中文 EN

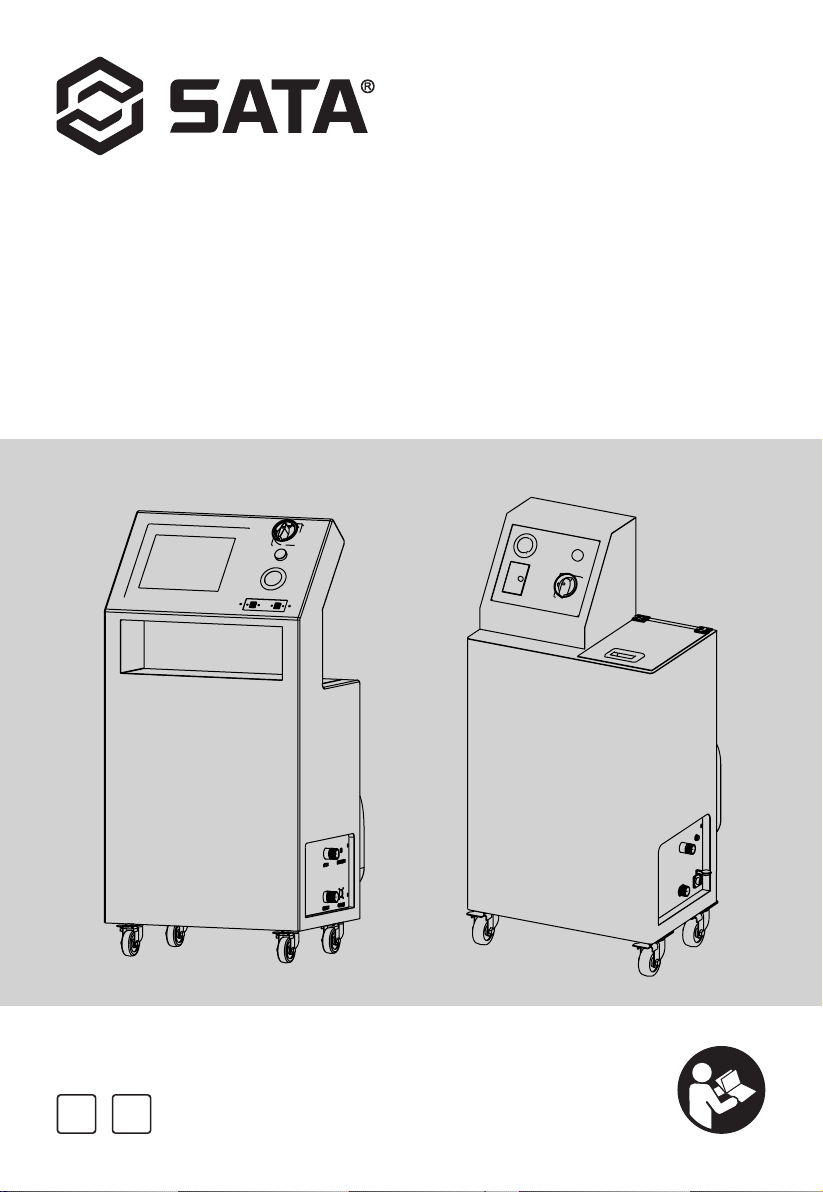

AE5736/AE5737

3

目录DIRECTORY

第一章 机器结构简图 ..........................................................................................................................................4

第二章 操作说明 .....................................................................................................................................................5

第三章 安全注意事项 ..........................................................................................................................................6

第四章 维护说明 ..................................................................................................................................................... 7

第五章 常见故障说明 .......................................................................................................................................... 7

第六章 产品参数表................................................................................................................................................8

第七章 产品装箱单................................................................................................................................................8

第八章 产品爆炸图................................................................................................................................................9

Chapter ⅠSchematic Diagram Of Machine Structure ..................................................................................11

Chapter ⅡOperating Instructions.........................................................................................................................12

Chapter ⅢSafety Precautions............................................................................................................................... 13

Chapter ⅣMaintenance Instruction.................................................................................................................... 14

Chapter ⅤCommon Fault Description................................................................................................................ 14

Chapter ⅥProduct Parameters Table..................................................................................................................15

Chapter ⅦPacking List Of Products.....................................................................................................................15

Chapter ⅧProduct Explosion Diagram............................................................................................................... 16