Schaeffler Technologies

MON 100

1

Page

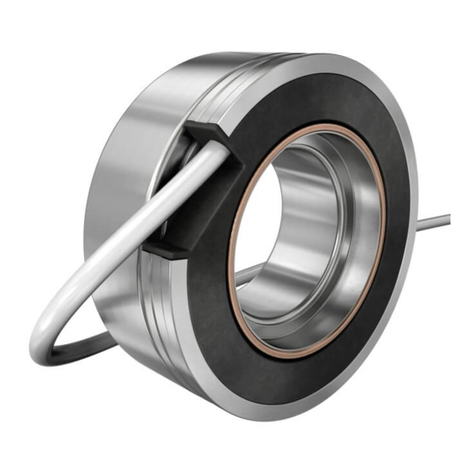

High precision bearings for combined loads

About the mounting manual

Symbols ................................................................................... 2

General safety guidelines

Usage for the intended purpose ................................................ 2

Qualified personnel .................................................................. 2

Safety guidelines ...................................................................... 3

Preparations for fitting

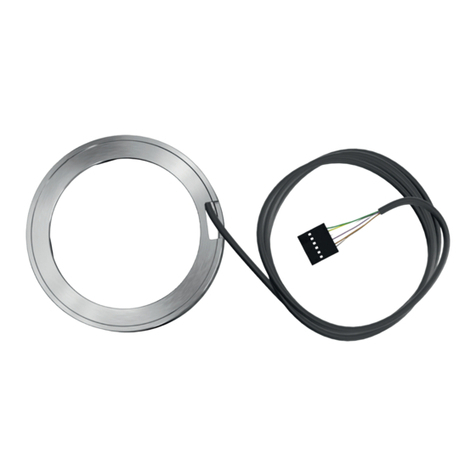

Bearings with magneto-resistive angular measuring system....... 5

Bearings with inductive angular measuring system.................... 7

Delivered condition of the bearings ........................................... 8

Initial greasing.......................................................................... 8

Bearing storage and storage life ................................................ 8

Compatibility and miscibility with anti-corrosion agents ............ 9

Cleaning of bearings ................................................................. 9

Removing bearings from packaging ........................................... 10

Transport of bearings ................................................................ 10

Design of fitting area................................................................. 12

Protection measures during fitting............................................. 13

Preparation of the adjacent construction ................................... 13

Selection of fasteners ............................................................... 14

Checking the tolerances of the screw mounting surfaces ........... 14

Fitting

Checking the dimensional and

running accuracy of the bearings............................................... 15

Locating the bearing rings......................................................... 15

Function and safety checks

Checking the bearing frictional torque ....................................... 19

Checking running accuracy........................................................ 19

Checking the fixing screws ........................................................ 20

Lubrication

................................................................................................ 21

Relubrication of bearings .......................................................... 22

Overlubrication......................................................................... 25

Initial operation ........................................................................ 25

Further information

Publication requests ................................................................. 26