Contents

EB 2512 EN

6.1 Starting up the plant....................................................................................6-2

6.1.1 Regulation of liquids....................................................................................6-2

6.1.2 Regulation of steam.....................................................................................6-2

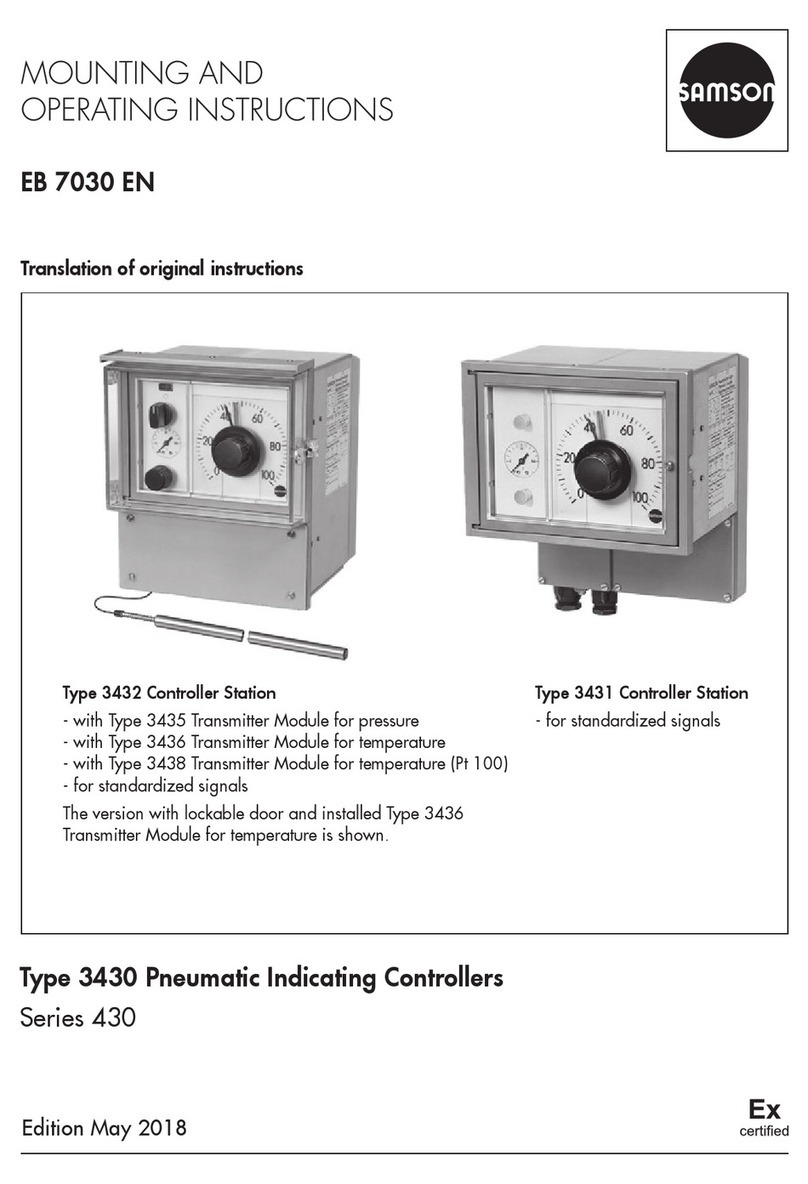

7 Operation..................................................................................................7-1

7.1 Adjusting the set point.................................................................................7-1

8 Malfunctions ..............................................................................................8-1

8.1 Troubleshooting ..........................................................................................8-1

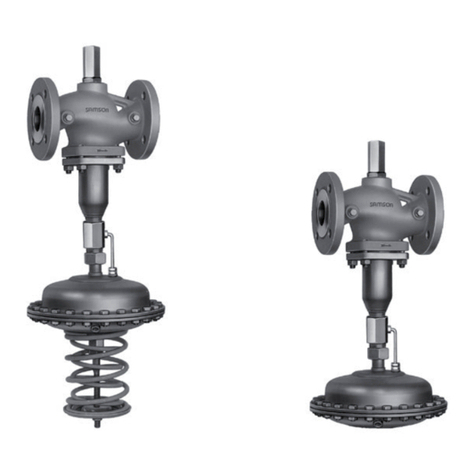

8.2 Emergency action .......................................................................................8-3

9 Servicing....................................................................................................9-1

9.1 Preparing the valve for service work.............................................................9-4

9.2 Installing the regulator after service work ......................................................9-4

9.3 Service work...............................................................................................9-4

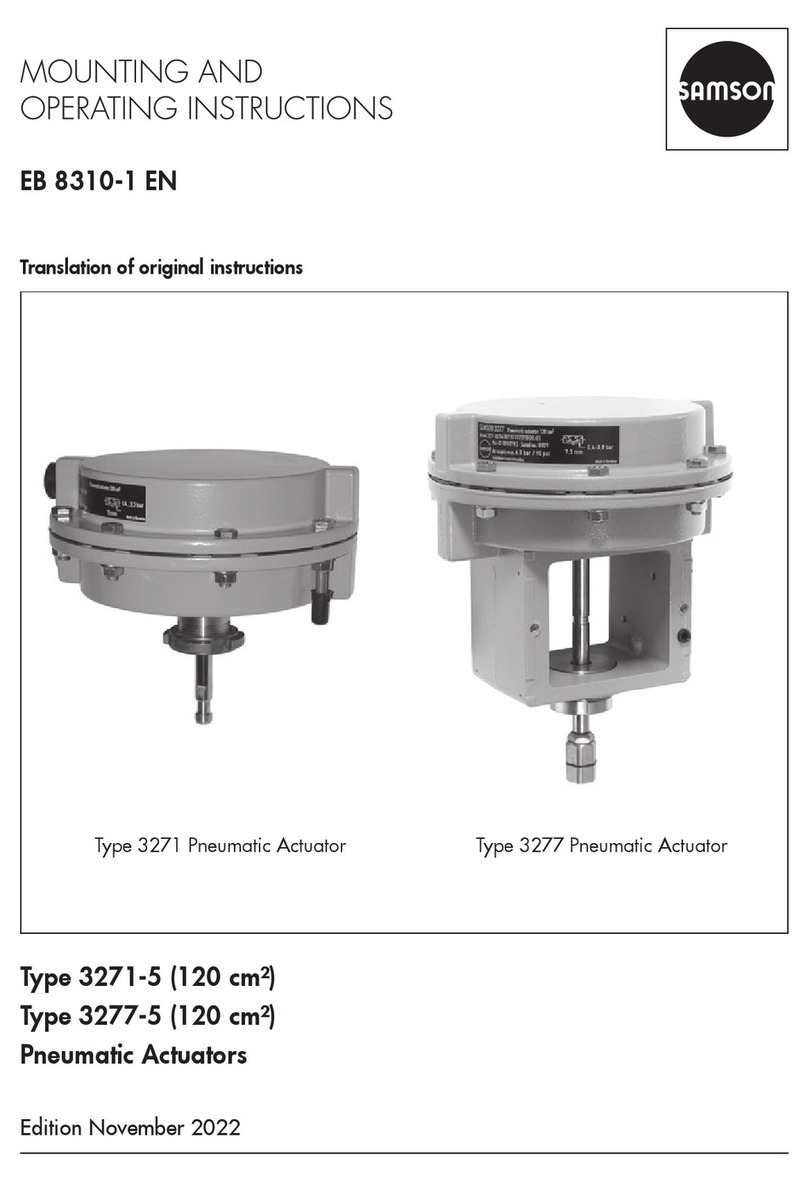

9.3.1 Replacing the actuator.................................................................................9-5

9.3.2 Replacing the set point springs.....................................................................9-6

9.3.3 Replacing the seat and plug.........................................................................9-7

9.3.4 Replacing the operating diaphragm .............................................................9-7

9.4 Ordering spare parts and operating supplies ................................................9-8

10 Decommissioning .....................................................................................10-1

11 Removal ..................................................................................................11-1

11.1 Removing the valve from the pipeline..........................................................11-1

11.2 Removing the actuator from the valve .........................................................11-1

12 Repairs ....................................................................................................12-1

12.1 Returning devices to SAMSON ..................................................................12-1

13 Disposal...................................................................................................13-1

14 Certicates...............................................................................................14-1

15 Annex......................................................................................................15-1

15.1 Tightening torques.....................................................................................15-1

15.2 Lubricant..................................................................................................15-1

15.3 Tools ........................................................................................................15-1

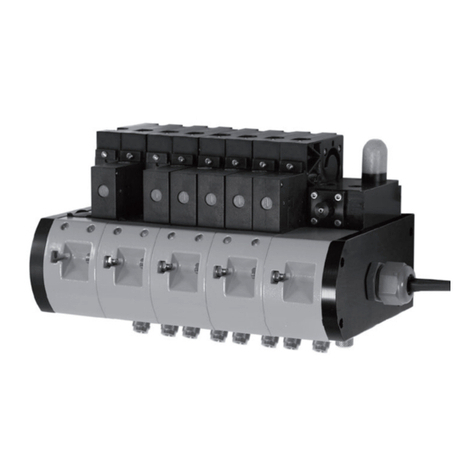

15.4 Accessories ..............................................................................................15-1

15.5 Spare parts ..............................................................................................15-2

15.6 After-sales service.....................................................................................15-4