Rhino-Rack RBLW Install guide

Other Rhino-Rack Automobile Accessories manuals

Rhino-Rack

Rhino-Rack Rhino 2500 series User manual

Rhino-Rack

Rhino-Rack RSF Rhino Sportz User manual

Rhino-Rack

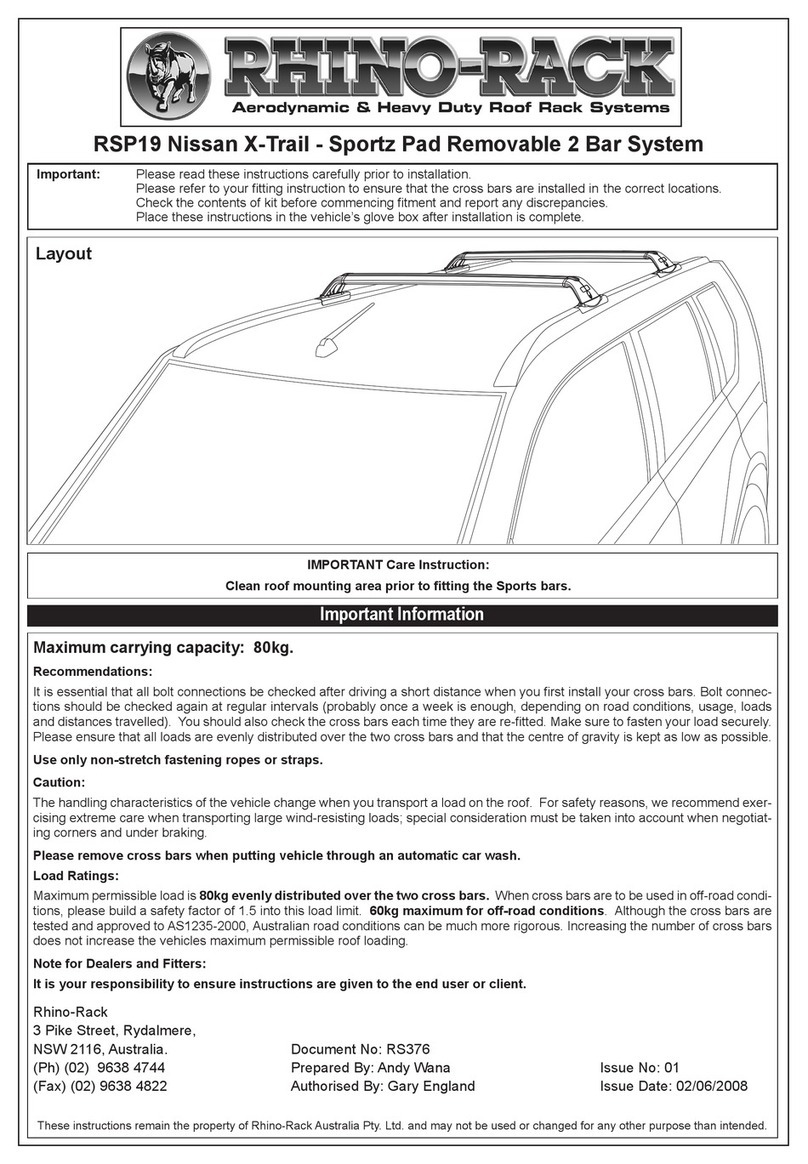

Rhino-Rack RSP19 User manual

Rhino-Rack

Rhino-Rack 43175 User manual

Rhino-Rack

Rhino-Rack Backbone RFRB1 User manual

Rhino-Rack

Rhino-Rack Rhino 2500 Series User manual

Rhino-Rack

Rhino-Rack DK064 User manual

Rhino-Rack

Rhino-Rack Pioneer 43180B User manual

Rhino-Rack

Rhino-Rack 43153 User manual

Rhino-Rack

Rhino-Rack RTD25L User manual

Rhino-Rack

Rhino-Rack S400-FK2 User manual

Rhino-Rack

Rhino-Rack Rhino Sportz SQRS User manual

Rhino-Rack

Rhino-Rack RSPT508 User manual

Rhino-Rack

Rhino-Rack MS15-680 User manual

Rhino-Rack

Rhino-Rack Rhino 2500 series User manual

Rhino-Rack

Rhino-Rack RBCA026 User manual

Rhino-Rack

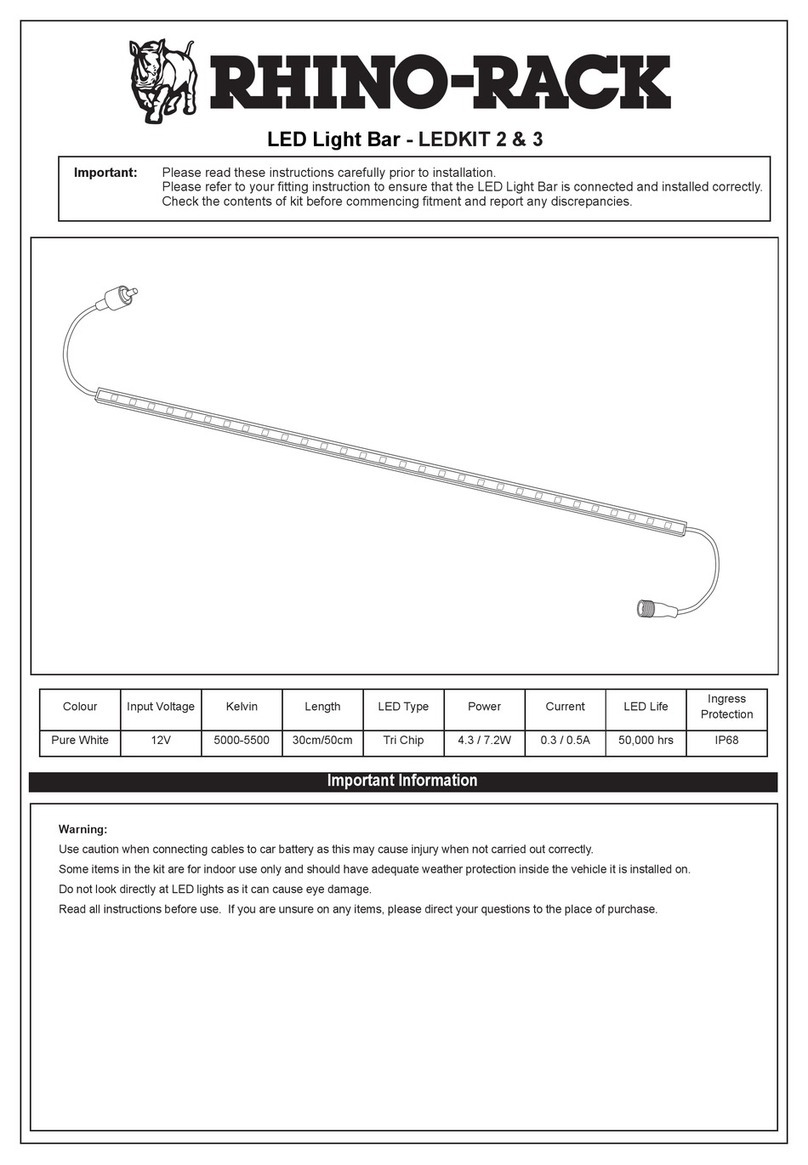

Rhino-Rack LEDKIT 2 User manual

Rhino-Rack

Rhino-Rack 33100 LH User manual

Rhino-Rack

Rhino-Rack MS15-470 User manual

Rhino-Rack

Rhino-Rack 572 User manual

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction