The Reliable Automatic Sprinkler Co., Inc., 103 Fairview Park Drive, Elmsford, New York 10523

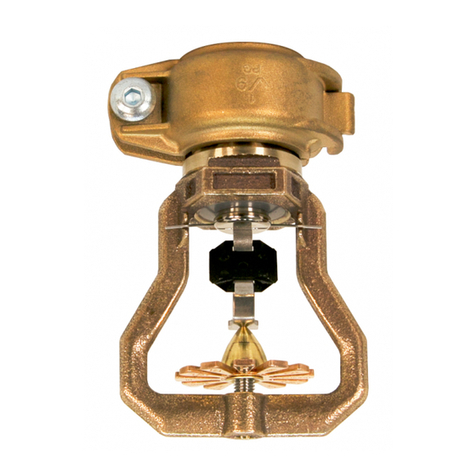

Model SWC

Concealed Quick Response

ExtendedCoverage

Horizontal Sidewall Sprinkler

Bulletin 163 Rev. G

Bulletin 163 Rev. G

TheSidewallConcealer®

Coverageto14ft.x 26ft.

(4.3mx 7.9m).300psi(20,7bar)Rated.

Features:

1. Tamper resistant cover plate can prevent

the sprinkler from being used for unintended

purposes. No exposed thermal element.

2. 8.0 K Factor.

3. Sprinkler is approved for both

175 psi (12,0 bar) and

300 psi (20,7 bar) applications.

4. Quickresponse,extendedcoverage performance.

5. Push-on/thread-off, sturdy convenient cover plate.

6. Factory assembled sprinkler and cup, shipped

completewithprotectivecap.

7. Sprinkler assembly and cover plate separately

packaged.

8. ½”(13mm)adjustment.

9. Utilizes the Model F1FR-300 QREC-9 Horizontal

SidewallSprinkler.

10. Coverplateavailableinstandardwhitepaint,special

bronze, blackpaint orflat whitefinishes.

Approval Organizations

1. Listed by Underwriters Laboratories Inc. and

UL certified for Canada (cULus).

2. NYC MEA 258-93-E

Patents: U.S. Patent No. 6,374,919

Product Description

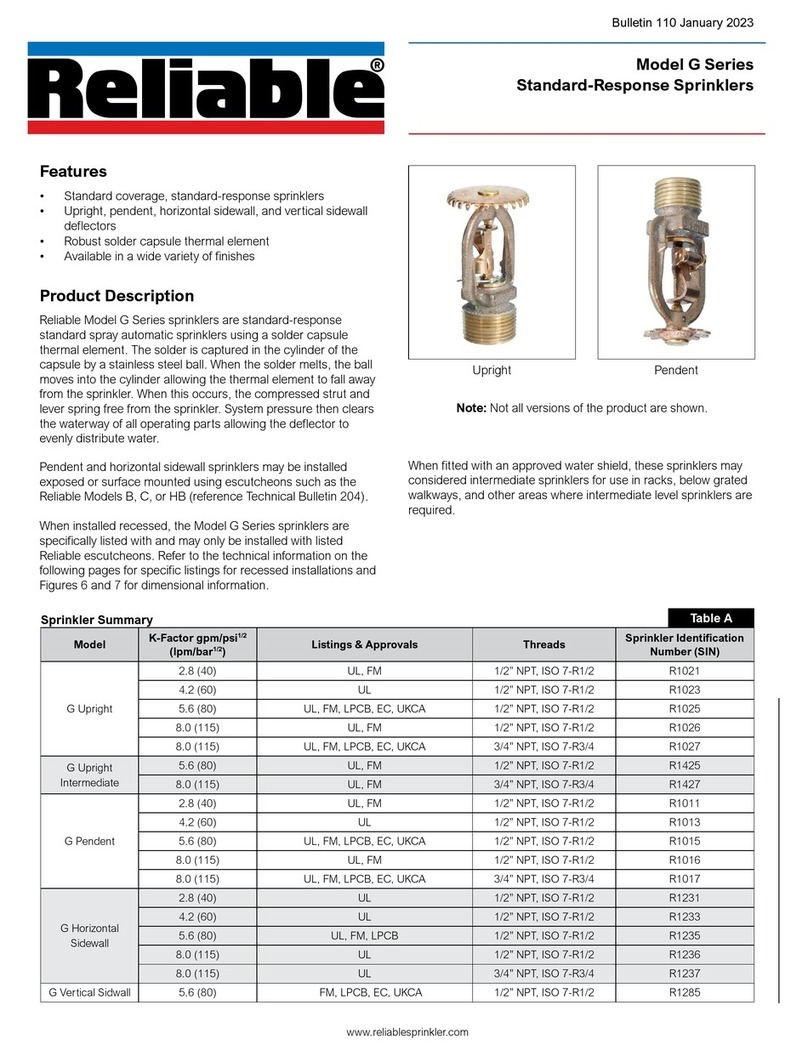

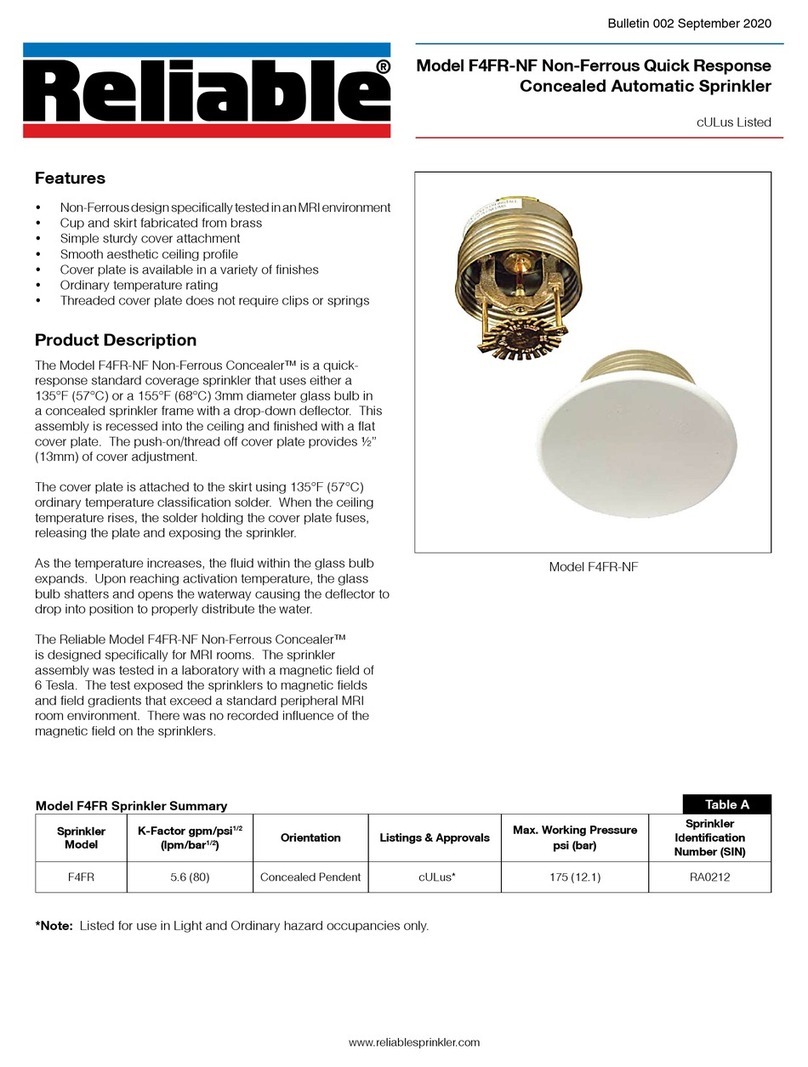

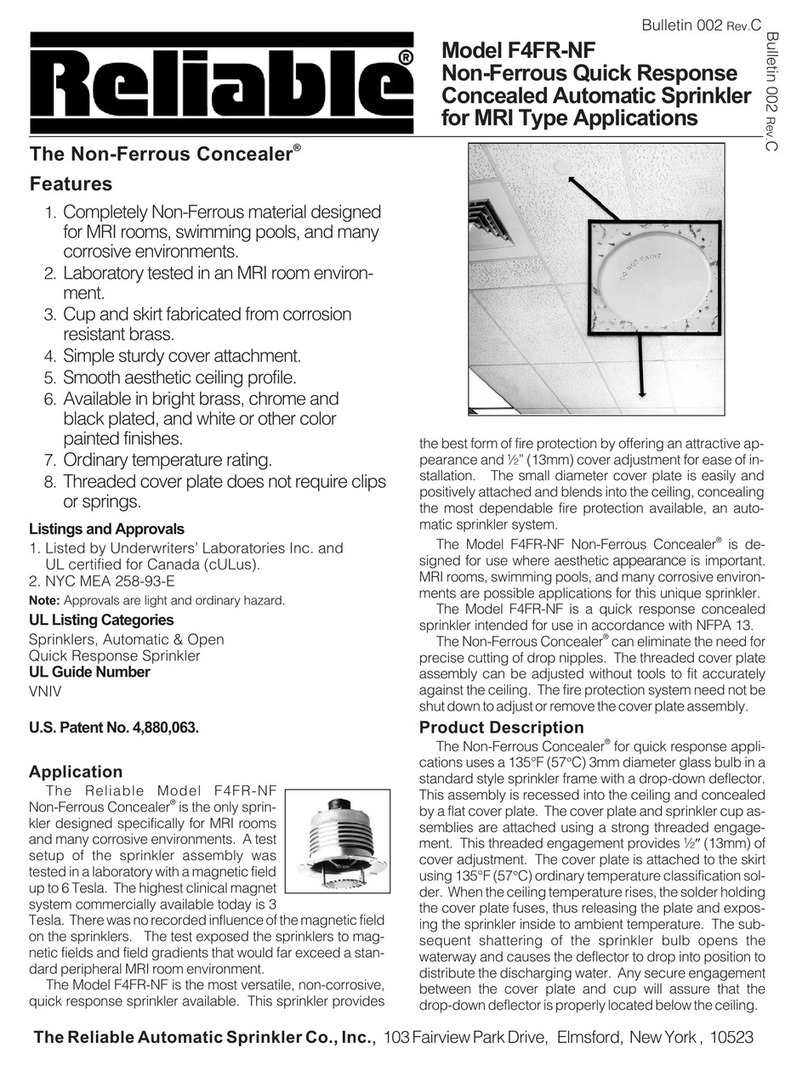

The Reliable Model SWC Concealed Quick Response Extend-

ed Coverage Horizontal Sidewall Sprinkler is an attractive, con-

cealed sprinkler assembly that utilizes a push-on/thread-off cover

plate assembly. The assembly is shipped with a protective cap.

The Model CCP/HSW cover plate is attached to the skirt us-

ing 135°F (57°C) ordinary temperature classification solder. The

sprinkler and cup are easily installed into the sprinkler fitting using

the Model GFR1 Sprinkler Wrench.

When the ambient temperature rises, the solder holding the

coverplate melts, allowing the release of this part and thus expos-

ing the sprinkler inside to the rising ambient temperature.

The Model SWC utilizes a 3.0mm frangible glass bulb. This

quick response enables the sprinkler to apply water to a fire soon-

er than standard sprinklers of the same temperature rating.

This sprinkler can handle a maximum service pressure of 300

psi (20,7 bar).

Application and Installation

The Model SWC sprinkler is intended for installation in light haz-

ard occupancies in accordance with NFPA 13. This sprinkler is

especially well-suited for use in student dormitories, hotels, hospi-

talsand care facilities,and can be used where the pressure enter-

ing the sprinkler system is in excess of 175 psi (12 bar).

Model SWC Concealed Horizontal Sidewall sprinklers utilize

a Model F1FR-300 QREC-9 Horizontal Sidewall Sprinkler with a

threaded cup which is factory attached to the sprinkler. The as-

sembly is completed by the installation of the attractive, 135°F

(57°C) rated Model CCP/HSW push on / thread off cover plate

assembly.

Apply a Teflon* - based thread sealant to the sprinkler threads.

After a 25/8” (67mm) diameter hole is cut in the wall, the sprinkler

is easily installed with the Model GFR1 Wrench. When installing

the sprinkler, the protective cap is removed and the wrench is

positioned into the sprinkler/cup assembly until the two wrench

faces engage the wrenching flats on the sprinkler. The sprinkler

is then tightened into the pipe fitting. When inserting or remov-

ing the wrench from the sprinkler/cup assembly, care should be

taken to prevent damage to the sprinkler. DO NOT WRENCH

ON ANY OTHER PART OF THE SPRINKLER. The cover plate

assembly is then pushed onto the cup. Cover plate assemblies

provide ½” (13mm) of cover adjustment. Final adjustment is

made by turning the cover plate clockwise until the skirt flange

makes full contact with the wall surface. Cover plate removal

requires turning in the counter clockwise direction.

Concealed cover plate/cup assemblies are listed only for use

with specific sprinklers. The use of any other concealed cover

plate/cup assembly with the Model F1FR-300 QREC-9 Horizon-

tal Sidewall Sprinkler or the use of the Model CCP/HSW con-

cealed cover plate assembly on any sprinkler with which it is

not specifically listed will void all guarantees, warranties, listings

and approvals.

* DuPont Registered Trademark