, G5-56, G5-42 and G5-28 are UL Listed

Quick Response Concealed sprinklers intended for use in

accordance with NFPA 13. FM Approves the G5-56 and the

G5-28 sprinkler as a standard response concealed sprinkler

intended for use in accordance with FM Loss Prevention Data

Sheet 2.0.

The Reliable Model G5-80, G5-56, G5-42 and G5-28 uses

a proven quick response fusible element in a standard style

sprinkler frame with a drop-down deflector. This assembly is

recessed into the ceiling and concealed by a flat cover plate

assembly. The threaded engagement provides ¾ (19mm) of

cover adjustment. The flat cover plate is attached to the skirt

using either 135°F (57°C) or 165°F (74°C) ordinary tempera-

ture classification solder.

When the ceiling temperature rises, the solder holding the

flat cover plate melts, the flat cover plate released thus expos-

ing the sprinkler inside to the rising ambient temperature.

The subsequent fusing of the element opens the waterway

and causes the deflector to distribute the water. Any secure

engagement between the cover plate and cup will assure that

the drop-down deflector is properly located below the ceiling.

Plain Cover Plate

Perforated Cover Plate