Operator’s manual

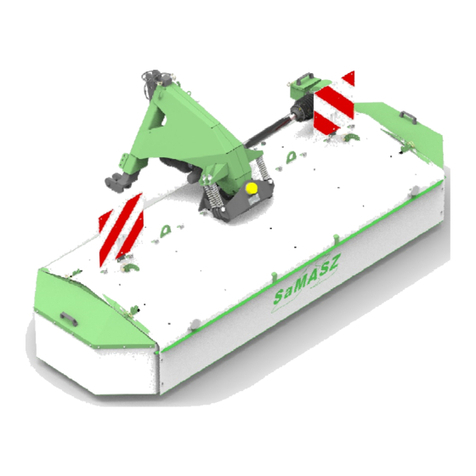

Rear drum mower

Z 010; Z 010/1; Z 010/2; Z 010/4

- 1 -

Contents Page

1.

IDENTIFYING THE MACHINE................................................................................................2

2.

INTRODUCTION.........................................................................................................................2

3.

TECHNICAL DATA.....................................................................................................................3

3.1.

Specifications ...........................................................................................................................3

3.2.

Design and working principle ..................................................................................................4

3.3.

Standard equipment and spare parts.........................................................................................5

4.

SAFETY ADVICE.........................................................................................................................6

4.1.

General rules.............................................................................................................................6

4.2.

Transport...................................................................................................................................8

4.2.1. Placing the mower onto a transport vehicle.....................................................................................8

4.3.

Operating elements...................................................................................................................9

4.4.

The articulated telescoping shaft..............................................................................................9

4.5.

Residual risk.............................................................................................................................9

4.6.

Warning decals.......................................................................................................................10

4.7.

Design and operation of safety breakaway device.................................................................13

5.

OPERATION OF THE MOWER..............................................................................................14

5.1.

Attaching the mower to the tractor.........................................................................................14

5.2.

Preparing the mower for transport..........................................................................................15

5.2.1. Standard design .............................................................................................................................15

5.2.2. Desing with hydraulic lifting (optional equipment) ......................................................................15

5.2.3. Mechanical lock of hydraulic lifting .............................................................................................16

5.3.

Preparing the mower for transport on public roads................................................................16

5.4.

Connecting the articulated telescopic shaft............................................................................17

5.5.

Adjustment of conditioner shaft’s position ............................................................................18

5.6.

Replacement of flails in conditioner’s shaft...........................................................................18

5.7.

Operation................................................................................................................................19

5.7.1. Standard design .............................................................................................................................19

5.7.2. Design with hydraulic lifting (optional equipment) ......................................................................19

6.

MOUNTING AND ADJUSTMENT..........................................................................................20

6.1.

Mounting and timing of the knives ........................................................................................20

6.2.

Replacing the knives...............................................................................................................20

6.3.

Adjusting the cutting unit.......................................................................................................21

6.4.

Adjusting the cutting height ...................................................................................................21

6.5.

3-point linkage support chain.................................................................................................21

6.6.

Maintenance and service ........................................................................................................22

6.6.1. Checking the knives and knife holders..........................................................................................22

6.6.2. Checking the V-belts tension.........................................................................................................22

6.6.3. Daily maintenance.........................................................................................................................23

6.6.4. After-season maintenance..............................................................................................................23

7.

LUBRICATION INSTRUCTION .............................................................................................24

8.

DEFECTS AND THEIR REPAIRS...........................................................................................25

9.

DISASSEMBLY AND WITHDRAWAL FROM WORK.......................................................26

9.1.

Disassembly............................................................................................................................26

9.2.

Scrapping................................................................................................................................26

10.

WARRANTY CARD................................................................................................................26

11.

WARRANTY TERMS..............................................................................................................27

11.1.

Warranty claims procedures ..............................................................................................27

11.2.

Warranty repairs record.....................................................................................................28