2

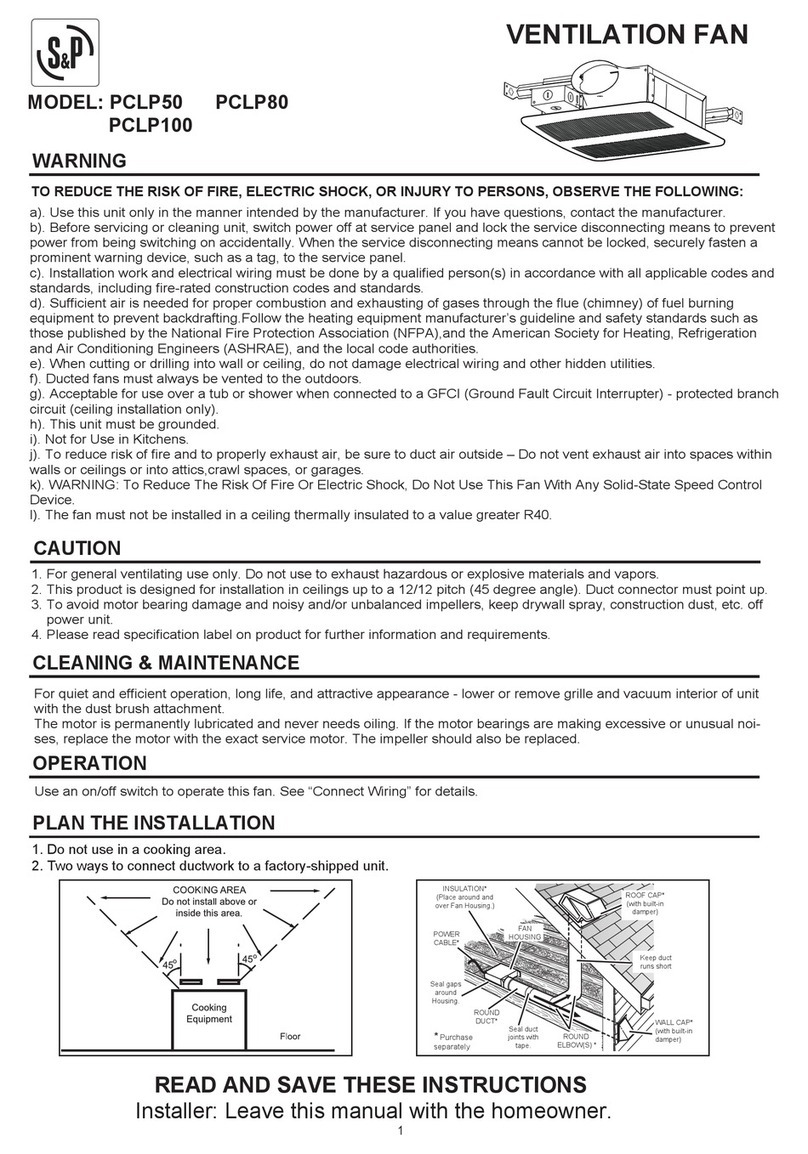

WARNINGS

READ AND SAVE THESE INSTRUCTIONS (LIRE AND CONSERVE INSTRUCTIONS). FAILURE TO

COMPLY WITH INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY

DAMAGE! IMPORTANT SAFETY INSTRUCTIONS (INSTRUCTIONS IMPORTANTES POUR LA

SÉCURITÉ) SAVE THESE INSTRUCTIONS (CONSERVEZ CES INSTRUCTIONS).

WARNING (AVERTISSEMENT): TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING (AVERTISSEMENT — POUR REDUIRE LE RISQUE D’INCENDIE,

DE CHOC ELECTRIQUE OU DE BLESSURE, RESPECTER LES CONSIGNES QUI SUIVENT):

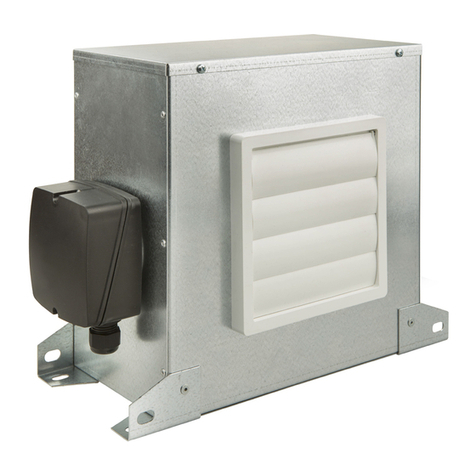

(1) Your clothes dryer installation incorporates a dryer exhaust power ventilator (DEDPV) which may

be in a different location than your dryer, such as in an attic, crawl space or basement (Votre secheuse

est equipee d’un ventilateur auxiliaire qui peut etre installe loin de la secheuse, comme dans un grenier,

un vide sanitaire ou un sous-sol).

(2) Your clothes dryer depends on the DEDPV for its safe and efficient operation. Operating your dryer

without a functional DEDPV will result in inefficient dryer operation, excess energy consumption and a

possible fire hazard. See warning on the alarm notification panel (Le ventilateur auxiliaire est essentiel

au fonctionnement securitaire de la secheuse. Desactiver ce ventilateur nuira au fonctionnement de

la secheuse, entrainera un augmentation de la consummation d’electricite et possiblement un risque

d’incendie. Lire la mise en garde sur le panneau d’indication d’alarme).

(3) The notification/annunciator panel shall be permanently installed within the space in which the

clothes dryer is installed. In the case of a dryer installed in an alcove provided with a door or doors

the notification/annunciator panel shall be installed within the alcove or be installed immediately

adjacent to the doors of the alcove. The notification/annunciator panel shall be located where it

will be readily visible after the dryer is installed without having to open any doors other than those

necessary to access the dryer (Le panneau d’alarme doit etre installe de facon permanente dans

l’espace ou se trouve la secheuse. Si la secheuse est installee dans une alcove fermee par une porte,

le panneau d’alarme doit etre installe dans l’alcove ou a proximite immediate de la porte de l’alcove.

Le panneau d’alarme doit etre visible une fois la secheuse installee sans avoir a ouvrir une porte autre

que celle donnant acces a la Secheuse).

(4) LED Indicator Light: A flashing light or no light indicates failure of the DEDPV. Immediately stop

using clothes dryer until DEDPV has been serviced, repaired or replaced. A constantly illuminated light

indicates normal DEDPV operation.

(5)RISK OF FIRE. This Clothes Dryer installation includes a Dryer Exhaust Duct Power Ventilator

(DEDPV).

(6) NE PAS UTILISER LA SECHEUSE SI UNE ALARME RETENTIT OU UN MESSAGE D’ERREUR

VISUEL S’ALLUME. APPELEX UN REPARTEUR.

(7) RISQUE D’INCENDIE. CETTE SECHEUSE EST DOTEE D’UN VENTILATEUR AUXILIAIRE. UN

SIGNAL LUMINEUX CLIGNOTANT OU L’ABSENCE DE SIGNAL LUMINEUX INDIQUE UNE

DEFAILLANCE DU VENTILATEUR AUXILIAIRE. CESSER IMMEDIATEMENT D’UTILISER LA SECHEUSE

JUSQU’A CE QUE LE VENTILATEUR AIT ETE REPARE. UN SIGNAL LUMIINEUX PERMANENT

INDIQUE QUE LE VENTILATEUR AUXILIAIRE FONCTIONNE CORRECTEMENT. NE PAS RETIRER

NI COUVRIR CE PANNEAU.

(8) Use this unit only in the manner intended by the manufacturer. If you have questions, contact the

manufacturer.

(9) Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting

means to prevent power from being switched on accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

(10) Installation work and electrical wiring must be done by qualified person(s) in accordance with all

applicable electrical and mechanical building codes and standards, including fire-rated construction.