RL9000 Series Weigh Module Kit

4Visit our website www.RiceLake.com

3.0 Troubleshooting

If the system powers up and gives some type of stable digital readout that varies with the

load on the system, any system problems are probably caused by factors other than the

load cells. The load cells are often blamed for a malfunctioning system, but 90% of the

time, the problem lies elsewhere. Look for mechanical causes for the problem first.

If the system can be calibrated but doesn’t return to zero, loses calibration, or

demonstrates non-linearity or non-repeatability, see the following chart for possible

causes and do the following checks.

1. Check the load cell mount for debris restricting load cell movement or debris

between scale and structure.

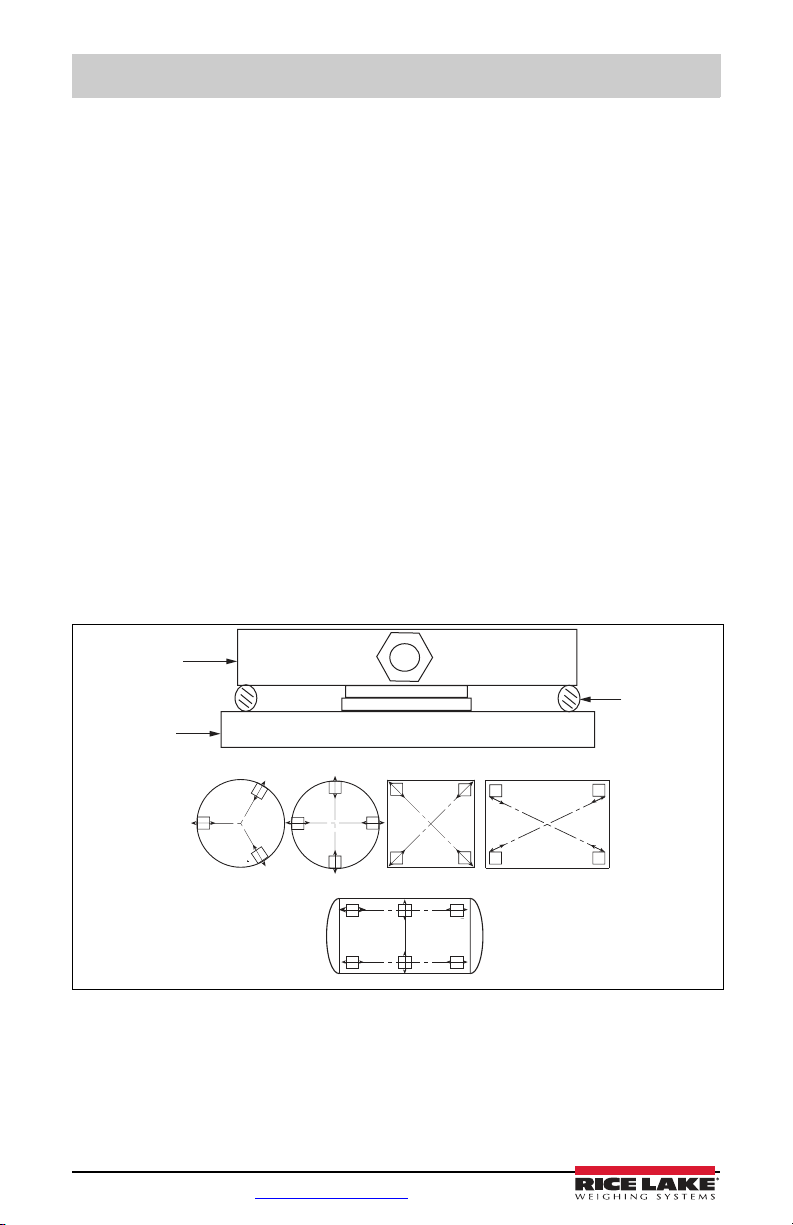

2. Check that tank/vessel and mounts are plumb, level and square at critical areas.

3. Check all piping and conduit for connections which restrict vessel movement.

4. If check rods are used, loosen all connections to finger tight only for testing.

5. Check load cell cables for physical or water damage.

6. Check all electrical connections, especially in the junction box.

If the problem is not found:

1. Check possible indicator malfunction by using a load cell simulator to input a known,

good signal into the indicator.

2. Disconnect each load cell’s signal leads at the junction box and check the individual

load cell outputs with a multimeter. Then check input/output impedances for

comparison with load cell manufacturer’s specifications.

If after all these checks the problem still cannot be isolated, reconnect all but one load cell.

Replace the load cell with a load cell simulator. Alternate so that each load cell is

individually disconnected and replaced with a simulator. If there is a problem with a

particular load cell, the symptom should disappear when that load cell is disconnected

and replaced with the simulator.

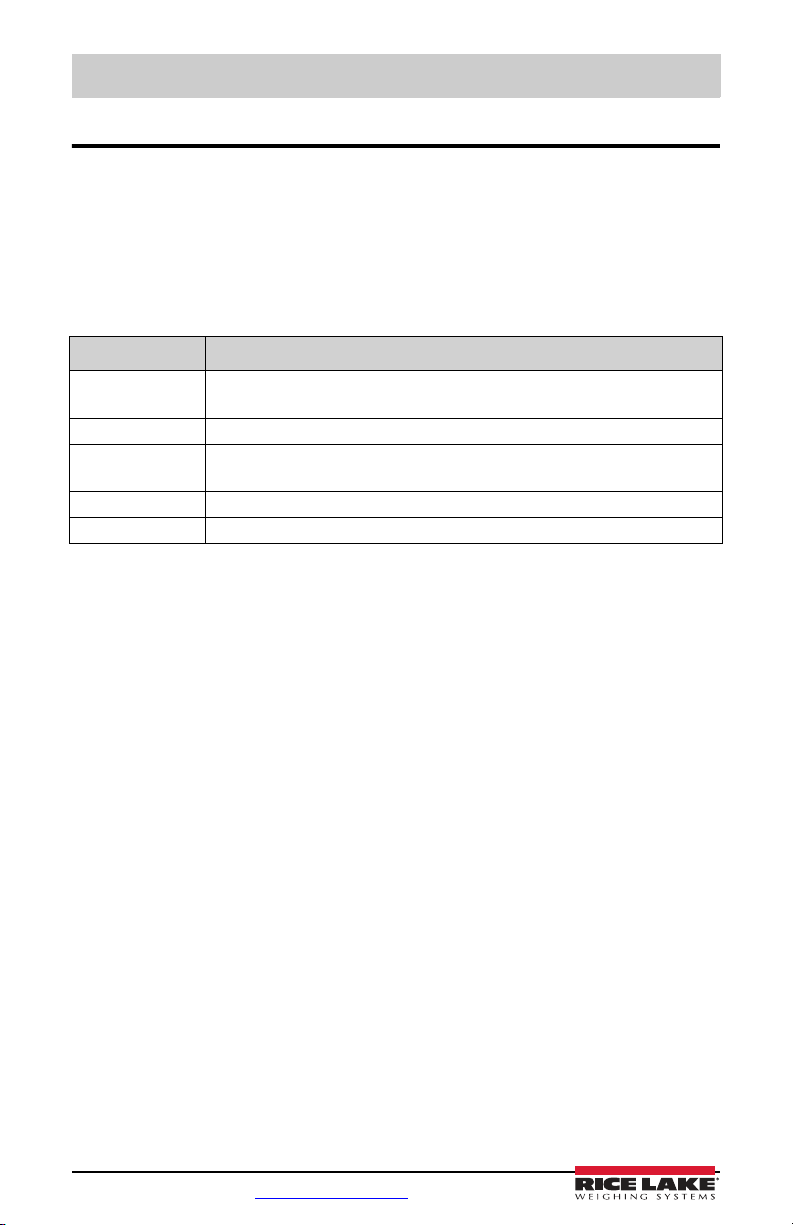

Symptom Probable Cause

No return to zero Mechanical binding of debris in seals or under the load cells; may have lost

system calibration

Non-linearity Thermal expansion or deflection under load causing binding or side load

Non-repeatability Loosen load cell mount; drifting caused by moisture, load cell overload or

shock damage; mechanical binding

Lost calibration Out of level or plumb; moisture problem; mechanical binding

Drifting readout Moisture in junction box, cables or load cell; mechanical binding

Table 3-1. Possible Causes