9

STARTING UP

WARNING Pay attention to the mains voltage! The mains voltage must

correspond to the voltage indicated on the technical data identification

place (1).

DANGER Before any intervention on the electrical tool take the plug out

from the socket

BEFORE STARTING THE TOOL

Before starting-up the tool, ensure that:

- the packaging is complete and does not show signs of having been damaged

during storage or transport;

- the tool is complete; check that the number and type of components comply

with that reported in this instruction booklet;

- the power supply and socket outlet can support the load reported in the table

and that indicated on the tool identification plate reproduced;

- the power supply cable and plug are in perfect condition;

- the ON/OFF (2) switch works properly though with the power supply

disconnected;

- all the parts of the tool have been assembled in the proper manner and that

there are no signs of damage;

- the ventilation slots (8) are not obstructed;

- the tool must be connected to a suitable and efficient aspiration device.

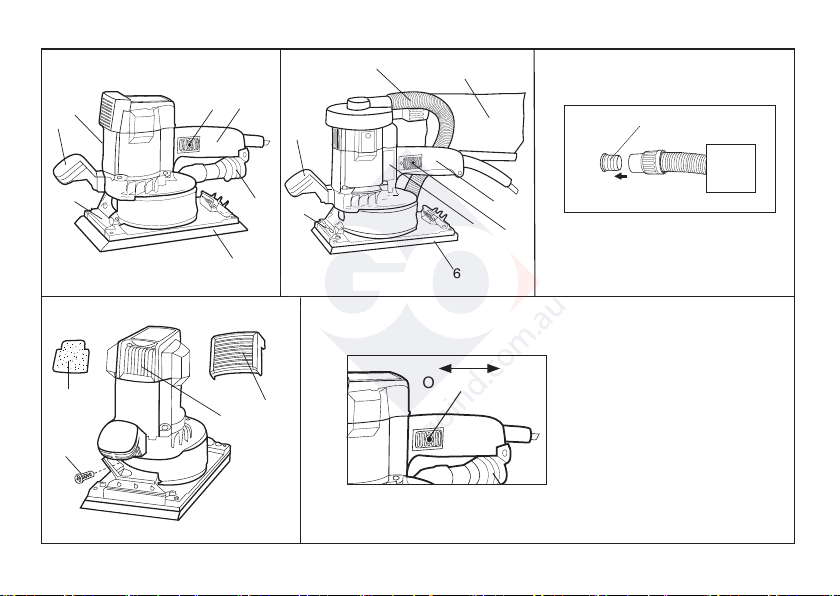

ASSEMBLY/REPLACEMENT OF THE ABRASIVE PAPER SHEET

ASSEMBLY:

ABRASIVE VELCRO PAPER

- Press the velcro backed abrasive paper in position, ensuring that the holes in

the paper coincide with the suction holes in the prefored rubber plate (6);

- make sure that there is no dust or other matter on the prefored rubber plate (6).

ABRASIVE PAPER

- insert the abrasive paper clamping lever (7) by pressing the lever release;

- repeat this operation on the opposite side of the plate, keeping the abrasive

paper taut and checking that the edges are parallel with the edges of the

prefored rubber plate (6) before releasing the paper clamping lever (7);

Sound pressure level / Sound power level 3 axis vibration level

LPA LWA Uncertainty ah Uncertainty

dB(A) m/s2

SL42AES 86 97 3 5,75 1,5

INFORMATOIN NOISE / MEAN ACCELERATION VALUE

The tools are suppressed in accordance for the prevention and elimination of radio

disturbances measured in accordance with standard: EN 62841

DANGER The indicate measurements refer to new power tools.

Daily usa causes the noise and vibration values to change.

Displayed emission values are comparative and are to be employed for

a provisional assessment of the operator’s risk exposure during the work period.

Appropriate evaluation of work period must also include tool’s idle and stop

periods. These emission values represent the tool’s main applications.

If the tool is used for other applications, with other accessories, or if it does not

undergo regular maintenance, emission values can significantly increase

during operations.

Use hearing protection!

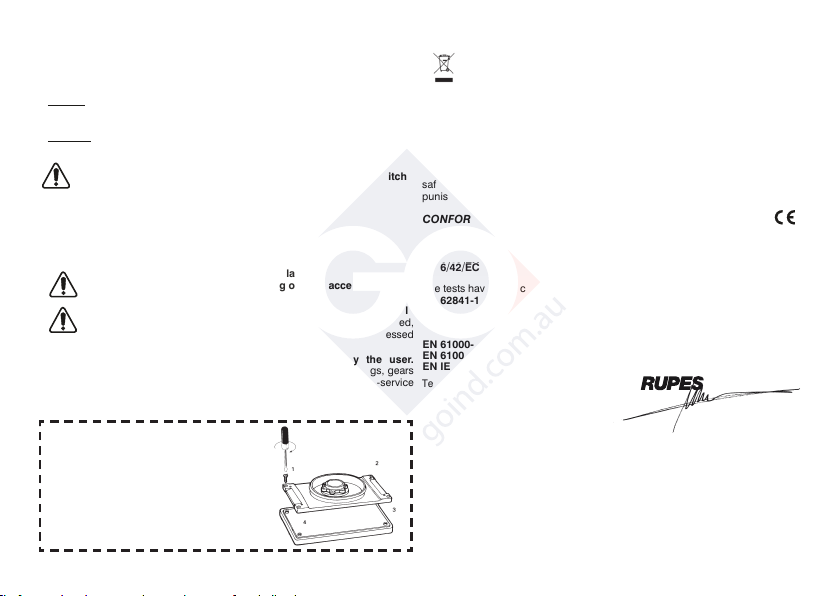

PARTS OF THE TOOL

1 - Technical data identification label

2 - ON/OFF switch

3 - Speed control

4 - Dust extraction flow control

5 - Auxiliary handle

6 - Rubber drilled velcroed plate,

7 - Paper clamping lever

8 - Motor ventilation slots

9 - 29 mm Ø suction port

10 - Heat protection

11 - Heat protection fixing screws

9

STARTING UP

WARNING Pay attention to the mains voltage! The mains voltage must

correspond to the voltage indicated on the technical data identification

place (1).

DANGER Before any intervention on the electrical tool take the plug out

from the socket

BEFORE STARTING THE TOOL

Before starting-up the tool, ensure that:

- the packaging is complete and does not show signs of having been damaged

during storage or transport;

- the tool is complete; check that the number and type of components comply

with that reported in this instruction booklet;

- the power supply and socket outlet can support the load reported in the table

and that indicated on the tool identification plate reproduced;

- the power supply cable and plug are in perfect condition;

- the ON/OFF (2) switch works properly though with the power supply

disconnected;

- all the parts of the tool have been assembled in the proper manner and that

there are no signs of damage;

- the ventilation slots (8) are not obstructed;

- the tool must be connected to a suitable and efficient aspiration device.

ASSEMBLY/REPLACEMENT OF THE ABRASIVE PAPER SHEET

ASSEMBLY:

ABRASIVE VELCRO PAPER

- Press the velcro backed abrasive paper in position, ensuring that the holes in

the paper coincide with the suction holes in the prefored rubber plate (6);

- make sure that there is no dust or other matter on the prefored rubber plate (6).

ABRASIVE PAPER

- insert the abrasive paper clamping lever (7) by pressing the lever release;

- repeat this operation on the opposite side of the plate, keeping the abrasive

paper taut and checking that the edges are parallel with the edges of the

prefored rubber plate (6) before releasing the paper clamping lever (7);

Sound pressure level / Sound power level 3 axis vibration level

LPA LWA Uncertainty ah Uncertainty

dB(A) m/s2

SL42AES 86 97 3 5,75 1,5

INFORMATOIN NOISE / MEAN ACCELERATION VALUE

The tools are suppressed in accordance for the prevention and elimination of radio

disturbances measured in accordance with standard: EN 62841

DANGER The indicate measurements refer to new power tools.

Daily usa causes the noise and vibration values to change.

Displayed emission values are comparative and are to be employed for

a provisional assessment of the operator’s risk exposure during the work period.

Appropriate evaluation of work period must also include tool’s idle and stop

periods. These emission values represent the tool’s main applications.

If the tool is used for other applications, with other accessories, or if it does not

undergo regular maintenance, emission values can significantly increase

during operations.

Use hearing protection!

PARTS OF THE TOOL

1 - Technical data identification label

2 - ON/OFF switch

3 - Speed control

4 - Dust extraction flow control

5 - Auxiliary handle

6 - Rubber drilled velcroed plate,

7 - Paper clamping lever

8 - Motor ventilation slots

9 - 29 mm Ø suction port

10 - Heat protection

11 - Heat protection fixing screws

9

STARTING UP

WARNING Pay attention to the mains voltage! The mains voltage must

correspond to the voltage indicated on the technical data identification

place (1).

DANGER Before any intervention on the electrical tool take the plug out

from the socket

BEFORE STARTING THE TOOL

Before starting-up the tool, ensure that:

- the packaging is complete and does not show signs of having been damaged

during storage or transport;

- the tool is complete; check that the number and type of components comply

with that reported in this instruction booklet;

- the power supply and socket outlet can support the load reported in the table

and that indicated on the tool identification plate reproduced;

- the power supply cable and plug are in perfect condition;

- the ON/OFF (2) switch works properly though with the power supply

disconnected;

- all the parts of the tool have been assembled in the proper manner and that

there are no signs of damage;

- the ventilation slots (8) are not obstructed;

- the tool must be connected to a suitable and efficient aspiration device.

ASSEMBLY/REPLACEMENT OF THE ABRASIVE PAPER SHEET

ASSEMBLY:

ABRASIVE VELCRO PAPER

- Press the velcro backed abrasive paper in position, ensuring that the holes in

the paper coincide with the suction holes in the prefored rubber plate (6);

- make sure that there is no dust or other matter on the prefored rubber plate (6).

ABRASIVE PAPER

- insert the abrasive paper clamping lever (7) by pressing the lever release;

- repeat this operation on the opposite side of the plate, keeping the abrasive

paper taut and checking that the edges are parallel with the edges of the

prefored rubber plate (6) before releasing the paper clamping lever (7);

Sound pressure level / Sound power level 3 axis vibration level

LPA LWA Uncertainty ah Uncertainty

dB(A) m/s2

SL42AES 86 97 3 5,75 1,5

INFORMATOIN NOISE / MEAN ACCELERATION VALUE

The tools are suppressed in accordance for the prevention and elimination of radio

disturbances measured in accordance with standard: EN 62841

DANGER The indicate measurements refer to new power tools.

Daily usa causes the noise and vibration values to change.

Displayed emission values are comparative and are to be employed for

a provisional assessment of the operator’s risk exposure during the work period.

Appropriate evaluation of work period must also include tool’s idle and stop

periods. These emission values represent the tool’s main applications.

If the tool is used for other applications, with other accessories, or if it does not

undergo regular maintenance, emission values can significantly increase

during operations.

Use hearing protection!

PARTS OF THE TOOL

1 - Technical data identification label

2 - ON/OFF switch

3 - Speed control

4 - Dust extraction flow control

5 - Auxiliary handle

6 - Rubber drilled velcroed plate,

7 - Paper clamping lever

8 - Motor ventilation slots

9 - 29 mm Ø suction port

10 - Heat protection

11 - Heat protection fixing screws

9

STARTING UP

WARNING Pay attention to the mains voltage! The mains voltage must

correspond to the voltage indicated on the technical data identification

place (1).

DANGER Before any intervention on the electrical tool take the plug out

from the socket

BEFORE STARTING THE TOOL

Before starting-up the tool, ensure that:

- the packaging is complete and does not show signs of having been damaged

during storage or transport;

- the tool is complete; check that the number and type of components comply

with that reported in this instruction booklet;

- the power supply and socket outlet can support the load reported in the table

and that indicated on the tool identification plate reproduced;

- the power supply cable and plug are in perfect condition;

- the ON/OFF (2) switch works properly though with the power supply

disconnected;

- all the parts of the tool have been assembled in the proper manner and that

there are no signs of damage;

- the ventilation slots (8) are not obstructed;

- the tool must be connected to a suitable and efficient aspiration device.

ASSEMBLY/REPLACEMENT OF THE ABRASIVE PAPER SHEET

ASSEMBLY:

ABRASIVE VELCRO PAPER

- Press the velcro backed abrasive paper in position, ensuring that the holes in

the paper coincide with the suction holes in the prefored rubber plate (6);

- make sure that there is no dust or other matter on the prefored rubber plate (6).

ABRASIVE PAPER

- insert the abrasive paper clamping lever (7) by pressing the lever release;

- repeat this operation on the opposite side of the plate, keeping the abrasive

paper taut and checking that the edges are parallel with the edges of the

prefored rubber plate (6) before releasing the paper clamping lever (7);

Sound pressure level / Sound power level 3 axis vibration level

LPA LWA Uncertainty ah Uncertainty

dB(A) m/s2

SL42AES 86 97 3 5,75 1,5

INFORMATOIN NOISE / MEAN ACCELERATION VALUE

The tools are suppressed in accordance for the prevention and elimination of radio

disturbances measured in accordance with standard: EN 62841

DANGER The indicate measurements refer to new power tools.

Daily usa causes the noise and vibration values to change.

Displayed emission values are comparative and are to be employed for

a provisional assessment of the operator’s risk exposure during the work period.

Appropriate evaluation of work period must also include tool’s idle and stop

periods. These emission values represent the tool’s main applications.

If the tool is used for other applications, with other accessories, or if it does not

undergo regular maintenance, emission values can significantly increase

during operations.

Use hearing protection!

PARTS OF THE TOOL

1 - Technical data identification label

2 - ON/OFF switch

3 - Speed control

4 - Dust extraction flow control

5 - Auxiliary handle

6 - Rubber drilled velcroed plate,

7 - Paper clamping lever

8 - Motor ventilation slots

9 - 29 mm Ø suction port

10 - Heat protection

11 - Heat protection fixing screws

Sound pressure level Uncertainty Sound power level Vibration level [m/s2]

[dB(A)] [dB(A)] [dB(A)] 3 axis Uncertainty

LpA K LwA ahK

SSPF 84 3 95 3.80 1,5

SSCA 84 3 95 3.80 1.0

1 - Étiquette d’identification

2 - Interrupteur de mise en marche - arrêt

3 - Poignée

4 - Poignée auxiliaire

5 - Vis de fixation poignée auxiliaire

6 - Plaque caoutchou perforée a velcro, plaque caoutchou perforée,

plaque caoutchou standard (selon le modèle)

7 - Levier de blocage du papier

8 - Outil perforateur de papier abrasif (optional)

9 - Grille porte-filtre (SSPF - SSCA)

10 - Filter anti-poussière (SSPF - SSCA)

11 - Fentes pour ventilation moteur

12 - Bouche d’aspiration Ø 29 mm

13 - Tuyau de raccord plaque - turbine d’aspiration (SSCA)

14 - Sac à poussière (SSCA )

REPLACEMENT:

ABRASIVE VELCRO PAPER

- Used abrasive paper can be removed by simply tearing them off;

- new velcro abrasive paper are mounted (see “ASSEMBLY”)

ABRASIVE PAPER

- Lift the paper clamping lever (7) by pressing the release device and remove

the used abrasive paper;

- apply the new abrasive paper following the instructions in the chapter on

“INSERTING THE ABRASIVE PAPER”.

Start the tool and check that there are no unusual vibration, no dismatching

movement of the abrasive disc. Otherwise switch-off the tool immediately and

eliminate the cause.

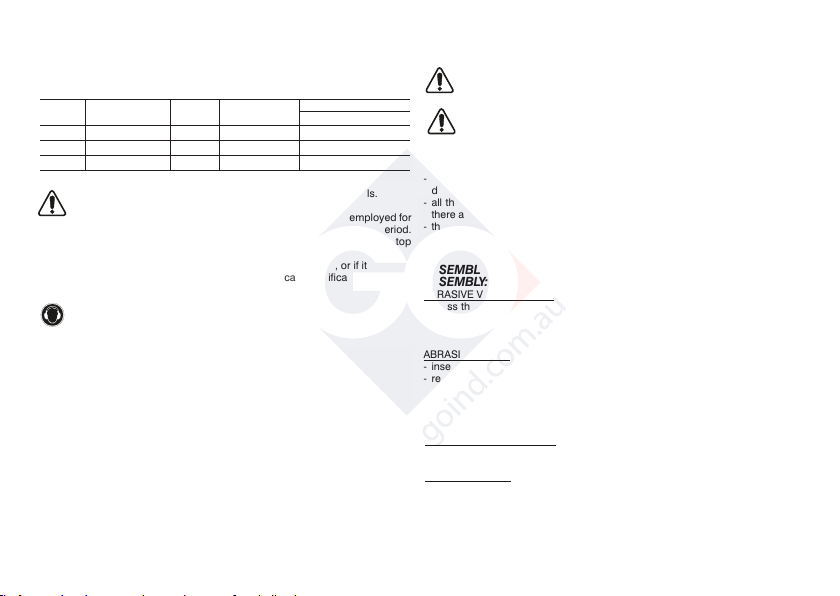

STARTING AND STOPPING

- Starting: push the slide of the ON/OFF (2) forward; if the tool is to be locked in

the ON position, apply pressure to the front part of the slide switch at the same

time.

- Stopping: release the slide ON/OFF (2).

If locked, press the ON/OFF switch in the lower partdownwards and release it

in the OFF position.

WARNING: after an interruption of the electrical energy, if the

ON/OFF switch is inserted, it is necessary to release the switch

(see Stopped).

ELECTRONIC RPM REGULATION

The rpm can be adjusted by rotating the wheel speed adjustment wheel (3)

located on the rear of the tool. The choice of speed depends on the

characteristics of the abrasive paper disc and the material to be worked.

ADJUSTING THE DUST EXTRACTION FLOW

The extraction flow can be adjusted by rotating the control flow adjustment

control (4).

ACCESSORIES

- Sheets of abrasive paper with suction holes.

- Sheets of abrasive paper with suction holes 400x70 mm.

MAINTENANCE

Immediately replace the damaged rub plate.

Optimal results are achieved only using original accessories.

All maintenance operations are carried out with the power supply

disconnected. At the end of each work session, or when required,

remove any dust from the body of the tool using a jet of compressed

air, paying particular attention to the motor ventilation slots.

No other maintenance operations must be undertaken by the user.

Maintenance and cleaning of the inner parts, like brushes, ball bearings, gears

etc. or others, must be carried out only by an authorized customer-service

workshop or on www.rupes.com.

Use only the original RUPES parts or accessories.

DISPOSAL (WEEE DIRECTIVE)

For EU countries only: According to the European Directive on Waste

from electrical and electronic equipment and its implementation in

conformity with national standards, exhausted electrical equipment

EN 50581: 2012

Vermezzo (MI), 01/01/2015

IL PRESIDENTE

G. Valentini

S.p.A

must be collected separately, in order to be recycled in an environmentally friendly

way. The product, when it reaches the end of its life, must not be dispersed in the

environment or thrown away as household waste. It must be disposed at

authorized recycling centres (contact your local authorities to know where to

dispose of the product according to the law). The correct disposal of the product

contributes to the health and preservation of the environment.

Illegal disposal of the product will entail penalties against the offenders.

Disposing of the product correctly contributes to protecting human health and

safeguarding the environment. Any illegitimate disposal of the product will be

punishable by law .

CONFORMITY DECLARATION

We declare on our responsability that the hand-held motor operated tool, which

is mentioned in the present operating manual, is in comformity with the Essential

Requirements of Safety of the following Directives:

2006/42/EU; 2004/108/EU; 2011/65/EU.

The tests have been carried out in accordance with following Standards:

EN 60745-1: 2009 + A11: 2010

EN 60745-2-4:2009+ A11:2011.

EN 55014-1: 2006 + A1: 2009 + A2: 2011

EN 55014-2: 1997 + A1: 2001 + A2: 2008

EN 61000-3-2: 2006 + A1: 2009 + A2: 2009

EN 61000-3-3: 2008

Technical file at:

RUPES S.p.A.

Via Marconi, 3A

20080 VERMEZZO (Mi) - Italy

TYPE

INSULATION CLASS

ABSORBET POWER W

ELECTRONIC OVERLOAD

ELECTRONIC SPEED CONTROL

n0 Empty RPM /min

Ø ORBITAL mm

VELCROED DRILLED RUBBER PLAT

PLATE DIMENSION mm

VACUUM SISTEM (*)

DUST EXTRACTION FLOW CONTROL

WEIGHT kg according to EPTA-Procedure 01/2003

SL42AES

/ II

550

•

•

3.000÷7.000

4,8

•

400 x 70

CENTRALIZED

YES

2,9

8

TECHNICAL DATA

GENERAL WARNINGS

All instructions concerning safety and the prevention of industrial accidents

can be found in file SAFETY INSTRUCTIONS, that forms integral part of this

documentation. This INSTRUCTION MANUAL only contains additional

information that specifically explain how to use the machine.

SPECIFIC USE

This electrical tool is designed to operate as a sander, suitable for dry

sanding of wood, plastic, metal, plaster and painted surfaces. Read all

safety warnings, instructions, illustrations and specifications supplied with

this tool. Failure to respect all instructions indicated below can cause an

electric shock, fire and/or a serious accident. Grinding, polishing, metal

brushing or cutting operations are not recommended with this tool.

Failure to follow all the instructions provided below may result in serious injuries.

Do not use accessories that are not specifically designed for the intended

use of the tool or that have not been recommended by the manufacturer.

The fact that an accessory can be fixed to the tool does not imply that it can be

used safely.

The rated speed of accessories must be at least equivalent to the maximum

speed of the tool. If operated at a greater speed than the rated one,

accessories may break and cause the ejection of chips.

The external diameter and thickness of accessories must be appropriate to

guarantee the protection and safety of the tool. Accessories with incorrect

dimensions cannot be adequately protected or controlled.

The conformation of the accessories must be correctly adapted to the

spindle of the tool. The accessories equipped with holes of the shaft that

do not correspond to the assembly components on the tool, will not remain

in balance, they will vibrate excessively and can cause a loss of control.

Do not use a damaged accessory. If the tool or accessory has suffered a fall,

examine any damages or install an accessory that is no damaged. After

examining and installing an accessory, all persons present, must keep a safe

distance from the rotating accessory and operate the tool at maximum empty

speed for one minute. Damaged accessories generally break during this test

period.

Use the electric tool only for dry sanding. The use of water or other liquid

coolants can cause electrocution or an electric shock.

Do not operate the electrical tool in the proximity of flammable material. The

sparks generated by sanding metal material can ignite these materials.

Avoid overheating the material being processed and in sanding.

Before taking a break, always empty the container of dust. The abrasion dust

in the dust collection bag or in the dust intake filter can set on fire under

unfavourable conditions, such as a trail of sparks produced while sanding the

metal.

Connect the tool to a device suitable dust extraction. To protect the health

wear masks

Use clamps to secure the work piece. Under no circumstances should you

hold the work piece with one hand and the electrical tool with the other hand,

while it is being used. By securing the work piece with clamps, you can have

both hands free to better operate the electrical tool.

The values shown are based on a nominal voltage of 230V/50Hz. In the case of voltages and frequencies of different power values may vary.

Refer to the label technical specifications to the nominal values of the tool.

(*) The tool must be connected to a suitable dust extraction system (not supplied).