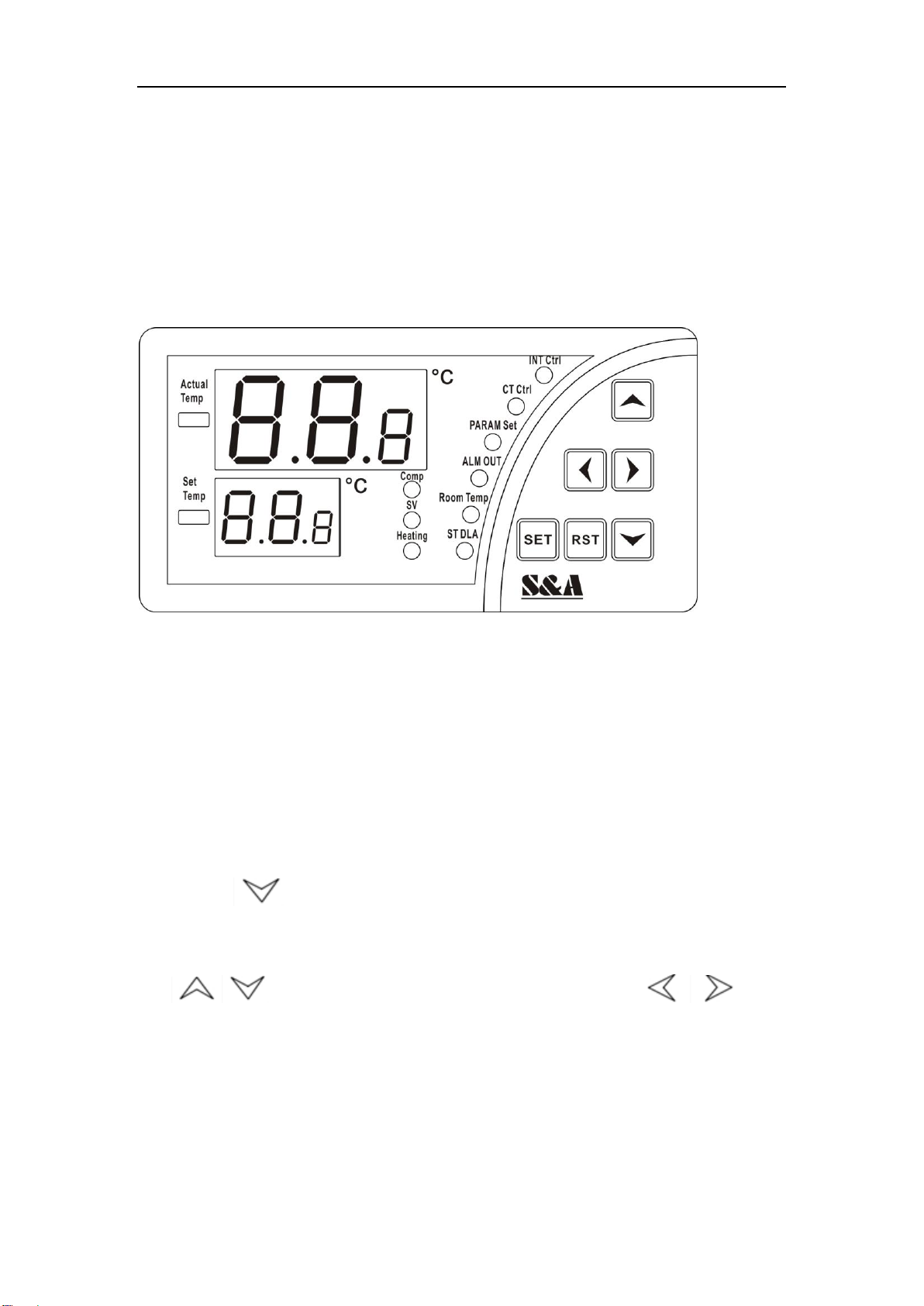

5、Advanced settings adjustment

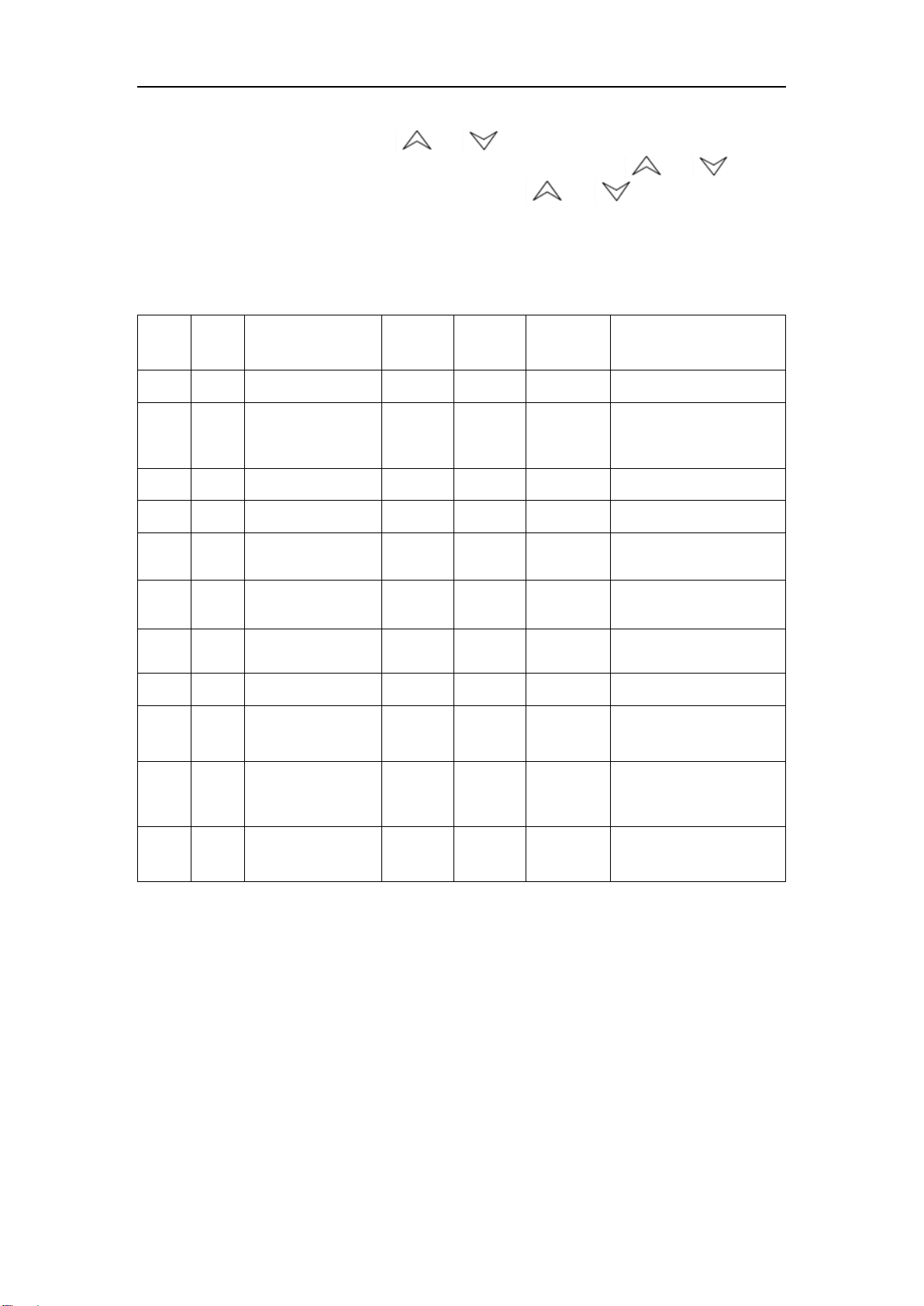

(1)Press and hold the ”button while press SET button for 5 seconds until 00

displayed in upper window and PAS in lower window. Then press keys to

select the password (default setting is 8), and then press the SET button, if

the password is correct, F0 displays, entering into setting status, means the

temperature controller is under parameter setting status. If the password is

incorrect, it returns to temperature display. To avoid operation mistake,

passwords could change by equipment user or equipment keeper.

(2)Enter setting status, press buttons to modify parameter content

follow by recycle,then press “ ”buttons to modify the parameter

values. Press confirm button RST at any time to exit parameters setting with

saving modified parameters and return to temperature display, then chiller

runs under the new parameters. If there is no any action within 20 seconds,

the controller will automatically exit parameters setting without saving the

modified parameters (under parameters setting status, system running in

original parameters). Under parameters setting status, SET key does not

work.

Note:

1. During parameters setting status, system runs under original parameters.

2.Under constant temperature control mode, the water temperature is

controlled by parameter F0.

3. Under intelligent control mode, the water temperature will be automatically

adjusted according

to ambient temperature changes. The temperature difference is controlled

by F1.

6. Advanced parameters adjustment cases:

(1)Case 1:26.8 ℃cooling UV laser settings

Chiller under constant temperature control mode, press SET button will

display setting water temperature value(F0),then press or

buttons to modify setting temperature value, set the temperature to

26.8 ℃,press RST button save parameter and exist then back to the

temperature display (If there is no any action within 20 seconds, the

controller will automatically exit parameters setting return to temperature

display without saving the modified parameters)

(2)Case 2:16℃cooling UV laser settings

Chiller under constant temperature control mode, press SET button will

display setting water temperature value(F0),then press or

buttons to modify setting temperature value, set the temperature to

16.0 ℃,press RST button save parameter and exist then back to the

temperature display (If there is no any action within 20 seconds, the

controller will automatically exit parameters setting return to temperature

display without saving the modified parameters)

(3)Case 3:Change alarm temperature of water temperature ,water temperature

higher 5 ℃than set value will alarm ,lower 10 ℃than set value will alarm.

Press and hold button while press SET button lasts 5 seconds the

temperature controller will display 0, then press button modifies 0 to

8(default setting password),and then press SET button will enter setting

content code display turns to F0 if password corrects (Will restore to actual

water temperature if password incorrect). Press or button