ASV115

Logic table for digital inputs

Configuration of connections Function with factory setting

DI05 (cqV.p.2) DI04 (cqV.p.1) var min max Damper closed

n. act. n. act. n. act. act. act. n. act. act. act.

n. act. act. n. act. n. act. act. act. act. n. act.

act. n. act. act. act. n. act. n. act. n. act. act.

act. act. act. n. act. n. act. act. n. act. n. act.

n. act.= connected switch or contacts are not activated, i.e. normally open contacts are open and normally closed are closed.

act. = connected switch or contacts are activated, i.e. normally open contacts are closed and normally closed are open.

In order to stabilise the sensor's measurement signal in case of

severely fluctuating pressure signals, the SAUTER CASE VAV

software can be used to set the filter time constant continuously in

a range from 0 to 5.22 s. Zero can be reset as required by using the

zeroing function.

Sensor technology

The measuring sensor used in the VAV controller is a static double-

membrane sensor manufactured using PCB technology. Thanks to

its symmetrical structure with two measuring cells which are (in

principle) independent, the sensor is position-compensated and

can, therefore, be operated in any fitted position. The differential

pressure is evaluated using the differential capacitance measure-

ment method. The unique design ensures highly accurate meas-

urement at differential pressures of up to < 1 Pa, allowing precise

control of air volume at a differential pressure of 1 Pa. This enables

users to set low min values for reduced mode in order to save

energy.

Power supply connection

The drive can be operated with 24 V d.c. or a.c. Automatic connec-

tion recognition is available only in a.c. mode. In d.c. mode, the full

nominal torque of 10 Nm is available within the specified tolerances.

If the controller is operated with 24 V d.c., the following function

differs from a.c. operation, in relation to analogue inputs AI01 and

AI02:

Thanks to the principle of using a static measuring method, the

sensor can also be used to measure pumped media which contain

dust or are contaminated with chemicals.

Functions with 24 V d.c.

Connec-

tion

Para-

meterised

function

Circuit

connec-

tion

Function

range

0…10 V

Function

range

2…10 V

Function

freely

configur-

able

AI 01 Standard NC

1) Vvar

2) Damper

closed 3)

AI NC max. pos. shift if factor shift > 0

AI/AO 02 AO not available

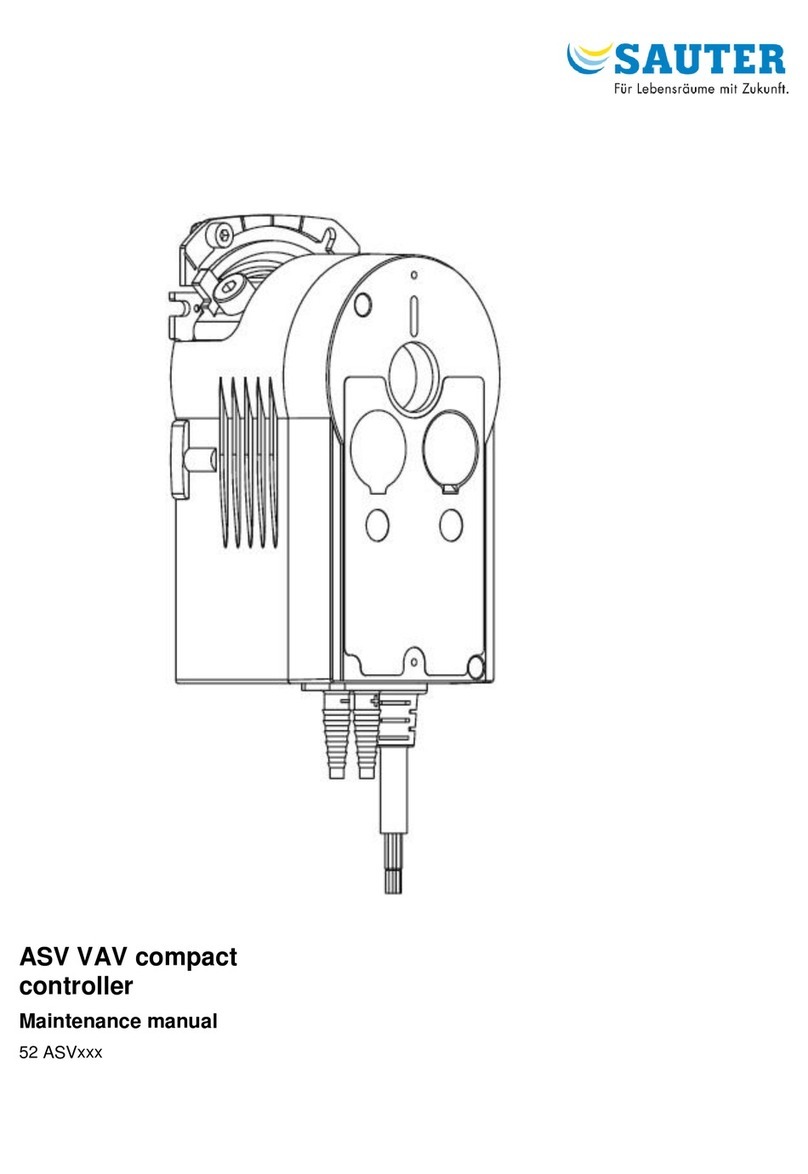

Sensor block diagram

6/13 www.sauter-controls.com

Bus

F

B10418

1) NC, not connected

2) It is recommended to put the setting for forced operation for LOW voltage additionally to

Vvar.

3) Connection is recognised as LOW voltage and, accordingly, the factory setting for

forced operation is performed; other parameters provide different behaviour.

After applying power, the working range of the damper drive is

determined automatically. For this purpose, the drive approaches

both limit stops and specifies the possible angle of rotation (factory

setting). The initialisation procedure in the event of a power failure

can be disabled by setting a parameter in the SAUTER CASE VAV

software tool.

The SAUTER CASE VAV software enables zeroing and setting of

damping factors by the user as required.

Sensor structure

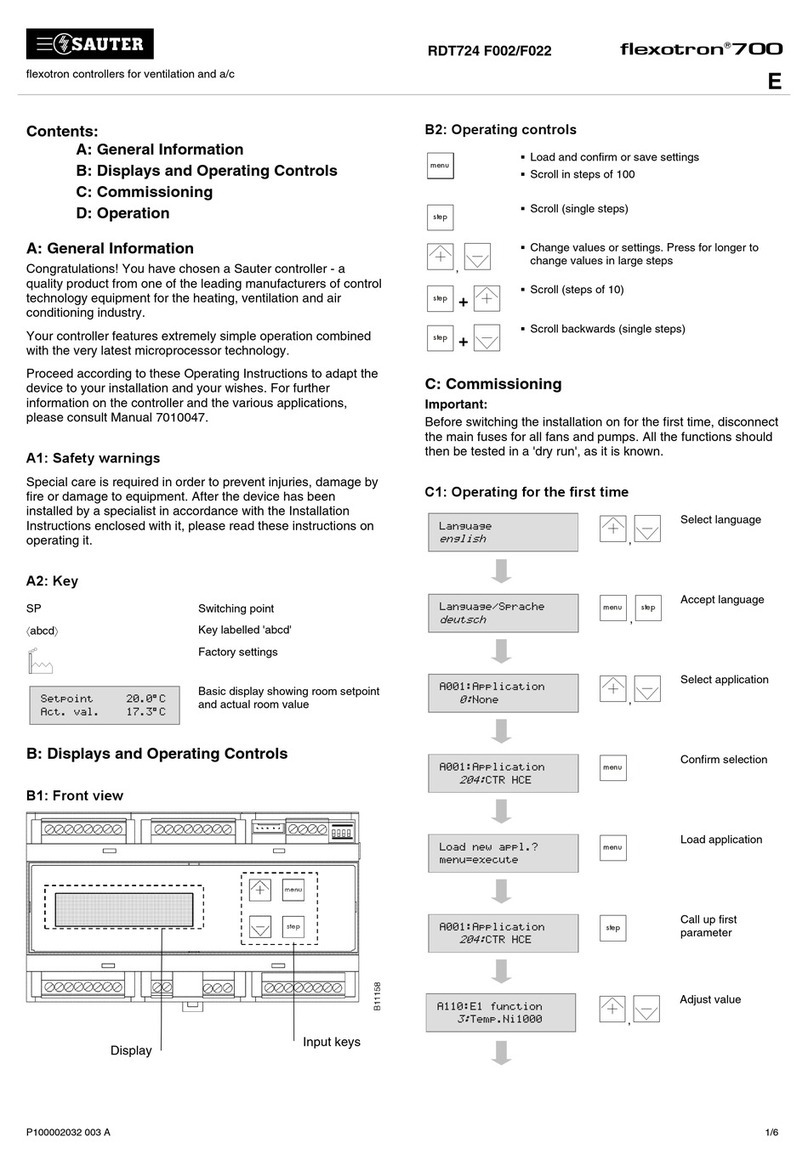

RS-485 / SLC interface function

GND

Pn

Pp

AcAp An

B11563

The VAV compact controller is fitted with an RS-485 interface which

is not galvanically separated. The baud rate used is 115.2 kbps,

which is a fixed setting. The SAUTER Local Communication (SLC)

protocol that is used specifies the master-slave bus access proce-

dure, with a maximum of 31 devices permitted in one network seg-

ment. The 32nd device is the parametering tool. The SAUTER CASE

VAV software is used to parameterise each individual device and to

configure the devices within the network segment. Physical access

to the bus system is gained either via the connection in the housing

cover or via three separate leads at the end of the cable.

CASE VAV function

The SAUTER CASE VAV software is available to parameterise the

air volume controller. This software tool enables you to configure all

the values required for operation via a comfortable user interface.

The connection is made via a USB interface on the PC/laptop and

via the jack on the drive, or via the RS-485 leads on the drive cable.

The drive parameterisation set comprises: software, including in-

stallation and operating instructions, fitting instructions, connection

plug, connection cable (length 1.2 m) and an interface converter for

the PC. The software is intended for use by OEM manufacturers,

commissioning and service technicians and experienced operators.

The following functions are available:

Key

Pp Connection for higher pressure

Pn Connection for lower pressure

Ac Common pole flange of the differential capacitor

Ap Positive pole flange

An Negative pole flange

GND Earth (ground)