Installation Instructions

Model G5-56 Dry sprinklers must only be installed in stan-

dard (ANSI B 16.3 class 150 and ANSI B 16.4 class 125)

pipe tees in the horizontal position, even at branch line ends.

Model G5-56 Dry sprinklers shall not be installed into elbows

or pipe couplings located on drop nipples to the sprinklers. In

all installations, including into CPVC piping, the dry sprinkler

shall be installed with protrusion into the fitting in accordance

with the installation diagrams in this Bulletin.

Installation of the Model G5-56 Dry sprinkler is not recom-

mended in copper pipe systems, as this may reduce the

life expectancy of the sprinkler. Do not install Model G5-56

Dry sprinklers with the standard (long) inlet fitting into CPVC

adapter fittings or tees that have an internal obstruction (see

Fig. 3); this will damage the sprinkler, the fitting, or both. A

short inlet (“PL”) version of the Model G5-56 Dry sprinkler is

available for use in existing installations with CPVC adapter

fittings or tees having an internal obstruction; Model G5-56

sprinklers with the short inlet fitting shall not be used on dry-

pipe sprinkler systems. The Model G5-56 Dry sprinkler and

the cover plate assembly are not intended for installation in

corrosive environments, including, but not limited to, those

with salt aerosols or chlorine.

Model G5-56 Dry sprinklers must be installed with the Ex-

posed Minimum Barrel Length required by Fig. 2 located in

a Heated Area. Do NOT install the sprinkler in ceilings which

have positive pressure in the space above.

The following steps must be followed for

installation:

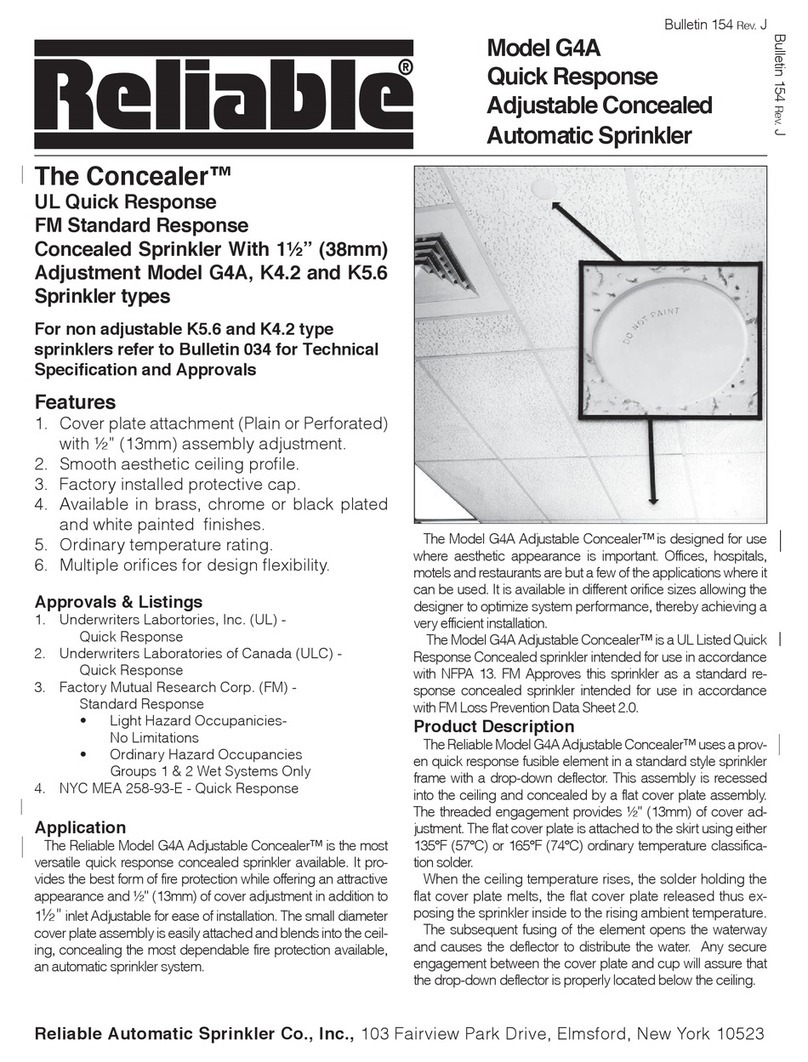

1. Cut a 25

/

8-inch (67mm) diameter hole in the ceiling di-

rectly in-line with the outlet of the tee.

2. Apply pipe joint compound or Polytetrafluoroethylene

(PTFE) tape to the threads of the sprinkler’s inlet fitting.

3. A protective cap is provided to protect the drop-down

sprinkler deflector from damage which could occur dur-

ing construction before the cover plate is installed. The

cap is factory installed inside the sprinkler cup. Remove

the cap to install sprinkler, Step 4, then reinstall cap until

the cover plate is installed.

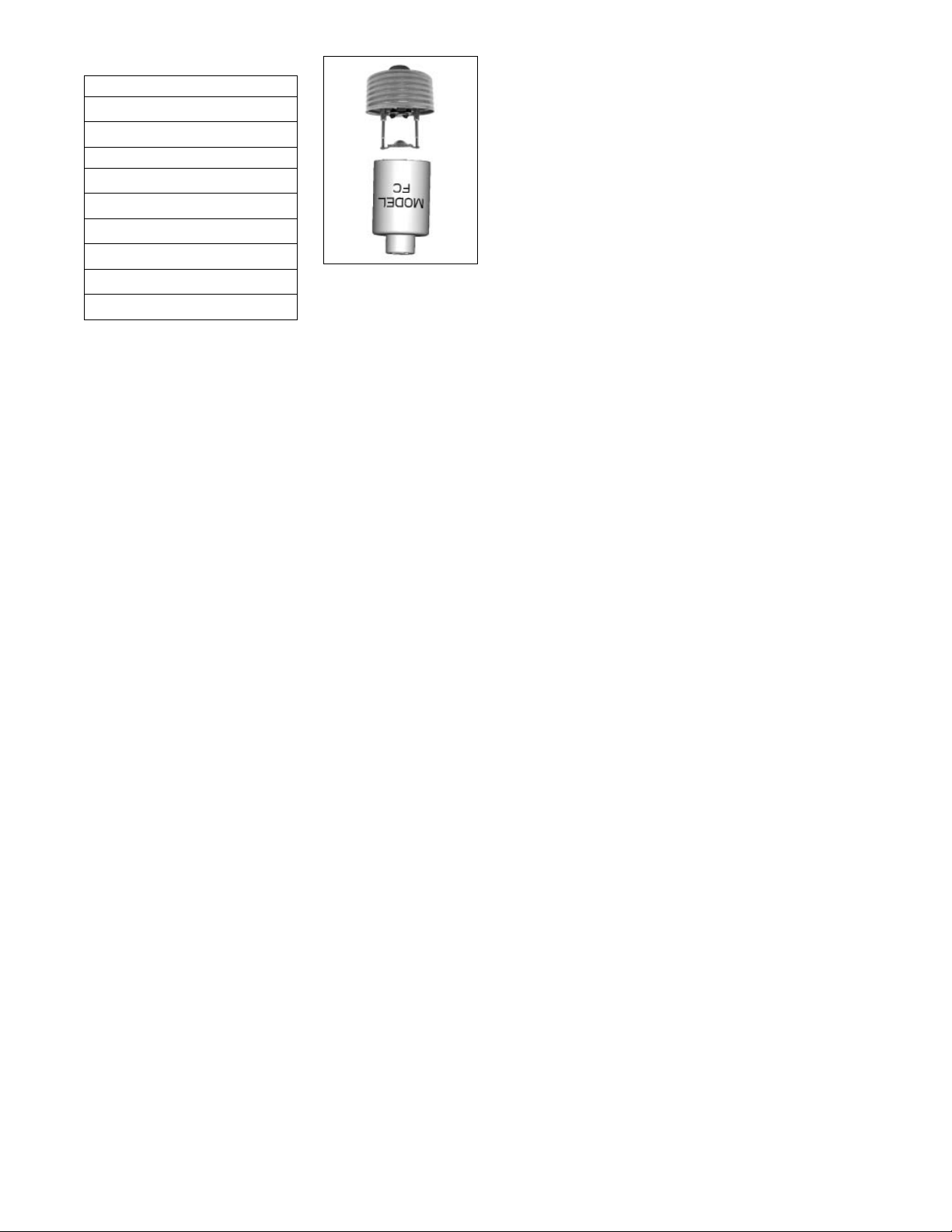

4. Install the sprinkler in the tee using the Model FC wrench.

The Model FC wrench has a socket drive which is in-

serted into the sprinkler’s cup and around the body of

the sprinkler prior to installation of the sprinkler. Do NOT

wrench any of the part of the sprinkler/cup assem-

bly. The sprinkler is then tightened into the pipe fitting

to achieve a leak free connection. The recommended

minimum to maximum installation torque is 22-30 lb-ft

(30 – 40 N-m). When inserting or removing the wrench

from the sprinkler/cup assembly, care should be taken to

prevent damage to the sprinkler. Reinstall the protective

cap following installation of the sprinkler, until the cover

plate is installed.

a. Alternatively, where access to the outer tube of the

sprinkler is available, the Model G5-56 Dry sprinkler

may be installed using a pipe wrench. The protec-

tive cap should not be removed to install the sprin-

kler with a pipe wrench. The pipe wrench shall only

be permitted to interface with the steel outer tube

portion of the sprinkler (Item #8 in Fig. 4). Do NOT

wrench any other portion of the sprinkler/cup as-

sembly. A pipe wrench can install the sprinkler into

the fitting with a large amount of torque; consider-

ation should be given to the need for future removal

of the sprinklers because the installation torque will

have to be matched or exceeded to remove the

sprinkler. The recommended minimum to maximum

installation torque is 22-30 lb-ft (30 – 40 N-m).

5. To install the cover plate, remove the protective cap and

install the cover plate by hand turning the cover in the

clockwise direction until it is tight against the ceiling.

Maintenance

The Model G5-56 Dry should be inspected and the sprinkler

system maintained in accordance with NFPA 25. Do not clean

sprinklers with soap and water, ammonia or any other cleaning

fluids. Replace any sprinkler that has been painted (other than

factory applied) or damaged in any way. Concealed sprinklers

cover plates can not be painted in the field, after installation

or have any other coating applied other than the factory finish.

A stock of spare sprinklers should be maintained to allow quick

replacement of damaged or operated sprinklers. Prior to instal-

lation, sprinkler should be maintained in the original cartons and

packaging to minimize the potential for damage to sprinklers

that would cause improper operation or non-operation.

Engineering Specification

Model G5-56 Dry Pendent Concealed Sprinkler

Dry pendent sprinklers shall be dry pendent concealed

sprinklers with a flat cover plate. Sprinklers shall be cULus

Listed as Quick Response for Light and Ordinary Hazard ap-

plications as well as FM Approved as Standard Response.

Sprinklers shall be available in lengths from 4¼ inches

(108mm) to 48 inches (1219mm) in ¼-inch (6.35mm) incre-

ments based on face of fitting to finished ceiling distance.

Sprinkler length shall be selected to provide the Exposed

Minimum Barrel Length based on the minimum design tem-

perature in the protected area and the minimum temperature

Model FC

Sprinkler Wrench

3.

Cover Plate Finishes(1)

Standard Finishes

Chrome

White Paint

Special Application Finishes(2)

Bright Brass

Finished Bronze

Black Plating

Black Paint

Off White

Satin Chrome

(1) Other finishes and colors are available on special order. Consult factory

for details. Coverplate custom paint is semi-gloss, unless specified oth-

erwise.

(2) For the perforated style coverplate, consult factory for availability on

these and other custom finishes.