Perform head cleans until the

deflection is reduced

Nozzles 100% and little to no

deflection

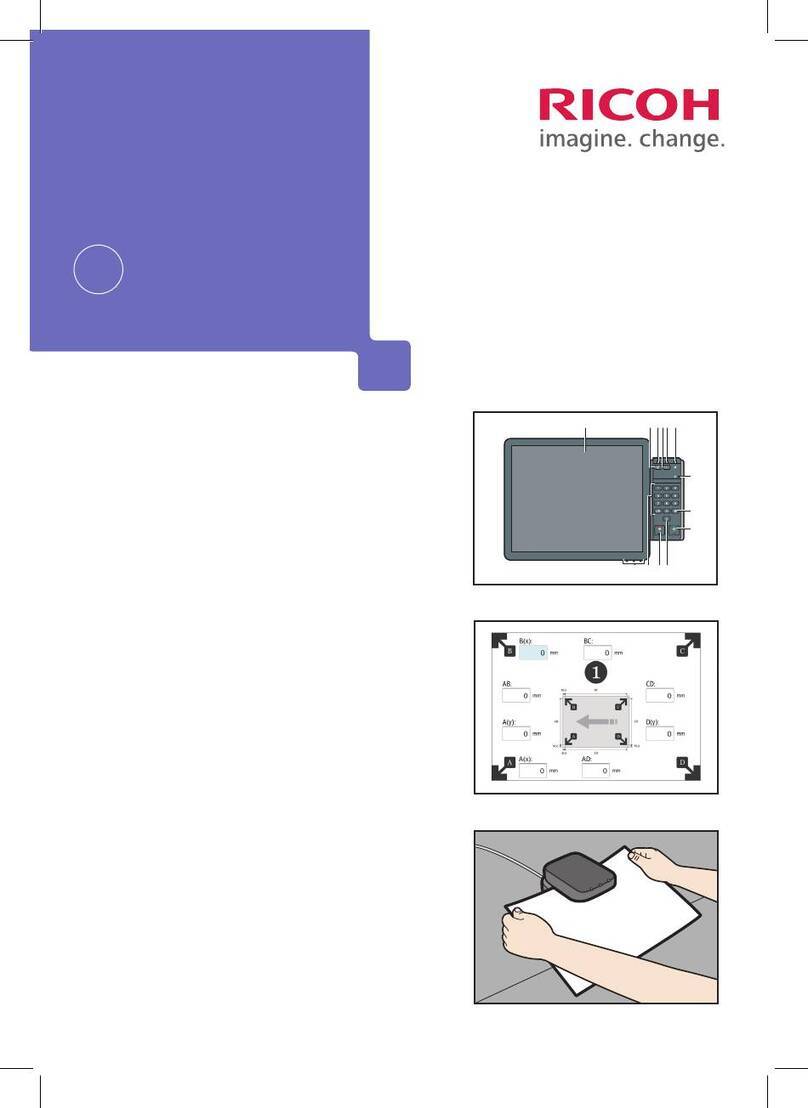

Perform table alignment procedure

(see section 7.2)

3) Horizontal banding -

thick horizontal lines

across the entire shirt

Nozzles 100% - appears in

solid colors of dark or gray -

bi directional banding - has to

do with the colors laying

down in different sequence

depending on which direction

the carriage is traveling

Uncheck the bi directional box in the

RIP.

Nozzles 100% - appears in

solid colors - the color is

inconsistent in the scanning

direction of the carriage. This

is caused by the different

drops of CMYK not combining

consistently

This can show in Speed Quality

mode for CMYK - Print in Fine

Quality mode for CMYK - if still

persists - print in 1200 X 1200 dpi

(Kothari RIP) or Superfine

4) Several nozzles out –

improves not at all or

just a little with

normal and strong

head cleans

During an initial ink fill - air

has been introduce to the

head or after a head clean

cleaning fluid or air was

inadvertently pushed into the

head by the cleaning

applicator

Let the printer sit overnight which

will give the air a chance to settle –

after the nozzle should be good

5) Dark shirt prints look

dull

White nozzles 100 % or near

100%. - In adequate amount

of pretreat on shirt - this can

cause the white ink to mostly

sink into the shirt

Increase the amount of pretreat

being sprayed on the shirt

White nozzles 100 % or near

100% but look dull. - White

ink has settled

If the white cartridges have not

been agitated per instructions - will

need to agitate the white ink

cartridges (2 min). Then perform 3

to 4 strong head cleans - this will

replace most of the settled ink

Missing many nozzles on one

or both white heads

Perform head cleans to recover the

nozzle to 100% or near 100%

6) Light shirt looks too

dull

Nozzle is 100% - Wrong

output profile is selected

If printing in 600 X 600 Dpi and using

a profile meant for 1200 X 1200 DPI

then the shirt will look dull

7) Cartridge reads 0%

but was just at a high

% (example 65%) at

the previous

operation. (before

Temporary loss of Comm

caused cartridge reading

error

Pull out the cartridge that reads 0%.

The status should change to NC and

the cartridges not loaded message

will appear in the status bar. Put the

cartridge back in and the % reading

should go back to normal. If the %