Table of contents page

2/ 28

1. User information 3..............................................................

1.1 Information about the instructions for the appliance 3. . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Symbols in front of the text 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Warning signs, danger symbols and information symbols 3. . . . . . . . . . . . . . . . . . . . .

1.4 Documenting the type plate data 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Safety instructions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Gas appliances safety notes 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Transport, Setup 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Inspection for transport damages 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Transport 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Setup 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

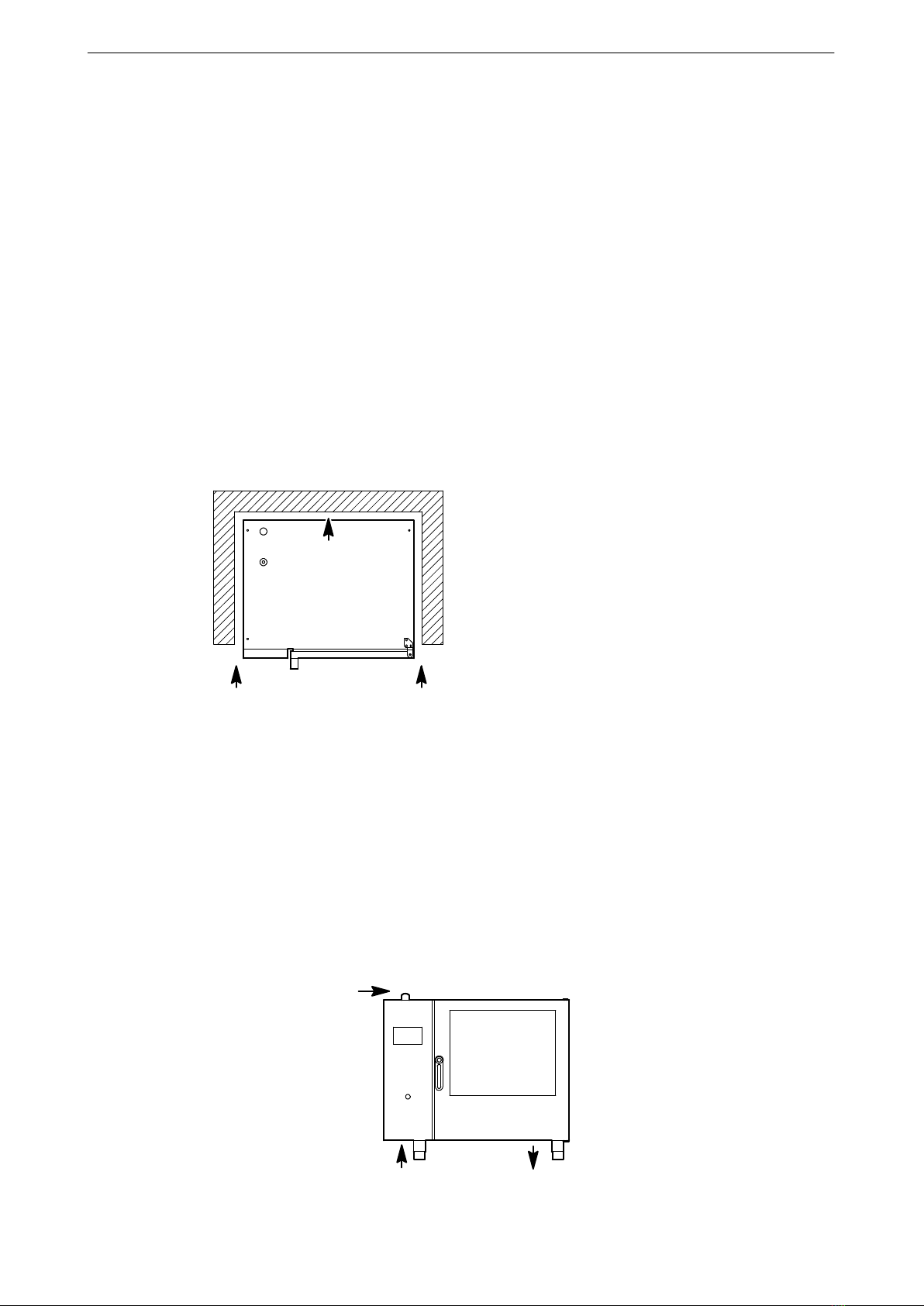

3.3.1 Observe the setup regulations 6.............................................

3.3.2 Choosing the setup location 7...............................................

3.3.3 Maintain clearances 7......................................................

3.3.4 Setup on tables and support structures 8.....................................

3.3.6 Setup of the upright appliances, e.g. Type 2011 9..............................

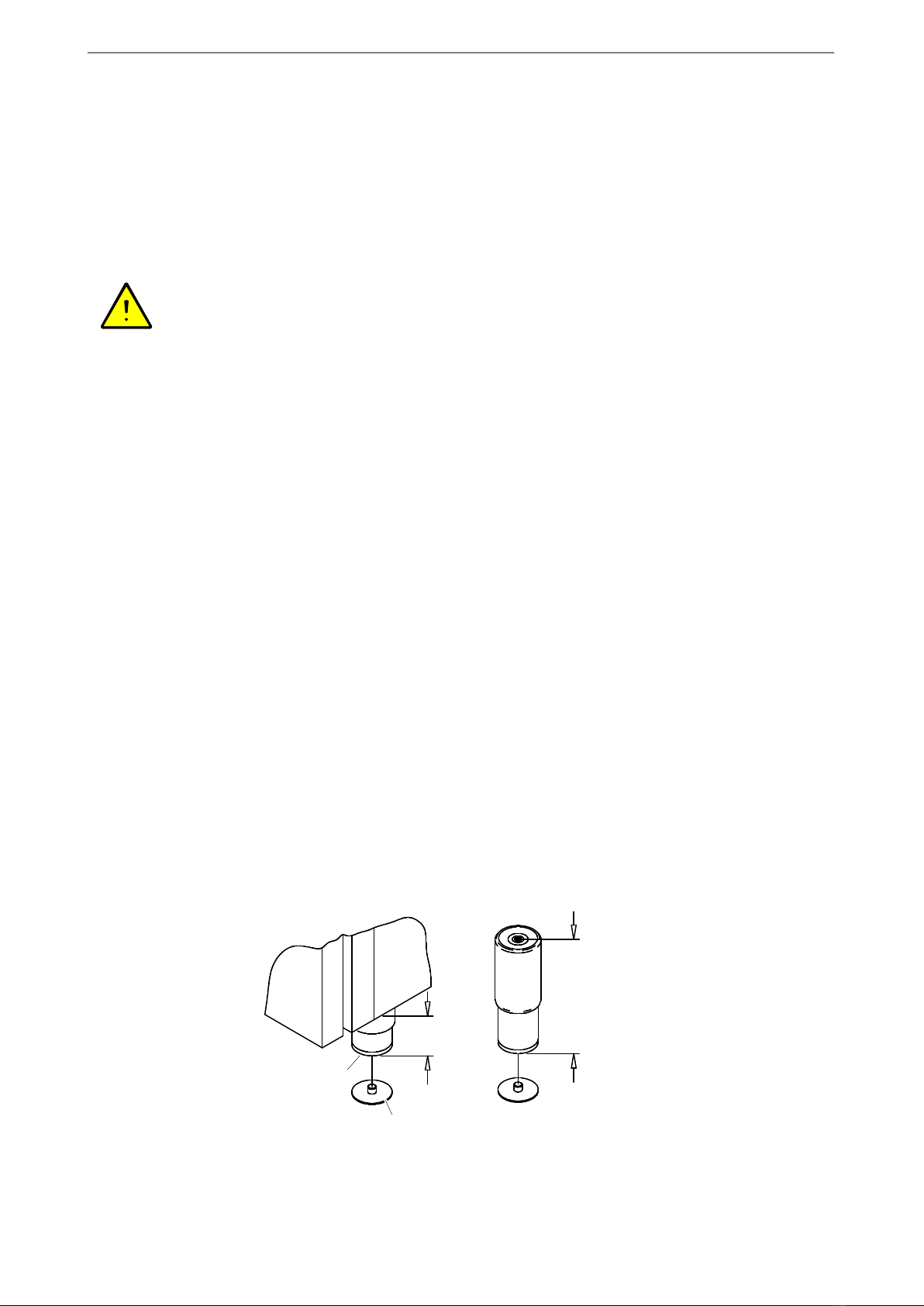

3.3.7 Installing the compensation frame for Type 2011/2021 (option) 10.................

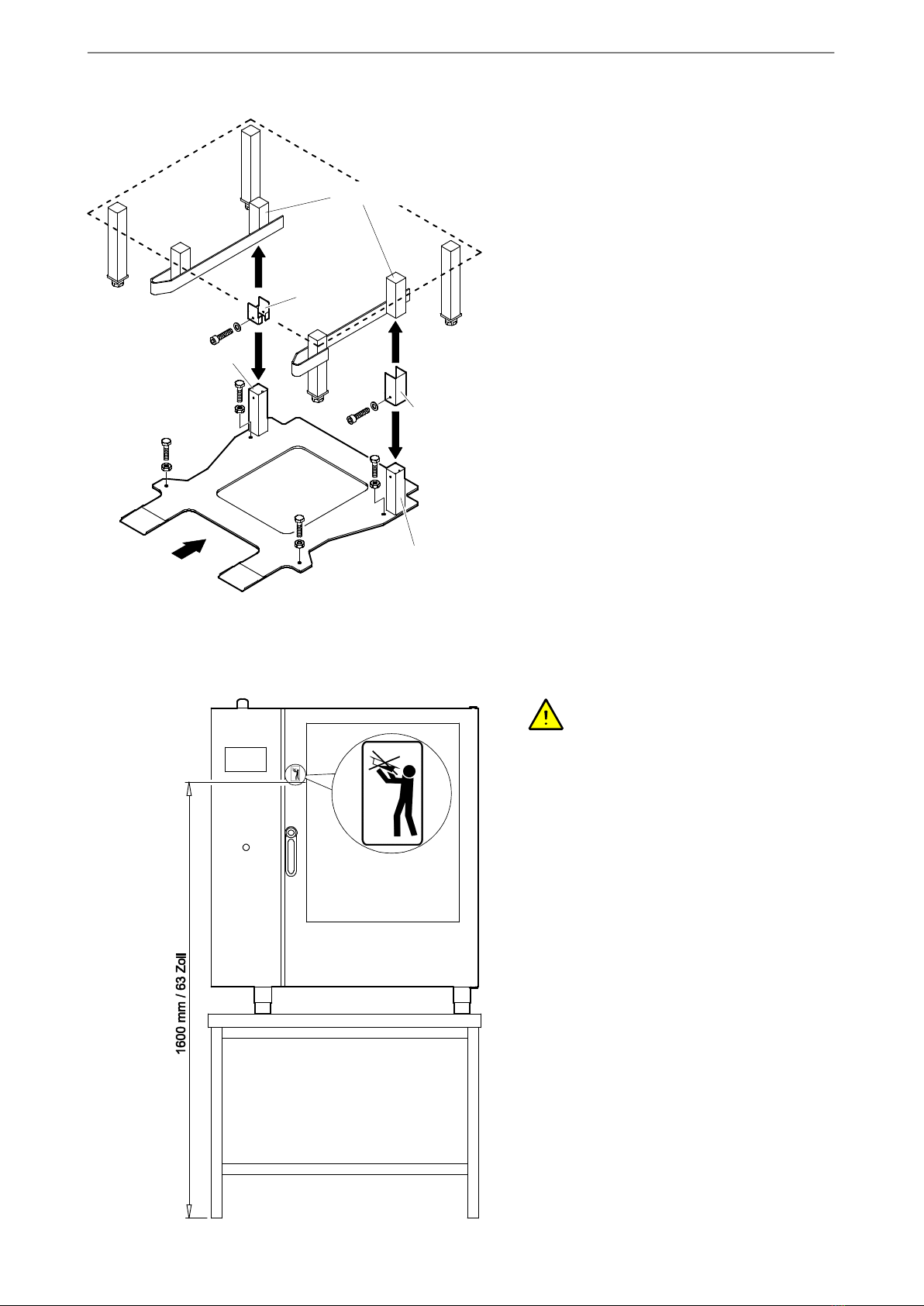

3.3.8 Apply the safety sticker ”Max. shelf level for liquid cooking products” 10. . . . . . . . . . . .

3.3.9 Appliance on wheels (option) 11..............................................

4. Water connection 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Information for water connection 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Choice of water softening device / water filter / water treatment 12. . . . . . . . . . . . . . . .

4.2.1 Water treatment systems 12.................................................

4.2.2 Do not use these systems. 12................................................

4.2.3 Water hardness conversion table by country 12.................................

4.2.4 Requirements on the soft- and cold-water connection 13.........................

4.3 Connection of soft- and cold water 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Connecting water drainage – connection examples 15................................

6. Electrical connection 16..........................................................

7. Initial commissioning 17..........................................................

8. Setting up, connecting gas appliances 18...........................................

8.1 Feed combustion air, extract exhaust gases 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Gas appliance Type A3 (≤ 14 kW) 18.........................................

8.1.2 Gas appliance Type A3 (> 14 kW) 19.........................................

8.1.3 Gas appliance Type B13BS, connection to a chimney 19........................

8.2 Appliance category K (I2K) Netherlands 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Connection pressure 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Consumptions (1023.25 mbar - 15°C) 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Combustion air, exhaust gas volume 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 CO, CO2 emissions 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 Connect gas supply, check gas pressures 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.1 Connect gas supply 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.2 Check flow pressure, output pressure 22......................................

8.8 Exhaust gas analysis/setting exhaust gas values (CO2) 23. . . . . . . . . . . . . . . . . . . . . .

9. Dimensions, connections, technical data 24.........................................

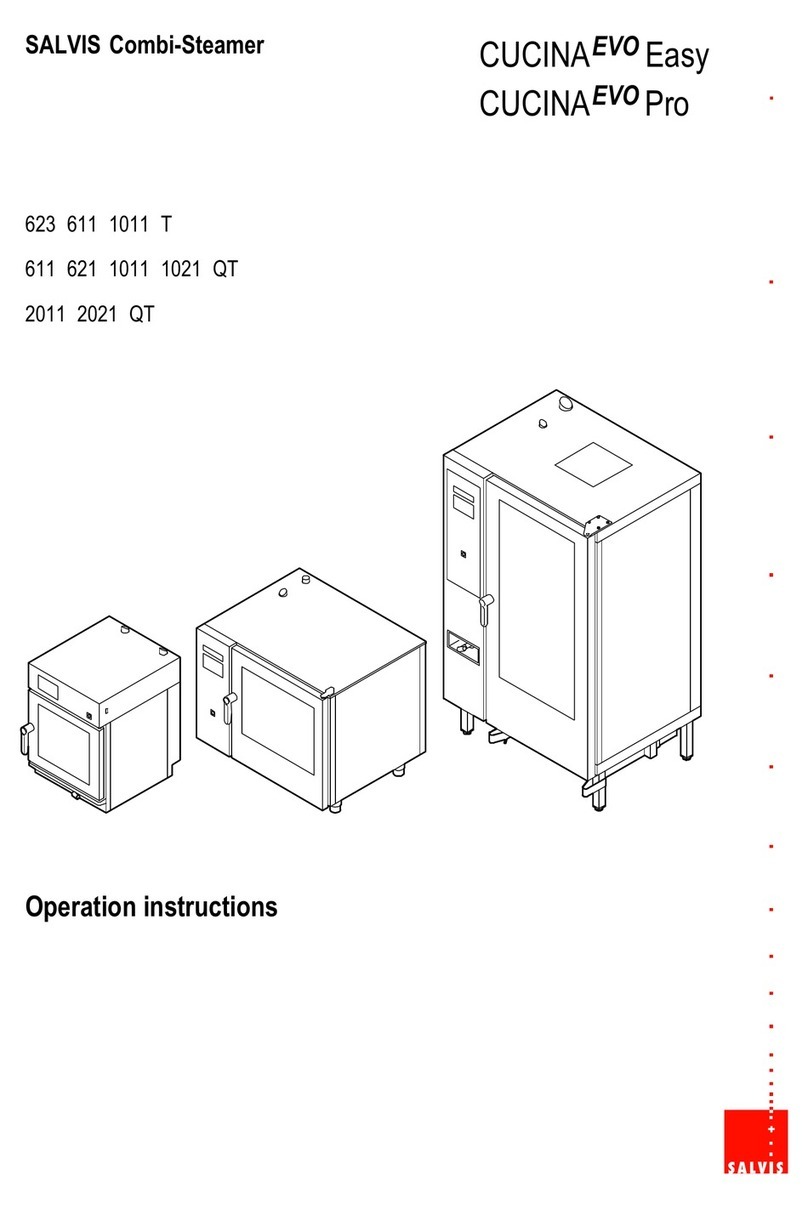

9.1 Dimensions: 611/621QT, 1011/1021QT 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Connections: 611/621QT, 1011/1021QT 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Connections: 2011QT, 2021QT 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Technical specifications 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .