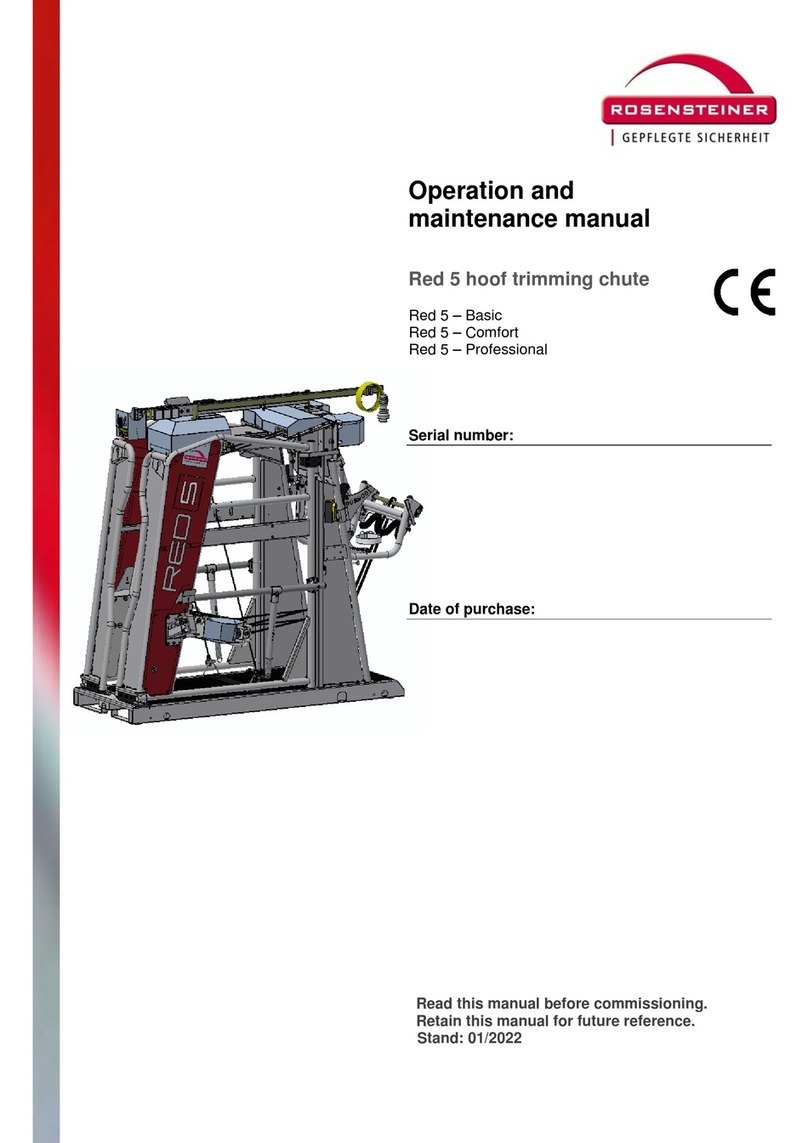

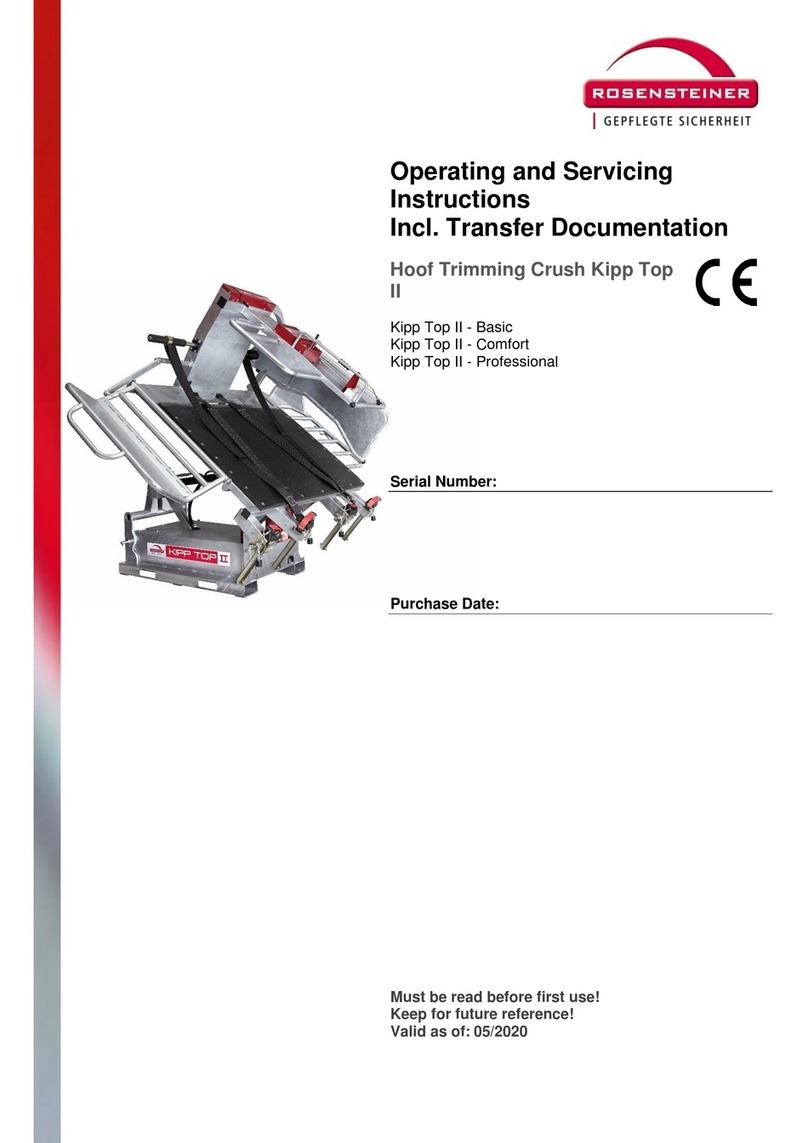

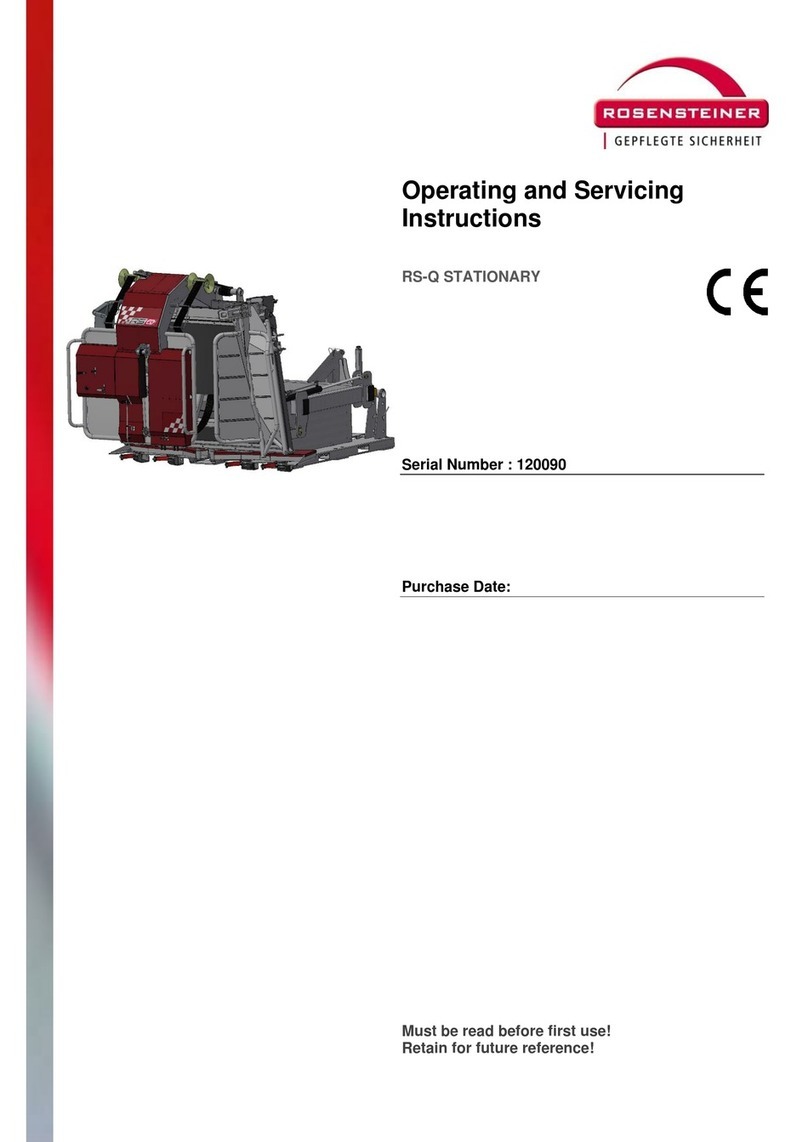

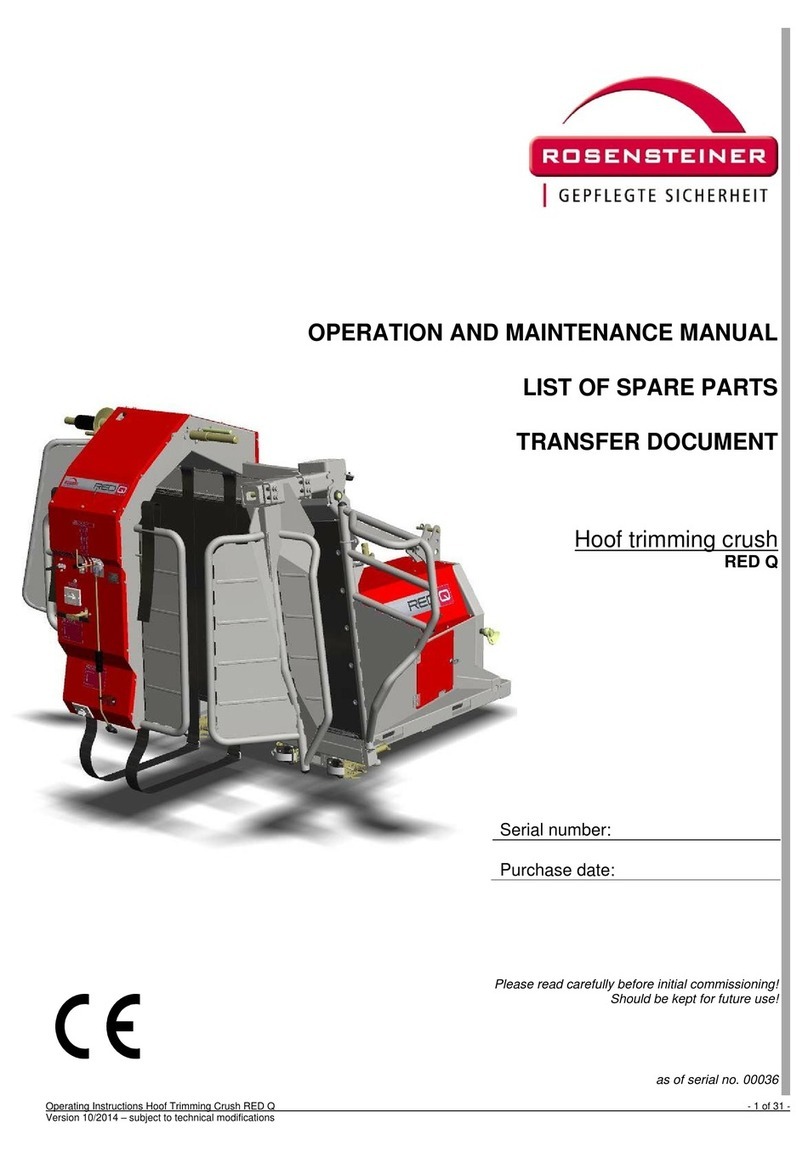

OPERATION AND MAINTENACNE MANUAL

BULL TOP

Operation manual Hoof trimming crush Bull Top - 2 of 13 -

Status 05/2022 –subject to technical modifications

TABLE OF CONTENTS

Table of contents............................................................................................................................................................................... 2

1. Introduction ............................................................................................................................................................................... 3

1.1. About this product.............................................................................................................................................................. 3

1.2. Proper use ......................................................................................................................................................................... 3

1.3. Selected examples of improper use................................................................................................................................... 3

1.4. EU- Declaration of conformity............................................................................................................................................ 4

1.5. Warranty ............................................................................................................................................................................ 4

1.6. Technical specifications..................................................................................................................................................... 4

1.7. Type label .......................................................................................................................................................................... 5

1.8. Structure and scope of the operation manual.................................................................................................................... 5

1.8.1. Structure........................................................................................................................................................................ 5

1.8.2. Target group.................................................................................................................................................................. 5

1.8.3. Changes to this operation manual................................................................................................................................. 5

1.8.4. Storage of this operation manual................................................................................................................................... 5

1.8.5. Spatial limits .................................................................................................................................................................. 5

1.8.6. Time limits ..................................................................................................................................................................... 5

1.8.7. Explanation of the information and safety instructions................................................................................................... 6

1.8.8. Pictograms in the operation manual and on the machine.............................................................................................. 6

2. Transportation........................................................................................................................................................................... 7

2.1. Attaching a hoof trimming crush to a traction engine........................................................................................................ 7

2.2. Transporting a hoof trimming crush using a traction engine .............................................................................................. 7

2.3. Removing a hoof trimming crush from a traction engine and setting it down..................................................................... 7

3. Commissioning / Operation...................................................................................................................................................... 8

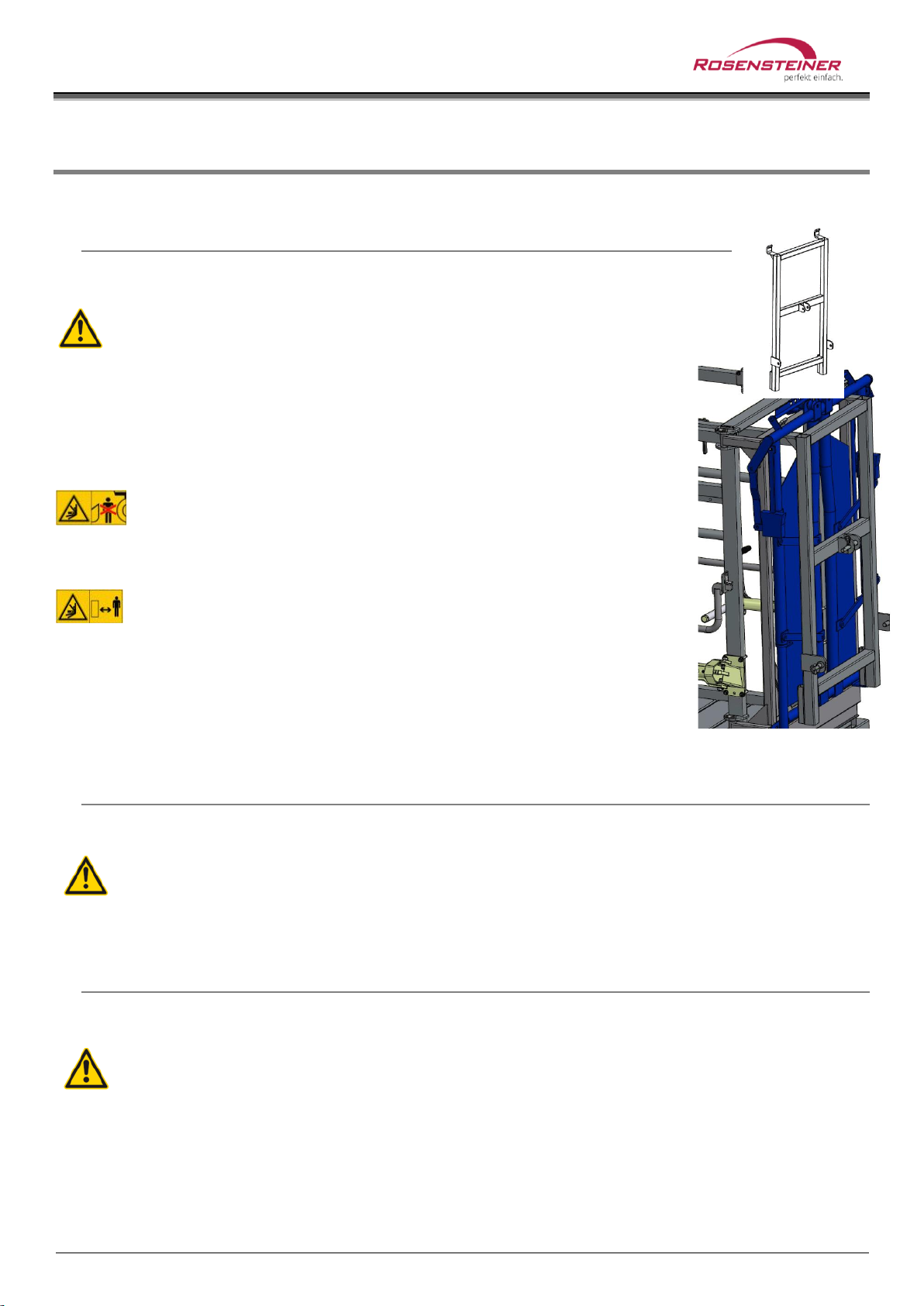

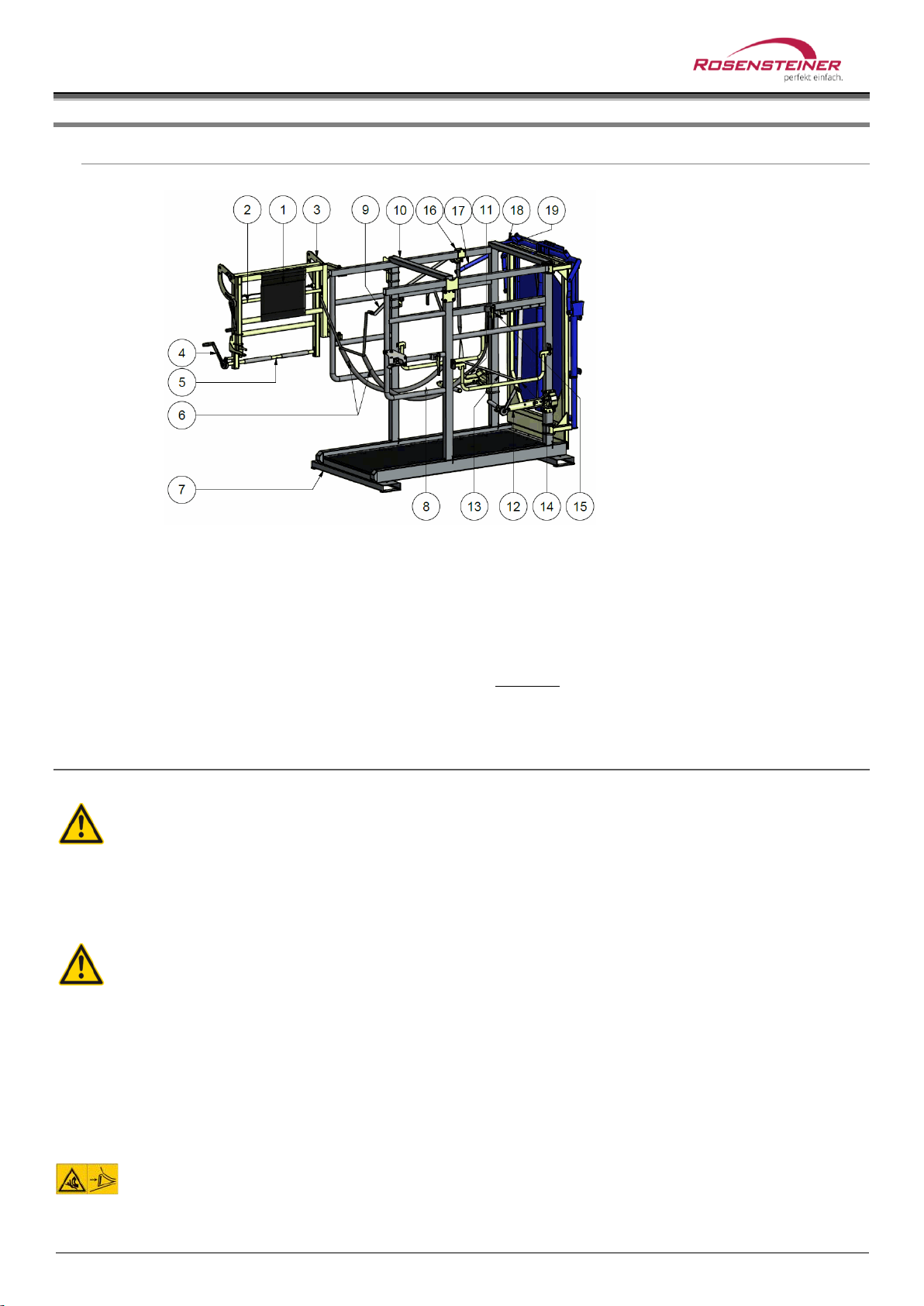

3.1. Device overview / main controls......................................................................................................................................... 8

3.2. Safety instructions before commissioning.......................................................................................................................... 8

3.3. Procedures for the commissioning of the hoof trimming crush .......................................................................................... 9

3.4. Commissioning and operating the headgate.................................................................................................................... 10

3.5. Animal protection / natural motion sequences................................................................................................................. 11

4. Cleaning................................................................................................................................................................................... 11

5. Maintenance / Service / Repairs............................................................................................................................................. 12

5.1. Safety information............................................................................................................................................................ 12

5.2. Electrical hazards............................................................................................................................................................. 12

5.3. Maintenance and care ..................................................................................................................................................... 12

6. Spare parts............................................................................................................................................................................... 13

7. Recurring inspections............................................................................................................................................................. 13

8. Scope of delivery / accessories ............................................................................................................................................. 13