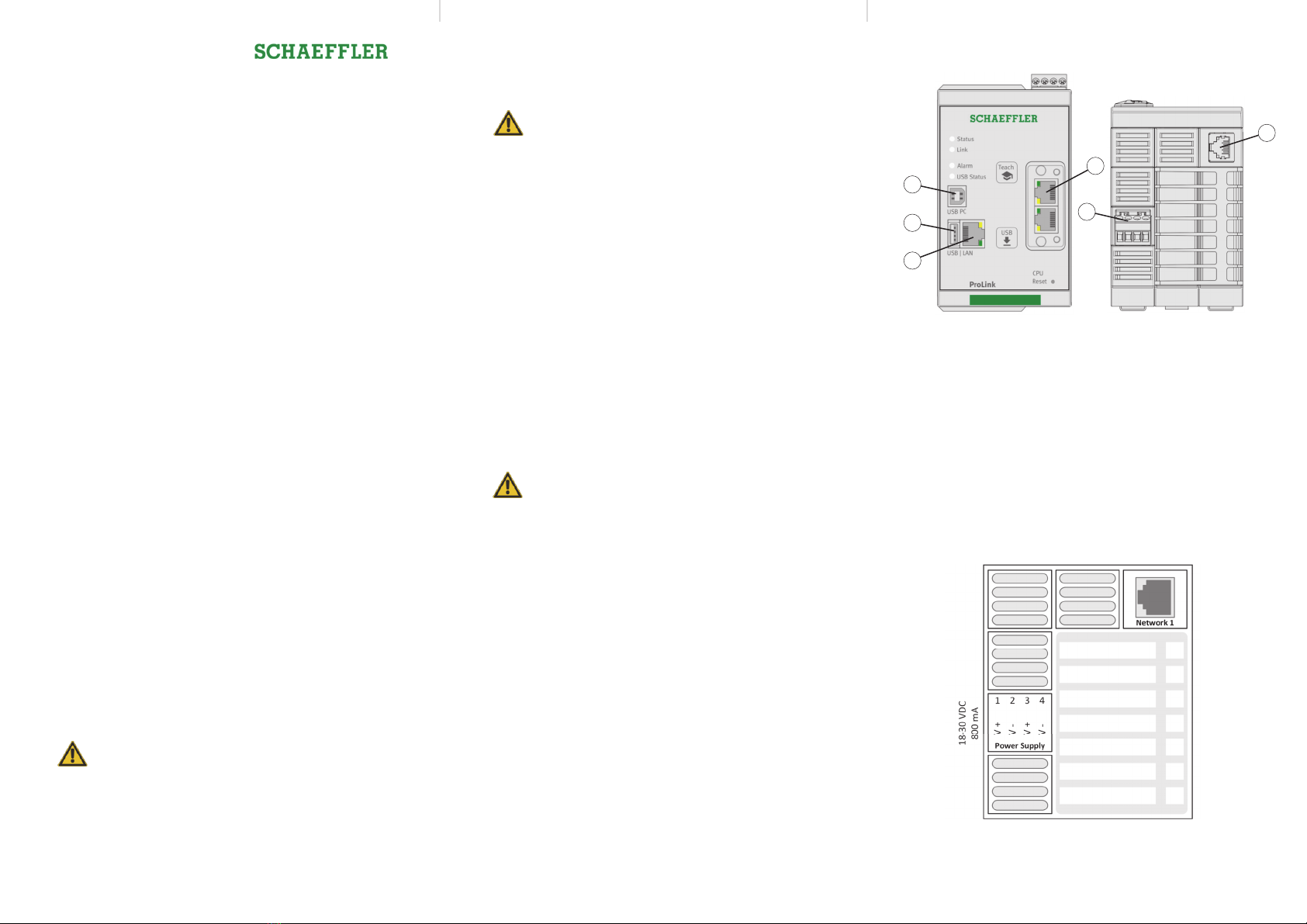

5 Connecons

(1) USB B (for future funcons)

(2) USB A (for future funcons)

(3) PC/Ethernet (SmartWeb configuraon)

Default IP address: 192.168.1.100

(4) Fieldbus connecon (for future funcons)

(5) Ethernet 1 (internal ProLink communicaon)

(6) Power supply connecon

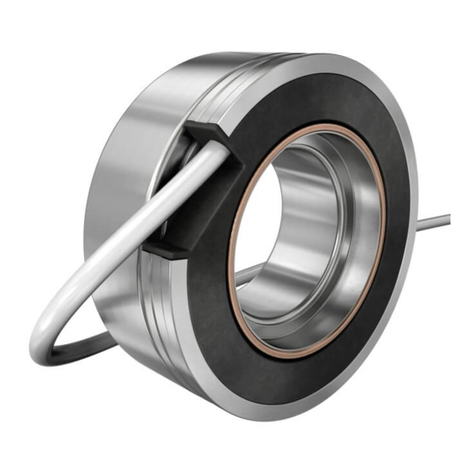

ProLink CPU Module

Connecon overview

1 General safety informaon

Read this document carefully before seng up the

Schaeffler ProLink device. Keep the document during

the enre service life of the device.

Adhere to the operang instrucons and the technical

data. Otherwise personal injury or damage to property

may occur.

The device must be suitable for the planned applicaons

and for the environmental condions without any

restricons.

Only use the device for its intended purpose (see

Funcons).

The manufacturer assumes no liability and warranty

for any consequences caused by incorrect use of the

device.

The device must be installed and electrically connected,

set up, operated and maintained by qualified and

authorised specialists.

Protect the device units and cables against damage.

2 Funcons

The ProLink CPU module collects data from the vibraon

modules and converts the data into characterisc values

and trends. Via the SmartWeb soware, this data can be

directly analysed on the device.

Electrostac discharge

The device contains components that can be damaged or

destroyed by electrostac discharge. To safely avoid

electrostac discharge, you must operate the device on a

grounded mounng rail. When handling the device observe

the required safety precauons against electrostac

Contact voltages and ambient condions

Mount the device in a control cabinet to protect it from

dangerous contact voltages and ambient condions. The

installaon of the control cabinet must be in accordance

with local and naonal regulaons.

3 Installing the device

1. Ensure that the device is disconnected from power.

2. Mount the device vercally in a control cabinet on a

35 mm DIN mounng rail.

3. Leave enough space between the device and the top

and boom of the control cabinet to ensure good

venlaon.

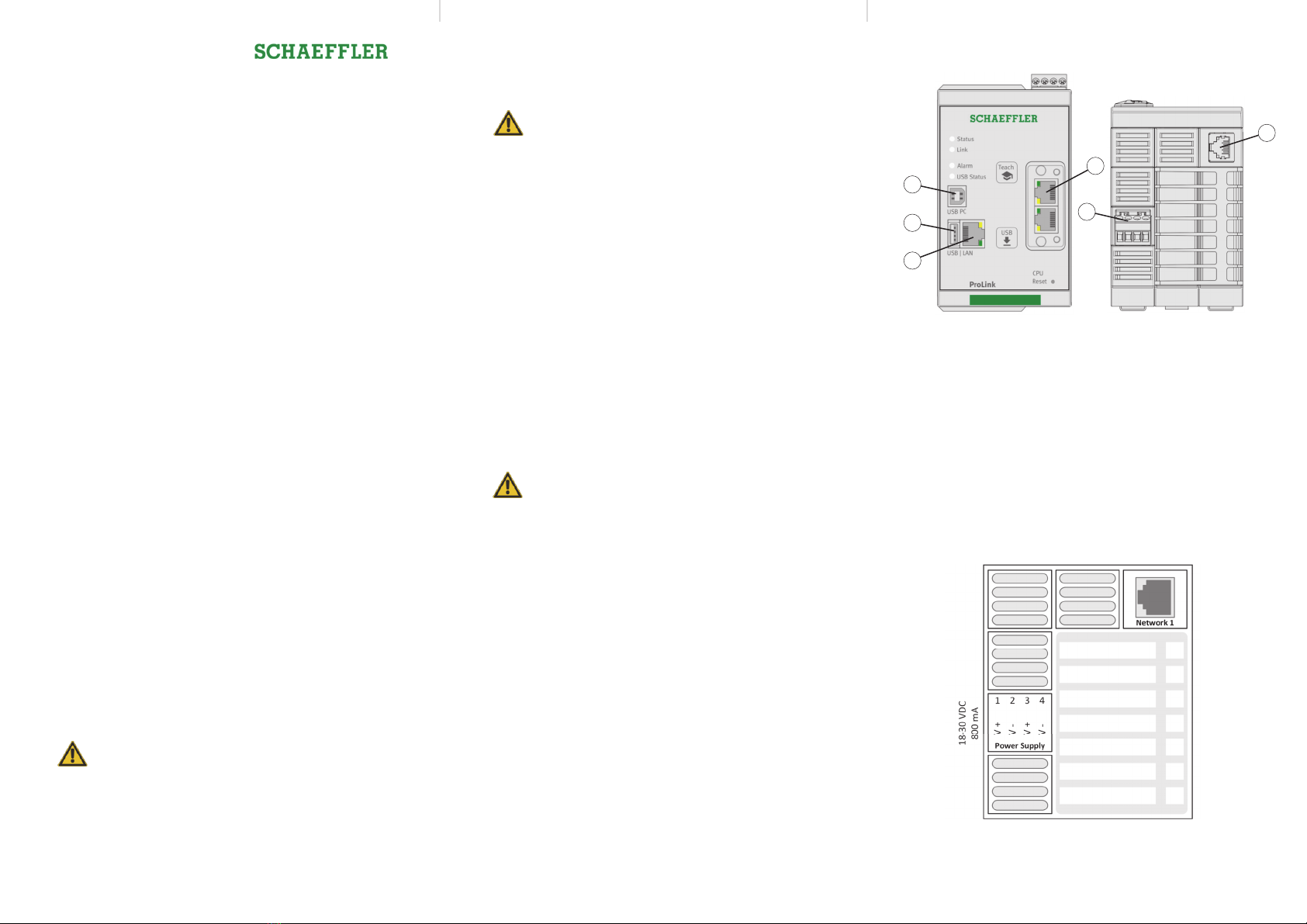

1. Connect the VDC power supply unit to the power supply

connecon of the CPU module.

2. Connect the power supply connecon of the CPU

module to the connecon of the vibraon module.

Please note the maximum cable lenght of 3 meters. See

also the illustraons in Connecons and Wiring.

4 Connecng the power supply

Electrical connecon

The device must be connected by a qualified electrician.

The local and naonal regulaons for the installaon of

electrical devices must be adhered to. 6 Wiring

1 2 3 4

1

3

Front view Top view

Top view

2

4

5

6

discharge (ESD) in accordance with EN 61340‐5‐1 and

IEC 61340‐5‐1.