Staubli MA417-1 User manual

1 / 24

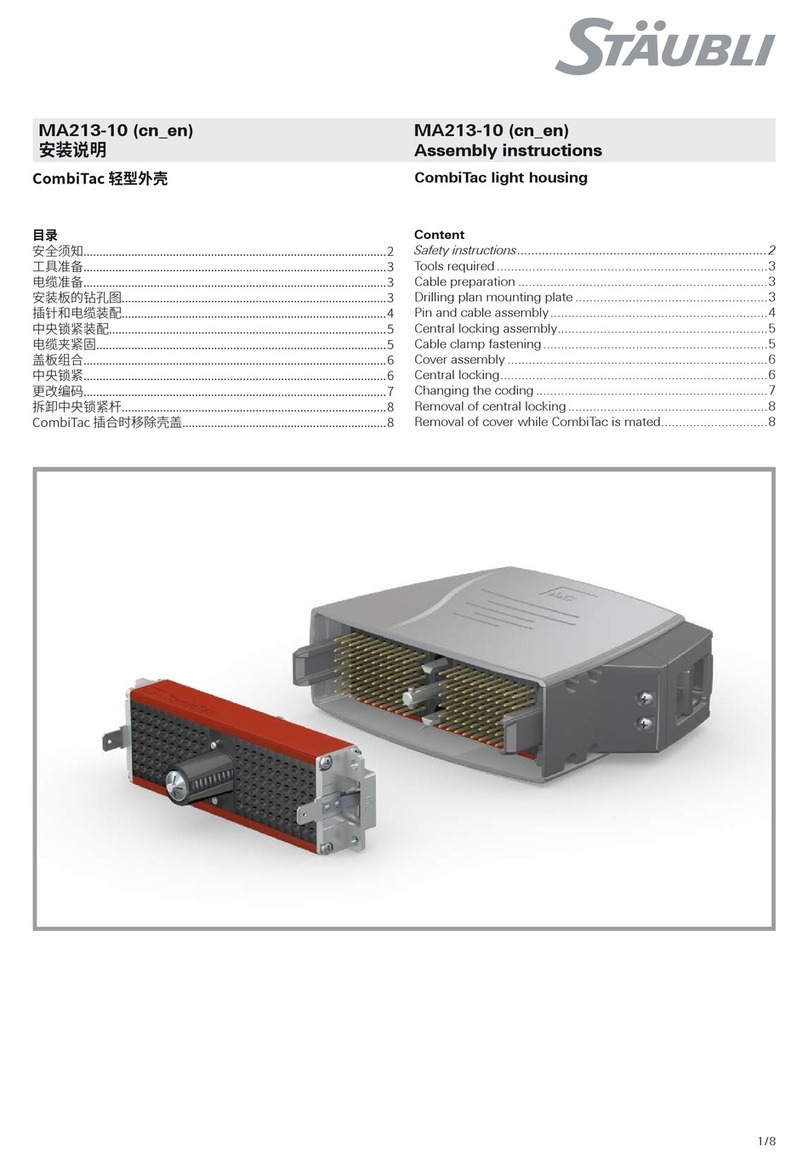

CTD-NET Coax 1.5 GHz

Coax 2.4 GHz

Coax SMA 6 GHz

MA417-1 (cn_en)

安装说明

目录

安全须知2

1 Gbit 模块 CTD-NET 4 – 10

同轴模块 RG58 15 GHz 11 – 13

同轴模块 RG316/RG58 24 GHz 14 – 19

同轴 SMA 6 GHz 20

支撑块安装22

支撑块拆卸23

注意事项24

CombiTac direqt

数据模块

MA417-1 (cn_en)

Assembly instructions

CombiTac direqt

Data Module

Content

Safety Instructions �����������������������������������������������������������������������2

1 Gbit module CTD-NET������������������������������������������������������4 – 10

Coaxial module RG58 1�5 GHz������������������������������������������11 – 13

Coaxial module RG316/RG58 2�4 GHz �����������������������������14 – 19

Coaxial SMA 6 GHz�������������������������������������������������������������������20

Insertion of carrier in frame���������������������������������������������������������22

Removing of carrier from frame��������������������������������������������������23

Notes ����������������������������������������������������������������������������������������24

2 / 24

安全须知 Safety instructions

仅可使用史陶比尔指定的组件和工具。自行装配时,切勿背离本

手册所述的制备及装配说明,否则史陶比尔无法保证产品安全性

或性能达到官方技术参数。请勿以任何方式修改产品。

Use only the components and tools specified by Stäubli� In case

of self-assembly, do not deviate from the preparation and assem-

bly instructions as stated herein, otherwise Stäubli cannot give

any guarantee as to safety or conformity with the technical data�

Do not modify the product in any way�

与史陶比尔元件互插的非史陶比尔原厂制造的连接器,在某些情

况下,某些制造商甚至将其描述为“与史陶比尔兼容”,但此类连

接器并不符合长期稳定安全的电连接要求。出于安全考虑,不得

与史陶比尔元件互插。因此,对此类连接器(即未经史陶比尔同

意)与史陶比尔元件互插而造成的任何损失,史陶比尔不承担任

何责任。

Connectors not originally manufactured by Stäubli which can be

mated with Stäubli elements and in some cases are even de-

scribed as ”Stäubli-compatible” by certain manufacturers do not

conform to the requirements for safe electrical connection with

long-term stability, and for safety reasons must not be plugged

together with Stäubli elements� Stäubli therefore does not ac-

cept any liability for any damages resulting from mating such

connectors (i�e� lacking Stäubli approval) with Stäubli elements�

如您未遵守上述警告,则史陶比尔电连接器股份公司(史陶比尔)

不承担任何责任。

Stäubli Electrical Connectors (Stäubli) does not accept any

liability in the event of failure to observe these warnings�

IEC 60417-6182

安装需电气专业知识 Installation, electro technical expertise

产品应由具备电气技能或受过此方面指导的人员依照适用的安

全法规进行装配或安装。

The products may be assembled and installed by electrically

skilled or instructed persons duly observing all applicable safety

regulations�

IEC 60417-6042

注意电击风险 Caution, risk of electric shock

请在断电状态下工作

操作电气装置时,请遵守五项安全规定。

各电气装置确定后,应按照规定顺序执行以下五项基本要求(除

非另有必要理由):

• 完全分离;

• 确保不会重新连接;

• 确认无工作电压;

• 进行接地和短路;

• 针对临近带电部件提供防护。

任何从事此工作活动的人员均应具备电气技能或受过此方面指

导,或者由同等能力的人员监督。

来源:EN 50110-1:2013

Work in a de-energized state

Follow the five safety rules, when working on electrical installa-

tions�

After the respective electrical installations have been identified,

the following five essential requirements shall be undertaken in

the specified order unless there are essential reasons for doing

otherwise:

•disconnect completely;

•secure against re-connection;

•verify absence of operating voltage;

•carry out grounding and short-circuiting;

•provide protection against adjacent live parts�

Any person engaged in this work activity shall be electrically

skilled or instructed, or shall be supervised by such a person�

Source: EN 50110-1:2013

最终应用时,还应检查防触电保护情况。 Protection against electric shock shall be checked in the end-use

applications too�

IEC 60417-6070

请勿在负载下进行连接和断开 Do not connect and disconnect under load

仅当额定电压不超过 AC 1000 V/DC 1500 V 时,可带电进行连接

与断开操作。

当额定电压超过AC 1000V/DC 1500 V时,仅允许在连接状态下带

电,不允许进行带负载断开或带电插合。这也适用于在单一型号

中同时配置电连接模块与气体和液体模块的情况。

Connecting and disconnecting when live is only permitted if the

rated voltage does not exceed AC 1000 V/DC 1500 V �

For rated voltages over AC 1000 V/DC 1500 V, the voltage must

only be applied in mated condition, disconnecting under load

or connecting when live is not permitted� This also applies for

electrical connections in close proximity to fluid and gas con-

nections�

3 / 24

安全须知 Safety instructions

ISO 7000-0434B

警告 Caution

每次使用连接器前,需检查外部是否有磨损(尤其是绝缘层)。如

果存在任何安全隐患,必须咨询具备电气技能的人员或更换连接

器。

Each time the connector is used, it should previously be inspect-

ed for external defects (particularly the insulation)� If there are any

safety concerns, an electrically skilled person must be consulted

or the connector must be replaced�

IP 防护(根据 60529:2013) IP protection according to 60529:2013

未插合的连接器必须防潮防尘。被污染的公母连接器不得插合在

一起。

Unmated plug connectors must be protected from moisture and

dirt� The male and female parts must not be plugged together

when soiled�

检查 Examine; Check

告知检查 To indicate examination or checking

产品使用说明或技巧 Useful hint or tip

欲了解更多技术参数,请参阅产品目录。 For further technical data please see the product catalog�

4 / 24

1245

6

3

6542

1

3

1 Gbit 模块 CTD-NET

序号/Pos. 描述/Description

1模块支撑块/Module carrier

2插针主体/Pin body

3固定夹/Retaining clip

4触子支撑块/Contact carrier

5锁紧圈/Clamp ring

6锁紧螺母/Nut

序号/Pos. 描述/Description

1模块支撑块/Module carrier

2插座主体/Socket body

3固定夹/Retaining clip

4触子支撑块/Contact carrier

5锁紧圈/Clamp ring

6锁紧螺母/Nut

插座侧 插针侧

1 Gbit module CTD-NET

Socket side Pin side

5 / 24

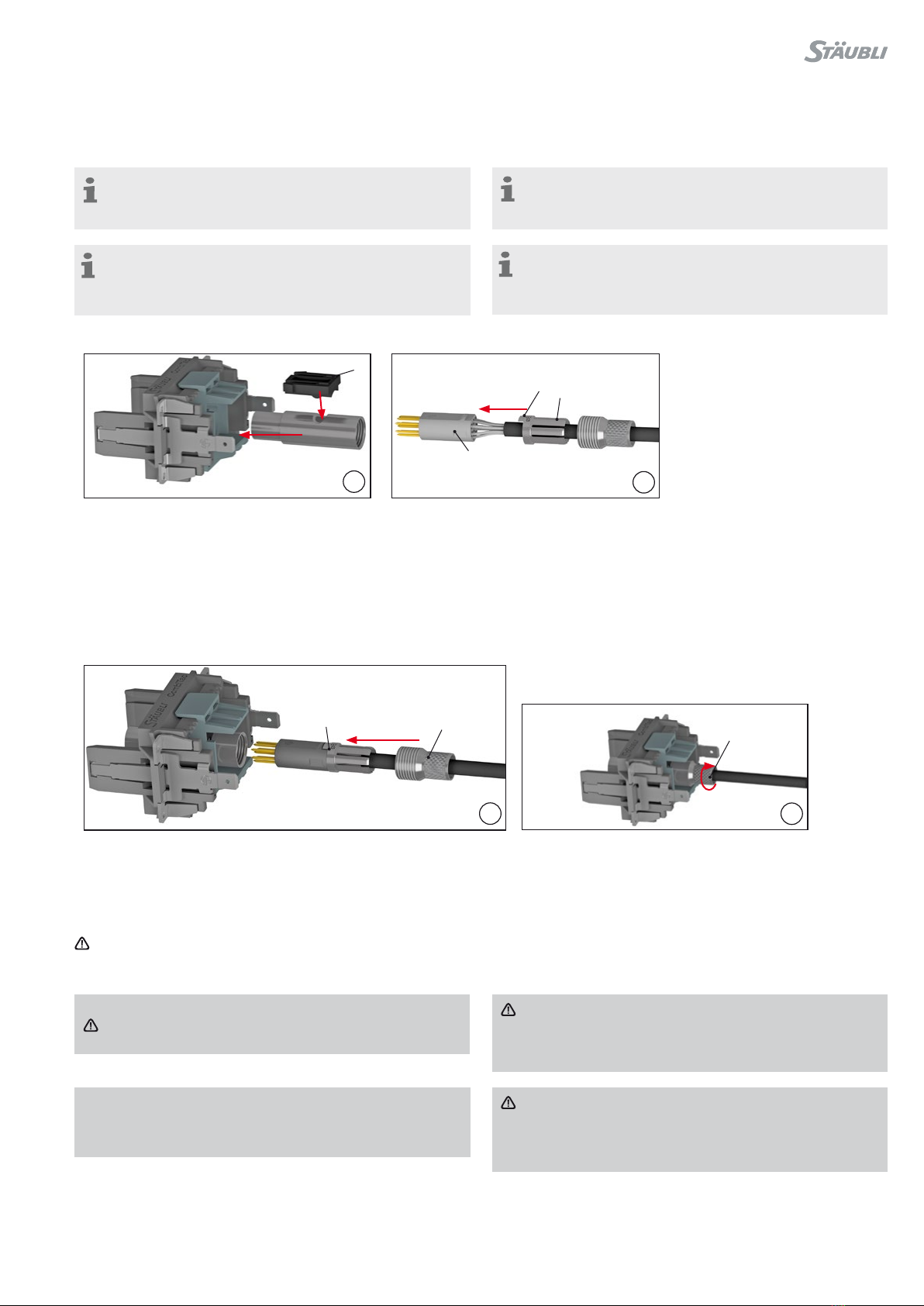

1

2

3

4

(图4)

螺丝刀

尺寸 2 和尺寸 3(用于拆卸框架中的支

撑 块 )。

(图3)

用于1Gbit模块的铜导电胶带,订货号

11012526。

(图2)

退针工具

CT-NET-AWZ,订货号 333048

(仅用于维修目的)。

注意事项:

操作说明 MA079,

wwwstaublicom/electrical

或

压接钳 CT-M-CZ

订货号 333800

以及定位块 MES-CZ,

订货号 183801

注意事项:

操作说明 MA419,

wwwstaublicom/electrical

(图1)

压接钳 CTD-M-CZ

订货号 333900

以及定位块 MES-CZ-CTD1NET,

订货号 333913

工具准备 Tools required

(ill. 1)

Crimping pliers CTD-M-CZ

Order No� 33�3900

and locator MES-CZ-CTD1NET,

Order No� 33�3913

Note:

Operating instructions MA419,

www�staubli�com/electrical

or

Crimping pliers CT-M-CZ

Order No� 33�3800

and locator MES-CZ,

Order No� 18�3801

Note:

Operating instructions MA079,

www�staubli�com/electrical

(ill. 2)

Extraction tool

CT-NET-AWZ, order No� 33�3048

(For repair purposes only)�

(ill. 3)

CU conductive tape for 1 Gbit

moduls, order No� 11012526�

(ill. 4)

Screwdriver

Size 2 and 3

(for repair/removal of carriers from

frame)�

6 / 24

6

4,5

5

表1/Tab. 1

步骤

Steps 电缆 1/Cable 1 电缆 2/Cable 2

1

18 18

2

33.1 3.2 3.3

4

(图6)

展开双绞线,进行剥线处理,长度45

mm。

(表1)

在不损坏屏蔽层的情况下,小心地剥去 18 mm 的电缆外绝缘层。

• 对于 1 型电缆,将屏蔽线拉回到外绝缘电缆上,并用 两圈导电胶

带固定。

• 对于 2 型电缆,切断屏蔽纸。先在外部绝缘层上缠一圈导电胶带

(见31);再将排绕线拉回压在导电胶带上(见32);最后用两圈

导电胶带固定排扰线(见33)。

(图5)

按指示顺序将螺母 M 和锁紧圈 Z 套到

电缆上。

电缆直径:

最小55 mm

最大75 mm

电缆准备 Cable preparation

(ill. 5)

Slip nut Mand clamp ring Zin the indi-

cated sequence onto the cable�

Cable diameter:

Min� 5�5mm

Max� 7�5mm

(Tab. 1)

Without damaging the shielding, carefully strip 18 mm of outer

cable insulation�

•For type 1 cable, pull the shield wires back over the outer insu-

lation cable and secure with 2 turns of conductive tape�

•For type 2 cable, cut o the shield paper� Place one turn of

conductive tape over outer insulation (3.1)� Pull back the drain

wire over the conductive tape (3.2) and finally secure the drain

wire with 2 turns of conductive tape (3.3)�

(ill. 6)

Fan out single wires and strip them to

4�5mm�

7 / 24

7

8

B

S

9

观察孔

(图9)

插座端标有 B,插头端标有 S。

触子编号在背面。

触子将从背面插入。

表2/Tab. 2

导线截面积

Conductor cross section 选择器位置

Selector position

mm² AWG

0.14 26 1

0.25 24 2

0.34 22 3

0.51) 20 4

0.751) 18 5

1) 单个主体最多接4组双绞线

1) Maximal four wires per connector

(图8)

根据导线截面积确定选择器位置(参见

表 2 )。

(Ø 1 mm,1.5 mm,3 mm 触子)

注意事项:

压接前后,必须能在观察孔中看到导

线。

(图7)

将导线尽可能深地插入压接套筒。

压接 Crimping

(ill. 7)

Insert wire into the crimping sleeve as

far as it will go�

(Ø 1 mm, 1.5 mm, 3 mm contacts)

Note:

Wire must be visible in the sight hole

before and after crimping�

(ill. 8)

See Tab� 2 for selector position

according to conductor cross section�

(ill. 9)

The female insert is marked with a B,

the pin insert is marked with an S�

The contact numbers are on the back

side�

The contacts will be inserted from back

side�

Sight hole

8 / 24

10

Ethernet/Profinet

CAT5

CAT5e

Interbus

Profibus

Ethernet/Profinet

11

Interbus

DO 1

/DO 2

DI 3

/DI 6

COM 4

Profibus

Line A 1

Line B 2

GND 4

Ethernet 100 MBit & Pronet

TX+ 1

TX- 2

RX+ 3

RX- 6

CANbus

根据总线规范进行单独配置 Individual configuration according to

BUS specifications

插针侧 插座侧

注意

未安装触子的孔位使用堵头封闭

CT-NET-BS,订货号 339589

(图11)

将触子推入有数字的一侧,直到锁止位

置。

表4/Tab. 4

触子编号

Contact No.

对号

Pair No. 颜色 Colour

11白色/橙色 white/orange

21橙色 orange

32白色/绿色 white/green

43蓝色 blue

53白色/蓝色 white/blue

62绿色 green

74白色/棕色 white/brown

8 4 braun brown

配置4对T568B(1 GBit Ethernet &

Pronet )

表3/Tab. 3

触子编号

Contact No.

对号

Pair No. 颜色 Colour

11白色/绿色 white/green

21绿色 green

32白色/橙色 white/orange

43蓝色 blue

53白色/蓝色 white/blue

62橙色 orange

74白色/棕色 white/brown

84棕色 brown

配置4对T568A(1 GBit Ethernet &

Pronet )

(图10)

从支撑块背面看,标有数字一面

触子支撑块的触子排列 Contact arrangement of the contact carrier

(ill. 10)

(Seen from the termination side)

Ethernet & Profinet up to 1 GBit

configuration with 4 pairs T568A

Ethernet & Profinet up to 1 GBit

configuration with 4 pairs T568B

(ill. 11)

Push the contacts through the number

indicated side until they lock into place�

Attention

Unused contact chambers should

be closed with blind plugs

CT-NET-BS, order No� 33�9589

Pin side Socket side

9 / 24

12

A

13

B

C

D

14

MB

15

M

将 CTD-NET 从支撑块中拔出

(图16)

前,请检查插头是否损坏(弯曲、断裂…)

• 轻拉电缆以检查触子是否被牢固地插入支撑块。

决于电缆外径。

注意

完成压接并且组装到触子支撑块中之后,以及在首次连接之

• 将整个装置插入触子支撑块中。

触子支撑块C的平面须与主体内平面贴合,确保位置正确。

• 握住电缆的同时拧紧螺母 M,以避免电缆旋转。

注意

只能用手拧紧螺母(不使用工具)。拧紧螺母后可见的螺纹量取

将螺母 M 推到锁紧圈 B 上。

(图15)

将锁紧圈 B 连接触子支撑块 C。

将引导部分 D 置于触子支撑块 C 的平面上区域上。

(图14)

(图12)

将固定夹A安装在插针主体的凹槽内,然后整体推入模块支撑块。

听到“咔哒”声,即表示已完全插入。

(图13)

注意事项:

关于如何在框架内插入及拆卸模块支撑块,请参阅第22 – 23

页。

触子支撑块安装

注意事项:

如果通用支撑块采用侧面出线的4号外壳,例如CT-CH4-S

(Order No 332404),请联系我们确认。

Assembly in contact carrier

Note:

Please refer to pages 22 – 23 for correct insertion and

removing of carrier in frame�

(ill. 12)

Mount retaining clip Ain the groove of the pin body and push

everything into contact carrier�

A “click” sound is heard once fully inserted�

(ill. 13)

Connect the clamp ring Bto the contact carrier C�

Place the leading part Dover the flat area of the contact

carrier C�

(ill. 14)

•Push nut Mover the clamp ring B�

(ill. 15)

•Insert the whole unit in the contact carrier�

Ensure that the position of the flat part is correct�

•Tighten nut Mwhile holding the cable to avoid any cable rota-

tion�

Attention

Tighten the nut only by hand (without tool)� The amount of

thread that is visible after tightening the nut depends on the

outside diameter of the cable�

Attention

After crimping and assembly into the contact carriers, and

before first connection, check that the plugs are not dam-

aged (bent, broken…)

•Check that contacts are securely inserted in the carrier by gen-

tly pulling the cable�

Clic

Note:

If the universal carrier is used in combination with the size4

housing with side cable entry, for example CT-CH4-S (Order

No� 33�2404), please contact us for clarification�

10 / 24

17

CT-NET-AWZ D

16

1

2

3

4

• 然后推动同芯棒 D ,将触子从背面推

出。

同轴 RG58 1.5 GHz

插座侧

触子孔位,直到听到咔哒声。

3. 再用螺丝刀按下固定夹另一侧。

4. 拔出触子主体

拔出触子

(图17)

• 将退针工具 CT-NET-AWZ 从正面插入

1. 对 CT-Net 主体持续轻微用力。

2. 用螺丝刀按下固定夹一侧。

Extraction of CTD-NET from

carrier

(ill. 16)

1. Apply a slight continuous force on

the CT-Net tube�

2. Use the screwdriver to press the first

clip�

3. Press the second clip with the

screwdriver�

4. Pull out the contact insert

Extraction of contacts

(ill. 17)

•Insert the extraction tool CT-NET-AWZ

from the front side into the contact

insert until you hear a click�

•Then with the drift Dpush out the

contact�

11 / 24

2

1

2133

1

2

3

按指定尺寸调整剥线器 CT-AIWZ/COAX,然后剥去电缆绝缘层。

电缆组装

(图3)

压接钳 CT-CZ/COAX

订货号 333010

电缆准备

剥线器 CT-AIWZ/COAX

订货号 333011

(图2)

(图1)

1模块支撑块/Module carrier

2固定夹/Retaining clip

3插针主体/Socket body

工具准备

2固定夹/Retaining clip

3插座主体/Socket body

序号/Pos. 描述/Description

1模块支撑块/Module carrier

序号/Pos. 描述/Description

插针侧

Coaxial RG58 1.5 GHz

Pin sideSocket side

(ill. 1)

Insulation stripper CT-AIWZ/COAX

Order No� 33�3011

(ill. 2)

Crimping pliers CT-CZ/COAX

Order No� 33�3010

Cable preparation

(ill. 3)

Adjust the insulation stripper CT-AIWZ/COAX according to the

indicated dimensions and strip the cable�

Tools required

12 / 24

5

6

7

8

9

4

A

C

注意事项:

关于如何在框架内插入及拆卸模块支撑块,请参阅第 22 - 23

页。

(图9)

• 将压接套筒压接在指定位置 RG58 =

541 mm 或 RG59 = 648 mm。

(图8)

• 将压接套筒套在屏蔽层上。

(图7)

• 将屏蔽线推到压接外壳上。

(图6)

• 将带线端子插入压接外壳中,直到触

子插入内部绝缘体中。

(图5)

• 将电缆穿过压接套筒C。

注意事项:

压接前后,必须能在观察孔中看

到导线。

(图4)

• 将电缆芯体沿轴向插入触子的压接套

筒直到底部止位。

• 放置压接钳。

• 进行压接。

注意事项:

插座和插头的电缆压接步骤相同。

Cable assembly

Note:

The assembly procedures for

sockets and plugs are identical�

(ill. 4)

•Insert single conductor in axial direc-

tion into crimping sleeve of contact as

far as it will go�

•Place in crimping pliers�

•Perform crimping process�

Note:

Wire must be visible in the sight

hole before and after crimping�

(ill. 5)

•Slip crimp sleeve C onto the cable�

(ill. 6)

•Insert the cable into the crimp hous-

ing until the contact engages in the

inner insulator�

(ill. 7)

•Push the shield wires over the crimp

housing�

(ill. 8)

•Slip the crimp sleeve over the shield�

(ill. 9)

•Crimp the crimp sleeve in the re-

quired position RG58 = 5�41 mm

or RG59 = 6�48 mm�

Note:

Please refer to pages 22 – 23 for correct insertion and

removing of carrier in frame�

13 / 24

A

1

2

3

4

10

11

(图11)

1. 对同轴同轴持续轻微用力。

2. 用螺丝刀按下固定夹一侧。

3. 再用螺丝刀按下固定夹另一侧。

4. 拔出触子主体

拔出触子

(图10)

将固定夹A安装在插针主体上,然后整体

推入模块支撑块。

听到“咔哒”声,即表示已完全插入。

(ill. 10)

Mount retaining clip Aon pin body and

push everything into contact carrier�

A “click” sound is heard once fully

inserted�

Extraction of contacts

(ill. 11)

1. Apply a slight continuous force on

the CT-Net tube�

2. Use the screwdriver to press the first

clip�

3. Press the second clip with the

screwdriver�

4. Pull out the contact insert

Clic

14 / 24

1

3456789 2

13456789 2

序号/

Pos. 描述/Description

1插座/Socket

2固定夹/Retaining clip

3绝缘套/Insulator

4插座/Socket

5垫片/Spacer

6套筒/Sleeve

7橡胶/Rubber

8锁紧圈/Ring

9螺母/Nut

订货号

Order No.

型号

Type

33.0230 CT-B-COAX-RG316/U

33.0231 CT-B-COAX-RG58

插座侧

序号/

Pos. 描述/Description

1插针/Pin

2固定夹/Retaining clip

3绝缘套/Insulator

4插针/Pin

5垫片/Spacer

6套筒/Sleeve

7橡胶/Rubber

8锁紧圈/Ring

9螺母/Nut

订货号

Order No.

型号

Type

33.0630 CT-S-COAX-RG316/U

33.0631 CT-S-COAX-RG58

插针侧

同轴 RG316/RG58 2.4 GHz

Coaxial RG316/RG58 2.4 GHz

Pin side

Socket side

15 / 24

3

4

5

2

1

6

(7)

(6)

(8)

螺母

锁紧圈

橡胶

电缆

(图6)

首先将单个零件(螺母 8、锁紧圈 7 和橡胶 6)按如下方式套在电缆

上。橡胶要靠近电缆一侧的尾端。

注意事项:

插针和插座侧的安装步骤相同!

电缆准备

(图5)

剪线钳

(图4)

螺丝刀尺寸 0

开口扳手压接:9 mm, 10 mm

开口扳手 SMA:8 mm, 11 mm

(图3)

剥线器。

使用适合 RG58、RG316/U、RG174、

RG188 的剥线器。

(图2)

定位块 MES-CZ-CTD0,6-COAX-RG,

订货号 333914

注意事项:

操作说明 MA419

wwwstaublicom/electrical

(图1)

压接钳 CTD-M-CZ,

订货号 333900

工作准备 Tools required

(ill. 1)

Crimping pliers CTD-M-CZ,

Order No� 33�3900

Note:

Operating instructions MA419

www�staubli�com/electrical

(ill. 2)

Locator MES-CZ-CTD0,6-COAX-RG,

Order no� 33�3914

(ill. 3)

Insulation stripper�

Use a suitable insulation stripper for

RG58, RG316/U, RG174, RG188�

(ill. 4)

Screwdriver size 0

Open-end wrench crimp: 9 mm, 10 mm

Open-end wrench SMA: 8 mm, 11 mm

(ill. 5)

Side cutting pliers

Cable preparation

Note:

Pin and socket side assembly procedure is identical!

(ill. 6)

First place single parts (nut 8, ring 7and rubber 6) on the cable as

shown� The rubber is on the side closest to the cable end�

Cable

Rubber

Ring

Nut

16 / 24

7

10 0/-0.2 (mm)

8

(6)

7 0/-0.2 (mm)

9

介电绝缘层

(图9)

将介电绝缘层剥去 7 0/-02 mm。

内层导体准备

橡胶

屏蔽编织层

(图8)

使屏蔽编织层成扇形散开。将橡胶 6 向前移动,直至与护套齐平。

屏蔽编织层均匀贴合在橡胶端面。

屏蔽编织层准备

注意

请勿损坏屏蔽编织层。

外部护套屏蔽编织层

(图7)

将绝缘层(外部护套)剥掉 10 0/-02 mm。这适用于所有类型电缆。

(ill. 7)

Strip the insulator (outer sheath) to 10 0/-0�2 mm� This applies to

all cable types�

Shielding braid Outer sheath

Attention

Do not damage the shielding braid�

Shielding braid preparation

(ill. 8)

Fan out shielding braid� Move rubber 6forward until it is flush with

the sheath� Place shielding braid around the rubber�

Shielding braid

Rubber

Inner conductor preparation

(ill. 9)

Strip the dielectric insulator to 7 0/-0�2 mm�

Dielectric insulator

17 / 24

10

(5)

11

(3)

(4)

12

压接区域

观察孔

介电绝缘层

屏蔽编织层

套筒

注意事项(图12):

压接前后,必须能在观察孔中看到导线。

(图11)

首先,将垫片 4 推到内层导线上,直至接触到介质绝缘层。然后,将

插针或插座 3 置于内层导线上,并将其推至垫片处。

最后,使用压接钳 CT-MC-Z(333380) 按照 MA079 操作说明进行

压接。

使用定位块 MES-CZ-CT0,6-COAX-RG(183808) 进行正确的压接

定位。

对于 RG58 电缆,将压接钳位置调整为“SEL No 4”,对于 RG174

、RG188、RG316/U 电缆,将压接钳位置调整为“SEL No2”。

垫片

内层导线

触子

介电绝缘层

内层导线端口

(图10)

将套筒 5 推到介电绝缘层上,直至接触到屏蔽编织层。

屏蔽套筒安装 Shielding sleeve assembly

(ill. 10)

Push the sleeve 5over the dielectric insulator until it touches the

shielding braid�

Inner conductor termination

Dielectric insulator

Pin or socket

Inner conductor

Spacer

(ill. 11)

First push the spacer 4over the inner conductor until the dielec-

tricum insulator� Then place the pin or socket 3over the inner

conductor and push back until it reaches the ring�

Finally, use the crimping pliers CT-MC-Z (33�3380) to crimp ac-

cording to MA079 operating instructions�

Use locator MES-CZ-CT0,6-COAX-RG (18�3808) for correct

crimp positioning�

For RG58 cables adjust crimping pliers position to “SEL No� 4”,

and “SEL No�2” for RG174, RG188, RG316/U cables�

Note (ill. 12):

The conductor must be visible in the sight hole, before and

after the crimping process�

Sleeve

Shielding braid Dielectric insulator

Sight hole

Crimp area

18 / 24

13

14

(2)

(3) (4)

15

(2)

(1)

(8) SW, A/F 10 mm

SW, A/F 9 mm

max. 1 mm

螺母

绝缘体

触子

(图15)

将触子 1 放在绝缘套 2 上,拧紧螺母 8。拧紧时,触子和螺母之间

最多只允许有 1mm 的间隙。

(图14)

将绝缘座 2 推到触子 3 上,然后放在垫片 4 上。

垫片触子

绝缘套

(图13)

使用剪线钳剪断伸出套筒的编织层。为防止编织层与内层导体接

触,编织层不能伸出套筒外。

编织电线不能伸出套筒。

编织电线

触子绝缘套及触子组装 Assembly of insulator and pin/socket

Braid wires

Braid wires should not project beyond the sleeve.

(ill. 13)

Use the side cutting pliers to cut o any braid wires that project

beyond the sleeve� To prevent contact between braid wires and

inner conductor, braid wires must not project beyond the sleeve�

Insulator

Pin or socket Spacer

(ill. 14)

Push the insulator 2over the pin or socket 3and onto the spacer

4�

(ill. 15)

Place the pin/socket 1over the insulator 2, and screw it onto

the nut 8� When screwed, a maximum 1 mm gap is permitted

between the pin/socket and nut�

Pin/socket

Insulator

Nut

19 / 24

16

(图16)

插入触子并用固定夹锁定。

支撑块内安装已压接触子

注意事项:

关于如何在框架内插入及拆卸模块支撑块,请参阅第 22 - 23

页。

Note:

Please refer to pages 22 – 23 for correct insertion and

removing of carrier in frame�

Assembly of crimped pin and socket contacts in

carrier

(ill. 16)

Insert contacts and lock with the retaining clip�

20 / 24

17 18

SW, A/F 8 mm

SW, A/F 11 mm

19

(图19)

插入触子并用固定夹锁定。

使用开口扳手防止 SMA 触子旋转。

注意事项:

关于如何在框架内插入及拆卸模块支撑块,请参阅第 22 - 23

页。

在支撑块中安装SMA触子

(图17 - 18)

将 SMA 连接器拧到 CombiTac SMA 触子上。最大拧紧扭矩为 1 N

m。

与 SMA 端口组装

同轴 SMA 6 GHz

Coaxial SMA 6 GHz

Assembly with SMA termination

(ill. 17 - 18)

Screw your SMA connector onto the CombiTac SMA contact�

Max� tightening torque 1 N m�

Assembly of SMA pin and socket contacts in

carrier

Note:

Please refer to pages 22 – 23 for correct insertion and

removing of carrier in frame�

(ill. 19)

Insert contacts and lock with the retaining clip�

The hexagon prevents the SMA contacts from rotating�

Other manuals for MA417-1

2

Table of contents

Other Staubli Industrial Equipment manuals