4

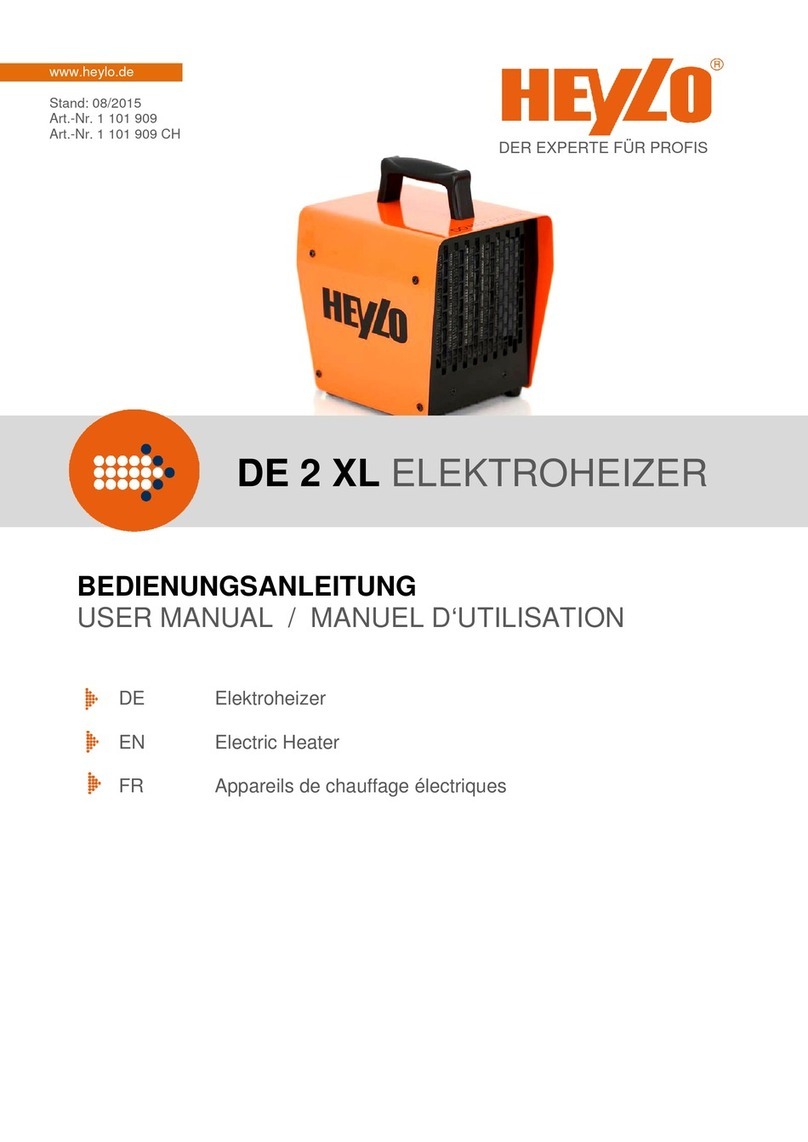

REMKO ELT 9-6

Safety information

Operation of the heaters must always take place in compliance with

the local building and fire protection regulations and regulations of the

employers‘ liability insurance associations.

The units were subjected to

extensive material, functional and

quality inspections and tests prior

to delivery. However, the units

may constitute a hazard if used by

untrained personnel, improperly or

not for the intended purpose.

The following information must be

observed

■

Before starting work, persons

responsible for the operation of

the units must check for obvious

defects on control and safety

devices and for the presence

and correct functioning of

protective devices.

Any noticed defects must be

reported to the responsible

supervisor!

■

Units that have defects liable

to affect their reliability must

immediately be switched off.

■

For using the units, the

respective local regulations and

electrical fuse protection ratings

must be observed.

■

Safety distances to flammable

objects must be observed.

■

The air inlet and air outlet vents

must be kept free at all times.

■

The air outlet vents must not

be restricted or pipes or hoses

connected.

■

Never insert foreign objects into

the units.

■

The units must not be covered

whilst in operation.

■

Safety devices must not be

overridden or blocked.

■

The units must not be used near

to baths, showers, swimming

pools, etc.

■

The units must not be used

directly below a wall socket-

outlet.

■

The units must not be exposed

to direct water jets.

e.g. high pressure cleaners, etc.

■

Never allow water to enter the

unit.

■

The units must not be installed

and used in locations subject to

fire and explosion hazards.

■

The units must not be installed

and used in oil, sulphur, or salt-

laden atmospheres.

■

All electrical cables of the units

must be protected against

damage, also damage caused by

animals.

Unit description

The units are portable electric

heaters for commercial use.

The units are designed solely

for electrical use and for fully

automatic, universal and problem-

free operation.

The units have special

encapsulated electric heating

resistors, a low noise and

maintenance axial flow fan, a

safety and cooling thermostat, an

integrated room thermostat and

power cable with earthing pin

plug.

The units comply with the

fundamental safety and health

requirements of the pertinent EU

directives.

The units are reliable and easy to

operate.

The units also have the following

applications:

■

Drying new buildings.

■

Concentrated heating of

outdoor workplaces or for use

in halls and manufacturing

facilities not subject to fire

hazards.

■

Continuous or temporary room

heating.

■

De-icing of machines, vehicles

and non-flammable stored

goods, maintaining the

appropriate safety distances.

ATTENTION

Safety devices must not be

overridden or blocked.