Division of BETA UTENSILI spa Via Volta. 18 - 20050 SOVICO MB) ITALY Tel. +39.039.20771-Fax + 39.039.2010742

9. Using the accessory – pick-up and manoeuvre

Use, load pick- p and manoe vre with the accessory m st be

made with great attention, delicately and witho t jerking. The

safety latch opens man ally by applying press re to the device

itself and it closes a tomatically as a res lt of the strength of

the spring. This safety latch does not hold the load nder

tension, that is the pick- p element is slack, precisely to permit

nhooking. For this reason, always check that it is the hook

which s pports the load.

! ATTENTION

The safety latch must never

support the load

Do not introd ce more than two arms into the hook, and when

there are two, ens re that maxim m angle

formed by vertical and straight line of load

is not more than 45°.

10. Restrictions on use.

Using the accessory for p rposes which

are not anticipated, its improper se, its

se in dangero s conditions and the fail re

to carry o t maintenance can all lead to

situations of serious danger to persons

thus exposed as well as to the work

setting, and can also affect the f nctioning

and safety of the accessory negatively.

The actions indicated below, which obvio sly do not cover all

possible examples of ‘bad use’ of the accessory, are however

those which co ld reasonably be predicted. So:

NEVER se the accessory to lift and move persons,

animals and things different from those which the hook is

designed to be sed.

NEVER raise loads with the point of the hook.

NEVER raise or move loads in flight (i.e. aircraft) nor se

the accessory to drag bo nd loads.

NEVER operate in areas where the se of non-

flammable/spark-proof components is req ired or in the

presence of strong electromagnetic fields.

NEVER weld metallic elements to the accessory, add

welded elements or se it as a weight for welding

p rposes.

11.Spare parts, inspection and maintenance.

This incl des operations of maintenance, carried o t by

personnel who have been trained for the p rpose, concerning

checks d ring se and possible actions as anticipated in the

‘Table of maintenance and check-up operations’.

The accessory m st be s bjected to the following checks:

visual: check for the presence of s rface defects s ch as

cracks, incisions, c ts or fiss res, abrasions.

functional: check the accessory and the connecting link

can move freely, the safety latch carries o t the f nction

of nhooking, and especially the spring keeps the

blocking mechanism f nctioning.

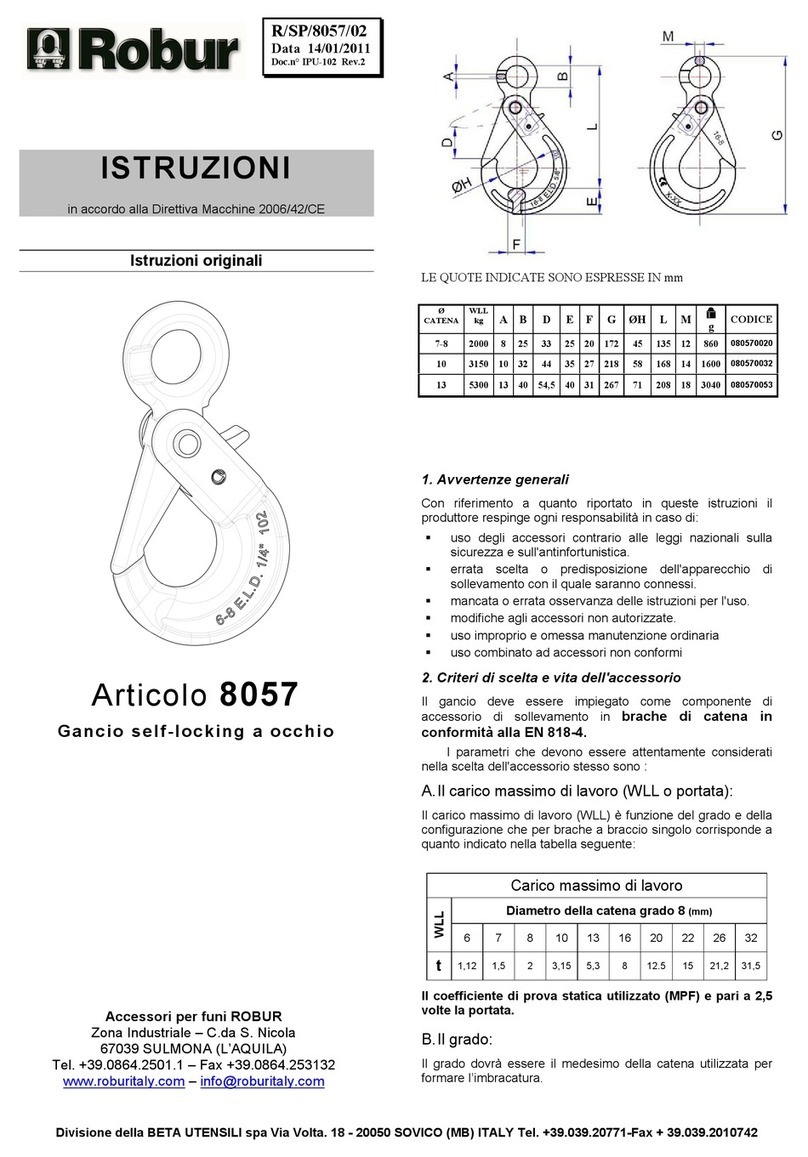

deformation: check that the accessory does not lose its

shape by meas ring its critical dimensions as indicated in

fig re 1 with a calliper.

wear: check that points of contact are not worn o t by

meas ring its critical dimensions as indicated in fig re 1

with a calliper.

state of preservation: check for the presence of

excessive oxidisation and corrosion, above all in cases

where it is sed in the open air; check for the presence of

cracks with s itable methods (e.g. penetrating liq ids) .

Records of these checks m st be kept safe

Please contact the man fact rer for any spare part

ATTENTION ! Always use original spare parts

The man fact rer declines any responsibility in case of

breakage, malf nction or damage to persons or properties

res lting from the se of spare parts that are not original.

12. Demolition and scrapping of the accessory

If the accessory sho ld t rn o t to be deformed , worn o t or at

the end of its life span as indicated by the man fact rer, and

therefore no longer sable, it m st be demolished and

scrapped.

Table of maintenance and check-up operations

Ordinary Periodical

Description of check-

up Day Week Month Year

Vis al X

F nctional X

Deformation X

Wear and tear X

State of preservation X

Replace the accessory

when:

It is permanently deformed

with a widening of the

apert re more than 10% of

the original meas rement

DANGER

Figure 1

There are section red ctions

and dimensional variations

more than 5% of the original

meas rement.

ACCESSORIES

FOR WIRE ROPE ROBUR

Ind strial Zone – C.da S. Nicola

67039 SULMONA (L’AQUILA)

Tel. +39.0864.2501.1 – Fax +39.0864.253132

www.roburitaly.com – info@roburitaly.com