Contents

1INTRODUCTION.........................................................................................................................3

1.1 About this Product............................................................................................................................... 3

1.2 Intended Use ....................................................................................................................................... 4

1.3 Examples of Incorrect Use ...................................................................................................................4

1.4 EU- Declaration of Conformity.............................................................................................................5

1.5 Guarantee Statement .......................................................................................................................... 5

1.6 Technical Data .....................................................................................................................................6

1.7 Ratings Plate........................................................................................................................................6

1.8 Structure and Scope of Applicability of the Operating Instructions......................................................6

1.8.1 Structure ......................................................................................................................................... 6

1.8.2 Target Group ................................................................................................................................... 6

1.8.3 Changes to these Operating Instructions......................................................................................... 7

1.8.4 Retention of these Operating Instructions.......................................................................................7

1.8.5 Locational Restrictions .................................................................................................................... 7

1.8.6 Time Limitations..............................................................................................................................7

1.8.7 Work Space Operation .................................................................................................................... 7

1.8.8 Explanation of the Information and Hazard Notices ........................................................................8

1.8.9 Pictograms in the Operating Instructions and on the Machine ........................................................8

2TRANSPORT POSITION ...........................................................................................................9

2.1 Attaching Hoof Care Crush to a Tractor................................................................................................9

2.2 Driving Hoof Care Crush with a Tractor.............................................................................................. 10

2.3 Removing Hoof Care Crush from the Tractor and Set Down............................................................... 10

3COMMISSIONING /OPERATION......................................................................................... 11

3.1 Appliance View / Main Operating Elements ...................................................................................... 11

3.2 Safety Instructions before Commissioning the Machine .................................................................... 12

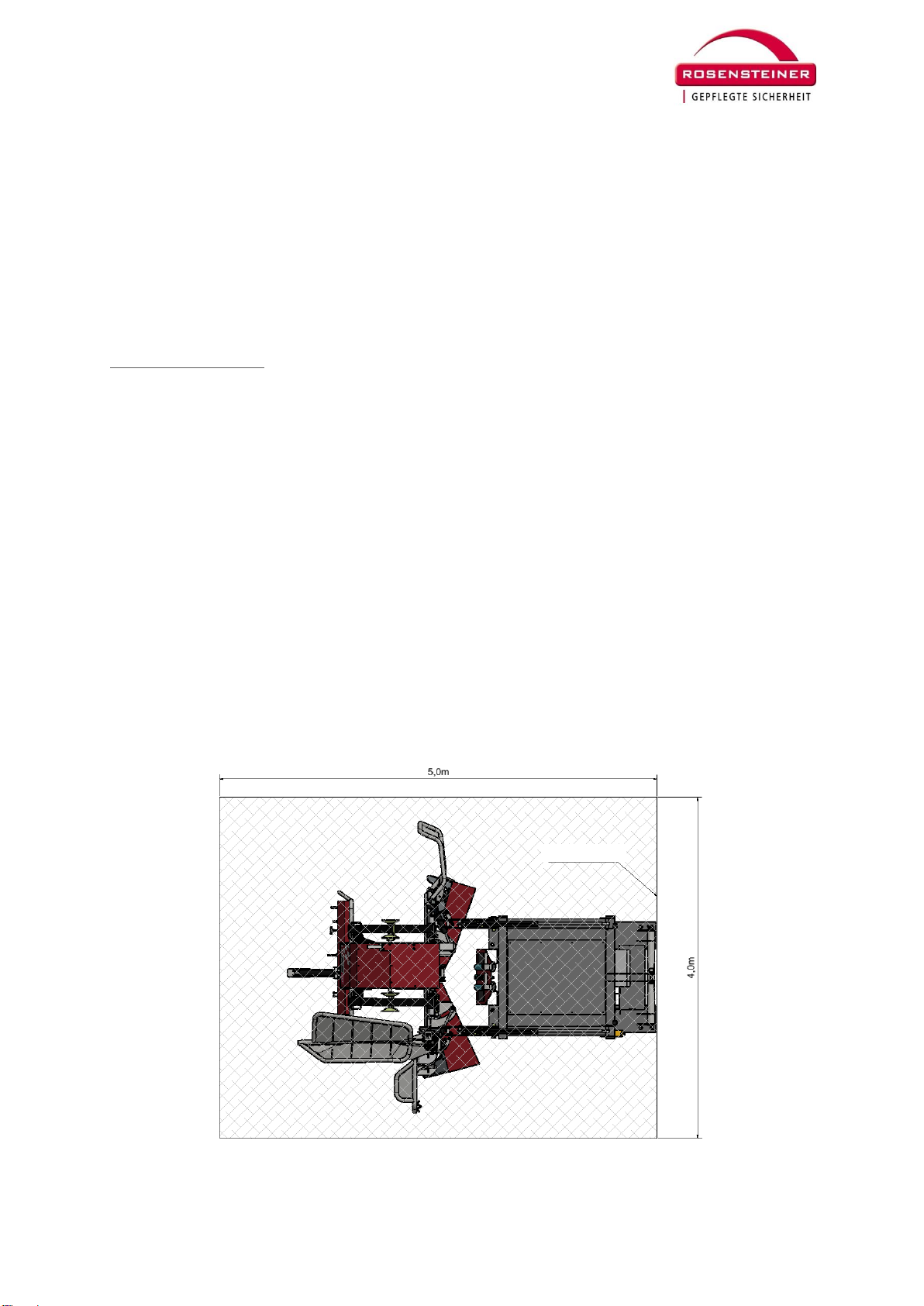

3.3 Hazard Area / Work Area................................................................................................................... 13

3.4 Procedure for Commissioning the Care and Treatment Crush............................................................ 13

3.5 Emergency Program Connection for External Hydraulics ................................................................... 15

4CLEANING ................................................................................................................................. 16

5SERVICING / MAINTENANCE / REPAIR........................................................................... 16

5.1 Safety Instructions............................................................................................................................. 16

5.2 Electrical Hazard ................................................................................................................................ 16

5.3 Servicing and Care ............................................................................................................................. 17

6REPLACEMENT PARTS ......................................................................................................... 17

7PERIODIC INSPECTION......................................................................................................... 18

8SCOPE OF DELIVERY / ACCESSORIES .............................................................................. 19