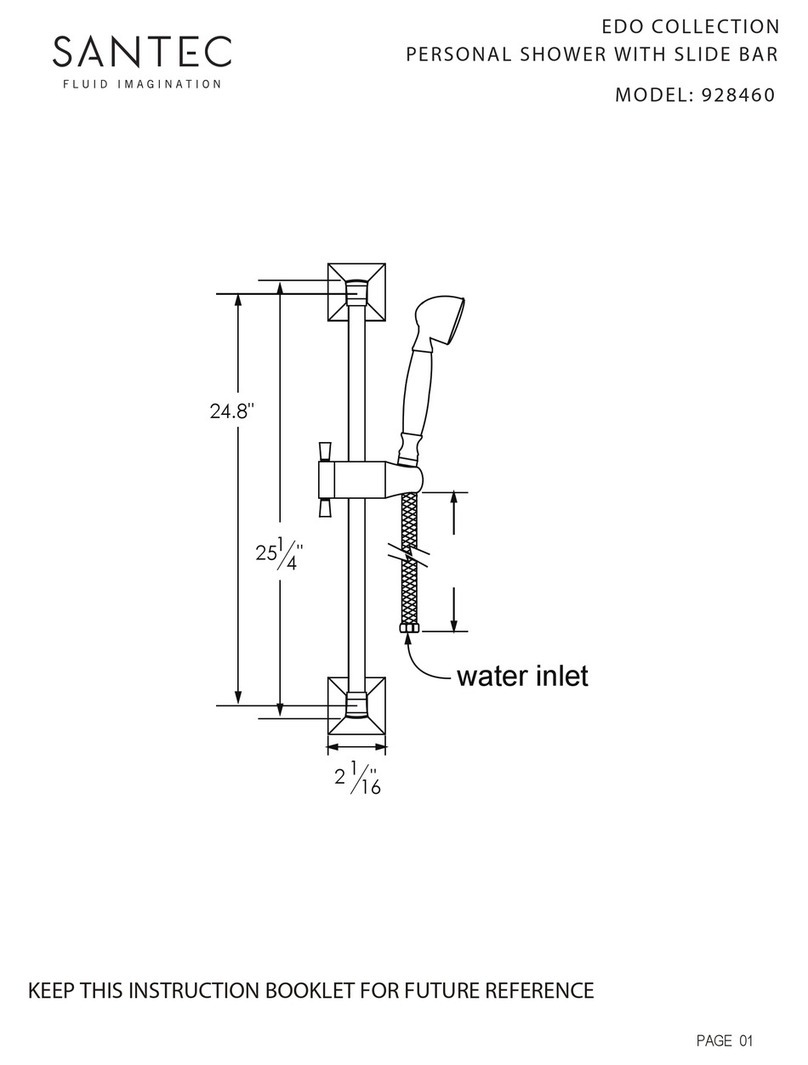

TROUBLE SHOOTING

MALFUNCTION CAUSE REMEDY

Shower control opening through hot.

Tub filler or Shower head drips after

shutting off the valve.

Shower insufficiently hot.

No flow of hot or cold water.

Valve body too deep into

the wall.

- Hot and cold water supplies have been connected

in reverse

- Water remains in the piping column to the shower

head (this is normal).

- Incorrect setting of the mechanical stop against the

stop post causing a partially opened cartridge.

- O-ring seal on the inlet of the cartridge is faulty.

- Adjustable handle position stop incorrectly set.

- Either the hot or cold side is not fully pressurized.

- Debris caught inside the inlet of the cartridge.

.

- The measured rough in or finished wall surface is

incorrect.

Rotate cartridge

- Allow approximately 3-5 minutes to drain column.

- Reset the mechanical stop as described in this page

- Check O-ring for cut or damage and replace if necessary.

- Check hot water source temperature setting.

- Be sure service stops (when applicable) are both wide open

and system is fully pressurized.

- Remove cartridge and flush out or remove any debris lodged

inside the hot or cold inlet.

install the extension kit.

PM460X(long sleeve).

PM461X (long plastic upper link)

NOTE: AT NO TIME TRY TO STOP DRIPPING BY APPLYING EXTREME FORCE WHEN CLOSING THE VALVE.

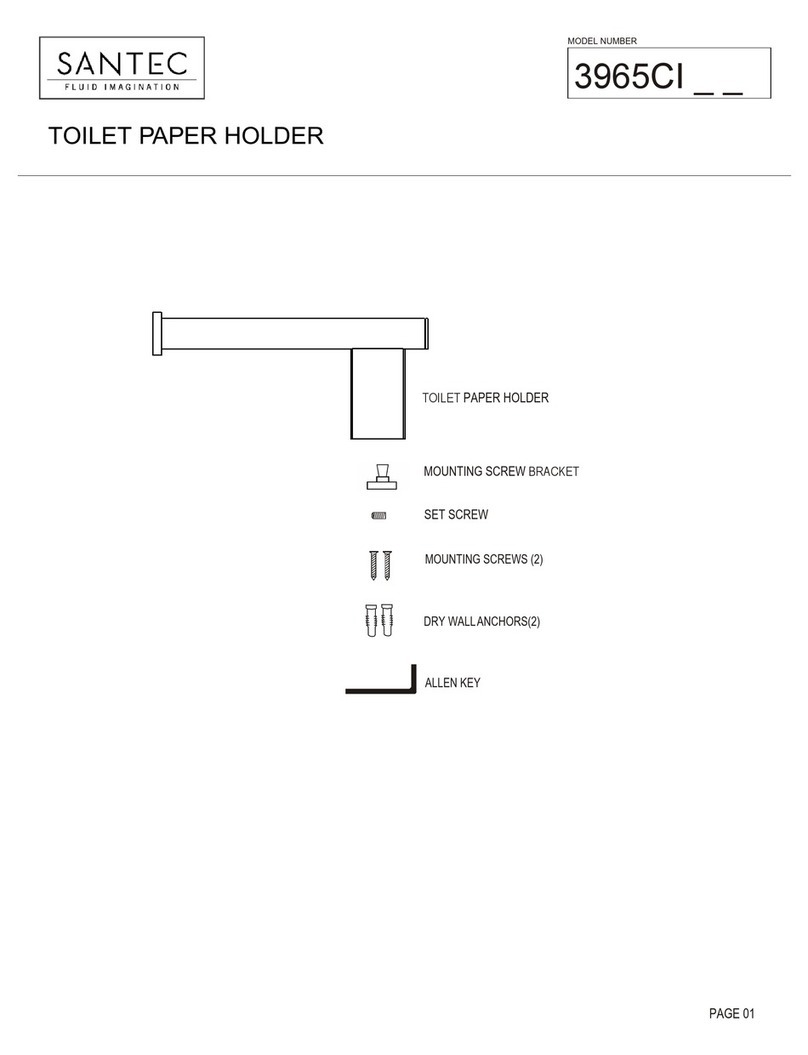

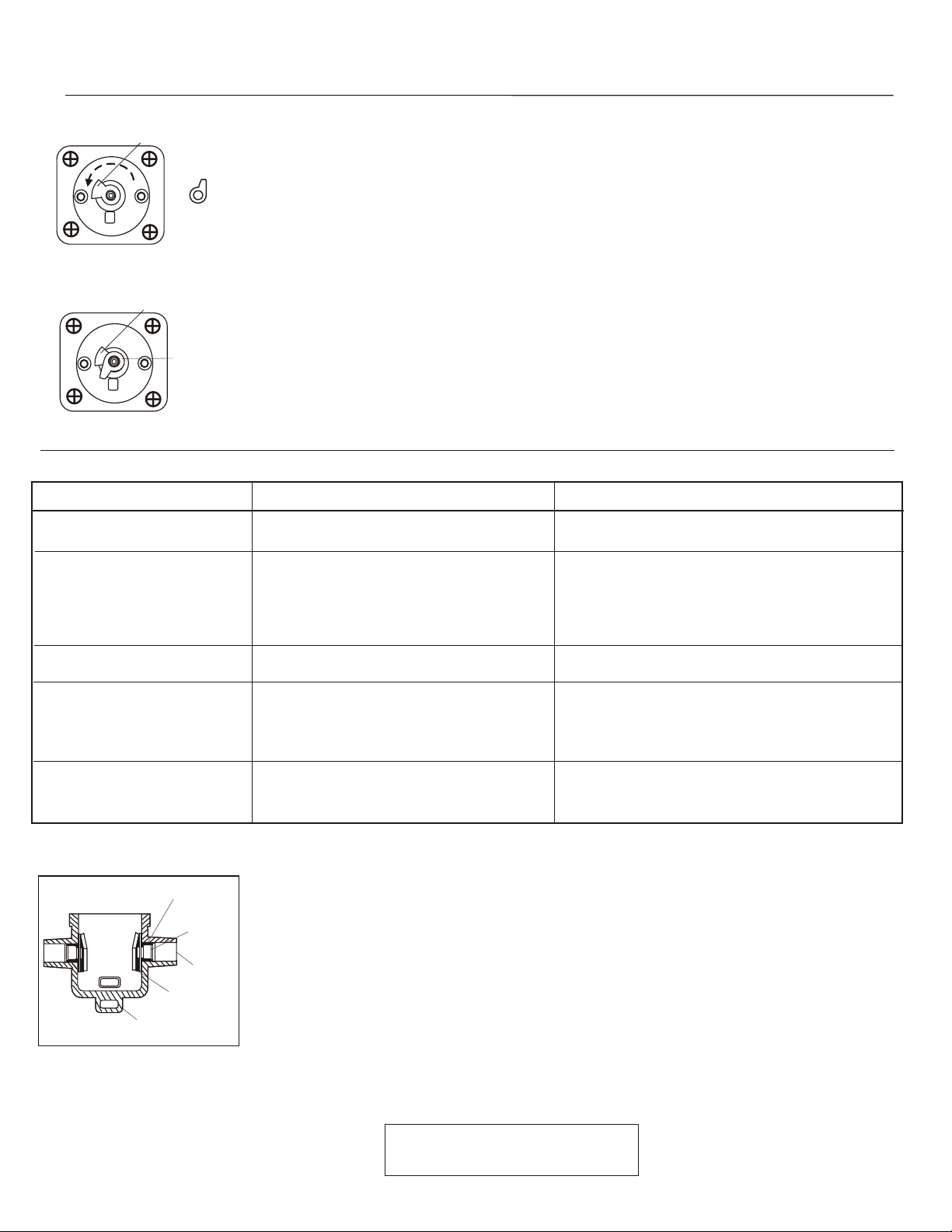

O-RING

FILTER

INLET

FILTER INSERT

VALVE

FILTER SCREEN REMOVAL AND CLEANING

The valve has filter screens that prevent debris from obstructing the pressure balancing cartridge.

If excessive in-line debris accumulates in the filter screen you will notice a decrease in flow from the valve.

PLEASE NOTE - SHUT OFF BOTH HOT AND COLD WATER SUPPLIES BEFORE SERVICING VALVE.

- The filter screen are attached to an insert that is fitted into the valve body inlets.

With the cartridge removed the 2 inserts and filter screens can be easily removed from the valve body.

- Remove the insert by pressing the top corner. This will rotate the insert allowing easy removal.

- There is a place on either side of the filter insert where you can get your finger nail underneath the filter screen.

By pulling the filter screen away from the insert it will "pop out".

- All debris can be now be easily removed from the filter screen.

Replace the filter screen into the insert and push together gently until it clicks into place.

- Place the insert back into the valve body, making sure the angled edge of the insert faces out.

The insert should sit flush against the wall of the valve body when properly installed.

Santec Inc.

3501 Challenger Street, Torrance, CA 90503

Tel: (310) 542-0063 Fax (310) 542-5681

www.santecfaucet.com 10/07

STOP POST

Illustration D1

Illustration D2

MECHANICAL STOP

STOP POST

LIMIT STOP

LIMIT STOP

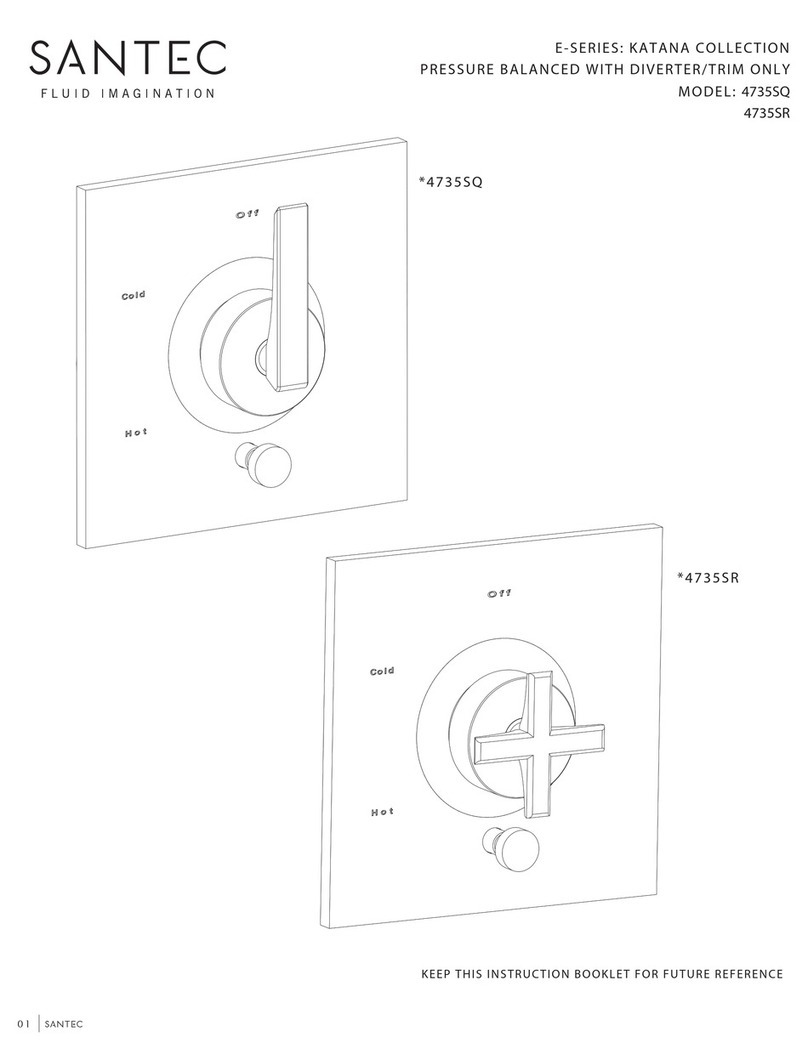

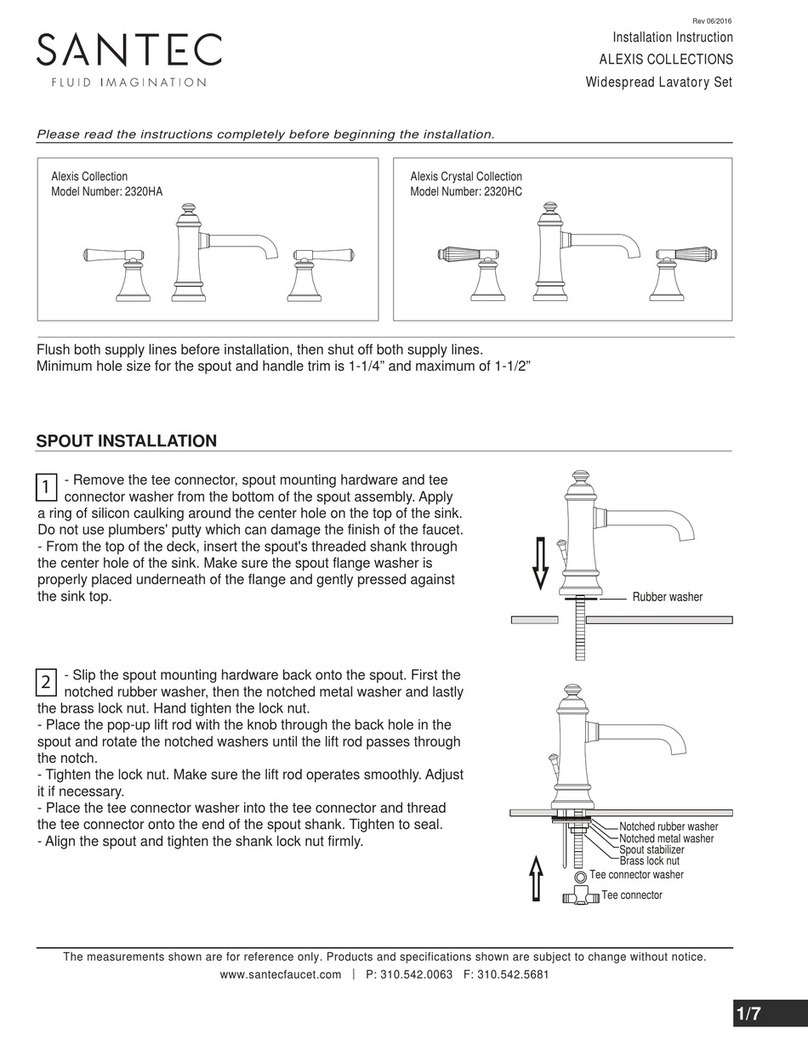

TEMPERATURE LIMIT STOP SET UP

-Santec Pressure Balanced Valve has a temperature limit stop ( please see Illustration C)

which once set properly can provide a safe and comfortable hot water.

Below is the limit stop installation procedure:

- Remove all Handle trim parts, including the trim plate.

- remove all internal parts up to the Limit Stop, do not remove the Mechanical Stop.

After Mechanical Stop is removed please follow the instruction bellow

- Turn the cartridge clockwise until it is stopped. Do not force to avoid damaging the cartridge.

- Insert the Mechanical Stop onto the cartridge

- Turn the cartridge counterclockwise to open the water line. Turn until it reaches the maximum

hot water desired by the user.

- Place Limit Stop as shown in the Illustration D2.

- Reinstall all the parts accordingly to the Illustration C.

MECHANICAL STOP

INSTALLATION INSTRUCTIONS

PAGE 04

Pressure Balanced Tub/Shower