9

GENERAL WARNINGS

The tool must be connected to a suitable dust extraction system

(not supplied).

SAFETY AND ACCIDENT PREVENTION INSTRUCTIONS

The safety and accident prevention instructions are reported in the

“SAFETY INSTRUCTION” booklet which forms an integral part of

these documents; the operating instructions indicate the

additional information required specifically for use of the tool.

Never use the tools without the safety guards.

Any operations carried out on the tool must be effected with the

tool disconnected.

Before starting the tool, ensure that it is held tightly and not in

contact with the work surface.

The electric tool must be connect to a suitable dust extraction unit

and applicable safety regulations must be observed if dusts

dangerous to health are likely to occur during sanding.

Due to risks that may arise during sanding, we recommend the

constant use of P.S.D. (personal safety devices such as gloves,

headphones, goggles, face masks, etc.) according to laws in

force to prevent or reduce accident probability.

Warning! Carry out the lubrication process outlined in the

maintenance paragraph. The appliance continues to work for a

few seconds after it has been switched off.

CORRECT USAGE

The sanders are designed for sanding wood, plastic, composite

materials, paint/varnish, filling material and similar materials.

Metal and materials with an asbestos content must not be

processed with these tools.

The tools must not be damp nor operated in a damp environment

for electrical safety reasons.

The tools may only be used for dry sanding.

Make sure the work piece is sufficiently fastened.

In the event of improper use, the user is fully liable for any

damages or accidents.

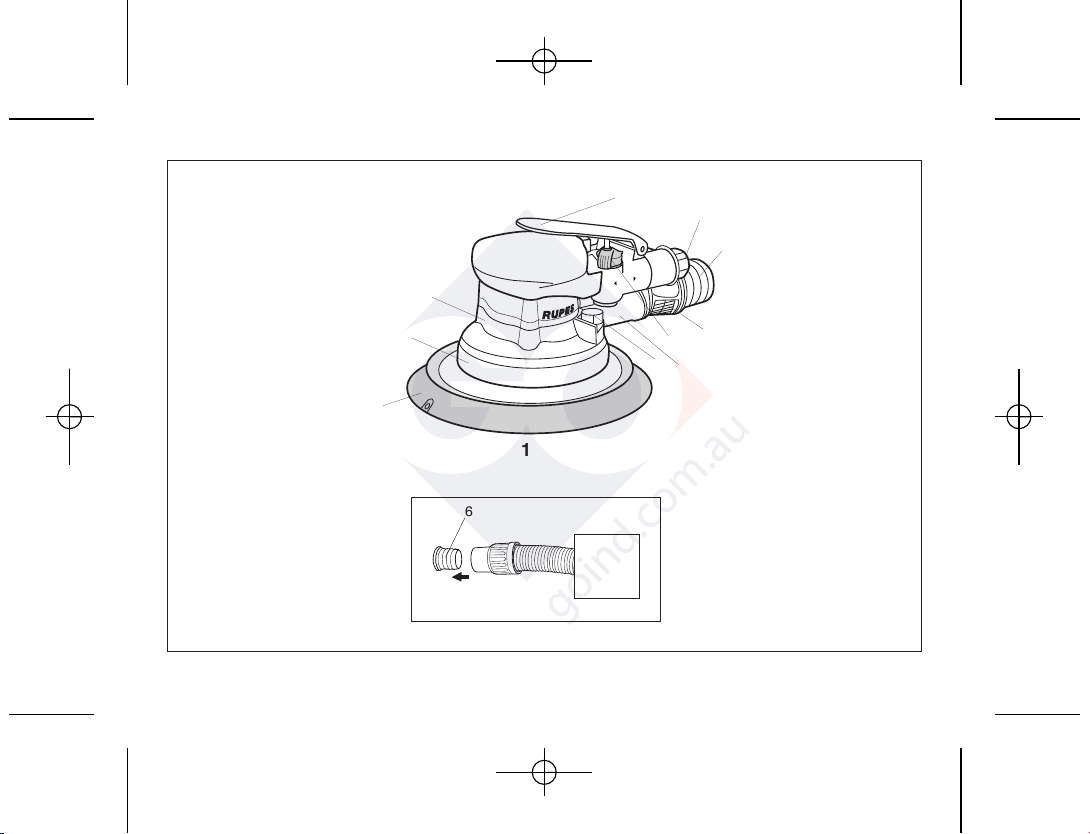

PARTS OF THE TOOL

1 - Identification plate

2 - Compressed air on/off lever

3 - Speed control

4 - Tool body

5 - Compressed air connection

6 - 29 mm. int. Ø suction pipe connection

7 - Dust extraction flow control

8 - Suction cowling

9 - Backing pad

10 - Backing pad release button

STARTING UP

Before starting-up the tool, ensure that:

- the packaging is complete and does not show signs of having

been damaged during storage or transport;

- the tool is complete; check that the number and type of components

comply with that reported in this instruction booklet;

- the available compressed air production and distribution plant is

capable of satisfying the requirements reported on the tool’s

identification plate.

ASSEMBLING THE TOOL

Assemble the compressed air connection (not supplied) by

screwing it into its seating (5).

COMPRESSED AIR CONNECTION

The tool is supplied without the compressed air connection; the

user can use either a quick release coupling or hose type

connection according to his needs, purke they have an hole of air

passing mm. 8. In the latter case the air line must be fixed to the

nozzle by a hose clip.