SATO E series Operating instructions

AND

SERIES PRINTERS

PROGRAMMING

REFERENCE

SATO M-84PRO ii

SATO Group of Companies

BARCODE SATO INTERNATIONAL PTE LTD

438A Alexandra Road #05-01/ 02,

Alexandra Technopark,

Singapore 119967

Tel: 65-6271-2122

Fax: 65-6271-2151

Website: www.barcodesato.com

Email: sale[email protected]

SATO EUROPE NV

Leuvensesteenweg 369,

1932 Sint-Stevens-Woluwe, Brussels, Belgium

Tel: 32 (0)-2-788-80-00

Fax: 32 (0)-2-788-80-80

Website: www.sato-europe.com

Email: info@sato-europe.com

SATO UK LTD

Valley Road, Harwich, Essex England

Co12 4RR, United Kingdom

Tel: 44-1255-240000

Fax: 44-1255-240111

Website: www.satouk.com

Email: [email protected]

SATO DEUTSCHLAND GMBH

Schaberweg 28, 61348

Bad Homburg, Germany

Tel: 49 (0)-6-1726-8180

Fax: 49 (0)-6-1726-818-199

Website: www.sato-deutschland.de

Email: [email protected]

SATO POLSKA SP Z O.O.

Ul Okolna 2, 50-422 Wroclaw

Poland

Tel: 48-71-335-23-20

Fax: 48-71-335-23-25

Website: www.sato-europe.com

Email: info@sato-europe.com

SATO AMERICA INC.

10350 Nations Ford Road Suite A,

Charlotte, NC 28273

Tel: 1-704-644-1650

Fax: 1-704-644-1662

Website: www.satoamerica.com

Email: satosales@satoamerica.com

SATO SHANGHAI CO, LTD

11 Floor, D, Pudong South Road 1111,

Pudong New Area, Shanghai,

China 200120

Tel: 86 (0)-21-58307080

Fax: 86 (0)-21-58307978

Website: www.barcodesato.com

Email: sales@satochina.com

BAR CODE SATO ELECTRONICS (S) PTE LTD

438A Alexandra Road #05-01/02,

Alexandra Technopark, Singapore 119967

Tel: 65-6271-5300

Fax: 65-6273-6011

Website: www.barcodesato.com

www.satosingapore.com

Email: sales@satosingapore.com

SATO BAR CODE & LABELLING SDN BHD

Suite B-08-11&12, Block B Plaza Mont'

Kiara, No.2, Jalan Kiara Mont' Kiara,

50480 Kuala Lumpur, Malaysia

Tel: 60-3-6203-5950

Fax: 60-3-6203-1209

Website: www.barcodesato.com

Email: sales@satosbl.po.my

BARCODE SATO (THAILAND) CO., LTD

370/8 Supattra Building, 5th Floor, Rama9

Road, Bangkapi, Huay Kwang

Bangkok 10320, Thailand

Tel: 662-719-7780-3

Fax: 662-719-7784

Website: www.barcodesato.com

Email: sales@satothailand.co.th

Programming Manual

iii e & Pro Series

Warranty and Copyright

SATO Europe NV makes no guarantee of any kind with regard to this material, including,

but not limited to, the implied guaranties of merchantability and fitness for a particular

purpose.

SATO Europe NV shall not be liable for errors contained herein or for any incidental con-

sequential damages in connection with the furnishing, performance, or use of this mate-

rial.

This document contains proprietary information which is protected by copyright.

All rights are reserved.

No part of this document may be reproduced or issued to third parties in any form what-

soever without the express permission of SATO Europe NV.

The information in this document is subject to change without notice.

© Copyright 2003 SATO Europe NV.

SATO Programming Reference v

TABLE OF CONTENTS

SECTION 1. PROGRAMMING CONCEPTS

The SATO Programming Language............................................................................... 1-1

Selecting Protocol Control Codes .................................................................................. 1-2

Using Basic .................................................................................................................... 1-2

The Print Area ................................................................................................................ 1-4

Rotated Fields ................................................................................................................ 1-8

Command Default Settings ............................................................................................ 1-9

Opposite Hand “Se” Printers ........................................................................................ 1-10

SECTION 2. COMMAND CODES

Bar Codes ......................................................................................................................2-2

Bar Codes, Expansion ................................................................................................... 2-7

Bar Codes, Variable Ratio ............................................................................................. 2-8

Base Reference Point ................................................................................................. 2-10

Characters,Custom-Designed...................................................................................... 2-12

Character Expansion.................................................................................................... 2-14

Character, Fixed Spacing............................................................................................. 2-15

Character Pitch ........................................................................................................... 2-16

Character, Proportional Spacing ................................................................................. 2-18

Clear Print Job(s) & Memory ....................................................................................... 2-19

Continuous Forms Printing .......................................................................................... 2-20

Copy Image Area ........................................................................................................ 2-21

Cut ............................................................................................................................... 2-23

Cut Job ........................................................................................................................2-24

Cut Last .......................................................................................................................2-25

Fonts U, S, M, OA, OB, XU, XS & XM ........................................................................ 2-26

Font, Raster ................................................................................................................. 2-28

Font, Vector.................................................................................................................. 2-29

Fonts WB, WL, XB & XL .............................................................................................. 2-31

Form Feed ................................................................................................................... 2-33

Form Overlay, Recall ................................................................................................... 2-34

Form Overlay, Store .................................................................................................... 2-35

Table of Contents

vi SATO Programming Reference

Graphics, Custom ....................................................................................................... 2-36

Graphics, BMP............................................................................................................. 2-38

Graphics, PCX ............................................................................................................. 2-39

Job ID Store ................................................................................................................. 2-40

Job Name .................................................................................................................... 2-41

ournal Print .................................................................................................................. 2-42

Lines and Boxes ......................................................................................................... 2-43

Line Feed .................................................................................................................... 2-45

Media Size ................................................................................................................... 2-46

Mirror Image ................................................................................................................ 2-47

Off-Line/Pause ............................................................................................................ 2-48

Postnet ........................................................................................................................2-49

Print Darkness ............................................................................................................ 2-50

Print Length, Expanded .............................................................................................. 2-51

Print Position................................................................................................................ 2-53

Print Quantity .............................................................................................................. 2-55

Print Speed .................................................................................................................. 2-56

Repeat Label................................................................................................................ 2-57

Replace Data (Partial Edit) ......................................................................................... 2-58

Reverse Image ............................................................................................................ 2-60

Rotate, Fixed Base Reference Point ........................................................................... 2-62

Sequential Numbering ................................................................................................ 2-64

Start/Stop Label ........................................................................................................... 2-66

SECTION 3. CALENDAR COMMANDS

Increment .......................................................................................................................3-2

Print ............................................................................................................................... 3-4

Set ................................................................................................................................. 3-6

SECTION 4. EXPANDED MEMORY

Clear Expanded Memory ............................................................................................... 4-2

Fonts, TrueType Recall.................................................................................................. 4-3

Fonts, TrueType Store .................................................................................................. 4-4

Format/Field Recall........................................................................................................ 4-5

Format/Field Store ........................................................................................................ 4-6

Form Overlay Recall ..................................................................................................... 4-7

Table of Contents

SATO Programming Reference vii

Form Overlay Store ....................................................................................................... 4-8

BMP Graphics Recall ..................................................................................................... 4-9

BMP Graphics Store ................................................................................................... 4-10

Graphics, Custom Recall ............................................................................................. 4-11

Graphics, Custom Store .............................................................................................. 4-12

Graphics, PCX Recall .................................................................................................. 4-14

Graphics, PCX Store.................................................................................................... 4-15

Initialize ....................................................................................................................... 4-16

Memory Area Select..................................................................................................... 4-17

Status .......................................................................................................................... 4-18

SECTION 5. TWO-DIMENSIONAL SYMBOLS

Data Matrix, Data Format............................................................................................... 5-2

Data Matrix, Print Data................................................................................................... 5-5

Data Matrix, Sequential Numbering ............................................................................... 5-6

Maxicode........................................................................................................................5-8

TPDF417...................................................................................................................... 5-10

QR Code ...................................................................................................................... 5-12

SECTION 6. CONFIGURATION COMMANDS

Custom Protocol Command Codes Download............................................................... 6-2

Printer Setting ...............................................................................................................6-4

Pitch Offset..................................................................................................................... 6-7

Print Mode .....................................................................................................................6-8

Print Type ...................................................................................................................... 6-9

Sensor Type ................................................................................................................ 6-10

Serial Interface Parameters ........................................................................................ 6-11

CR/LF Delete ............................................................................................................... 6-12

Zero Slash.................................................................................................................... 6-13

Auto Online .................................................................................................................. 6-14

Online Feed.................................................................................................................. 6-15

Test Print......................................................................................................................6-16

SECTION 7. BI-DIRECTIONAL COMMUNICATIONS

ENQUIRE/ACK/NAK ...................................................................................................... 7-2

Status Response............................................................................................................ 7-2

Table of Contents

viii SATO Programming Reference

COMMAND CODE QUICK REFERENCE

Basic Commands...........................................................................................................A-1

Calendar Commands ...................................................................................................A-10

Expanded Memory Commands ...................................................................................A-11

Configuration Commands ............................................................................................A-14

Legacy Commands ......................................................................................................A-15

APPENDIX B. BAR CODE SPECIFICATIONS

Codabar .........................................................................................................................B-2

Code 39 .........................................................................................................................B-3

Interleaved Two of Five (I 2/5) .......................................................................................B-4

UPC-A/EAN-13 ..............................................................................................................B-5

EAN-8 ............................................................................................................................B-7

Industrial Two of Five.....................................................................................................B-8

Matrix Two of Five..........................................................................................................B-9

Code 128 .....................................................................................................................B-10

MSI...............................................................................................................................B-11

Code 93 .......................................................................................................................B-12

UPC-E..........................................................................................................................B-13

Bookland (UPC/EAN Supplements).............................................................................B-14

UCC-128 ......................................................................................................................B-15

Postnet.........................................................................................................................B-17

Data Matrix...................................................................................................................B-18

Maxicode......................................................................................................................B-20

PDF417........................................................................................................................B-22

Code 128 Character Table...........................................................................................B-23

APPENDIX C. CUSTOM CHARACTERS AND GRAPHICS

Custom Designed Character Example...........................................................................C-1

Custom Designed Graphics Example ............................................................................C-4

PCX Graphics Example .................................................................................................C-8

Table of Contents

SATO Programming Reference ix

APPENDIX D. CUSTOM PROTOCOL COMMAND CODES

Description .................................................................................................................... D-1

Download Command Structure ..................................................................................... D-2

Reset............................................................................................................................. D-2

Download Procedure..................................................................................................... D-3

SATO Programming Reference Page 1-1

SECTION 1.

PROGRAMMING CONCEPTS

INTRODUCTION

This section presents the commands that are used with the SATO Series “e” and PRO

printers to produce labels with logos, bar codes and alphanumeric data. All of the

SATO Programming Language commands use the same syntax. Some commands

reference a physical point on the label using horizontal and vertical dot reference

numbers. The allowable range for these references is dependent upon the particular

printer to accomodate different print widths and resolutions. These differences are

noted in tables under the commandsaffected

The following information is presented in this section:

• The SATO Programming Language

• Selecting Protocol Control Codes

• Using Basic

• The Print Area

• Command Codes

THE SATO PROGRAMMING LANGUAGE

A programming language for a printer is a familiar concept to most programmers. It is

a group of commands that are designed to use the internal intelligence of the printer.

The commands, which are referred to as SATO Command Codes, contain

non-printable ASCII characters (such as <STX>, <ETX>, <ESC>) and printable

characters. These commands must be assembled into an organized block of code to

be sent as one data stream to the printer, which in turn interprets the command codes

and generates the desired label output. The programmer is free to use any

programming language available to send the desired data to the printer.

The command codes used by the printers are based upon “Escape” (1B

hexadecimal) sequences. Typically there are four types of command sequences:

<ESC>{Command}

These commands generally tell the printer to perform a specific action, like “clear the

memory.”

<ESC>{Command} {Data}

Commands with this format tell the printer to perform a specific action which is

dependent upon the following data, like “print X labels”, where the value for X is

contained in the data.

<ESC>{Command} {Parameter}

Section 1. Programming Concepts

Page 1-2 SATO Programming Reference

These commands set the operational parameters of the printer, like “set the print

speed to 3.”

<ESC> {Command} {Parameter} {Data}

Some commands can contain both Parameter and Data elements, such as “print a

Code 39 symbol containing the data.”

SELECTING PROTOCOL CONTROL CODES

Protocol codes are the special control characters that prepare the printer to receive

instructions. For example, the <ESC> character tells the printer that a command code

will follow and the <ENQ> character asks for the printer status. There are two

pre-defined different sets of Protocol Control codes to choose from. Each set is made

up of six special characters. The Standard Protocol Control codes are non-printable

characters, and the Non-Standard Protocol Control codes are printable characters.

The Non-Standard set may be useful on host computers using protocol converters or

in an application where non-printable ASCII characters cannot be sent from the host.

This manual uses the Standard Protocol Control codes for all of the examples.

Alternately, the user may define and download a set of custom Protocol Control

Codes (see Appendix E).

The Protocol Control codes are selected by DIP switch DSW2-7.

USING BASIC

It may be useful to test your printer using a BASIC program on a PC. You may also

write your actual production programs in BASIC. Whatever the reason, if you will be

working in BASIC, some of the following hints may help you get started:

1. Set the WIDTH of the output device to 255 characters to avoid automatically

sending <CR> and <LF> characters after every line. The command string should

be continuous and uninterrupted by <CR> and/or <LF> commands. The examples

given in this manual are printed on separate lines because they will not fit on one

line and do not contain any <CR> and/or <LF> characters. If these characters are

needed, they are explicitly noted by the inclusion of <CR> and<LF> notations.

CONTROL

CHARACTER

STANDARD

DSW2-7 OFF

NON-STANDARD

DSW2-7 ON DESCRIPTION

STX 02 Hex 7 B Hex = { Start of Data

ETX 03 Hex 7 D Hex= } End of Data

ESC 1B Hex 5 5 E Hex = Command code to follow

ESC 1B Hex 5E Hex = ^ Command code to follow

ENQ 05 Hex 40 Hex = @ Get printer status, Bi-Com mode

CAN 18 Hex 21 Hex = ! Cancel print job, Bi-Com mode

Off-Line 40 Hex 5D Hex = ] Take printer Off-Line

Section 1. Programming Concepts

SATO Programming Reference Page 1-3

2. If you are using the printer’s RS232C interface, it is necessary to set the COM

porton on the PC such that the CTS and DSR signals will be ignored. Send your

OPEN “COM” statement in the following way:

OPEN “COM1:9600,E,8,1,CS,DS”AS #1

This sets the RS232C communication parameters of the host PC’s COM1 port for

9600 baud, Even parity, 8 Data bits, 1 Stop bit and directing the port to ignore the

CTS and DSR control signals.

3. You may want to minimize keystrokes and program size by assigning the

<ESC>character to a string variable since this character is used quite often.

The following two examples in BASIC show a typical example using thesehints. Both

of these examples use the Standard Protocol codes.

PRINTING WITH THE PARALLEL PORT

PRINTING WITH THE RS232C PORT

5 REM CL612 Parallel Example Identifies the program as a CL612 parallel

port print label. The “REM” prevents this

data from being sent to the printer and

displays it only on thescreen.

10 E$=CHR$(27) Sets the “E$” string as an <ESC>character

20 WIDTH “LPT1”255 Sets the width of the output to 255

characters

30 LPRINT E$;"A"; Sends an “<ESC>A” command code tothe

LPT1 parallel port

40 LPRINT E$;"H400";E$;"V100";E$;"XL1SATO"; Sends the data “SATO” to be to be placed

400 dots horizontally and 100dots

vertically on the label and printed in the

“XL” font.

50 LPRINT E$;"Q1"; Instructs the printer to print one label.

60 LPRINT E$; “Z”; Tells the printer that the last commandhas

been sent. The printer can nowcreate and

print the job.

REM CL612 RS232 Example Identifies the program as a CL612e

RS232C port print label. The “REM”

prevents this data from being sent to

the printer and displays it only on the

screen.

10 E$=CHR$(27) Sets the“E$”string as an

<ESC>character.

Section 1. Programming Concepts

Page 1-4 SATO Programming Reference

THE PRINT AREA

The maximum print area for the different printer models is listed in Table 1. Many of

your label applications may not require labels that fill the entireprint area, therefore it

is important to understand how to work with labelsthat do not use the entire print area.

The goal is to help you avoid printing where no label exists, which may lead to print

head damage, not to mentionfrustration when you cannot see the printed output.

The diagram below illustrates the maximum print area and a sample 2 inch wide by 3

inch long label placed within this area. As can be seen, your label will be oriented

against the inside left edge of the printer as viewed from the front of the printer. The

normal reference point is located at the H1, V1 position of the print area in the normal

print orientation (no rotation).

OPEN COM1:9600,N,8,1,CS,DS AS #1 Opens the COM1 port for output and

sets the parameters as 9600 baud, No

parity, 8 Data bits, 1 Stop bit and

instructs the port to ignore the CTS and

DSR control signals.

30 PRINT #1,CHR$ (2); Sends an <STX> (ASCII Code a

decimal “2”) to the printer instructing it

to prepare to receive a message.

50 PRINT #1,E$;"A"; Sends an “<ESC>A” command code to

Print Port #1 opened by statement 20

above.

60 PRINT #1,

E$;"H400";E$;"V100";E$;"XL1SATO";

Sends the data “SATO” to be placed

400 dots horizontally and 100 dots

vertically on the label and printed in

the“XL” autosmoothed font.

50 PRINT #1, E$;"Q1"; Instructs the printer to print a quantity of

one label.

60 PRINT #1, E$; “Z”; Tells the printer that the last

commandhas been sent. The printer

can nowcreate and print the job.

70 PRINT #1,CHR$ (3); Sends an <ETX> (ASCII Code decimal

“3”) to the printer telling it that this is the

end of the message.

Identifies the program as a CL612e

RS232C port print label. The “REM”

prevents this data from being sent to

the printer and displays it only on the

screen.

Section 1. Programming Concepts

SATO Programming Reference Page 1-5

l

There are three methods available to make sure your printed output will appear

correctly on your label. They are as follows:

Table 1: Print Area

CL412e

M-84 Pro-3

CL612e

M-10e

M-8490Se

M-84 Pro-6

M-5900RVE

M-8459E

M-8485Se

CL608e

M-8460Se

CL408e

M-8400RVe

M-84 Pro-2

Resolution

dpi/dpmm

305

12

305

12

305

12

305

12

609

24

203

8

203

8

203

8

203

8

Max Print Width

(Hmax)

dots/inches/mm

1248

4.1

104

1984

6.5

165

6400

10.5

266.7

1344

4.4

112

2496

4.1

104

896

4.4

112

1024

5.0

128

1216

6.0

152

832

4.1

104

Std Print Length

(Vmax)

dots/inches/mm

2136

7.0

178

2136

7.0

178

3600

11.8

300

2136

7.0

178

4272

7.0

178

2136

7.0

178

1424

7.0

178

1424

7.0

178

1424

7.0

178

Expanded Print

Length

(Vmax Expanded)

dots/inches/mm

9999

32.8

833

9999

32.8

833

10080

16.5

420

9999

32.8

833

9999

16.4

416

9999

49.2

1249

9999

49.2

1249

9999

49.2

1249

9999

49.2

1249

Section 1. Programming Concepts

Page 1-6 SATO Programming Reference

1. Media Size Command. Use the <ESC>A1 Media Size Command. This command

specifies the width and length of the label. The printer will automatically calculate

the correct offsets for printing labels of that size. However, if you specify a label

size with this command, the labels loaded should match the size specified to cor-

rectly position the label.

2. Base Reference Point Command. Send the <ESC>A3 Base Reference Point

command as part of your data to the printer to set a new base reference point for

your label.

Calculate the distance (in dots) from the normal base reference point to the clos-

est edge of the label.

For an M-8400RVe 8 dpmm printer , this would be:

LABEL WIDTH = 2" X 25.4 MM/IN X 8 DPMM = 406 DOTS

The new Base Reference Point then becomes:

NEW BASE REFERENCE POINT = MAXIMUM PRINT WIDTH - LABEL WIDTH

= (832 DOTS) - (406 DOTS) = 426 DOTS

Issue the Base Reference Point command <ESC>A3 after the Start command in

your data stream.

<ESC>A<ESC>A3H0426V0001. . . . . .

This resets the reference point for all the following data.

3. Add the correct offset to all horizontal commands. Use the normal base refer-

ence point from the print area and use the horizontal position for each field to

properly locate it on the label.

Calculate the distance (in dots) from the normal base reference point to the clos-

est edge of the label.

For an M-8400RVe 8 dpmm printer:

Label Width = 2" x 25.4 mm/in x 8 dpmm = 406 dots

New Base Reference Point = Maximum Print Width - Label Width

= (832 dots) - (406 dots) = 426 dots

Each <ESC>H command would have the value “426” added to it to correctly posi-

tion each field.

Note: The <ESC>A3 Base Reference Point command can also shift the reference

point in a negative direction (toward the outside edge of the label).

The Command Code subsection contains a sample label output for each command

code. These samples reflect how the printed information would appear on a five inch

wide label. If you want to test any of the sample label outputs and are using labels

less than five inches in width, we suggest that you add the Base Reference Point

command to the data stream in order for the images to print on your labels.

You must be careful not to print off the label surface as the label provides a heat sink

Section 1. Programming Concepts

SATO Programming Reference Page 1-7

for the print head elements. Doing so will cause irrepairable damage to the head. This

damage is not covered under the print head warranty. The addition of the Base

Reference Point command to the sample data stream may help to adjust the print for

your labels. See the following two examples or refer to the Base Reference Point

command description.

For example, the following illustrates a sample data stream for a M-8400RVe printer

and the resulting label assuming a 4 inch wide label:

<ESC>A

<ESC>H0050<ESC>V0100<ESC>L0303<ESC>XMSATO

<ESC>H0050<ESC>V0200<ESC>B103100*SATO*

<ESC>H0070<ESC>V0310<ESC>L0101<ESC>XUSATO

<ESC>Q1<ESC>Z

If you are using a 2 inch wide label, the entire image may not appear on your label. By

adding the following Base Reference Point command to the second line of the data

stream, the base reference point will be changed, causing theimage to be shifted over

toward the inside of the printer where it can beprinted on the narrower label.

<ESC>A

<ESC>A3H0406V0001

<ESC>H0050<ESC>V0100<ESC>L0303<ESC>XMSATO

<ESC>H0050<ESC>V0200<ESC>B103100*SATO*

<ESC>H0170<ESC>V0310<ESC>L0101<ESC>XUSATO

<ESC>Q1

<ESC>Z

The image is moved horizontally to the right 2 inches (406 dots) so that itcan be

printed on a 2 inch wide label. For more information, see the Base Reference Point

command description.

Section 1. Programming Concepts

Page 1-8 SATO Programming Reference

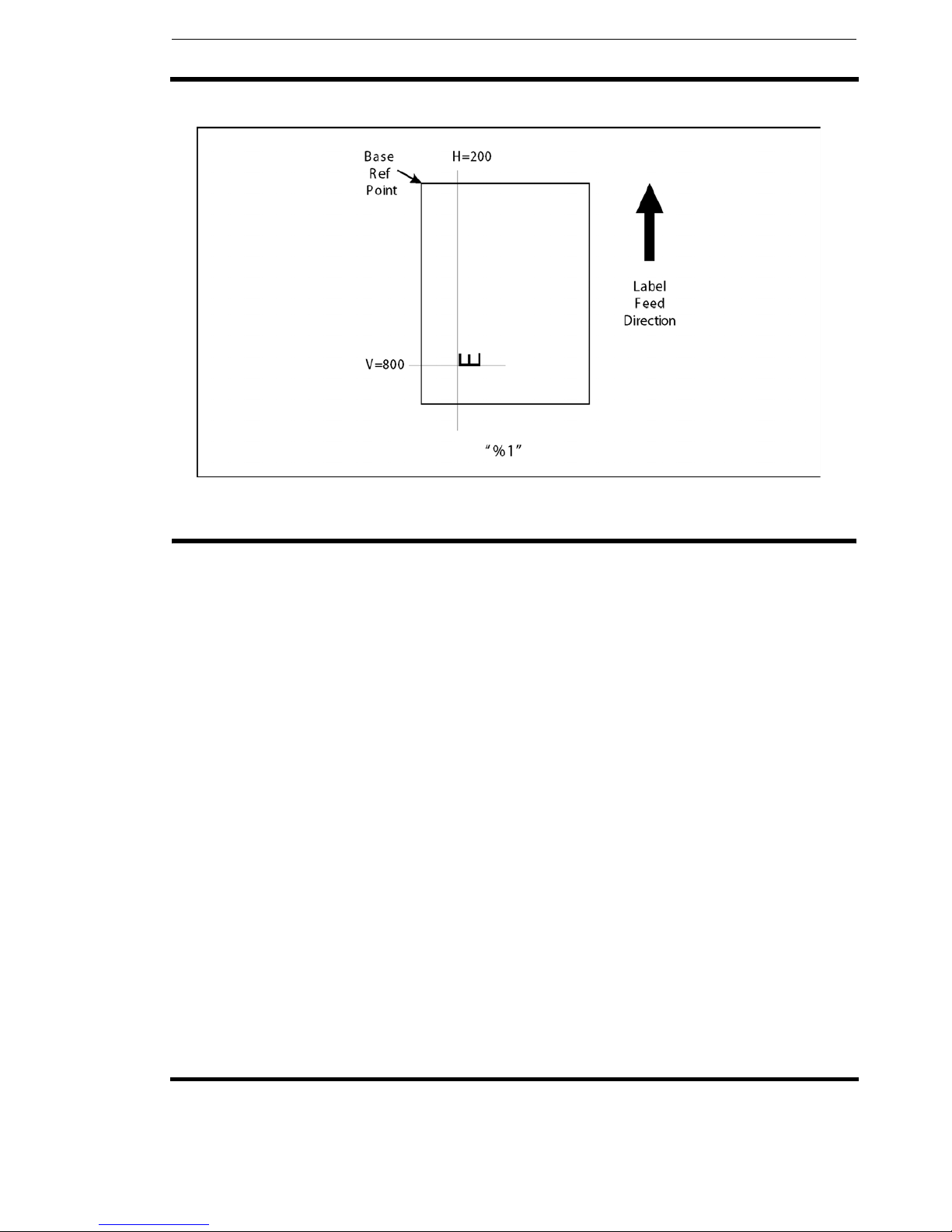

ROTATED FIELDS

The M-8400RVe printer can rotate each print field in 90° increments using the Rotate

command.

• <ESC>% - The field rotates, but the base reference point for the field remains

the same.

The following data stream will rotate the print field but will not change the base

reference point of the field:

<ESC>A<ESC>%1<ESC>V800<ESC>H200<ESC>L0202<ESC>XB1E<ESC>Q1<ESC>Z

Section 1. Programming Concepts

SATO Programming Reference Page 1-9

COMMAND DEFAULT SETTINGS

There are some types of commands that must have a value specified before a label

can be printed. If the data stream does not contain these commands, a default value

is assumed. The commands and the corresponding default values are:

COMMAND DEFAULT NOTE

Print Rotation 0° (1)

Vertical Reference Point 0 (1)

Horizontal Reference Point 0 (1)

Character Pitch 2 ( 1)

Base Reference Point H=0, V=0 (2)

Character Expansion 1 (1)

Print Darkness - (1)(3)

Print Speed (DSW2-8 = On) - (2)(3)

Print Speed (DSW2-8 = Off) - (2)(3)

Proportional Spacing Enabled (1)

Cutter Command Disabled (1)

Section 1. Programming Concepts

Page 1-10 SATO Programming Reference

NOTES:

1. The settings for these commands will revert to the default value when the printer

receives an <ESC>Z or an <ESC>*.

2. The values transmitted with these commands will remain in effect until a new

command is received.

3. This default setting is printer dependent.

OPPOSITE HAND”SE” PRINTERS

The standard “Se” print engine is referred to as a“right-hand”printer (i.e., when facing

the Control Panel, the label comes out from left to right). The M-8485Se, M-8460Se

and M-8490Se are also available in a “left-hand” (i.e., the label comes out right-to-left)

version. The M-8459Se is only available in the standard Right-Hand configuation.

The only difference in the print area is the horizontal base reference point for the

label.With the standard “Se” printer, the reference point is the first print position

nearest the inside frame. With the “left-hand” version, the reference point is the first

print position away from the frame. The same command stream sent to both printers

should print an identical label except the image may be shifted because of the relative

positioning of the label under the print head.

SATO Programming Reference Page 2-1

SECTION 2.

COMMAND CODES

This section contains the basic Command Codes for the SATO “e” and PRO Series

printers. Commands for the oprions and specialized functions are provided in the

following sections. Commands must be sent to the printer in an organized fashion in

order for the label(s) to print.

The purpose of this section is to:

• Explain the different commands and provide examples of their usage.

• To provide a detailed reference for programming the printers.

Each command begins on a separate page with its own heading. A uniform layout is

used to help you find key information about each command. For each Command

Code in this section, there will be a sample data input stream to the printer and the

expected print output. By studying the examples, you can learn how to use the

particular command within a whole block of printer code. Pay particular attention to

the “Special Notes” with each command to learn other important information.

The subject commands are highlighted in bold letters in the Reference Sheets. There

are two parts of most, but not all, commands. The first is the command character

which immediately follows the <ESC> code. It is always an upper case alpha or a

special character (such as an “&” or a “%”). It is never a lower case alpha character. If

the command requires additional variable information, it is represented by a group of

lower case alpha characters immediately following the command character. For

example, if an aaaabb is listed following the basic command, the printer will look for

six characters immediately following the command. The first four would represent the

value of aaaa and the next two the value of bb.

The maximum number of characters defined in a parameter is represented by the

number of characters shown in the command structure. For example, a command

followed by an aaaa can have up to four characters. In general, commands with only

one parameter following the command can be entered without the leading zeroes.

However, certain commands require the exact number of matching characters. A

command with two parameters listed following the command code without a comma

delimiter, such as aaaabbbb require the exact number of digits to be entered. If the

value of aaaa is “800” and the value of bbbb is “300”, then the parameters must be

entered as “08000300”. It is recommended that you make it a practice to always enter

leading zeros to prevent any mistakes.

NOTE: These examples assume the use of the Standard Protocol Command

Codes, a parallel interface and a 5 inch wide label in a M-8400RVe printer.

The labels for all other printers will be similar, but, because of different

resolutions and print widths may be larger or scaled differently.

An alphabetical listing of the command codes is contained in Appendix A:Command

Code Quick Reference.

Section 2: Command Codes

SATO Programming Reference PN 9001096 Rev. A Page 2-3

Bar Codes

Command Structure 1:3 narrow/wide bar ratio: <ESC>Babbcccd

2:5 narrow/wide ratio: <ESC>BDabbcccd

1:2 narrow/wide bar ratio: <ESC>Dabbcccd

a=

0 Codabar

1 Code 39

2 Interleaved 2 of 5 (I 2/5)

3 UPC-A / EAN-13

4 EAN-

5 Industial 2 of 5

6 Matrix 2 of 5

7 reserved

8 reserved

9 reserved

A MSI

B reserved

C Code 93

D reserved

E UPC-E

F Bookland

G Code 128

I UCC 128

bb = Number of dots (01-12) for narrow bar and narrow

space

ccc = Bar height in dots (001-999)

d = UCC 128 only. Not used for other bar code types

0 No human readable text

1 Human readable at top

2 Human readable at bottom

Example: <ESC>BD103200

Placement: Immediately preceding data to be encoded

Default: None

Command Function To print bar code images on a label. With this command, there are 14

standard bar code symbologies available to be printed and three two

dimensional symbols (see Section 5. Two Dimensional Symbols). Each of

the bar code symbologies are unique, and it is important to know the

differences. See Appendix B for specific information on using each

individual bar code symbol.

This manual suits for next models

1

Table of contents

Other SATO Printer manuals

SATO

SATO M-8400 Guide

SATO

SATO CX200 User manual

SATO

SATO CL4NX RIDF User manual

SATO

SATO Argox D4 Series User manual

SATO

SATO M-84Pro Series User manual

SATO

SATO CG4 Series User manual

SATO

SATO M10e Series User manual

SATO

SATO MB200 User manual

SATO

SATO MI-6308 User manual

SATO

SATO M-5900RVe Series User manual

SATO

SATO GT408e User manual

SATO

SATO GL4 Series User manual

SATO

SATO CL408e User manual

SATO

SATO FX3-LX Release note

SATO

SATO CL408e/412e Instruction Manual

SATO

SATO CL408-412e User manual

SATO

SATO M-8400RVe Series User manual

SATO

SATO LM412e User manual

SATO

SATO GT400 series User manual

SATO

SATO CG208 DT/TT User manual