3/6www.sauter-controls.com

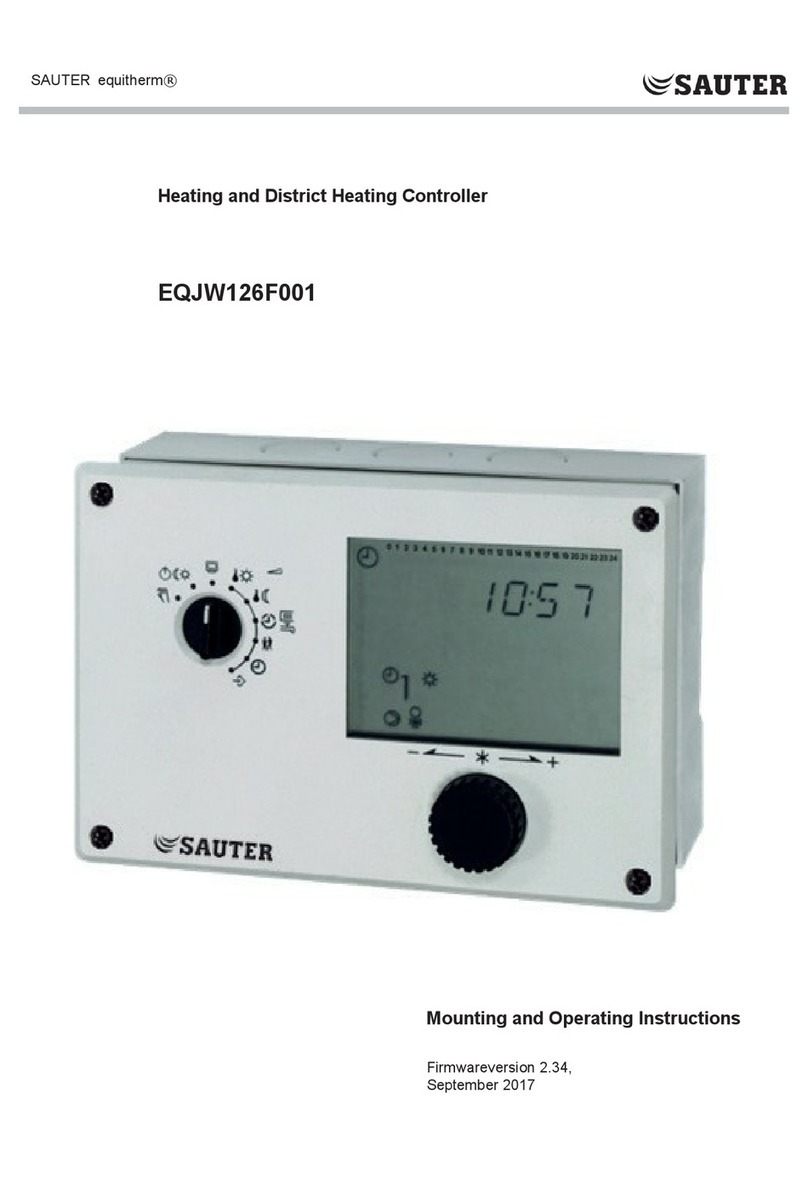

3. Press the input knob

4. Turn the input knob, show code

5. Press the input knob; the first SERVice

parameter appears

The commissioning level provides access to the main

SERVice parameters. These are shown in italics in the

following list (cf. 3.6).

View/change service parameters3.4.1

1.

°C

°C

Turn the input knob; select SERVice

parameter

2. Press the input knob; the value of the

parameter appears

3. Turn the input knob; the value of the

parameter changes

4. Press the input knob to confirm the new

value

Press the ESC key to cancel the operation. The value is not accepted

unless it was already confirmed beforehand. The parameters in the

communication level can be viewed/amended in the same manner.

Access to SERVice mode3.4.2

In the SERVice position, it is possible to choose between

commissioning, SERVice and communication levels. After pressing

the input knob at the relevant display, proceed as described for the

commissioning mode.

1. Set rotary switch to

2. Press the input knob

For further steps, see Section 3.4.1 and 3.4.2

Floor drying3.5

SERVice parameter SP60 (for second heating circuit: SP260, cf. 3.6)

is used to activate a floor drying process (functional heating or screed

curing). After the floor drying has been completed, the controller

operates regularly according to the switch position and the switching

commands. SERVice parameter SP60 (or SP260) then shows ‚9‘.

Extract from list of SERVice parameters3.6

For a detailed description, see document 7010042.

No. Explanation

SP01 X.xx Software version (read only)

SP02 - Show device status (0 = OK, >0 = error has occurred)

SP03 Logbook (read only)

SP04 0

Software reset

0 = no reset; 1 = default SE + CP; 2 = default switching

commands; 3 = default SE + CP + switching commands

SP05 0 Manual mode

0 = not enabled; 1 = enabled

SP06 1

Control model

1 = one regulating valve, primary, re-adjusted HC sec.

2 = one regulating valve, secondary, re-adjusted HC +DW

sec.

3 = two regulating valves, primary, for HC/HC +DW

4 = two re-adjusted circuits (2 x HC)

5 = two re-adjusted circuits (1 x HC, 1 x DW) sec.

6 = two re-adjusted circuits (1 x HC, 1 x DW with HC)

7 = direct control of DW and HC, plus one re-adjusted HC

8 = two regulating valves (1 primary for HC, 1 for direct DW

charge w/o mixing control)

For details, see ‹Application› sheet.

No. Explanation

SP07 0

Effect of binary input (terminal 21, 22) on HC1

0 = No influence on HC1

1 = HC in standby mode if contacts are closed

2 = HC in reduced mode if contacts are closed

3 = HC in nominal mode if contacts are closed

4 = pulse input for metering

5 = seepage limitation

6 = input for alarm

SP08 0

Measure room temperature for HC1

0 = no room temperature measurement; 1 = connect room

sensor; 2 = connect EGS52/15 or EGT333 with room

sensor; 3 = connect EGS52/15 or EGT333 without room

sensor; 4 = second flow sensor for domestic water

SP09 0

Transmit room temperature for HC1

0=not active; 1=active if TRi > TRs; 2= active if TRi < TRs; 3=

active if TRi <> TRs

SP10 20 Sampling time (in minutes) for TR1 when transmitted

SP11 0 Adjust room temperature TR1

SP12 0 Adjust outside temperature TA

SP13 0 RMeasure return temperature TRF1

0 = not active; 1 = max. limitation of TRF; 2 = maintain TRF

SP14 0 Adjust return temperature TRF1

SP15 40 P-band for PI-controller, control unit 1

SP16 240 Integral action time for PI-controller, control unit 1

SP17 120 Valve running time for first control unit

SP18 5 Minimum limitation TFfor HC1 in °C

SP19 75 Maximum limitation TFfor HC1 in °C

SP20 90 Upper limit of max. limitation for TRF for HC1,2 in °C

SP21 90 Lower limit of max. limitation for TRF for HC1,2 in °C

SP22 0 TA, at which the floating part of the limiting function of T

begins for HC1,2

SP23 1.0 Slope of limiting function for TRF for HC1,2

SP24 90 Limit value for TRF for charge of drinking water in °C

SP25 5 Level of intervention for control of control unit 1 when limit

value for TRF1 is breached

SP26 no Limit lmp/min for max. through flow/output of heating and

DW

SP27 no Limit lmp/min for max. through flow/output of heating only

SP28 no Limit lmp/min for max. through flow/output of DW only

SP29 0 Level of intervention for TF1 in K/min when limit is breached

for through flow/output

SP30 no Limit lmp/min for min. through flow/output

SP31 1

Functions for domestic water:

0 = no treatment of domestic water

1 = treatment of domestic water, 1 sensor

2 = treatment of domestic water, 2 sensors

3 = treatment of domestic water with through flow control

SP32 60 Max. setpoint for DW in °C

SP33 5 MOD 1,2: switching difference DW in K

SP34 70 Max. setpoint for increased DW temperature

SP35 10 Setpoint boost for DW in K

SP36 -30

TAlimit value for charging domestic water in °C

TA< limit value →parallel mode

TA> limit value → domestic water with priority

SP37 4 Integral action time for charge pump for DW in min

SP38 1.4 Slope of heating characteristic HC1

SP39 0.0 Portion of external heat in K

SP40 10 Setpoint boost when request for re-adjusted circuit or via

device bus in K

SP41 15 Heating limit in °C

SP42 21

Measurement of outside temperature for heating limit

0 = unattenuated; <>0 = time constant for attenuation in

hours

SP43 -16 Design temperature in °C

SP44 2 After-run factor for heating pump

(× valve›s running time)

SP45 1 Frost-protection function

0= not enabled; 1 = enabled

SP46 0

Configurable output

0 = no function; 1 = pilot-timer function; 2 = second charge

pump; 3 = RPM change-over for pump, HC1; 4 = RPM

change-over for pump, HC2; 5 = collective-alarm notice;

6 = circulation pump; 7 = heat requirement

SP47 0 Anti-jamming facility for pumps

0 = not enabled; 1 = enabled

SP48 25.10 Summertime/wintertime change-over

SP49 25.03 Wintertime/summertime change-over P55 = P56 denotes

no change-over

SP50 0 Optimisation for HC1

0 = not enabled; 1 = enabled