4

REMKO ELT 18-HT

The units are portable electric

heating units for industrial

applications at various locations.

The units are operated exclusively

with electric power and have been

designed for high-temperature

applications with an air outlet

temperature of up to 120°C.

The air outlet temperature is

altered by manually adjusting the

fan speed.

The units can be operated using no

more than one high-temperature

hose (accessory) with a ø of

305 mm and a length of 7.6 m.

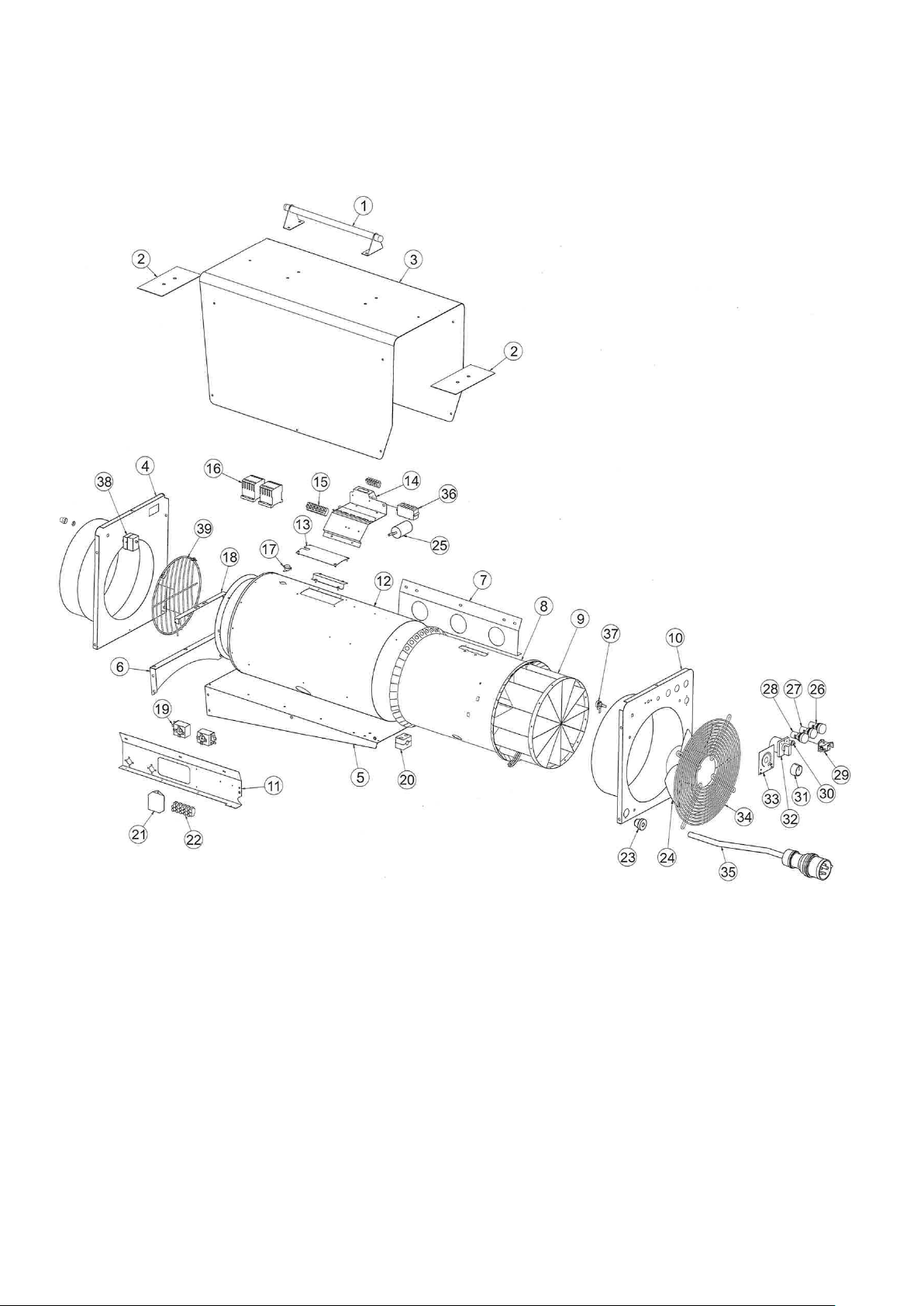

The units are equipped with

special-purpose, highly efficient

electrical heating coils for

immediate and consistent heat

generation, low-maintenance axial

fans, a safety thermostat, a room

thermostat socket and a mains

cable with earthed safety plug.

The units conform to the

fundamental health and safety

requirements of the appropriate

EU stipulations.

The units are dependable and offer

ease of operation.

The units may be used among

other things for the following:

■

Drying heat-resistant materials

■

Generating process heat for

industrial applications

■

Hardening plastics

■

Pest control

■

Drying out construction

work / heating

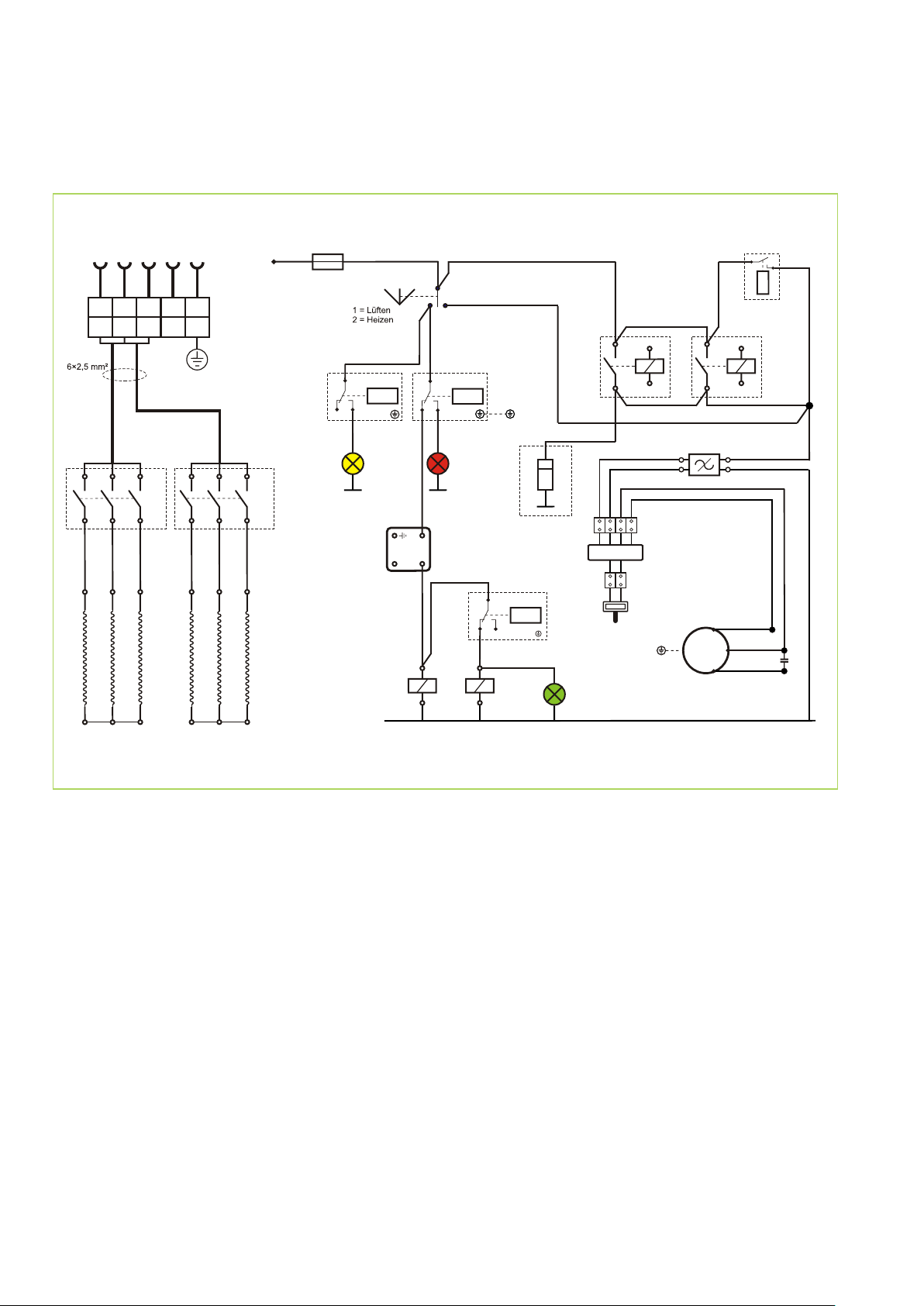

Safety notesUnit description

The units have been subjected

to extensive material, functional

and quality inspections prior to

delivery. However, dangers can

arise from the units if they are used

improperly or not as intended by

untrained personnel!

Please observe the following notes:

■

In the event of defects that

endanger the operational safety

of the unit, operation must be

discontinued immediately

■

Observe the respective local

electrical regulations and the

necessary safety measures when

using the units

■

Maintain safety distances to

combustible materials

0.5 m at the side of the unit and

on the air inlet side

2.0 m on the air outlet side

■

An unobstructed air inlet and air

outlet must be guaranteed at all

times

■

The units must not be covered

during operation

■

Never insert foreign objects into

the units

■

The units must not be operated

in the vicinity of bathtubs,

showers, swimming pools etc.

■

The units must not be operated

directly below a wall socket

■

The units must not be exposed

to direct jets of water

CAUTION

Extensions to the connection

cable must only be conducted

by authorised specialist

electricians, taking into

consideration the unit capacity,

cable length and local use.

■

The units must not be installed

or operated in potentially

flammable or explosive

environments

■

The units must not be operated

in locations where:

combustible gaseous, air or

dust-air mixtures could be

produced; flammable small parts

could be sucked in, set alight on

the heating coil and blown out

in a glowing state

■

Flooring and ceilings must be

fire retardant

■

The air inlet and outlet must not

be constricted

■

The relevant safety guidelines

of the Employer's Liability

Insurance Association or

property insurer must be

observed

■

The units must be installed

in a stable position and must

not topple over or slide out of

position during operation

■

The units must not be left

unattended during operation

■

The units must not be operated

in an environment with an

ambient temperature of over

60°C

■

All electrical cables for the

units must be protected against

damage, even damage caused

by animals