Table of Contents

Recording Form For Machine Serial Number ....................................................................................................................... 2

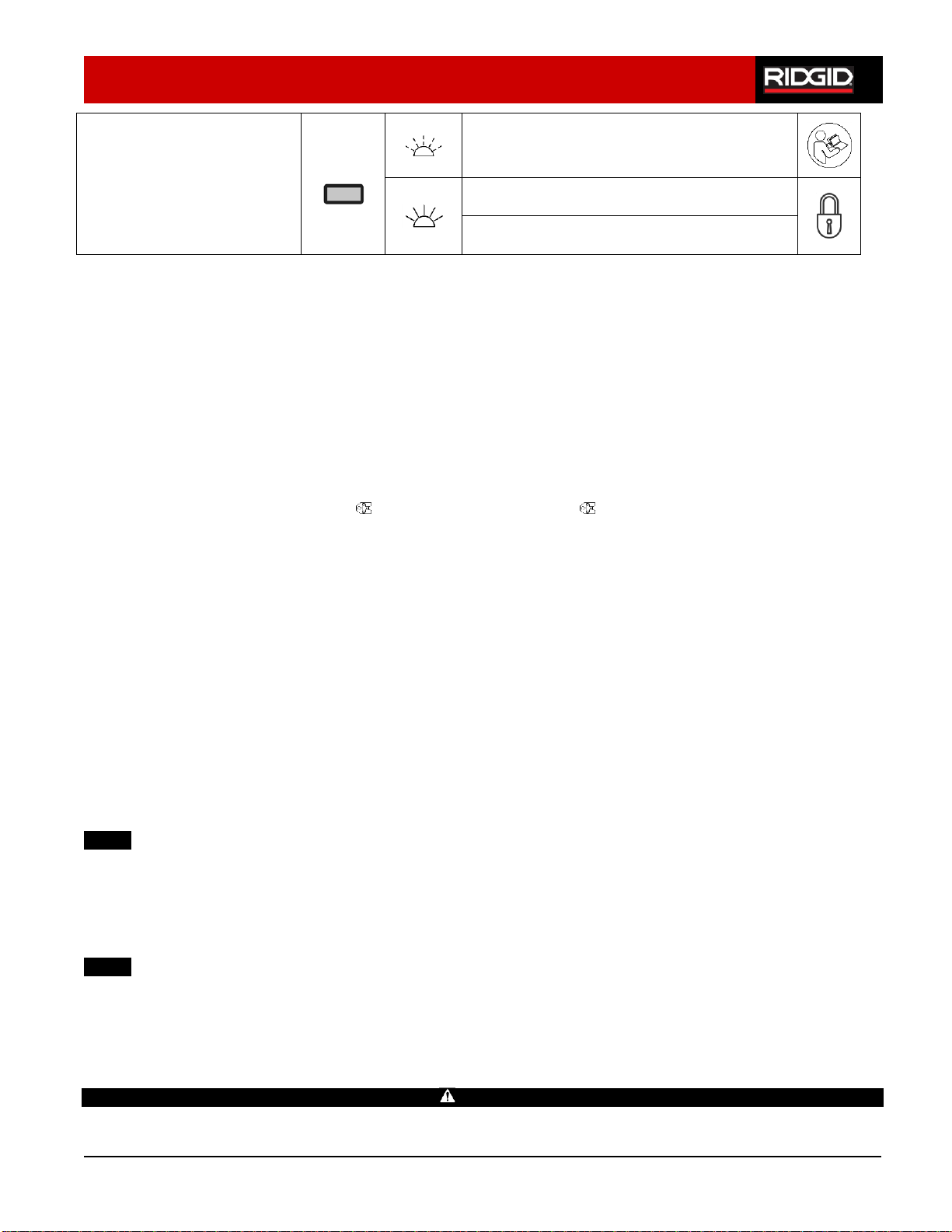

Safety Symbols .................................................................................................................................................................... 3

General Safety Rules*.......................................................................................................................................................... 3

Work Area................................................................................................................................................................................................. 3

Electrical Safety......................................................................................................................................................................................... 3

Personal Safety ......................................................................................................................................................................................... 4

Power Tool Use And Care ......................................................................................................................................................................... 4

Battery Tool Use And Care........................................................................................................................................................................ 5

Service ...................................................................................................................................................................................................... 5

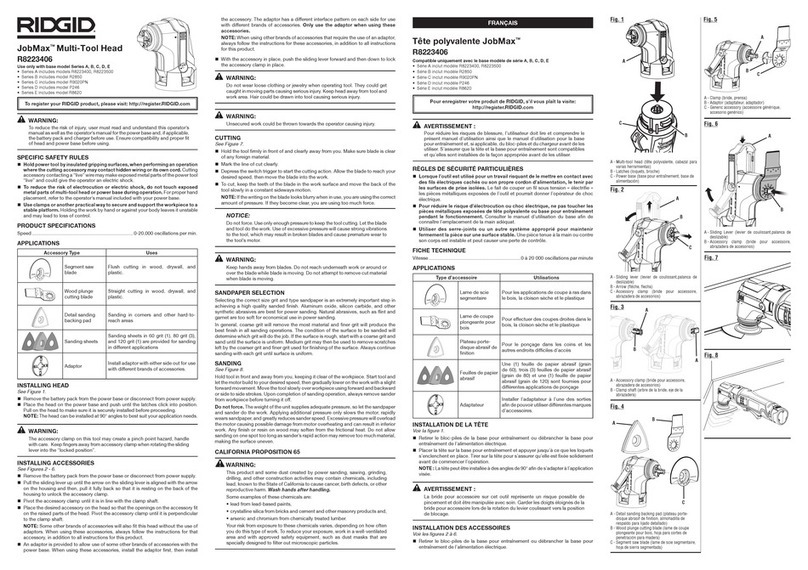

Specific Safety Information.................................................................................................................................................. 5

Press Tool Safety....................................................................................................................................................................................... 5

RIDGID Contact Information ................................................................................................................................................ 6

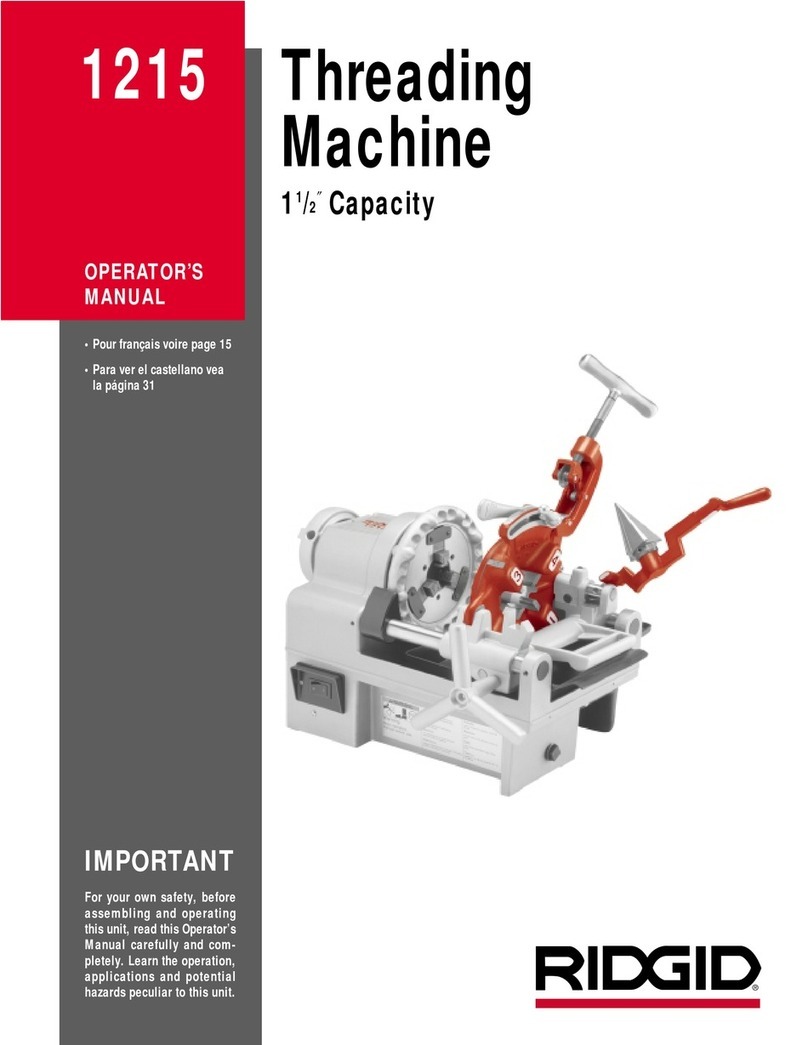

Description .......................................................................................................................................................................... 6

Tool Status Lights...................................................................................................................................................................................... 8

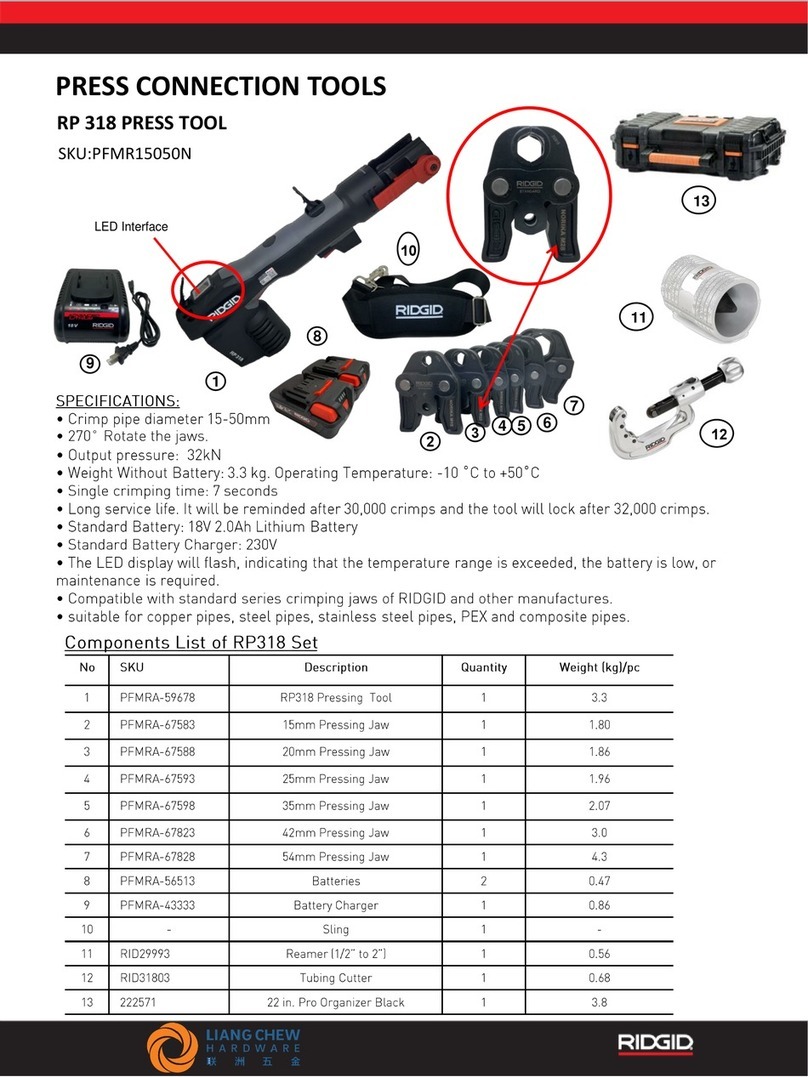

Specifications (need information)........................................................................................................................................ 9

Standard Equipment ................................................................................................................................................................................. 9

Pre-Operation Inspection .................................................................................................................................................... 9

Setup and Operation Instructions...................................................................................................................................... 10

Removing/Installing Attachment ............................................................................................................................................................ 10

Changing Tool Configuration (Long / Standard)...................................................................................................................................... 11

Preparing Connection ............................................................................................................................................................................. 12

Pressing A Fitting With Typical Scissor Jaws ........................................................................................................................................... 12

Pressing A Fitting With Typical Actuator And Press Ring Set .................................................................................................................. 13

Inspecting The Pressed Connection ........................................................................................................................................................ 14

Storage .............................................................................................................................................................................. 15

Maintenance Instructions.................................................................................................................................................. 15

Cleaning And Lubrication........................................................................................................................................................................ 15

Troubleshooting...................................................................................................................................................................................... 15

Required Maintenance By RIDGID Independent Service Center ............................................................................................................ 15

Service And Repair.................................................................................................................................................................................. 16

Optional Equipment .......................................................................................................................................................... 16

Disposal............................................................................................................................................................................. 16

EC Declaration of Conformity ............................................................................................................................................ 16

Electromagnetic Compatibility (EMC) ................................................................................................................................ 17

Back Cover......................................................................................................................................................................... 17

This draft is based on RP 340 Press Tool Operator’s Manuals.

The format is as per new RP 240/241, RE6/60/600 Series Tools Operator’s Manual and PEX One Crimp Tool Operator’s

Manual.

Recording Form For Machine Serial Number