Temperature Ratings and Approvals

Temperature

Classification

Temperature

Rating Link

Color

Frame

Color

Maximum Ambient

Temperature Approvals

Sprinkler

Identification

Number

(SIN)

°F °C °F °C

Ordinary 165 74 Black Uncolored 100 38 cULus, FM, VdS, LPCB, CNBOP

RA1914

Intermediate 212 100 White White 150 66 cULus, FM, VdS, LPCB, CNBOP

Installation Data

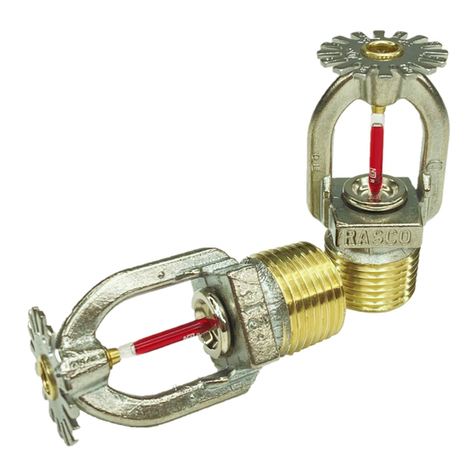

Sprinkler Type Thread Size

Nominal K-

Factor Maximum

Working Pressure

Finish

US Metric

Pendent ¾” (R¾) 16.8 240 175 psi (12.1 bar) Bronze

Installation Criteria

The following general guidelines are provided for

information only. NFPA and, where applicable, FM

Global standards shall be consulted for complete de-

sign and installation criteria.

Orientation: Pendent, deflector should be parallel

with the ceiling or roof.

System Type: Wet Pipe Systems Only.

Maximum area of coverage: 100 ft2(9.3m2), greater

coverage areas are allowable in some cases.

Minimum area of coverage: 64 ft2(5.8m2).

Maximum slope ceiling: 2/12 pitch (9.5°).

Maximum spacing: 12 ft (3.7m) for building heights

up to 30 ft (9.1m) and 10 feet (3.1m) for building

heights greater than 30 ft (9.1m).

Minimum spacing: 8 feet (2.4m).

Deflector distance from walls: At least 4 inches

(102mm) from walls, and no more than one-half the

allowable distance permitted between sprinklers.

Deflector to Top of Storage: at least 36 in (900mm).

Deflector to ceiling Distance: 6 - 14 in (150 - 350mm)

per NFPA 13.

Center Line of Thermal Sensing

Element To Ceiling Distance: 2 - 13 in (50 - 330mm)

for smooth ceilings or 4 - 13 in (100 - 330mm) for non-

smooth ceilings per FM Data Sheet 2-0.

Maintenance

The Model JL-17 ESFR Sprinkler should be inspected

and the sprinkler system maintained in accordance with

NFPA 25. Do not clean sprinkler with soap and water,

ammonia or any other cleaning fluid. Replace any sprin-

kler that has been painted (other than factory applied) or

damaged in any way. A stock of spare sprinklers should

be maintained to allow quick replacement of damaged or

operated sprinklers. Prior to installation, sprinklers should

be maintained in the original cartons and packaging until

used, to minimize the potential for damage to sprinklers

that would cause improper operation or non-operation.

Once operated, automatic sprinklers cannot be reassem-

bled and reused. New sprinklers of the same size, type

and temperature rating must be installed. A cabinet of re-

placement sprinklers should be provided for this purpose.

Model JL-17 ESFR Sprinkler Specification

Sprinklers shall be Early Suppression Fast Response

(ESFR) pendent sprinklers specifically tested and [cULus

Listed] [FM Approved] [VdS Approved] [LPCB Approved]

for commodity storage applications. Sprinkler frame and

deflector to be of bronze construction. Fusible link assem-

bly shall utilize the strut and lever principle of operation with

approved fast response black-painted or white-painted

beryllium-nickel thermal element. Water seal shall consist

of a PTFE coated Bellville spring washer and brass cap as-

sembly containing no plastic parts. ESFR sprinklers shall

have a nominal K-factor of 16.8 (240 metric) with [¾” NPT]

[ISO 7-R¾] threaded end connections. Sprinkler tempera-

ture rating shall be [Ordinary 165°F (74°C)] [Intermediate

212°F (100°C)]. ESFR pendent sprinklers shall be Reliable

Model JL-17 (Bulletin 019).

Ordering Information

Specify:

1. Sprinkler: Model JL-17

2. Temperature rating: [Ordinary 165°F (74°C)]

[Intermediate 212°F (100°C)]

3. Thread type: [3/4” NPT] [ISO 7-R3/4]

2.