Table of contents page

2 / 24

1. User information 3.............................................................

1.1 Information about the instructions for the appliance 3..........................

1.2 Symbols in front of the text 3...............................................

1.3 Warning signs, danger symbols and information symbols 3.....................

1.4 Documenting the type plate data 4..........................................

2. Safety instructions 4...........................................................

3. Transport, Setup 5.............................................................

3.1 Inspection for transport damages 5..........................................

3.2 Transport 5..............................................................

3.3 Setup 5..................................................................

3.3.1 Observe the setup regulations 5.............................................

3.3.2 Choosing the setup location 6...............................................

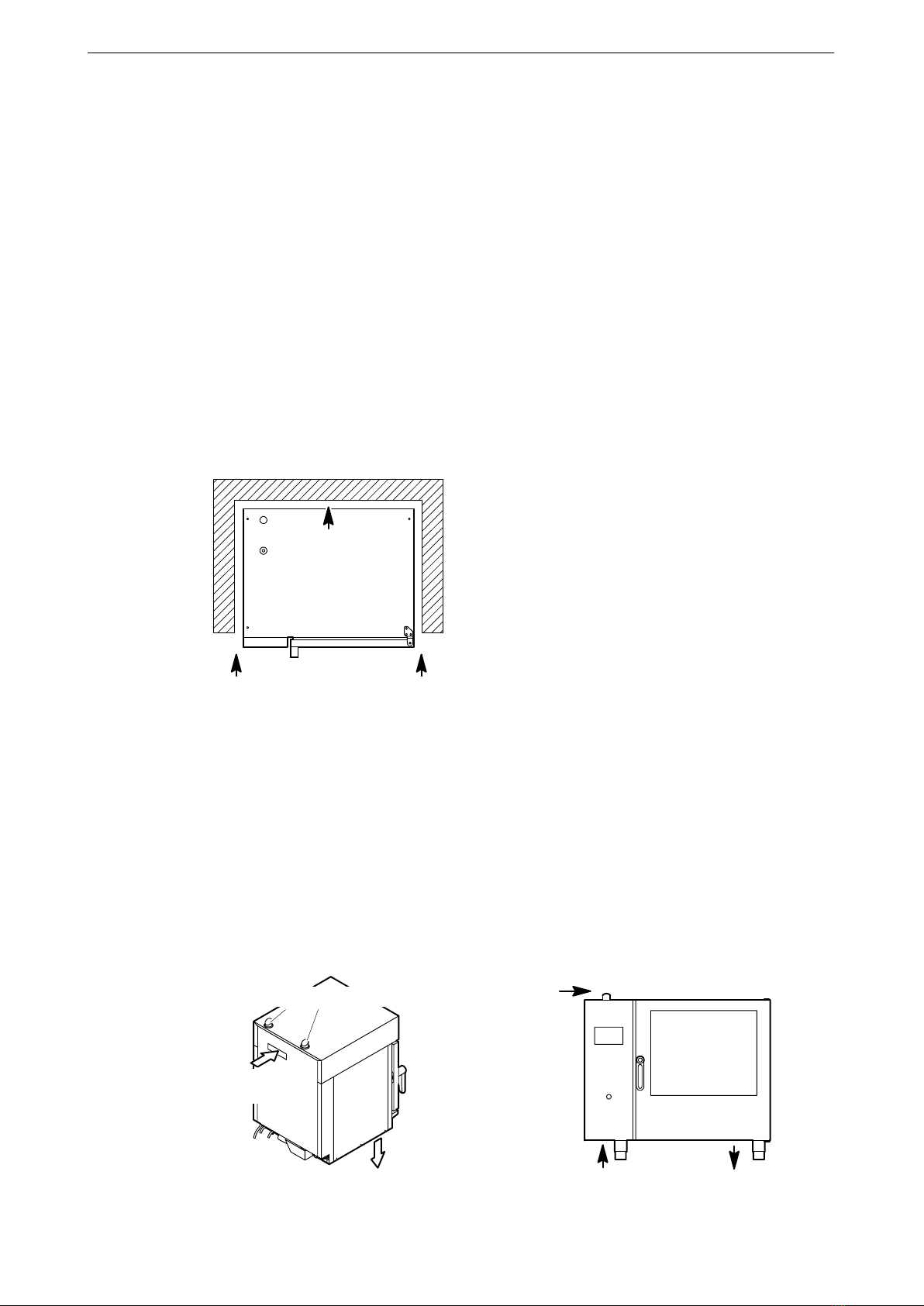

3.3.3 Maintain clearances 6......................................................

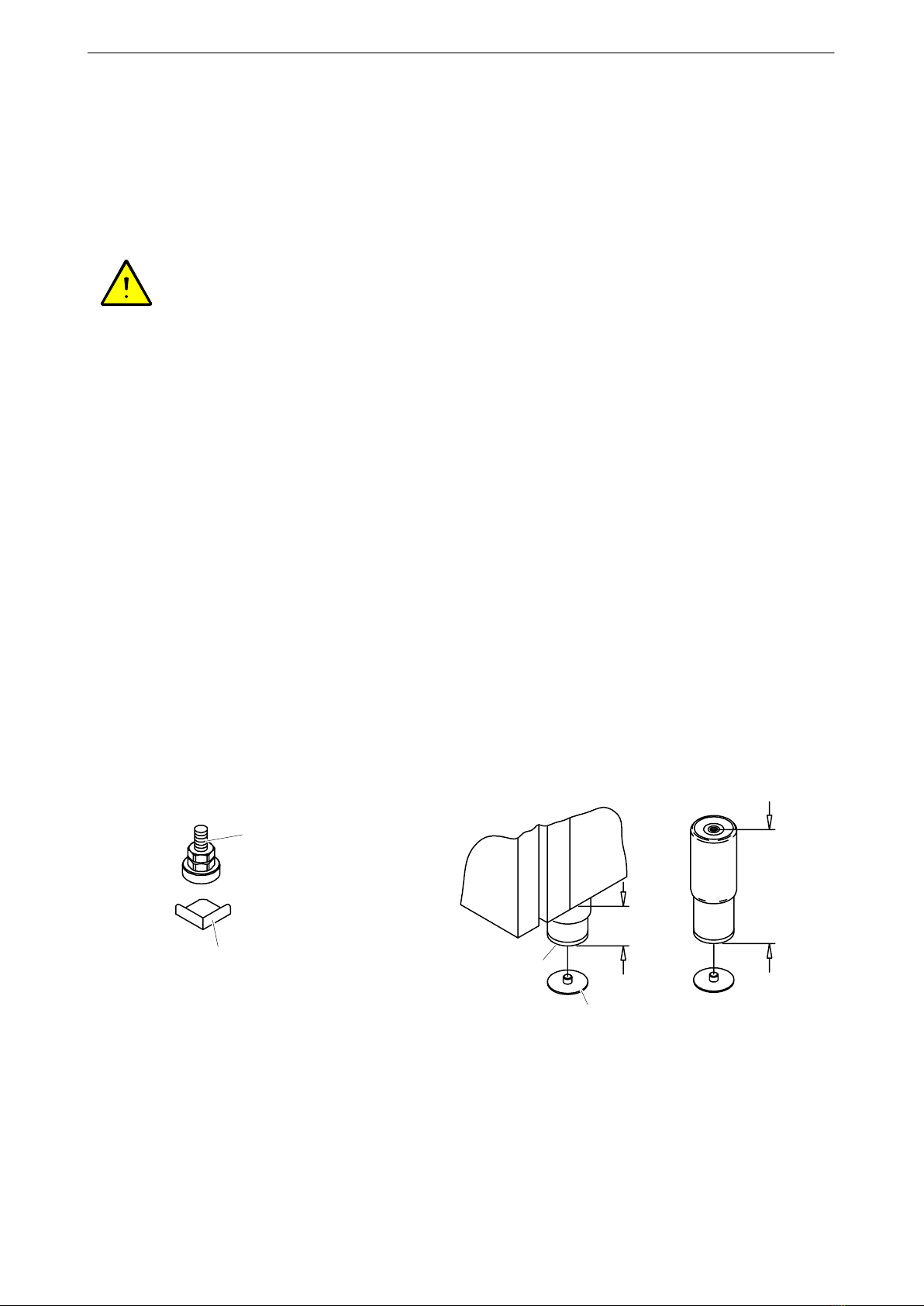

3.3.4 Setup on tables and support structures 7.....................................

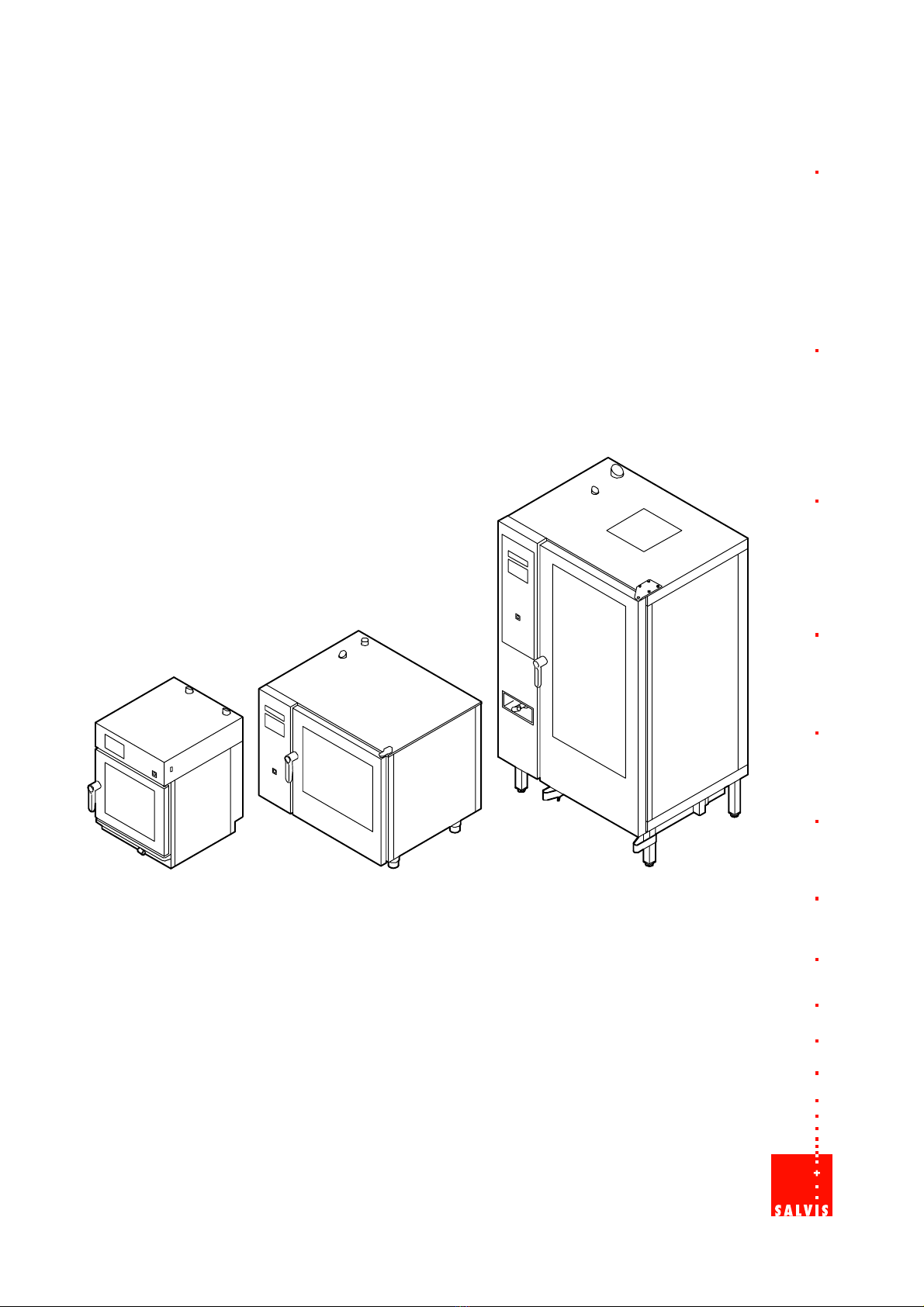

3.3.6 Setup of the upright appliances, e.g. Type 2011 8..............................

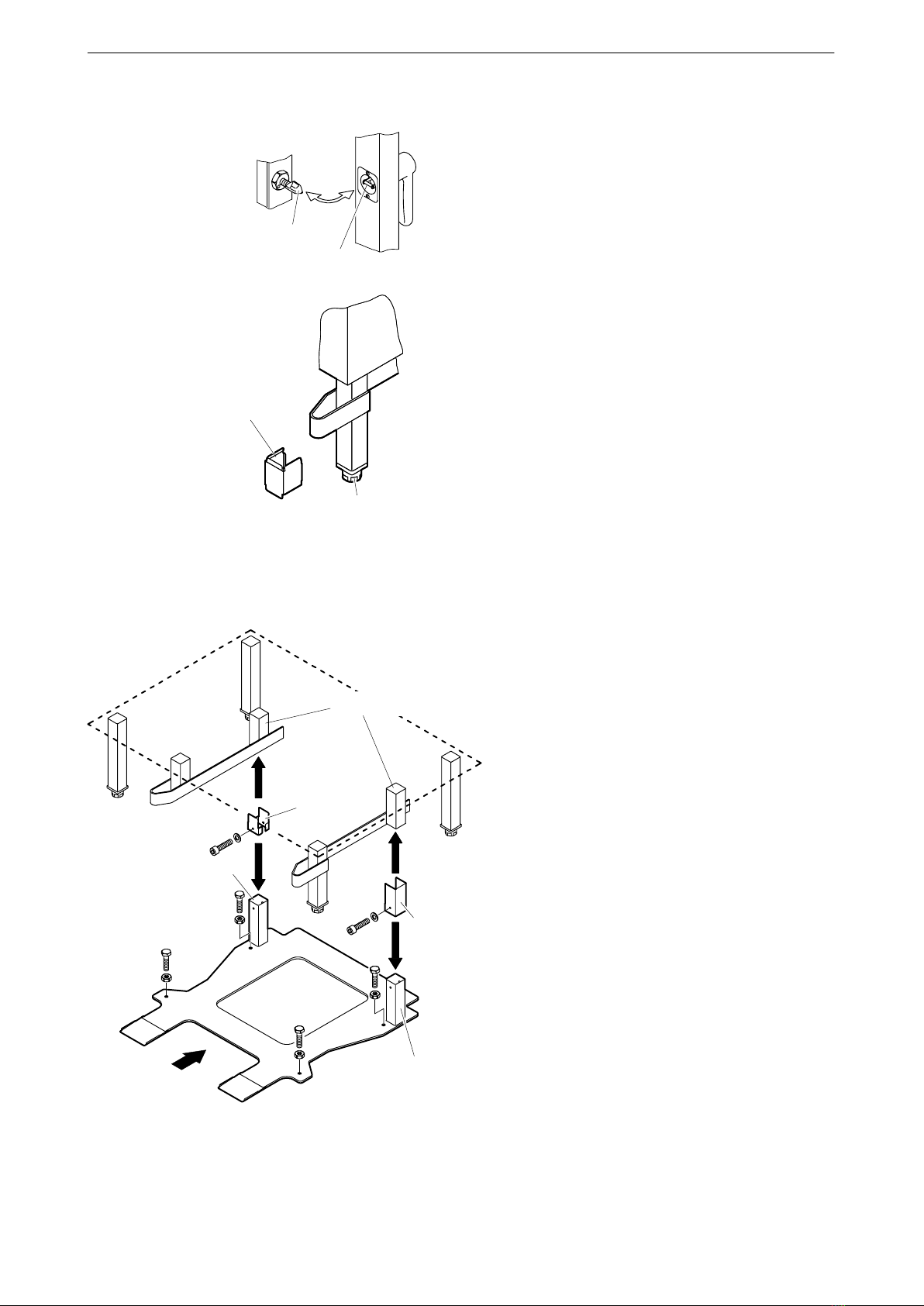

3.3.7 Installing the compensation frame for Type 2011/2021 (option) 8.................

3.3.8 Apply the safety sticker ”Max. shelf level for liquid cooking products” 9............

4. Water connection 9............................................................

4.1 Information for water connection 9...........................................

4.2 Choice of water softening device / water filter / water treatment 10................

4.2.1 Water treatment systems 10.................................................

4.2.2 Do not use these systems. 10................................................

4.2.3 Water hardness conversion table by country 10.................................

4.2.4 Requirements on the soft‐ and cold‐water connection 11.........................

4.3 Connection of soft‐ and cold water 12.........................................

5. Connecting water drainage – connection examples 13............................

6. Electrical connection 14........................................................

6.1 Connection to an energy optimisation unit (option) 15...........................

6.2 Connection to a load shedding unit 15........................................

7. Initial commissioning 15........................................................

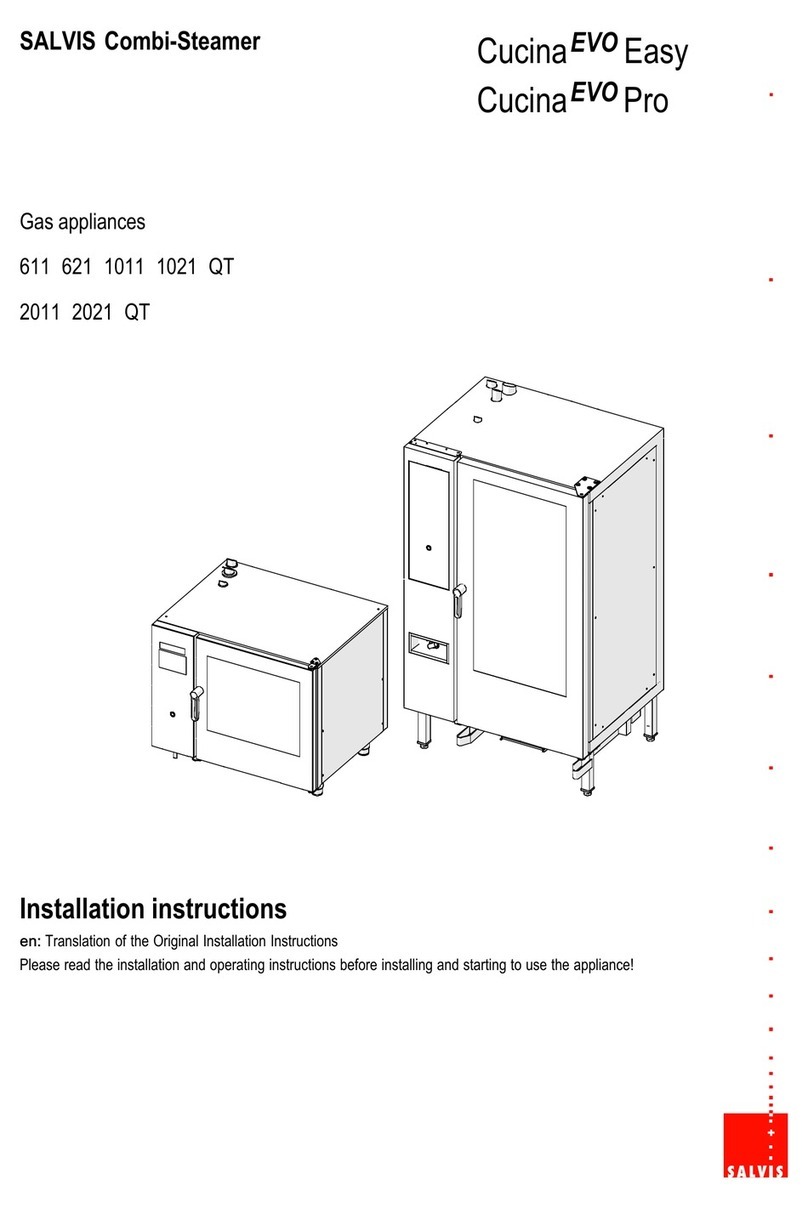

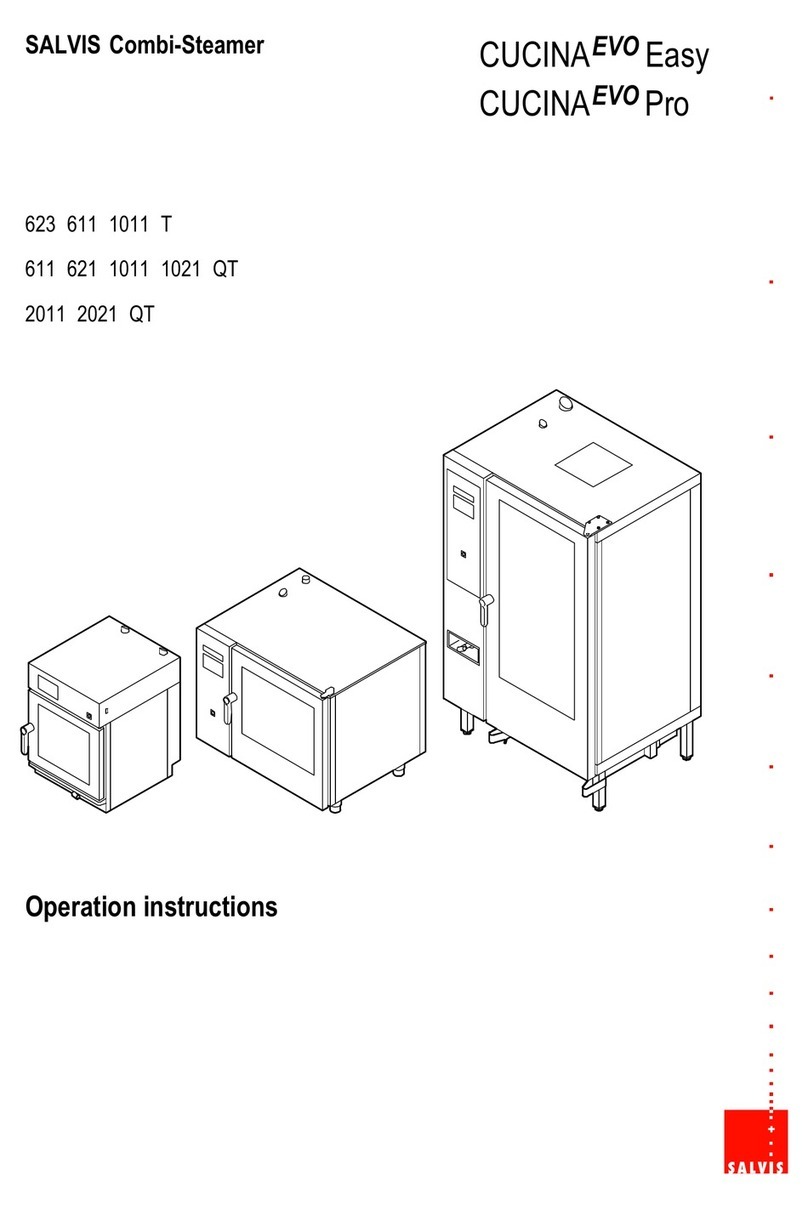

8. Dimensions, connections, technical data 16......................................

8.1 Dimensions and connections 623T, 611T, 1011T 16..........................

8.2 Dimensions and connections 611/621QT, 1011/1021QT 17....................

8.3 Dimensions and connections 2011/2021QT 18................................

8.4 Technical data: 623T, 611T, 1011T 19......................................

8.5 Technical data: 611/621QT, 1011/1021QT 19................................

8.6 Technical data: 2011/2021QT 20............................................

8.7 Technical specifications condensation cover (optional) 20.......................