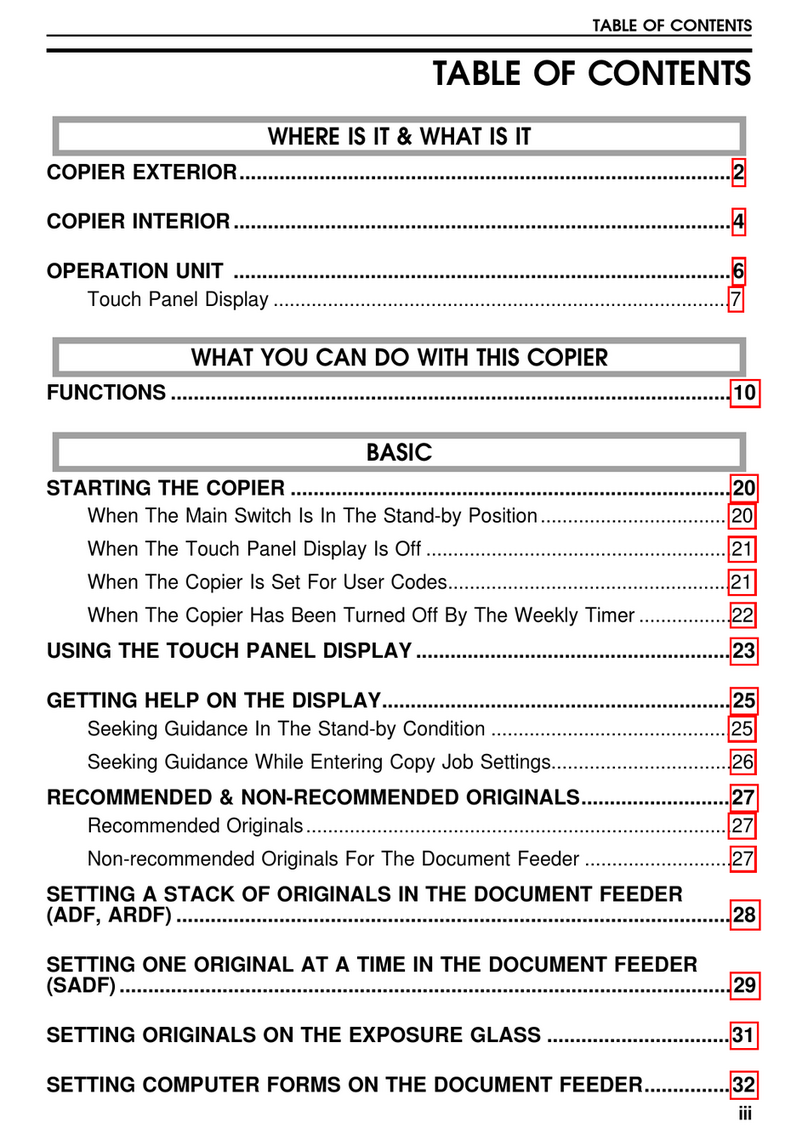

6.8 ORIGINAL FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

6.9 PAPER FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

6.10 ROLL FEEDER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

6.11 OTHERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

REPLACEMENT AND ADJUSTMENT

1. EXTERIOR COVERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1 LEFT SIDE COVER REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1.1 Left Upper Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1.2 Left Lower Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.2 RIGHT SIDE COVER REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.2.1 Right Upper Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.2.2 Right Lower Front, Right Lower Middle, and Right Lower Rear Covers . . 5-1

1.3 REAR COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.3.1 Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

2.1 ORIGINAL FEED UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

2.2 EXPOSURE GLASS REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

2.3 EXPOSURE LAMP REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

2.4 FIBER OPTICS ARRAY REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

2.5 LIGHT SENSOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

3. DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

3.1 DEVELOPMENT UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

3.2 DEVELOPER REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

3.3 TONER DENSITY SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 5-9

3.4 PTL REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

3.5 DEVELOPMENT BIAS VOLTAGE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 5-11

3.5.1 Bias Voltage for Image Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

3.5.2 Bias Voltage for Non-image Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

4. DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

4.1 DRUM UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

4.2 DRUM REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

4.3 CLEANING BLADE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

4.4 CHARGE CORONA UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

4.5 CHARGE CORONA WIRE REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Rev. 06/2004

A163 iv SM