RIGHT ANGLE NewCrank 3-LEG CRANK HEIGHT ADJUSTABLE... User manual

Other RIGHT ANGLE Desktop manuals

RIGHT ANGLE

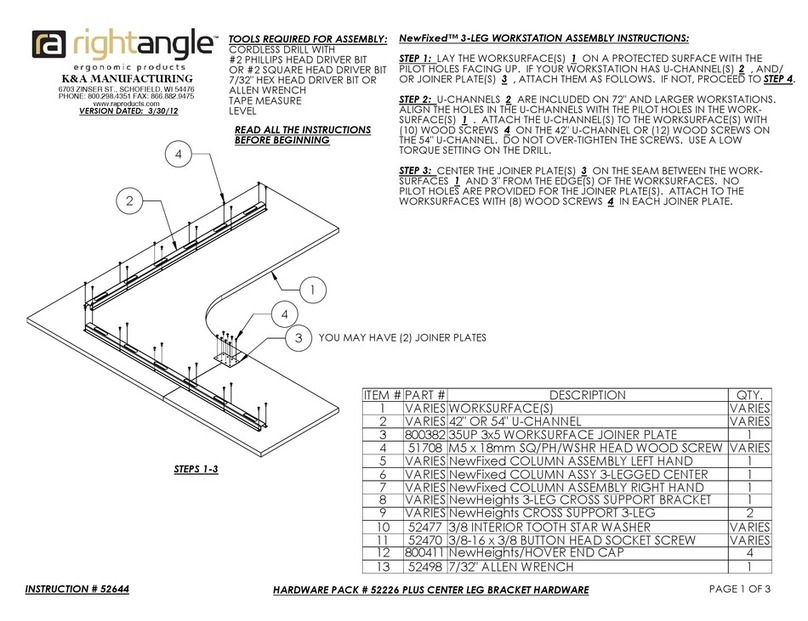

RIGHT ANGLE NewFixed 3-LEG WORKSTATION User manual

RIGHT ANGLE

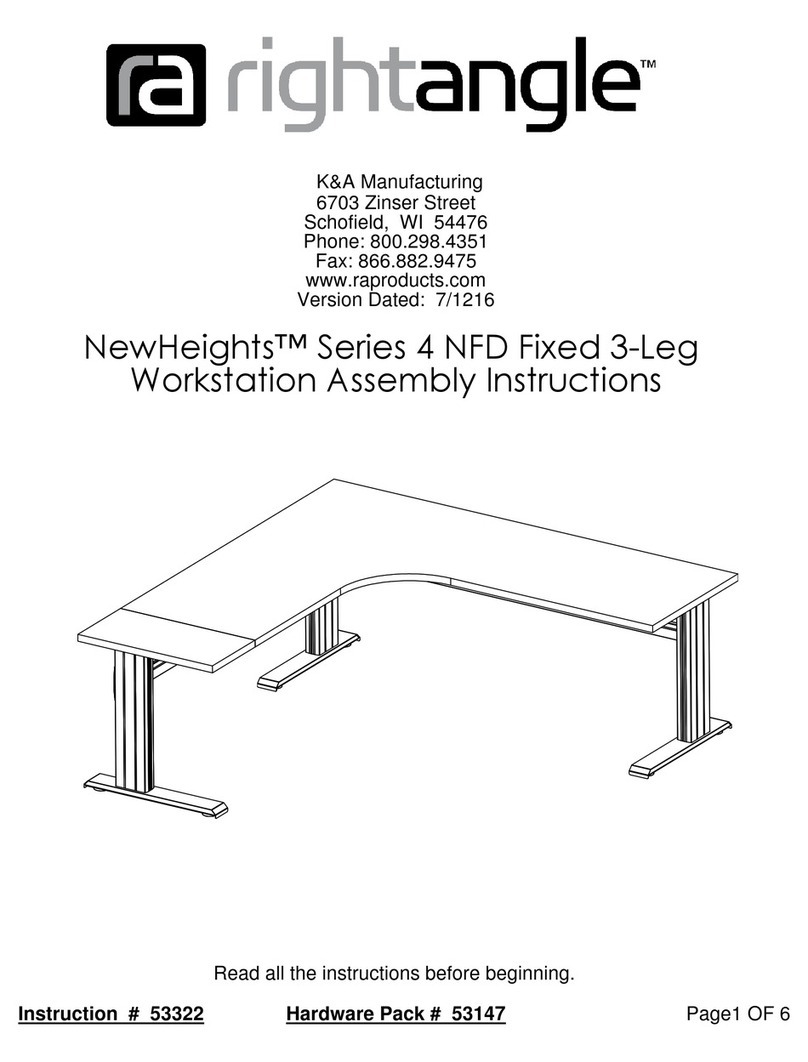

RIGHT ANGLE NewHeights 4 NFD Series User manual

RIGHT ANGLE

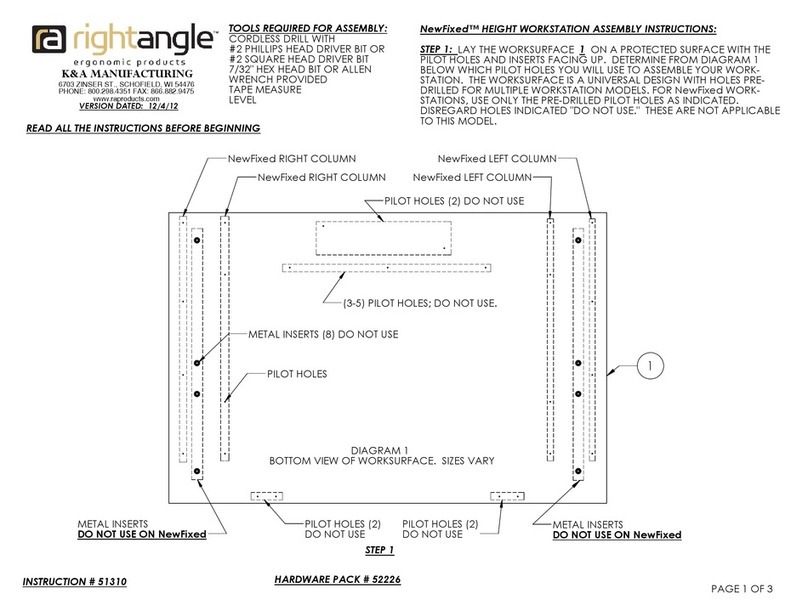

RIGHT ANGLE NewFixed HEIGHT WORKSTATION User manual

RIGHT ANGLE

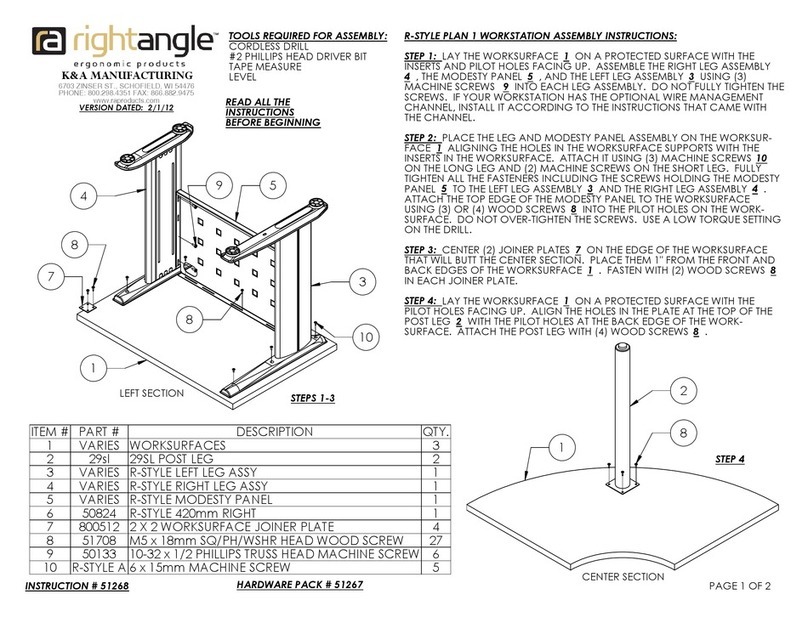

RIGHT ANGLE R-STYLE PLAN 1 WORKSTATION User manual

RIGHT ANGLE

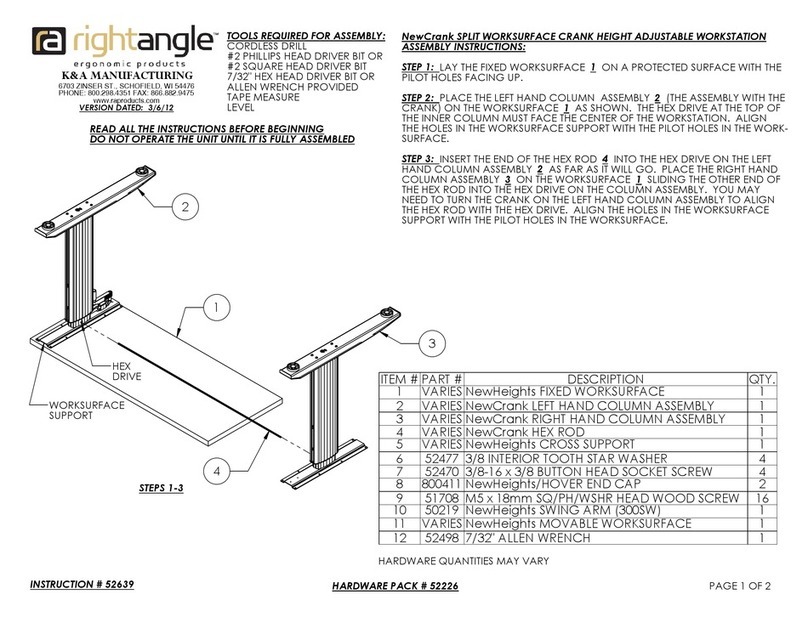

RIGHT ANGLE NewCrank SPLIT WORKSURFACE CRANK HEIGHT ADJUSTABLE... User manual

RIGHT ANGLE

RIGHT ANGLE NewHeights 4 Series User manual

RIGHT ANGLE

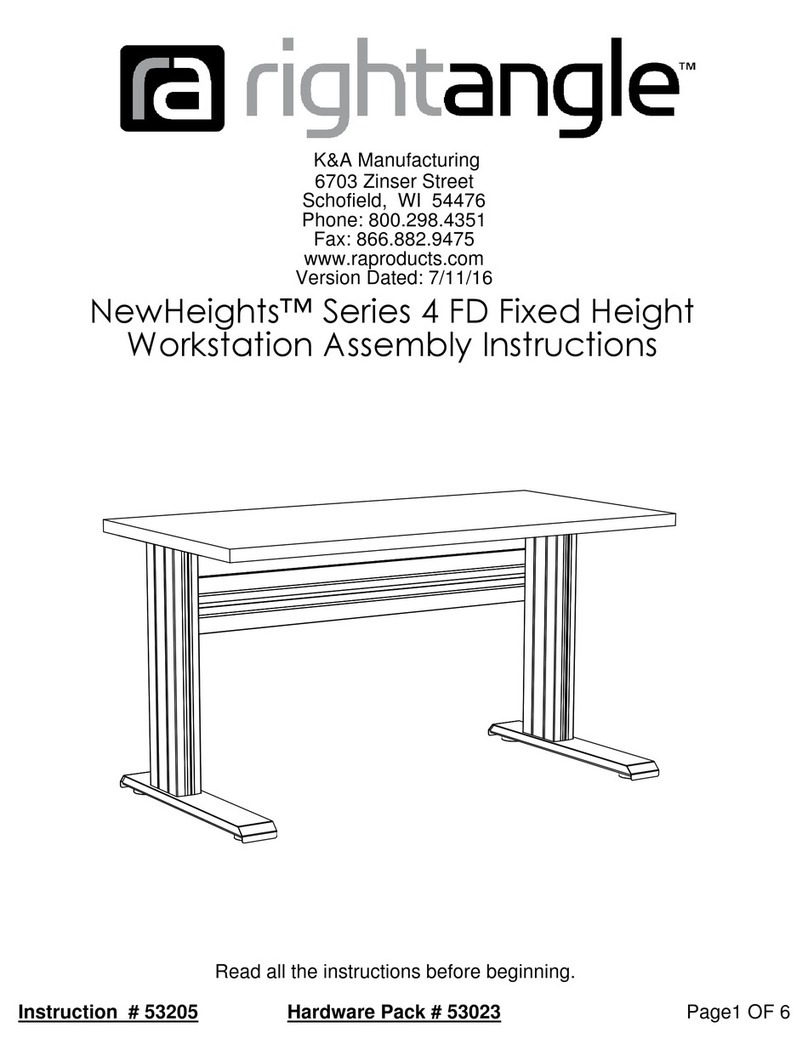

RIGHT ANGLE NewHeights 4 FD Series User manual

RIGHT ANGLE

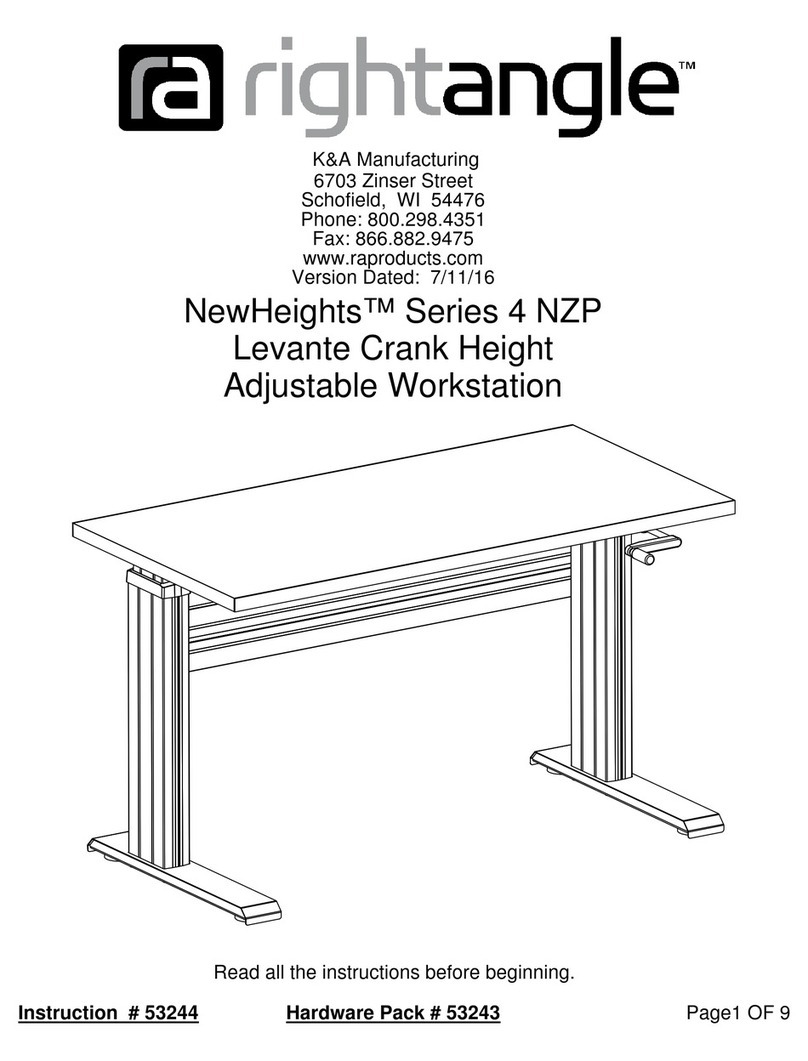

RIGHT ANGLE NewHeights 4 NZP Series User manual

RIGHT ANGLE

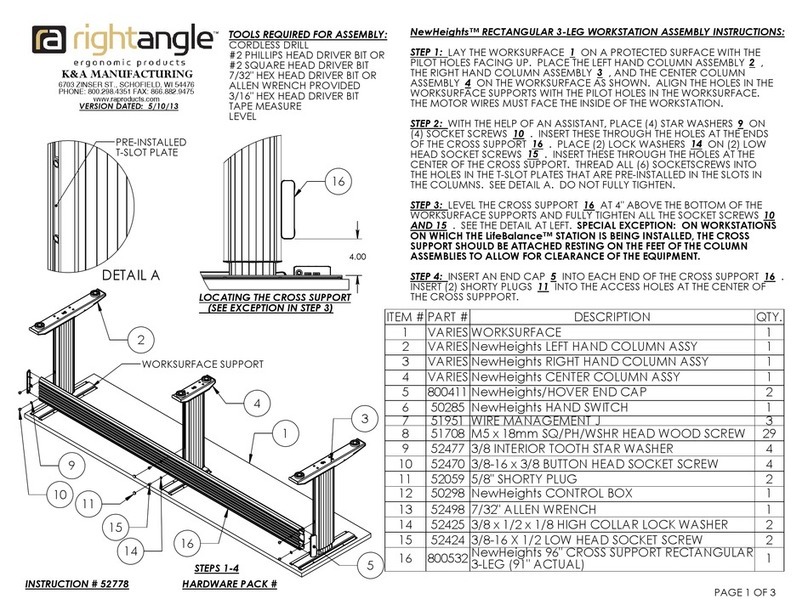

RIGHT ANGLE NewHeights RECTANGULAR 3-LEG WORKSTATION User manual

RIGHT ANGLE

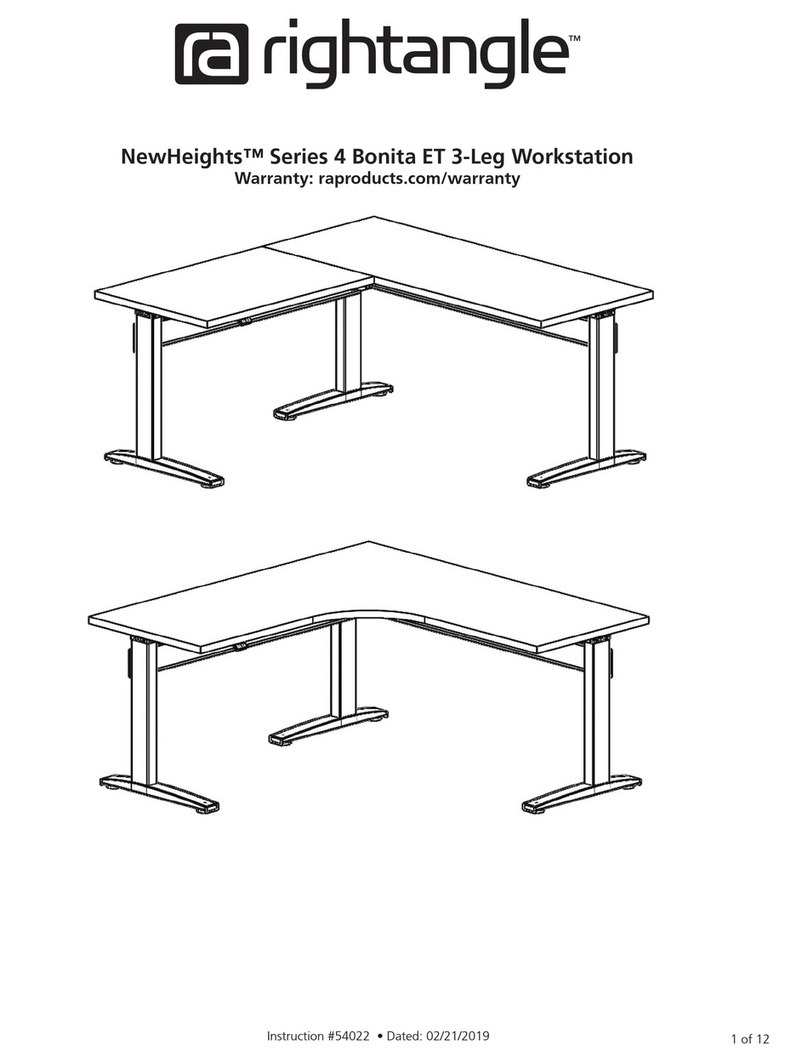

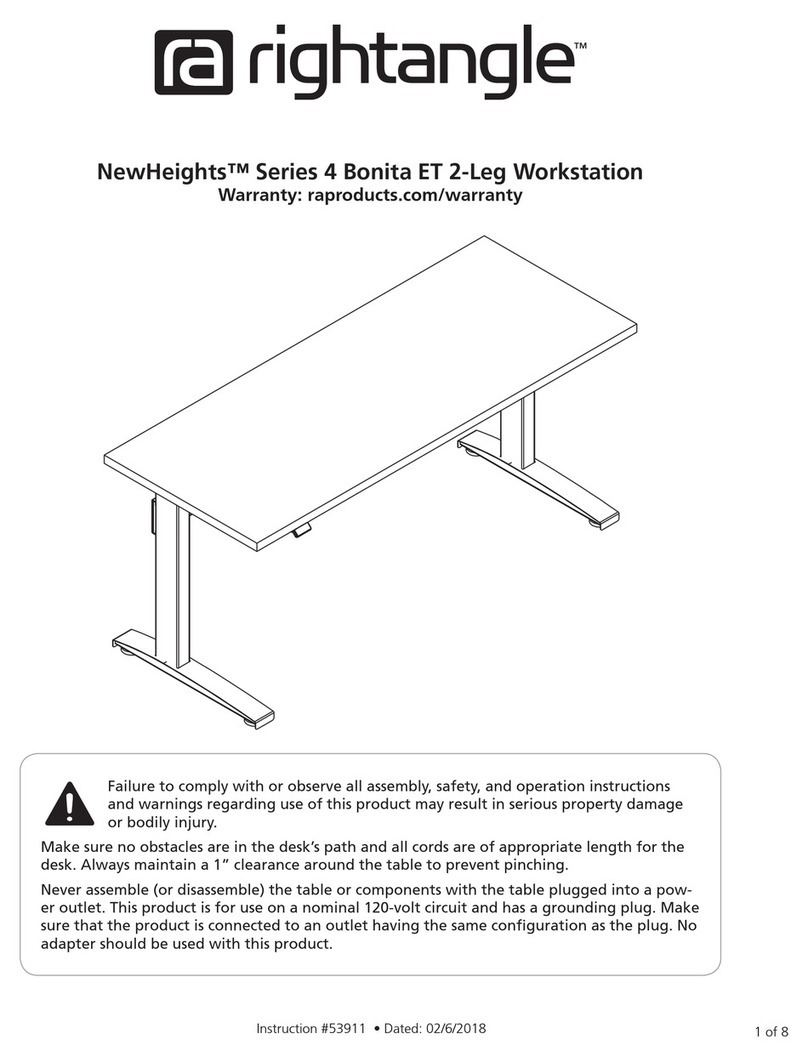

RIGHT ANGLE NewHeights 4 Bonita ET User manual

RIGHT ANGLE

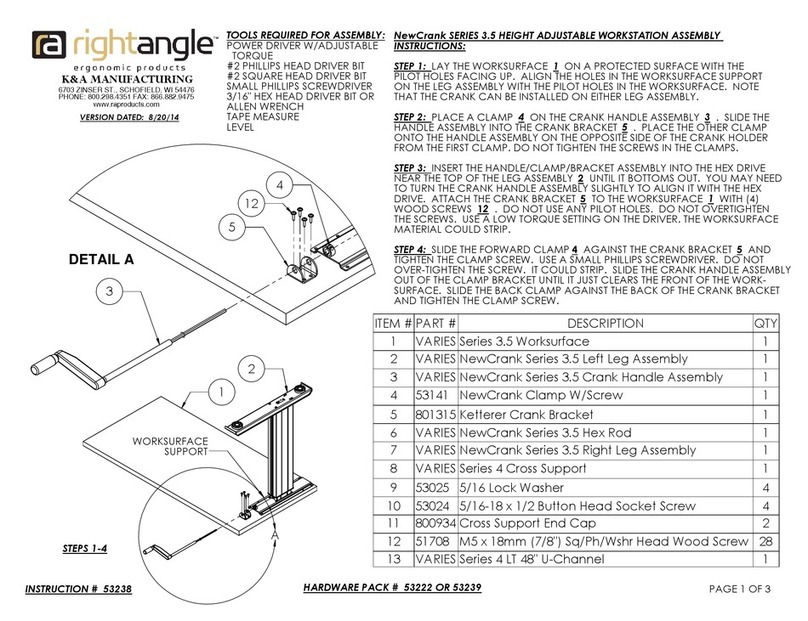

RIGHT ANGLE NewCrank 3.5 Series User manual

RIGHT ANGLE

RIGHT ANGLE NewHeights Elegante XT Series User manual

RIGHT ANGLE

RIGHT ANGLE NewHeights Series User manual

RIGHT ANGLE

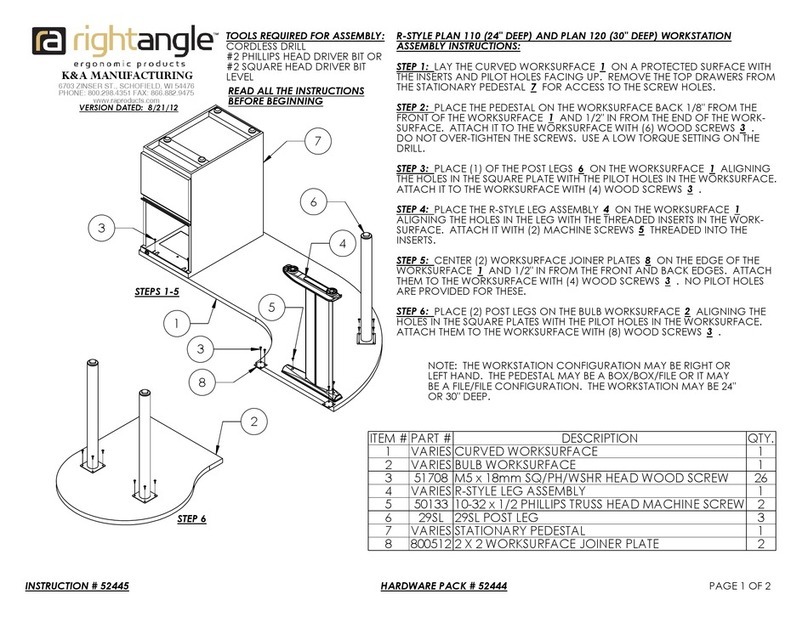

RIGHT ANGLE R-STYLE PLAN 110 User manual

RIGHT ANGLE

RIGHT ANGLE NewHeights ELECTRIC HEIGHT ADJUSTABLE... User manual

RIGHT ANGLE

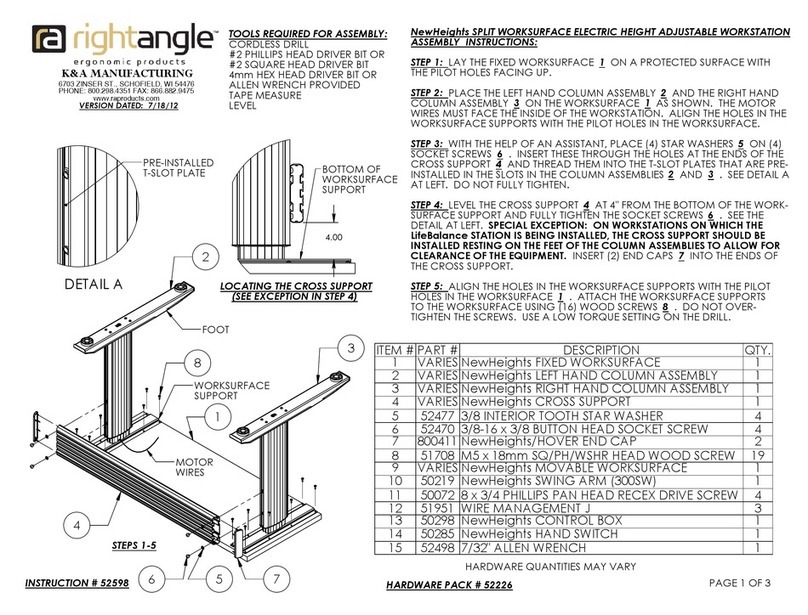

RIGHT ANGLE NewHeights SPLIT WORKSURFACE ELECTRIC HEIGHT ADJUSTABLE... User manual

RIGHT ANGLE

RIGHT ANGLE NewHeights Series User manual