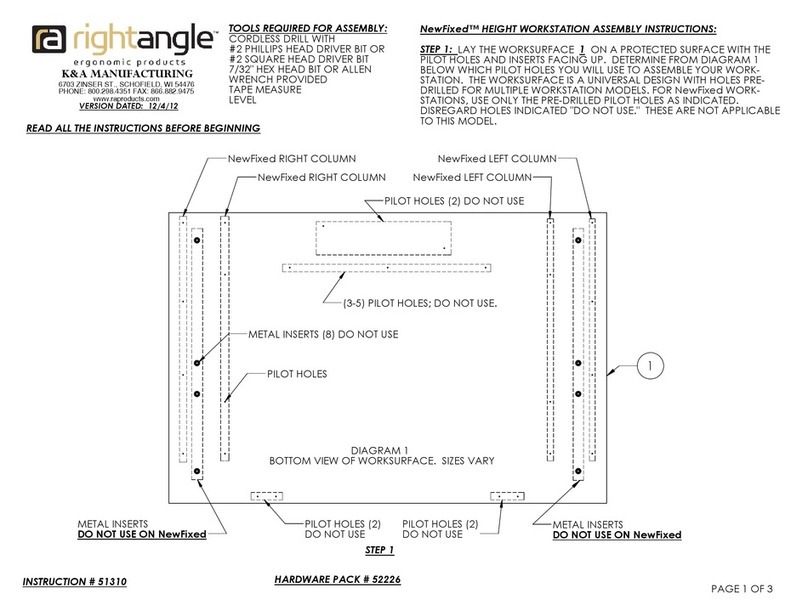

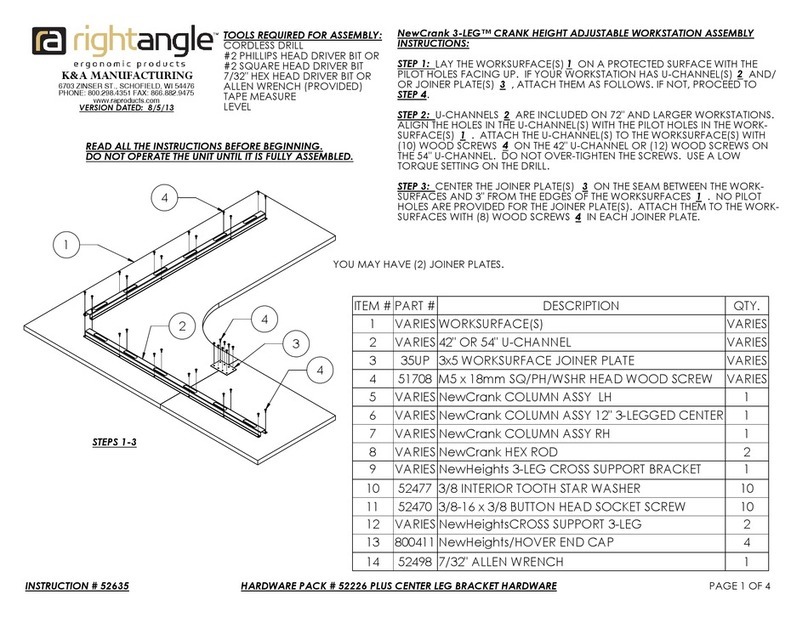

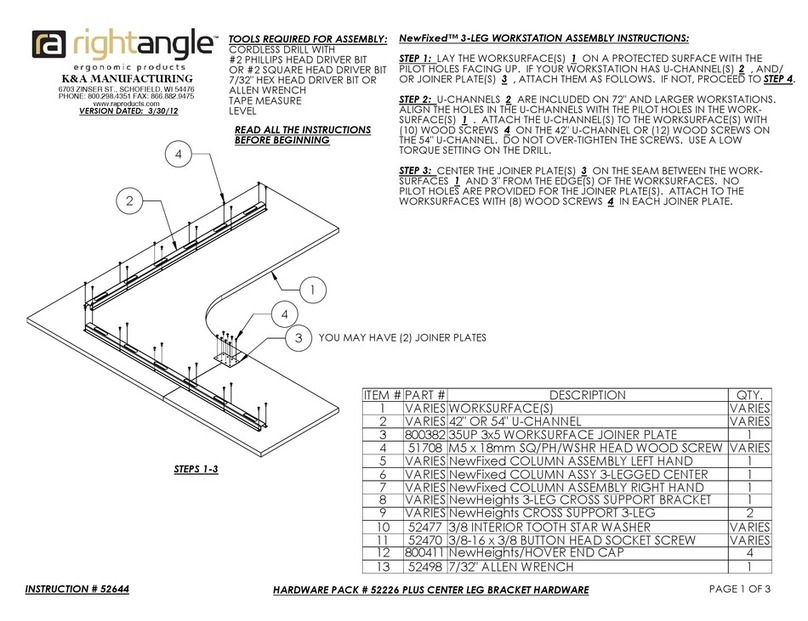

ARE FOR THIS PAGE ONLY.

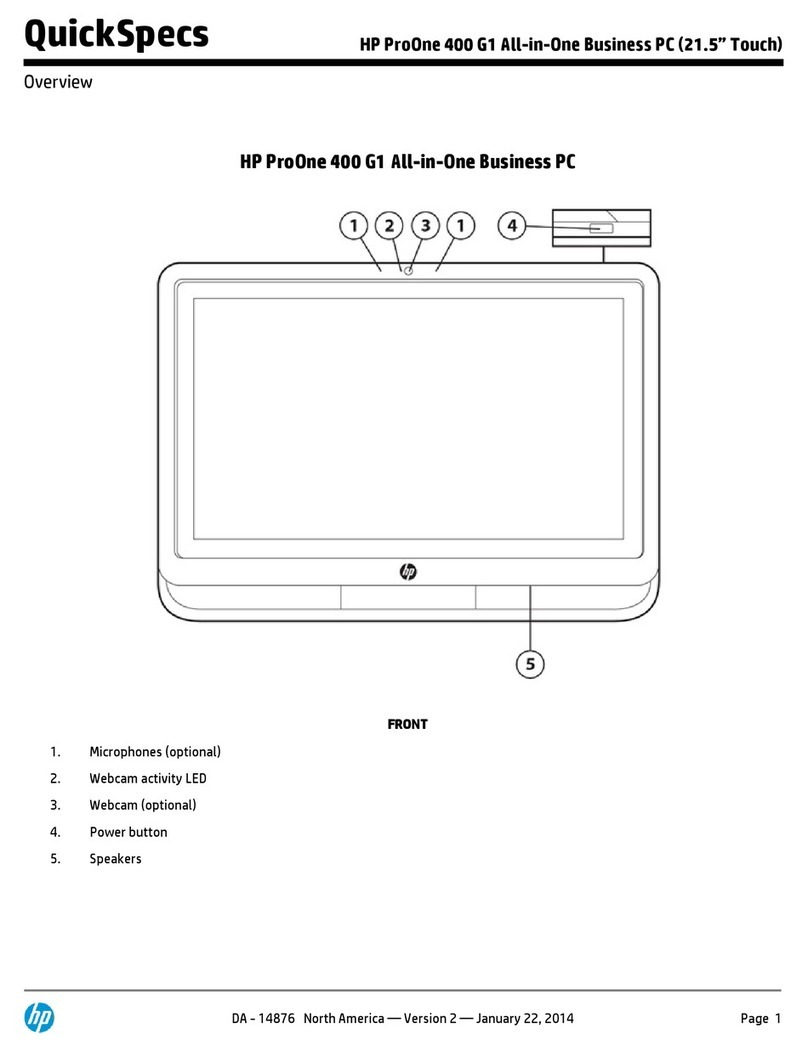

1

4

3

2

OF WORKSTATION NOT

SHOWN FOR CLARITY.

5

OTHER CO PONENTS

PART NU BERS SHOWN

6

FRONT

HAND SWITCH

6703 ZINSER ST., SCHOFIELD, WI 54476

PHONE: 800.298.4351 FAX: 866.882.9475

.raproducts.com

K&A MANUFACTURING

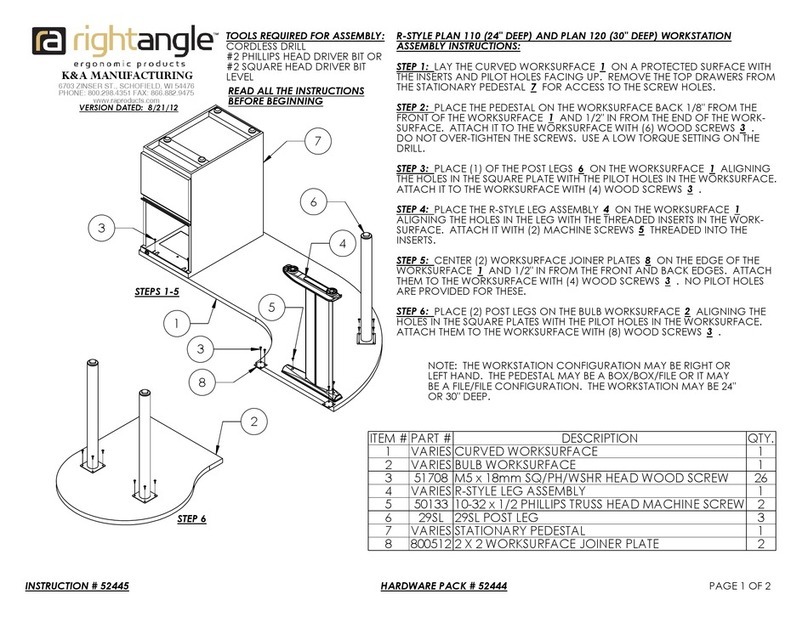

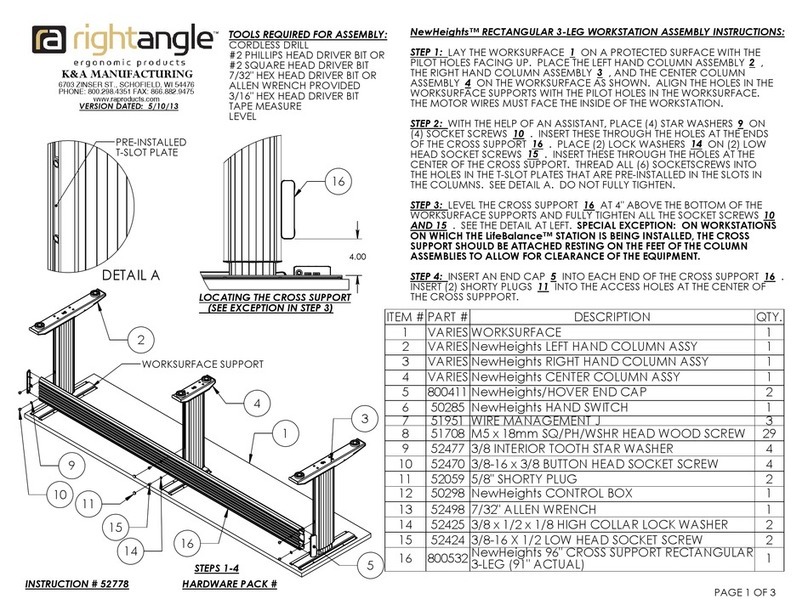

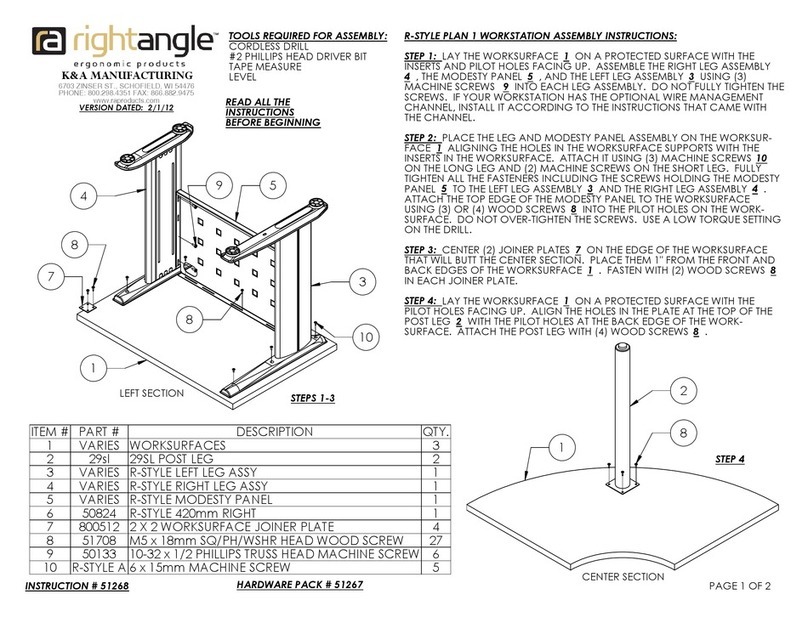

ITE # PART # DESCRIPTION QTY.

1 VARIES LT WORKSURFACE 1

2 VARIES TRACK ASSE BLY 1

3 52236 3/16" ALU INU RIVET WASHER .198x.510x.067 2

4 52678 8-18X1/2 PHIILLIPS PAN SELF DRILL SCREW 2

5 51708 5 x 18mm SQ/PH/WSHR HEAD WOOD SCREW 2

6 VARIES LT U-CHANNEL 1 PAGE 6 OF 6

VERSION DATED 1/16/14

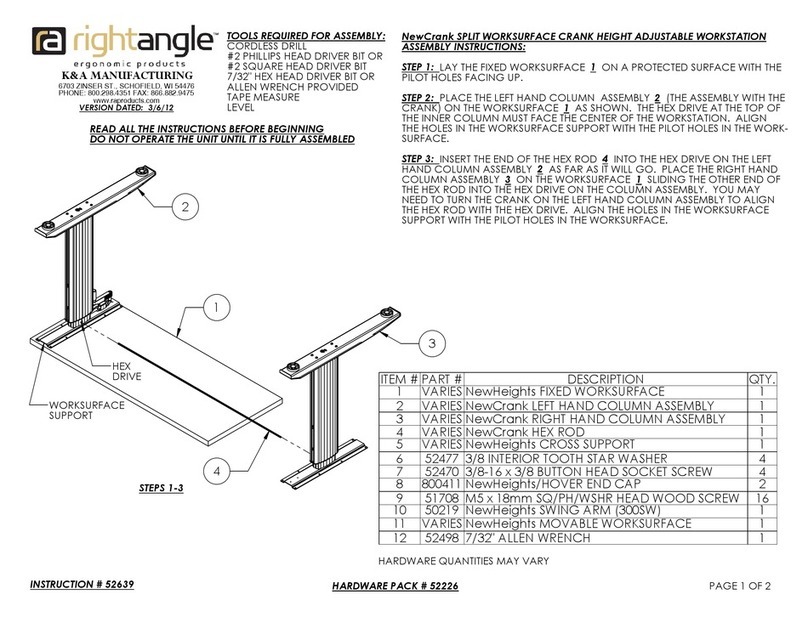

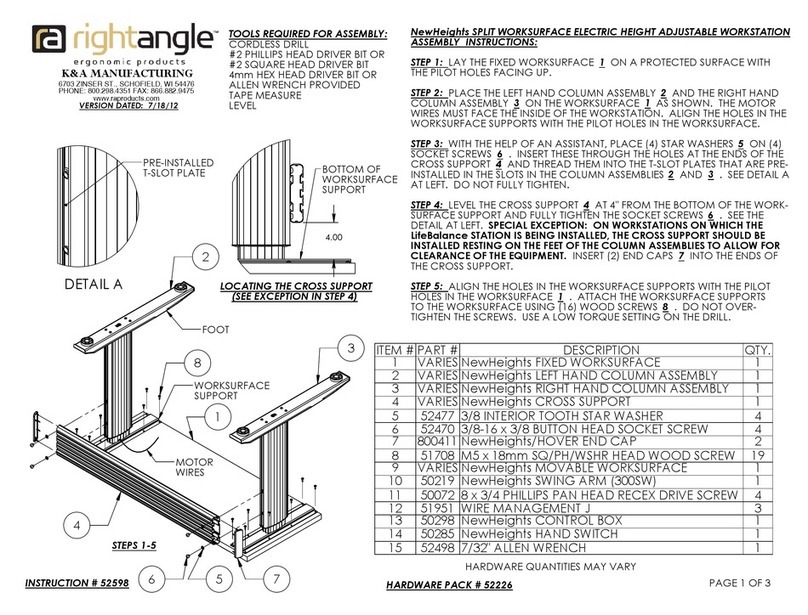

INSTRUCTIONS TO INSTALL A TRACK ON A NewHeigh s SERIES 4 LT WORKSTATION:

STEP 1: PLACE THE FRONT OF THE TRACK 2 AGAINST THE BOTTO OF THE WORK-

SURFACE 1 AND THE BACK OF THE TRACK AGAINST THE U-CHANNEL 1 .

STEP 2: ALIGN THE HOLES IN THE TRACK 3 WITH ONE OF THE SETS OF PILOT HOLES

IN THE U-CHANNEL 1 KEEPING THE FRONT OF THE TRACK 1/8"-5/8" FRO THE

FRONT OF THE WORKSURFACE 2 . PLACE (2) WASHERS 4 ON (2) SELF DRILLING

SCREWS 5 . DRIVE THE THROUGH THE TRACK AND INTO THE U-CHANNEL

1 .

STEP 3: ATTACH THE FRONT OF THE TRACK 3 TO THE WORKSURFACE 2 USING (2)

WOOD SCREWS 6 . DO NOT OVER-TIGHTEN THE SCREWS. USE A LOW TORQUE

SETTING ON THE DRILL.

STEP 4: CO PLETE THE TRACK INSTALLATION USING THE INSTRUCTIONS THAT

CA E WITH THE PRODUCT YOU ARE INSTALLING.

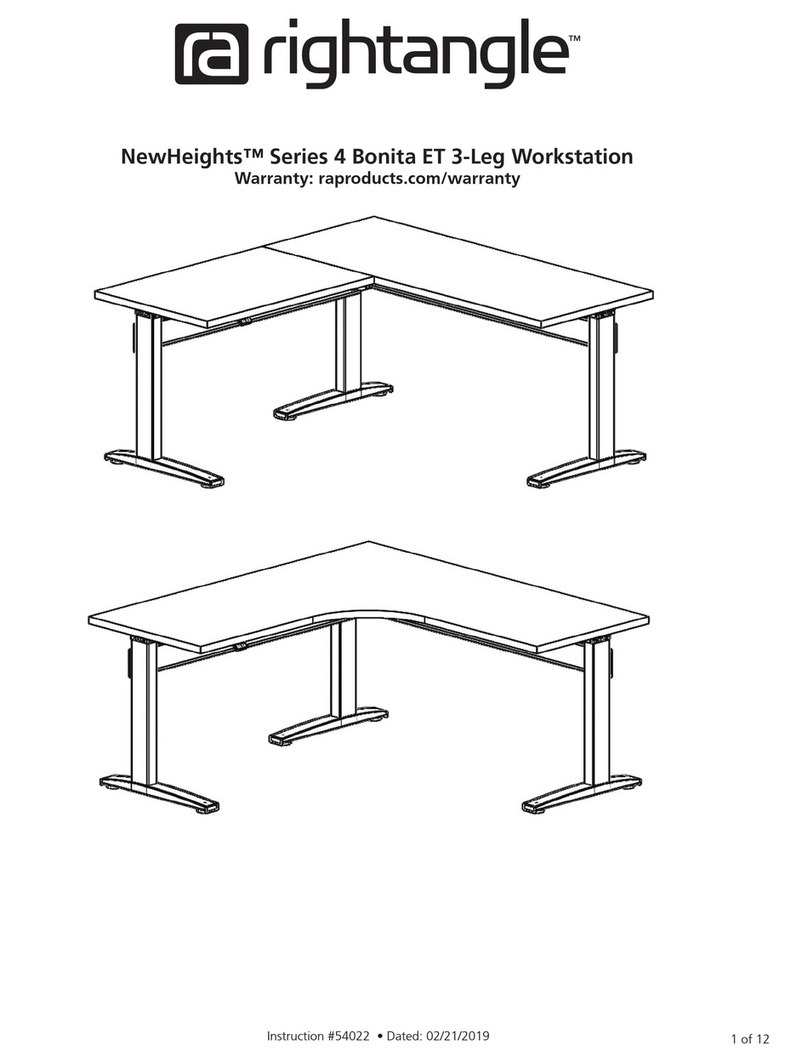

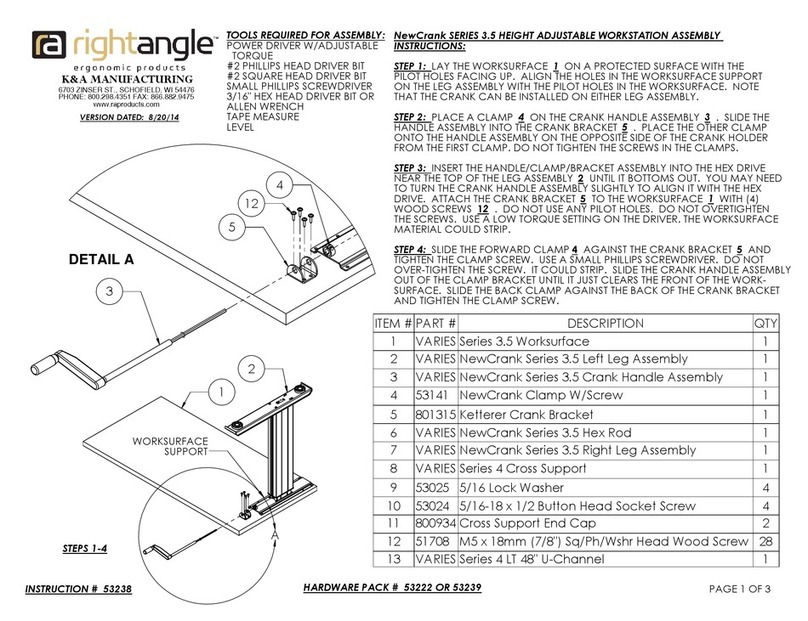

RESET PROCEDURE AND TROUBLESHOOTING: IF THE WORKSTATION

STOPS OPERATING OR GETS STUCK IN ANY POSITION, UNPLUG AND

PLUG BACK IN ALL THE CORD CONNECTIONS INCLUDING THE

POWER CONNECTION ON THE CONTROL BOX. THEN REPEAT THE

RESET PROCEDURE AS NOTED ON PAGE 3. THE WORKSTATION

SHOULD BE READY FOR USE.

IF THE WORKSTATION LEG ASSE BLIES ARE AT UNEVEN HEIGHTS,

IT USUALLY IS CAUSED BY AN I PROPERLY INSTALLED HEX ROD.

DISASSE BLE ONE OF THE LEGS THAT POINT IN THE SA E DIRECTION

FRO THE WORKSURFACE AND AKE SURE BOTH ENDS OF THE HEX

ROD ARE PROPERLY ENGAGED IN THE HEX DRIVES NEAR THE TOP

OF THE LEG ASSE BLIES.

IF YOU CONTINUE HAVING PROBLE S WITH THE TABLE OPERATION,

CONTACT RIGHTANGLE™ SERVICE AT 800-298-4351 OR

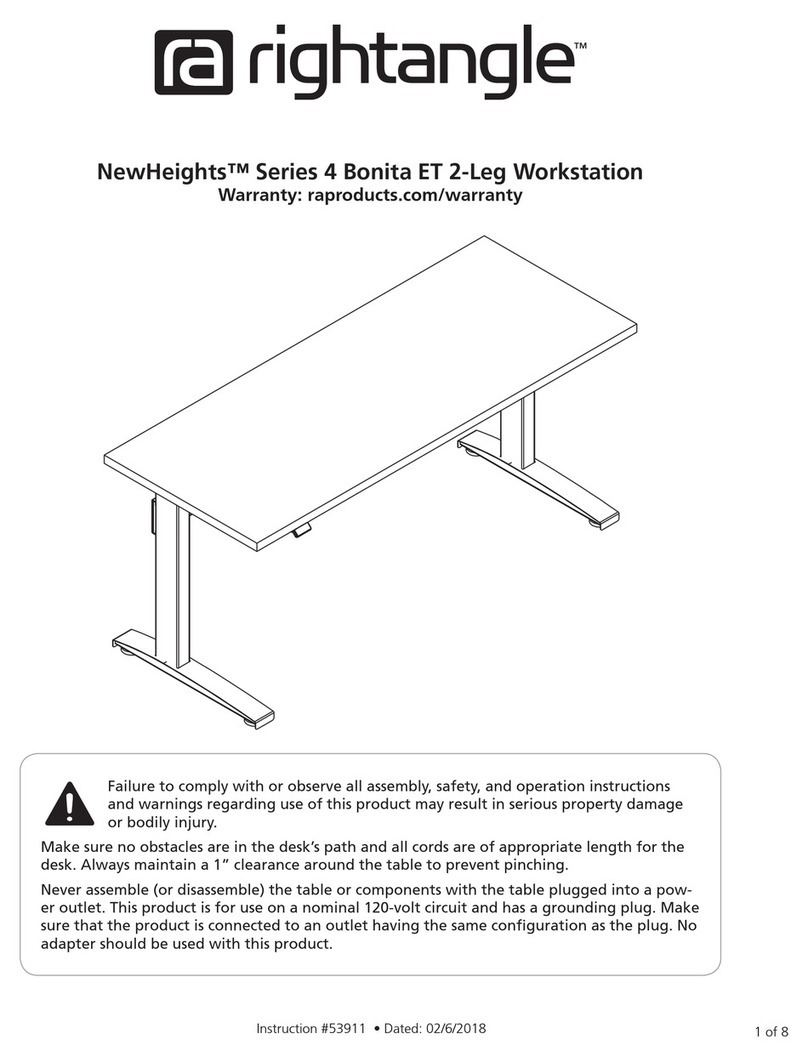

WARRANTY INFORMATION: NewHeights™ PRODUCTS ARE

WARRANTED TO BE FREE OF DEFECTS DUE TO ANUFACTURING

OR ATERIALS AS FOLLOWS: 2 YEARS ON THE GEAR AND/OR

OTOR, INCLUDING THE CONTROL BOX AND HAND SWITCH.

5 YEARS ON THE SUPPORT BRACKETS, ALU INU COLU NS

AND FEET. WE WILL REPLACE ANY DEFECTIVE PART AFTER

INSPECTION BY AN AUTHORIZED AGENT. COSTS INCURRED

DUE TO PRODUCT REPLACE ENT SUCH AS INSTAL-

LATION LABOR CHARGES OR TRANSPORTATION ARE NOT

COVERED UNDER THIS WARRANTY. WHEN CORRESPONDING

WITH RIGHTANGLE™ PRODUCTS, PROVIDE THE ODEL AND

SERIAL NU BERS LOCATED ON THE CONTROL BOX.