Some important information to help you Maintain your product.

The following information is all you need to keep your product looking new.

Clean your product using a mild detergent diluted in water and then polished off using a soft cloth.

If you live in a hard water area, periodically clean your product using a 50/50 solution of white vinegar and water. The solution

should be left on the enclosure for approximately 5 minutes then rinsed off using warm water. This method of cleaning should

remove lime scale residue.

Simple maintenance.

Our products are generally maintenance free, however it may be necessary to lubricate wheel assemblies and other moving parts

from time to time.

It is strongly recommended that a quality silicone spray is used.

A list of Don'ts:

1 - Don't use acidic based products which are unsuitable for cleaning enamel surfaces.

2 - Don't use Abrasive cleaners or cleaners containing bleach or solvents, these products will adversely affect the finish of the

aluminium profiles.

3 - Don't use scouring pads, powder or any sharp instruments when cleaning the enclosure.

TROUBLE SHOOTING GUIDE.

Problem Solution

LEA ING 1. Check the Tray has been sealed correctly prior to installation of the enclosure Step 1.

2. Check the inside gap has been sealed correctly between the tray and wall profiles Steps 2 & 5.

3. Check that the base of the enclosure is sealed to the tray top from the outside only Step 7.

4. Check that a bead of silicon the width of the wall profile has been applied Steps 2 & 5.

5. Check to see if both wall profiles have been sealed vertically inside and outside where they meet

the tiled wall Step 7.

6. Check that the base of the enclosure hasn’t been sealed to the tray top on the inside of the cubicle.

Important: This enclosure should be water tested conforming to BS EN 14428

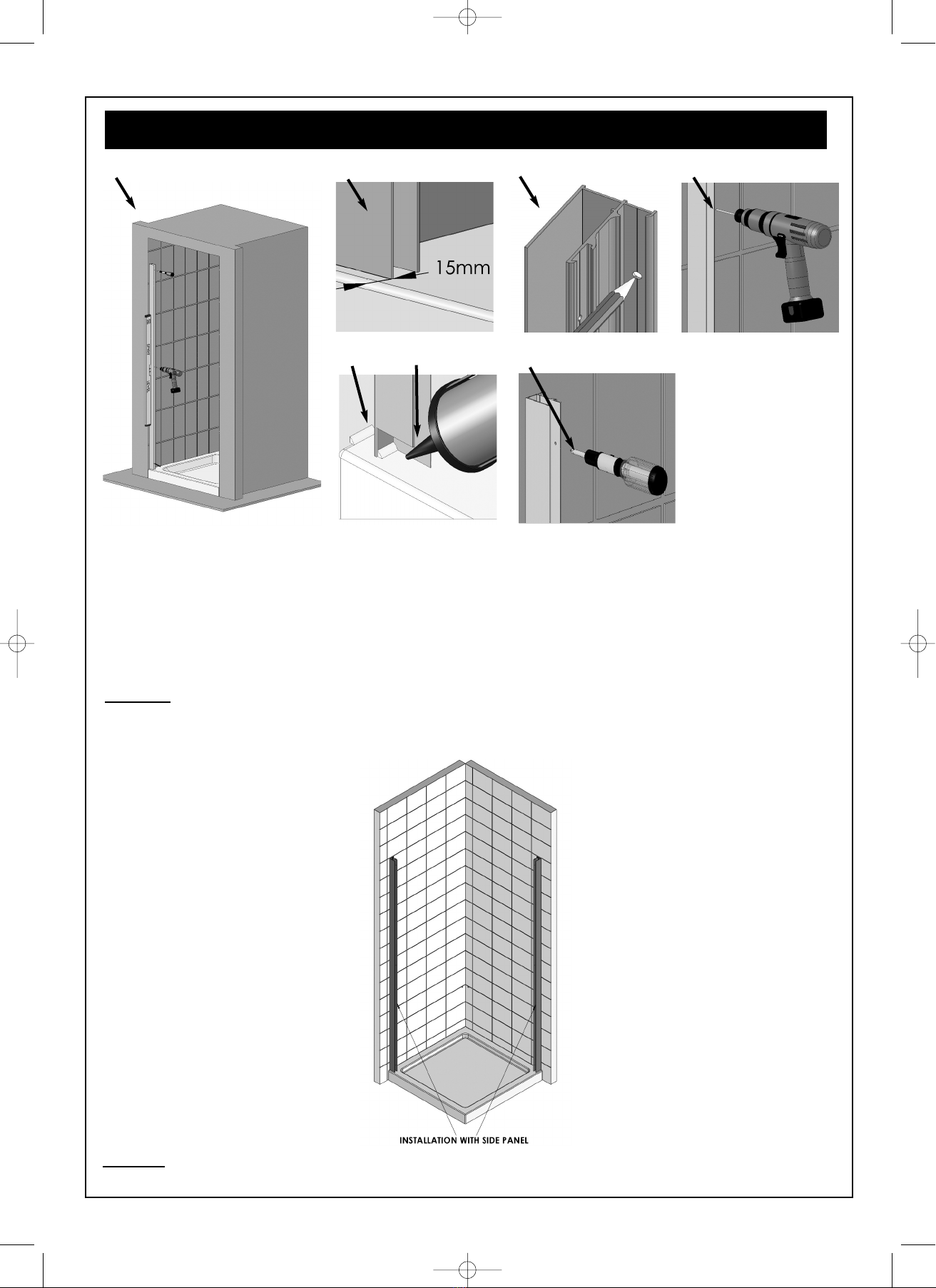

ENCLOSURE 1. Check that the enclosure has been fitted onto a tiled wall or a similar sealed surface.

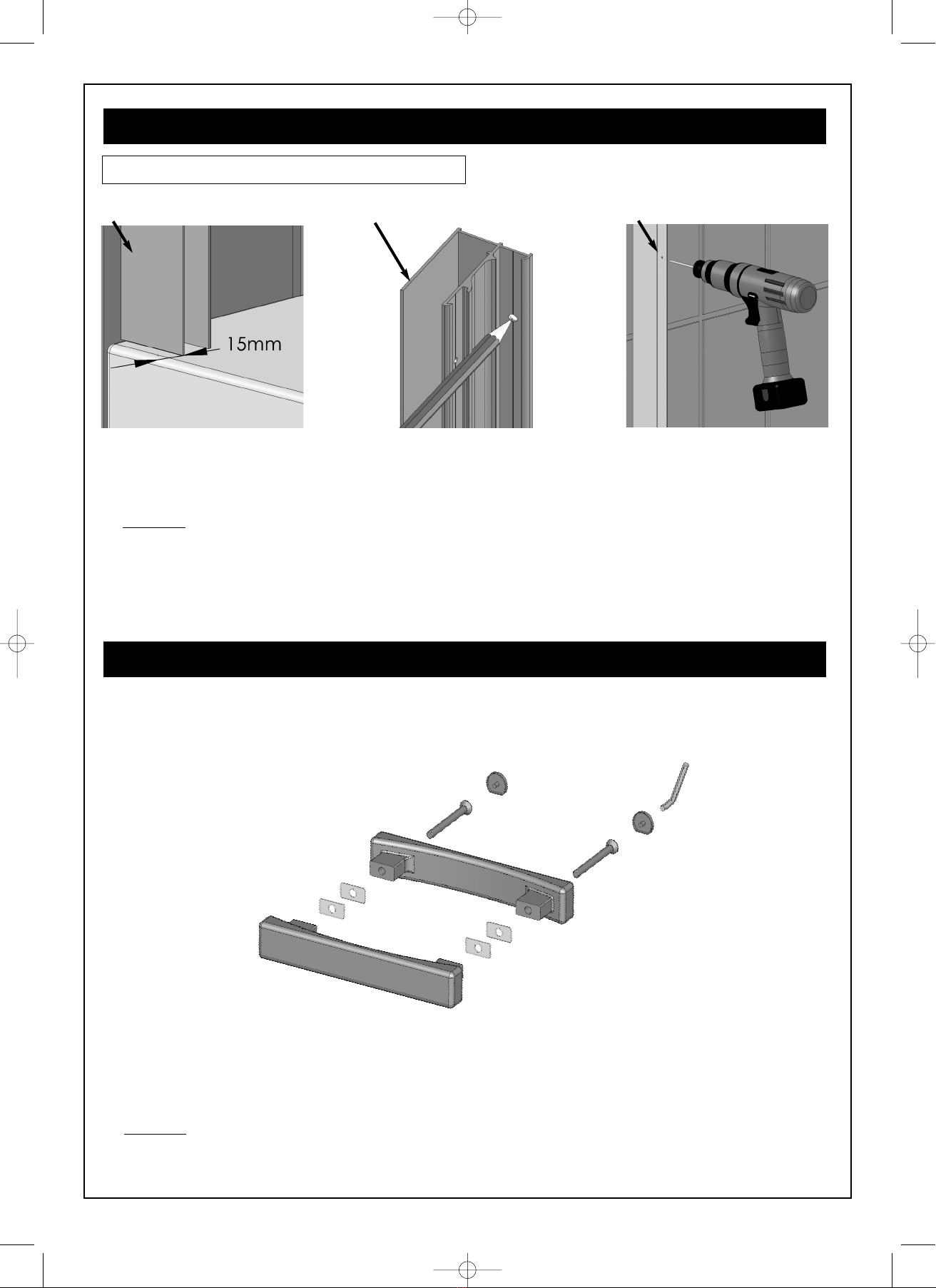

ALIGNMENT ON THE 2. Check that the wall profiles have been fitted 15mm in from the front outside edge of the tray Steps

TRAY OR FLOOR 2 & 3.

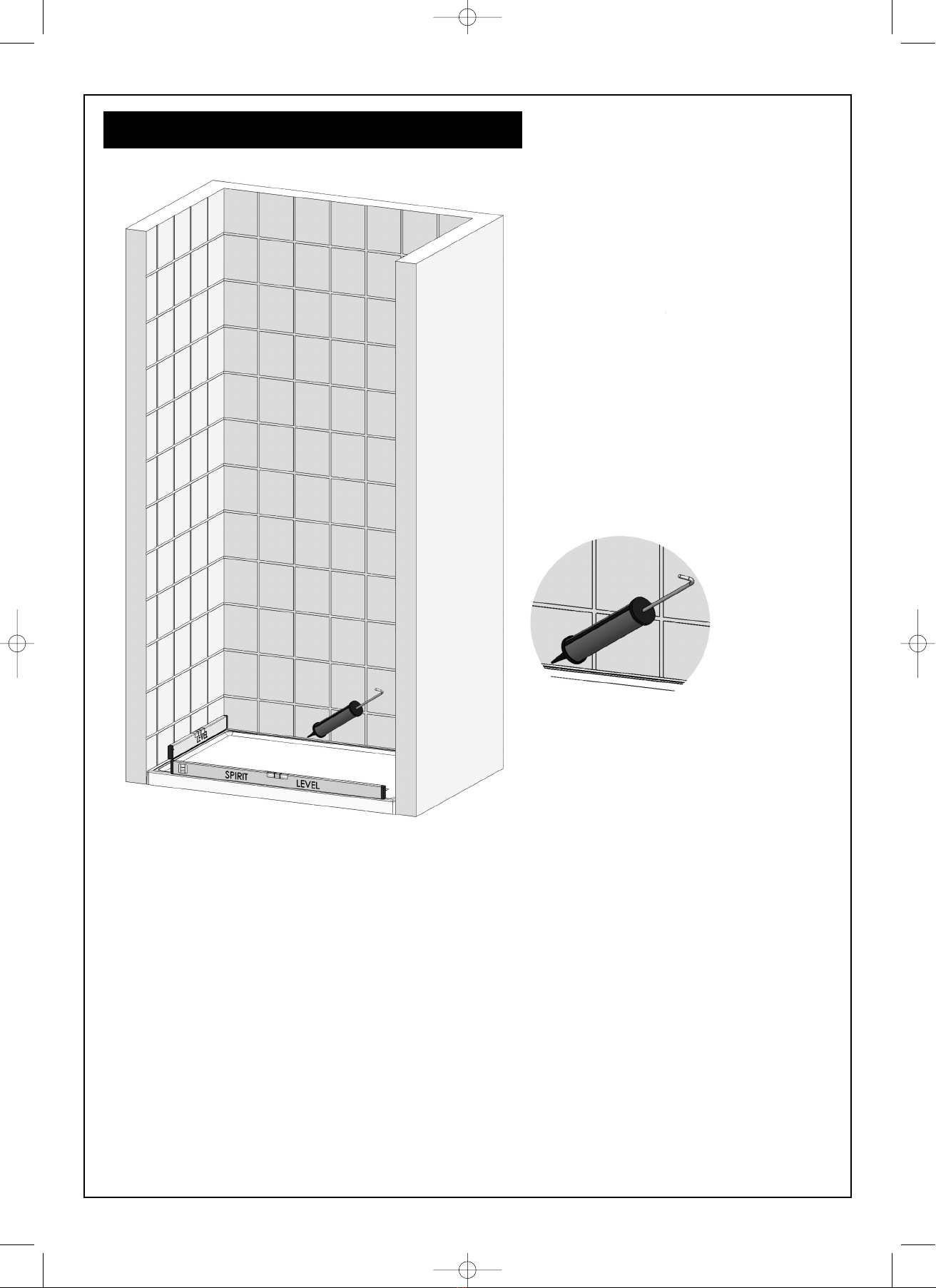

3. Check that the wall profiles have been fitted completely vertical (the bubble must be in the centre of

the two lines on a spirit level) Steps 2 & 3.

4. Check that the enclosure is completely vertical and level.

DOOR NOT 1. Check that the tray is completely level (the bubble must be in the centre of the two lines on a spirit

OPERATING / level), this could have an effect on the positioning of the door when adjusted, you might not have

CLOSING enough adjustment within the wall profile due to compensating for an out of level tray Step 1.

CORRECTLY 2. Check that the wall profiles are completely vertical (the bubble must be in the centre of the two

lines on a spirit level) Steps 2 & 3.

3. Check that the channels which the doors slide in has got some silicon lubrication gel in. (If not,

please apply some form of lubrication agent in the channels).

4. If the door does not hang vertically, you have further adjustment at the top of each wheel assembly.

Using the Allen key (supplied) turn the adjustment screw. Turning the adjustment screw clockwise

will lift the door, and turning the adjustment screw anti clockwise will lower the door Step 6.